Laser Cutting Rayon Fabric

Introduction

What is Rayon Fabric?

Rayon, often dubbed "artificial silk," is a semi-synthetic fiber derived from regenerated cellulose, typically sourced from wood pulp, offering a soft, smooth, and versatile fabric with good drape and breathability.

Types of Rayon

Viscose Rayon Fabric

Rayon Modal Fabric

Lyocell Rayon

Viscose: A common type of rayon made from wood pulp.

Modal: A type of rayon with a soft and luxurious feel, often used for clothing and bedding.

Lyocell (Tencel): Another type of rayon known for its durability and sustainability.

Rayon's History and Future

History

The history of rayon began in the mid-19th century when scientists sought to create an affordable alternative to silk using plant-based cellulose.

In 1855, Swiss chemist Audemars first extracted cellulose fibers from mulberry bark, and in 1884, Frenchman Chardonnet commercialized nitrocellulose rayon, despite its flammability.

In the early 20th century, British scientists Cross and Bevan invented the viscose process, which was industrialized by Courtaulds in 1905, ushering in mass production of rayon for clothing and wartime supplies.

Despite competition from synthetic fibers, rayon maintained its market position through innovations like high-strength industrial threads and Modal.

In the 1990s, environmental demands led to the development of Lyocell (Tencel™), a closed-loop produced fiber that became a symbol of sustainable fashion.

Recent advancements, such as forest certification and non-toxic processes, have addressed environmental concerns, continuing rayon’s century-long evolution from a silk substitute to a green material..

Future

Since its inception, rayon has remained remarkably relevant. Its combination of affordability, flexibility, and desirable luster ensures its continued prominence in the textile sector. Thus, the future of rayon isn't just bright—it's positively radiant.

Essential Care Tips for Rayon Fabrics

Rayon Applications

Clothing

Apparel: Rayon is used in a wide range of garments, from casual t-shirts to elegant evening gowns.

Shirts and blouses: Rayon's breathability makes it suitable for warm weather clothing.

Scarves and accessories: Rayon's smooth surface and ability to dye bright colors make it suitable for scarves and other accessories.

Rayon Shirt

Rayon Shirt

Home Textiles

Bedding: Rayon is used in blankets, sheets, and other bed linens.

Curtains: Its smooth surface and ability to dye bright colors make it suitable for curtains.

Materical Comparison

Linen is known for its durability, while rayon tends to degrade over time. Polyester, on the other hand, excels in maintaining its structure, being resistant to wrinkles and shrinking even after washing and repeated use.

For everyday wear or items that require durability, rayon may still be a better choice than cotton, depending on the specific needs of the garment.

Rayon Bed Sheet

How to Cut Rayon?

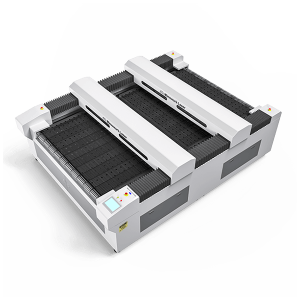

We choose CO2 laser cutting machines for rayon fabric due to their distinct advantages over traditional methods.

Laser cutting ensures precision with clean edges for intricate designs, offers high-speed cutting of complex shapes in seconds, making it ideal for bulk production, and supports customization through compatibility with digital designs for bespoke projects.

This advanced technology enhances efficiency and quality in textile manufacturing.

Detailed Process

1.Preparation: Select the appropriate fabric to ensure optimal results.

2.Setup: Calibrate the laser power, speed, and frequency according to the fabric type and thickness. Ensure the software is correctly configured for precise control.

3.Cutting Process: The automatic feeder transfers the fabric onto the conveyor table. The laser head, guided by the software, follows the cutting file to achieve accurate and clean cuts.

4.Post-Processing: Examine the cut fabric to ensure quality and proper finishing. Perform any required trimming or edge sealing to achieve a refined result.

Rayon Bed Sheet

Related Videos

How to Create Amazing Designs with Laser Cutting

Unlock your creativity with our advanced Auto Feeding CO2 Laser Cutting Machine! In this video, we demonstrate the remarkable versatility of this fabric laser machine, which effortlessly handles a wide range of materials.

Learn how to cut long fabrics straight or work with rolled fabrics using our 1610 CO2 laser cutter. Stay tuned for future videos where we'll share expert tips and tricks to optimize your cutting and engraving settings.

Don't miss your chance to elevate your fabric projects to new heights with cutting-edge laser technology!

Laser Cutter with Extension Table

In this video, we introduce the 1610 fabric laser cutter, which enables continuous cutting of roll fabric while allowing you to collect finished pieces on the extension table—a major time-saver!

Upgrading your textile laser cutter? Need extended cutting capabilities without breaking the bank? Our dual-head laser cutter with an extension table offers enhanced efficiency and the ability to handle ultra-long fabrics, including patterns longer than the working table.

Any Question to Laser Cutting Rayon Fabric?

Let Us Know and Offer Further Advice and Solutions for You!

Recommended Rayon Laser Cutting Machine

At MimoWork, we specialize in cutting-edge laser cutting technology for textile production, with a particular focus on pioneering innovations in Velcro solutions.

Our advanced techniques tackle common industry challenges, ensuring impeccable outcomes for clients across the globe.

Laser Power: 100W/150W/300W

Working Area (W * L):1600mm * 1000mm (62.9” * 39.3 ”)

Laser Power: 100W/150W/300W

Working Area (W * L): 1800mm * 1000mm (70.9” * 39.3 ”)

Laser Power: 150W/300W/450W

Working Area (W * L): 1600mm * 3000mm (62.9’’ *118’’)

Related Articles

FAQs

1. Is Rayon a Good Quality Fabric?

Rayon is a fabric with numerous appealing qualities. It has a smooth texture, is highly absorbent, affordable, biodegradable, and adaptable for various uses. Additionally, it flows gracefully when draped.

2. Will Rayon Fabric Shrink?

Rayon fabric is prone to shrinking, particularly during laundering and drying. To reduce the risk of shrinkage, always refer to the care label for specific instructions.

The care label provides the most reliable guidance for maintaining your rayon garments.

Green Rayon Dress

Blue Rayon Scarf

3. What Are the Disadvantages of Rayon Fabric?

Rayon also has some drawbacks. It is prone to wrinkling, shrinking, and stretching over time, which can affect its longevity and appearance.

4. Is Rayon a Cheap Fabric?

Rayon serves as a more affordable alternative to cotton, offering a cost-effective option for consumers.

Its accessible price point makes it widely available to more people, particularly those looking for quality fabrics without a high price tag.

This budget-friendly material is a popular choice for those seeking practical yet functional textiles.