Laser Welding vs TIG Welding: Niki cyahindutse muri 2024

Gukoresha Laser Welding ni iki?

Ikiganza cya Laser Welding Icyuma

Intoki zo gusudiraikoresha igikoresho cyoroshye cya laser kugirango ihuze ibikoresho, mubisanzwe ibyuma.

Intoki ya laser yo gusudira iremerakininikuyobora no kumenya neza,

Kandi itanga ubuziranenge bwo hejuru, busukuye hamwentoyaubushyuhe,

Kugabanyakugoreka no gukenera gutunganywa nyuma ya weld.

Abakoresha barashobora guhindura byoroshye imbaraga n'umuvuduko wa laser,

GushobozaIgenamitererekubikoresho bitandukanye n'ubunini.

Imbonerahamwe y'ibirimo:

Laser Weld Isukura Niki?

Akamaro k'isuku muri Welding

Isuku-mbere yo gusukura kuri TIG yo gusudira

Ku bijyanye no gusudira,

Isuku igira uruhare runini mu kubigerahoubuziranengeibisubizo.

Iri hame rireba byombi gusudira TIG hamwe no gusudira lazeri,

Ariko uburyo bwo gutegura ibikoresho buratandukanye cyane.

Kubikorwa byose byo gusudira,

Kuba hari umwanda nka ingese, irangi, n'amavuta

Birashobokakumvikana cyaneubusugire bwa weld.

Iyi myanda irashobora gukurura ingingo zidakomeye, ubwoba, nizindi nenge

Ibyo bigabanya imbaraga zibicuruzwa byanyuma.

Uku Nuburyo WoweBIKWIYEKemura ibi byanduye:Isuku ya Laser Weld.

Laser Welding vs TIG Welding: Gusukura Laser Weld

Ubuso busukuye butanga ubuziranenge bwo hejuru

Isuku ya Laser Weld yo Gusukura Intoki

Mugihe gusudira TIG gushingiraimfashanyigishouburyo bwo gukora isuku nko gusya inguni no guhanagura acetone,

Intoki za laser welding zitanga byinshibyoroshyeubundi hamwe nubushobozi bwayo bwogukora isuku.

Ibi bishya ntabwo byongera imikorere gusa

Ariko kandi iremeza ko gahunda yo gusudira ikora neza bishoboka,

Kurangiza biganisha kubisubizo byiza.

Gutegura gusudira TIG:

Muri TIG (Tungsten Inert Gas) gusudira, gutegura neza ni ngombwa.

Mbere yo gutangira gahunda yo gusudira,

Birasanzwe gukoreshaingunigukuraho ingese cyangwa ibifuniko hejuru yibikoresho.

Iri suku ryimashini rifasha kwemeza ko ubuso butarangwamo umwanda.

Gukurikira ibi, guhanagura neza hamweacetoneni Bisanzwe.

Acetone nigisubizo gikomeye cyaneikuraho nezaamavuta yose asigaye cyangwa yanduye,

Kureka ubuso busukuye kuri weld.

Ubu buryo bubiri bwo gukora isuku burashobora gutwara igihe,

Ariko ni ngombwa kugirango ugere kuri weld ikomeye kandi iramba.

Amaboko ya Laser Welding Gutegura

Ibinyuranye, lazeri yo gusudira itanga

Birenzehouburyo bworoshyeKuri Gutegura.

Hamwe na3-muri-1gusudira laser, inzira iba yoroshye cyane.

Izi mashini zateye imbere mubisanzwe ziza zifite ibikoreshoguhinduranya amajwi

Ibyo bituma habaho isuku hejuru mbere yo gusudira.

Bitandukanye nuburyo gakondo, aho hakenewe ibikoresho bitandukanye nibikoresho byogusukura,

Abasudira ba Laser barashobora gusukura bitagoranye hejuru yumurongo wa laser.

Ibi ntibitwara igihe gusa ahubwo binagabanyaingano y'ibikoreshobikenewe ku rubuga.

Laser Welding vs TIG Welding Yahindutse muri 2024

Twandikire Kubindi Byerekeranye na Handheld Laser Welding Sisitemu

Kuki Ukoresha Shielding muri Welding?

Guhitamo Gukingira Gaz Bitanga Uruhare Rwingenzi

Gukingira Gazi yo gusudira TIG: Argon

Ku bijyanye no gusudira,

Guhitamo gukingira gaze ningirakamaro kugirango habeho ibisubizo byiza.

By'umwihariko, gusudira TIG hamwe no gusudira intoki za laser bifite ibisabwa bitandukanye

Mugihe cyo gukingira imyuka, bigira ingaruka kumikorere ndetse nigiciro.

Gukingira gaze muriTIG Welding

Muri TIG (Tungsten Inert Gas) gusudira,

Gazi yambere ikingira ikoreshwa niubuziranengeargon.

Iyi gaze nziza yatoranijwe kubushobozi bwayo buhebuje bwokurinda ikidendezi

Biturutse ku kwanduza ikirere, cyane cyane okiside.

Oxidation irashobora gushikanainengemu gusudira, nk'ububabare hamwe n'ingingo zidakomeye,

Nindekumvikanaubusugire rusange bwicyuma.

Kubera imikorere yayo,

Gusudira TIG akenshi bisaba abikomejeitangwa rya argon murwego rwo gusudira.

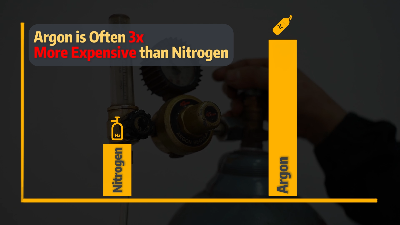

Ariko, argon irashobora kubahenze cyane, biganisha kumafaranga menshi yo gukora,

Cyane cyane mumishinga isaba gusudira cyane.

Gukingira gaze muriIntoki za Laser Welding

Ubundi buryo bwo gukingira gaz yo gusudira Laser: Azote

Ku rundi ruhande, gusudira kwa lazeri akenshi bifashisha azote nka gaze ikingira.

Azote ntabwo yonyineingirakamaromu gukumira okiside

Ariko nanone ni byinshi cyanebidahenzekuruta argon.

Itandukaniro ryibiciro rirashobora kuba ryinshi;

Azote irashobora kuba hafiinshuro eshatubihendutse kuruta argon nyinshi.

Ibi bituma azote ihitamo neza ubucuruzi bushaka kugabanya ibicironta gitamboubuziranenge.

TIG vs Laser Welding: Shielding Amahitamo

Kugera ku Kuzigama Mugihe Ukomeza Ubwiza

Kugereranya Ibiciro Hagati ya Argon na Azote

Guhindura azote muri lazeri yo gusudirabyinshiibyiza

Kuzigama:

Hamwe nagikomeyeitandukaniro ryibiciro hagati ya argon na azote,

Gukoresha azote birashobora gutuma uzigama cyane mugihe.

Ubu niingirakamaro cyaneku mishinga minini cyangwa ubucuruzi

Ibyo bikora ibikorwa byo gusudira kenshi.

Kurinda neza:

Azote itangagukingira bihagijeKurwanya okiside,

Kugenzura niba gusudira kugumaisuku kandi ikomeye.

Mugihe argon izwiho kurinda hejuru,

Azote iracyahariamahitamo mezaibyo byujuje neza ibikenewe byinshi byo gusudira.

Gereranya uburyo bwo gusudira: Laser vs TIG Welding

Witonze witonze tekinike igera kubisubizo byiza

Inguni iboneye yo gusudira Laser: Impamyabumenyi 45

Iyo gaze ikingira imaze kugenda neza,

Igihe kirageze cyo kwibanda kubikorwa byo gusudira.

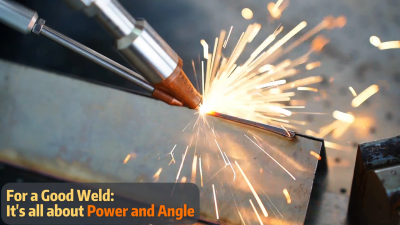

Byombi TIG (Tungsten Inert Gas) gusudira hamwe na laser yo gusudira

Sabatekinorojikugera ku bisubizo byo mu rwego rwo hejuru,

Ariko, baratandukanye mubisabwa byabo nuburyo bwabo.

TIG WeldingUbuhanga

Intego yo kubungabunga electrode kuri anintera nziza n'umuvudukogukora no kuyobora pisine.

Iyi ntera irashobora gutandukana bitewe nibikoresho nubunini burimo gusudwa.

Kugumana inguni nziza, mubisanzwe hafiDogere 15 kugeza kuri 20,

Ifasha mukugera kuri weld ihamye kandi isukuye.

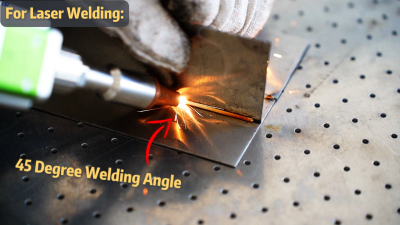

Intoki za Laser WeldingUbuhanga

Imwe mu nyungu zo gusudira laser nubushobozi bwo gushiraho inguni ihamye

MubisanzweDogere 45, kwemerera gucunga byoroshye inzira yo gusudira.

Inguni imaze gushyirwaho, kubungabungaumuvuduko uhamyeni urufunguzo.

Intoki za laser zo gusudira mubisanzwe zitanga umusaruroubushyuhe bukeugereranije no gusudira TIG.

Ibi bivuze ko harihoibyago bike byo kurwana cyangwa kugoreka,

Kubikora neza kubikorwa byuzuye kubikoresho byoroshye.

Laser Weld Imbaraga vs TIG: Kwamagana Ibinyoma

Ibitekerezo Byibisanzwe Kubijyanye no gusudira Laser

Kubikoresho byiza bya Laser Welding: Imbaraga & Inguni

Imwe mu nyungu zingenzi zo gusudira lazeri ni ubushobozi bwayo bwo gutanga ingufunezaaho bikenewe.

Hamwe naIgenamiterere ryiburyona anInguni nziza

MubisanzweDogere 45gusudira laser birashobora kugera kubintu byiza byinjira nimbaraga.

Imbaraga Zisohoka

Imbaraga zo gusudira laser ni ngombwa.

Hasi cyane yingufu zisohoka zirashobora kuvamokwinjira bidahagije, biganisha ku ntege nke.

Ibinyuranye, urwego rwimbaraga rukwiye rutuma lazeri ishonga ibintu neza, bigakora ingingo zikomeye.

Gukoresha ibikoresho bidafite imbaraga ntibishobora gutanga ibisubizo byifuzwa.

Byombi TIG na Handheld Laser Welding irakora

Urashaka kumenya byinshi kubyerekeye gusudira Laser Welding?

Intoki za Laser Welding: Uburyo bwo Kubungabunga Ibikoresho

Kwitaho neza no kwitondera amakuru arambuye bizemeza umusaruro no kwizerwa

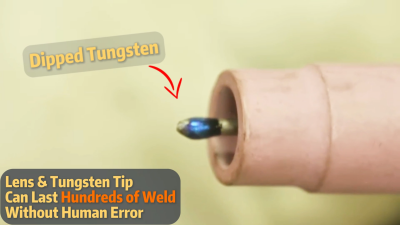

Wari uzi ko gusudira kwa TIG (Tungsten Inert Gas) byombi hamwe no gusudira bya laser byashyizwe mubikorwa nka

Uburyo budasanzwe bwo gusudira?

Ibi bivuze ko, mubihe byiza kandi hamwe nubwitonzi bukwiye,

Ibyingenzi byingenzi bikoreshwa muribi bikorwa birashobora kumara igihe kirekire

Utarinze gukenera gusimburwa kenshi.

Ibidakoreshwa

Ikosa rya Tungsten Ikosa ryo gusudira TIG

Tungsten electrode nikintu gikomeye muburyo bwo gusudira TIG.

Bitandukanye na electrode ikoreshwa ikoreshwa mubundi buryo bwo gusudira,

nka MIG gusudira, tungsten electrodentishongamugihe cyo gusudira.

Ahubwo, ikomeza ubunyangamugayo bwayo, yemerera gukoresha igihe kirekire.

Nyamara, electrode irashobora kwanduzwa cyangwa "kwibizwa" iyo ibonyehafi cyane ya pisine yashongeshejwe.

Mubihe nkibi, bigomba gucibwa inyuma nubutaka kugirango bigarure ingingo ityaye kandi ikora neza.

Kubungabunga buri giheya tungsten electrode ni ngombwa kugirango igere ku isuku nziza, nziza.

Amaboko ya Laser Welding Gutegura

Ibikoresho bya Laser byo gufata neza Laser Welding Kubungabunga

Mu gusudira intoki za lazeri, lens ya laser ikora nkibintu byibanze kumurongo wa laser.

Lens ihagaze neza irashobora kumara igihe kirekire, itanga imikorere ihamye.

Ariko, niba lens yacitse kubera guhagarara nabi cyangwa guhura nubushyuhe bukabije

Bizakenera gusimburwa.

Kubungabunga lens mumeze neza ni ngombwa,

Nkuko byangiritse byoroheje bishobora kugira ingaruka kumikorere ya laser, biganisha kuri suboptimal weld.

Urashaka Igitabo Cyuzuye Cyerekeranye na Welding ya Laser?

Intoki za laser welding zitanga ibyiza byinshi,

Ariko birasaba kandi kwitondera byimazeyo protocole yumutekano.

Iyi ngingo izasesengura ibyingenzi byingenzi byerekeranye numutekano wo gusudira laser.

Nka gutanga ibyifuzo kubijyanye no gukingira gaze no guhitamo insinga zuzuza ubwoko bwicyuma gisanzwe.

Ese gusudira Laser birakomeye nka TIG Welding?

Gusudira Lasergusudira kwa TIG (Tungsten Inert Gas) byombi bizwiho ubuziranenge n'ubwiza mu guhuza ibyuma.

Ariko nigute bahagurukirana muburyo bw'imbaraga?

Muriyi videwo, tuzibira muburyo butandukanye muriimikorere yo gusudira,guhuza ibikoresho, nakuramba muri rusangehagati ya laser na TIG gusudira.

Intoki za Fibre Laser Welding (Intoki ya Laser Weld)

Agaciro kiyongereye kuri Handheld Laser Weld Ahantu nyaburanga

Gitoya ya Laser Welder ituma gusudira Igiciro-cyiza & Byoroshye

Hamwe nimashini yoroheje kandi ntoya.

Imashini igendanwa ya laser welder ifite ibikoresho byimukanwa bya laser welder imbunda aribyoyoroheje.

Kandi byoroshye kubikorwa byinshi byo gusudira kuriInguni iyo ari yo yosenahejuru.

Hitamo ubwoko butandukanye bwa laser welder nozzles.

Sisitemu yo kugaburira ibyuma byikora ituma ibikorwa byo gusudira byoroha kandi byoroshye kubatangiye.

Ibintu 5 byerekeranye no gusudira Laser (Ko wabuze)

Niba wishimiye iyi videwo, kuki utayitekerezahokwiyandikisha kumuyoboro wa Youtube?

Bifitanye isano Porogaramu Urashobora gushimishwa:

Handheld Laser Weld ni Ihitamo ryiza kubikorwa byo gusudira intoki

Kandi Kazoza gatangirana nawe!

Igihe cyo kohereza: Nzeri-14-2024