You Have a Guide to Freezing Laser Welding Machine

A Comprehensive Guide to Freezing Laser Welding Machines

Laser welding technology is revolutionizing manufacturing with its precision and efficiency.

However, operating in cold environments can pose challenges to laser welding machines.

This guide provides essential information about operating temperatures, precautions, and antifreeze measures to keep your laser welding equipment functioning optimally.

Table of Content:

Handheld Laser Welding Operating Temperature Requirements

One of the critical factors for the proper functioning of a handheld laser welding machine is the operating temperature.

If the laser is exposed to environments below 5°C, several issues can arise:

• Physical Damage: In severe cases, the internal pipes of the water cooling system may deform or rupture, leading to costly repairs and downtime.

• Operational Failures: At low temperatures, internal water circuits and optical devices may fail to operate normally. This can lead to inconsistent performance or complete shutdowns.

Optimal Temperature Range

To ensure smooth operation, it's essential to maintain the following temperature ranges:

• Operating Environment: 5°C to 40°C

• Cooling Water Temperature: 25°C to 29°C

Exceeding these temperature limits can affect the stability of laser output and may even damage the laser itself.

Keeping your equipment within these parameters is crucial for longevity and performance.

Want to Know if Other Climates

Affect Laser Machines?

Precautions for a Laser Weld Machine Anti-freeze

To protect your laser welding machine from cold-related issues, consider implementing the following precautions:

1. Temperature Control

• Install Climate Control Systems: Use air conditioning or heating facilities to keep the operating environment above 5°C. This ensures that your laser equipment can function normally without needing special antifreeze measures.

2. Chiller Management

• Continuous Operation: Keep the chiller running 24/7. A circulating cooling system prevents the water from freezing, even if the indoor temperature drops.

• Monitor Indoor Conditions: If the indoor temperature is low, ensure that basic antifreeze measures are in place. Keeping the cooling water flowing is vital.

3. Long-Term Storage

• Drain Water During Downtime: If the laser equipment will not be used for an extended period or during power outages, it’s essential to drain the water in the chiller. Store the unit in an environment above 5°C to prevent any freezing issues.

• Holiday Precautions: During holidays or when the cooling system cannot operate continuously, remember to drain the water from the cooling system. This simple step can save you from significant damage.

Find Out Whether Laser Welding

Is Suitable for Your Region and Industry

Equipment Uses Antifreeze as Coolant

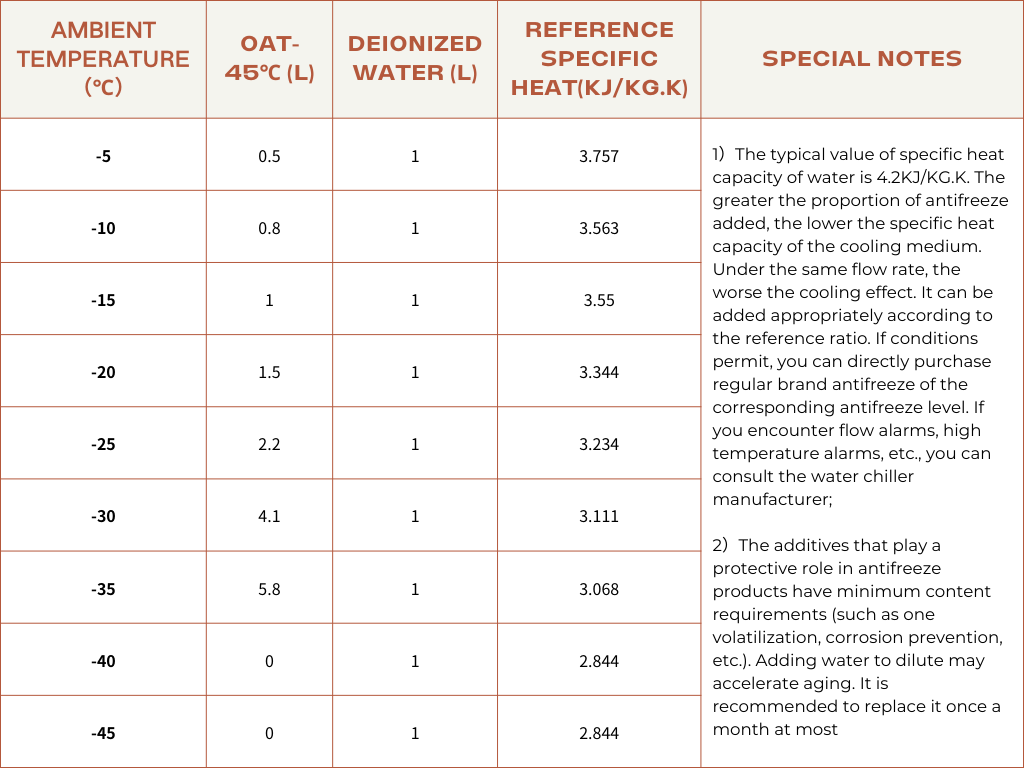

Coolant Addition Ratio Guide Table:

TIPS: OAT-45℃ refers to an Organic Acid Technology coolant that is specifically formulated to operate effectively at low temperatures, down to -45 degrees Celsius.

This type of coolant provides superior protection against freezing, corrosion, and scaling in automotive and industrial cooling systems.

Any antifreeze cannot completely replace deionized water and cannot be used for a long time throughout the year.

After winter, the pipelines must be cleaned with deionized water or purified water, and deionized water or purified water must be used again as coolant.

At the same time, during holidays such as the Spring Festival holiday or during long power outages, please drain the water in the laser and water-cooling machine related pipelines and replace it with water for cooling; if antifreeze is used for cooling for a long time, it may cause corrosion damage to the laser cooling system.

04 Drain the equipment coolant In extremely cold weather in winter, all cooling water in the laser, laser output head and water-cooling machine must be drained clean to effectively protect the entire set of water-cooling pipelines and related components.

Handheld Laser Weld: What to Expect in 2024

Handheld laser welding offers precision and portability for efficient material joining.

It's ideal for tight spaces and minimizes thermal distortion.

Discover tips and techniques for optimal results in our latest article!

5 Things About Laser Welding (That you Missed)

Laser welding is a precise and fast technique with several key benefits:

It minimizes heat-affected zones, works with various materials, requires little cleanup, and boosts productivity.

Discover how these advantages are transforming manufacturing!

High-Capacity & Wattage for Various Welding Applications

The 2000W handheld laser welding machine is characterized by small machine size but sparkling welding quality.

A stable fiber laser source and connected fiber cable provide a safe and steady laser beam delivery.

With the high power, the laser welding keyhole is perfectible and enables the welding joint firmer even for thick metal.

Portability for Flexibility

With a compact and small machine appearance, the portable laser welder machine is equipped with a moveable handheld laser welder gun which is lightweight and convenient for multi-laser welding applications at any angle and surface.

Optional various types of laser welder nozzles and automatic wire feeding systems make laser welding operation easier and that is friendly for beginners.

High-speed laser welding greatly increases your production efficiency and output while enabling an excellent laser welding effect.

Versatility of laser welding?

Handheld Laser Welder Machine from 1000w to 3000w

If you enjoyed this video, why not consider subscribing to our Youtube Channel?

Related Applications You Might be Interested:

Every Purchase Should be Well Informed

We can Help with Detailed Information and Consultation!

Post time: Jan-03-2025