Laser Cutting for SEG Wall Display

Confused about what makes Silicone Edge Graphics (SEG) a go-to for high-end displays?

Let’s decode their structure, purpose, and why brands love them.

What Are Silicone Edge Graphics (SEG)?

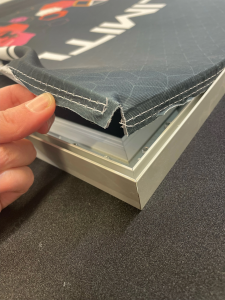

SEG Fabric Edge

SEG is a premium fabric graphic with a silicone-edged border, designed to stretch tautly into aluminum frames.

Combines dye-sublimated polyester fabric (vivid prints) with flexible silicone (durable, seamless edges).

Unlike traditional banners, SEG offers a frameless finish – no visible grommets or seams.

SEG’s tension-based system ensures a wrinkle-free display, ideal for luxury retail and events.

Now that you know what SEG is, let’s explore why it outperforms other options.

Why Use SEG Over Other Graphic Options?

SEG isn’t just another display – it’s a game-changer. Here’s why professionals choose it.

Durability

Resists fading (UV-resistant inks) and wear (reusable for 5+ years with proper care).

Aesthetics

Crisp, high-resolution prints with a floating effect – no hardware distractions.

Easy Installation & Cost-Effective

Silicone edges slip into frames in minutes, reusable for multiple campaigns.

Sold on SEG? Here's what we offer for Large Format SEG Cutting:

Designed for SEG Cutting: 3200mm (126 inches) in Width

• Laser Power: 100W/150W/300W

• Working Area: 3200mm * 1400mm

• Conveyor Working Table with Auto Feeding Rack

How Are Silicone Edge Graphics Made?

From Fabric to Frame-Ready, Uncover the Precision behind SEG Production.

Design

Files are optimized for dye-sublimation (CMYK color profiles, 150+ DPI resolution).

Printing

Heat transfers ink onto polyester, ensuring fade-resistant vibrancy. Reputable printers use ISO-certified processes for color accuracy.

Edging

A 3-5mm silicone strip is heat-sealed to the fabric’s perimeter.

Check

Stretch-testing ensures seamless tension in frames.

Ready to see SEG in action? Let’s explore its real-world applications.

Where Are Silicone Edge Graphics Used?

SEG isn’t just versatile – it’s everywhere. Discover its top use cases.

Retail

Luxury store window displays (e.g., Chanel, Rolex).

Corporate Offices

Branded lobby walls or conference dividers.

Events

Trade show backdrops, photo booths.

Architectural

Backlit ceiling panels in airports (see “SEG Backlit” below).

Fun Fact:

FAA-compliant SEG fabrics are used in airports globally for fire safety.

Wondering about costs? Let’s break down the pricing factors.

How to Laser Cut Sublimation Flag

Cutting sublimated flags with precision is made easier with a large vision laser cutting machine designed for fabric.

This tool streamlines automatic production in the sublimation advertising industry.

The video showcases the operation of the camera laser cutter and illustrates the process of cutting teardrop flags.

With a contour laser cutter, customizing printed flags becomes a straightforward and cost-effective task.

How Are Silicone Edge Graphics Costs Determined?

SEG pricing isn’t one-size-fits-all. Here’s what impacts your quote.

SEG Wall Display

Larger graphics require more fabric and silicone. Economy polyester vs. premium fire-retardant options. Custom shapes (circles, curves) cost 15-20% more. Bulk orders (10+ units) often get 10% discounts.

What Does SEG Mean in Printing?

SEG = Silicone Edge Graphic, referring to the silicone border enabling tension-based mounting.

Coined in the 2000s as a successor to “Tension Fabric Displays.”

Don’t confuse it with “silicon” (the element) – it’s all about the flexible polymer!

What Is SEG Backlit?

The glowing cousin of SEG, Meet SEG Backlit.

Backlit SEG Dispaly

Uses translucent fabric and LED lighting for eye-catching illumination.

Ideal for airports, theaters, and 24/7 retail displays.

Costs 20-30% more due to specialized fabric/light kits.

Backlit SEG increases nighttime visibility by 70%.

Finally, let’s geek out on SEG fabric’s makeup.

What Is SEG Fabric Made Of?

Not all fabrics are equal. Here’s what gives SEG its magic.

| Material | Description |

| Polyester Base | 110-130gsm weight for durability + color retention |

| Silicone Edge | Food-grade silicone (non-toxic, heat-resistant up to 400°F) |

| Coatings | Optional antimicrobial or flame-retardant treatments |