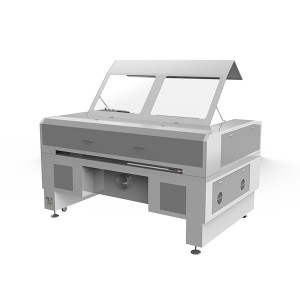

CO2 Mashiinka Xardhitaanka Laser ee alwaax (Plywood, MDF)

▶ Sawir-qorista Laser-ka ee Qoryaha

Xogta Farsamada

| Goobta Shaqada (W *L) | 1300mm * 900mm (51.2" * 35.4") |

| Software | Software-ka khadka tooska ah |

| Awoodda leysarka | 100W/150W/300W |

| Isha Laser | CO2 Tube Laser Glass ama CO2 RF Birta Laser tube |

| Nidaamka Xakamaynta Makaanikada | Talaabada Xakamaynta Suunka Matoorka |

| Shaxda Shaqada | Miiska Shaqada Shanlada Malabka ama Jeexitaanka Middida Miis-Shaqada |

| Xawaaraha ugu badan | 1 ~ 400mm/s |

| Xawaaraha Dardargelinta | 1000 ~ 4000mm/s2 |

| Cabbirka Xidhmada | 2050mm * 1650mm * 1270mm (80.7'' * 64.9'' * 50.0'') |

| Miisaanka | 620kg |

cusboonaysiinta Ikhtiyaarka: CO2 RF Metal Laser Tube Showcase

Multifunction in Wood Laser Engraver

Naqshad laba-dhinac ah

Dhisme xasiloon oo badbaado leh

◾ Iftiinka ishaarka

Iftiinka ishaadu waxay tilmaami kartaa xaalada shaqada iyo shaqada mashiinka laysarka, waxay kaa caawineysaa inaad sameyso xukunka saxda ah iyo hawlgalka.

◾ Badhanka Degdegga ah

Xaalad lama filaan ah oo lama filaan ah ku dhacdo, badhanka deg-degga ahi waxa uu noqon doonaa dammaanad qaadka badbaadada adiga oo hal mar joojinaya mishiinka.

◾ Wareegga Badbaadada ah

Hawlgalka fudud ayaa shardi u ah wareegga si fiican u shaqeeya, kaas oo ammaankiisu yahay dhismaha wax soo saarka badbaadada.

◾ Shahaadada CE

Lahaanshaha xuquuqda sharciga ah ee suuqgeynta iyo qaybinta, MimoWork Laser Machine ayaa ku faantay tayada adag oo la isku halayn karo.

◾ Caawimaadda Hawada la hagaajin karo

Caawinta hawadu waxay afuufi kartaa burburka iyo jajabyada ka yimaadda dusha sare ee alwaax xardhan, waxayna siinaysaa shahaado hubinta ka hortagga gubashada alwaax. Hawo ciriiri ah oo ka timaadda bamka hawo-mareenka ayaa la geeyaa khadadka xardhay iyada oo loo marayo sanbabada, nadiifinta kulaylka dheeraadka ah ee ku soo ururay qoto dheer. Haddii aad rabto inaad gaadho aragti gubasho iyo mugdi ah, hagaaji cadaadiska iyo xajmiga socodka hawada rabitaankaaga. Wixii su'aalo ah oo aad nagala tashato haddii aad ku wareersan tahay taas.

La cusboonaysiiyay

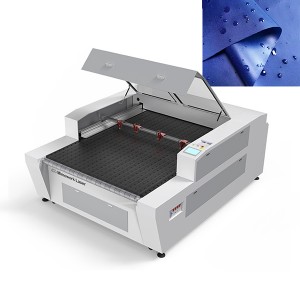

Kamarada CCD ee alwaaxdaada daabacan

Kamarada CCD waxay aqoonsan kartaa oo heli kartaa qaabka daabacan ee looxa alwaax si ay uga caawiso laysarka goynta saxda ah. Calaamadaha alwaaxyada, taarikada, farshaxanka iyo sawirka alwaax ee ka samaysan alwaax daabacan ayaa si fudud loo farsamayn karaa.

Habka wax soo saarka

Tallaabada 1.

>> Si toos ah ugu daabac qaabkaaga sabuuradda alwaax

Tallaabada 3.

>> Ururi qaybaha aad dhammaysay

(Alwaha xardhaynta iyo gooyaha ayaa kor u qaada wax soo saarkaaga)

Ikhtiyaarada kale ee cusboonaysiinta ee aad doorato

Servo Motors

Matoorada aan Brushless DC

Isku-dhafka Laser Head

Diirada tooska ah

Kubadda & Maroojin

Tusaalooyinka Qorista Laser-ka

Nooc noocee ah Mashruuc Alwaax ah ayaan ku Shaqeyn Karaa CO2 Laser Engraver?

• Calaamadaha gaarka ah

• Saxaarad alwaax ah, Sariiro, iyo Sariiro

•Qurxinta Guriga (Farshaxanka gidaarka, saacadaha, nalalka iftiinka)

•Halxiraalaha iyo Xarfaha alifbeetada

• Qaababka dhismaha/Prototypes

Muqaal Videos

Laser Sawirka Qoryaha Ku Xardhay

✔Naqshad dabacsan oo la habeeyey oo la gooyey

✔Nadiifi iyo qaabab xardho adag

✔Saamaynta saddex-geesoodka ah oo leh awood la isku hagaajin karo

Alaabta caadiga ah

- Goynta laysarka iyo alwaax xardhan (MDF)

Bamboo, Balsa Wood, Beech, Cherry, Chipboard, Cork, Hardwood, Alwaax Laamidan, MDF, Multiplex, alwaax dabiici ah, alwaax, alwaax adag, alwaax adag, alwaax, Teak, Weelasha, Walnut…

Vector Laser Xardho Alwaax

Xadhkaha laysarka ee alwaax waxa loola jeedaa isticmaalka gooyo leysarka si loo sawiro ama u xardho naqshadaha, qaababka, ama qoraalka dusha sare ee alwaax. Si ka duwan xaradhka raster-ka, kaas oo ku lug leh gubanaya pixels si loo abuuro sawirka la rabo, xardhitaanka vector waxay isticmaashaa wadooyin lagu qeexay isla'egyada xisaabta si loo soo saaro khadad sax ah oo nadiif ah. Habkani wuxuu u oggolaanayaa in lagu xardho fiiqan oo faahfaahsan oo alwaax ah, maaddaama laysarka uu raacayo waddooyinka vector si loo abuuro naqshadeynta.

Wax su'aalo ah oo ku saabsan sida looxa xardho laser ah?

Mashiinka Laser Wood La Xiriira

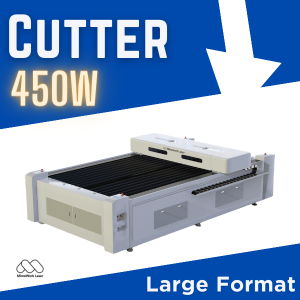

Alwaax iyo Akril Laser Cutter

• Ku habboon agabka adag ee qaabka weyn

• Goynta dhumucda badan oo leh awoodda ikhtiyaarka ah ee tuubada laysarka

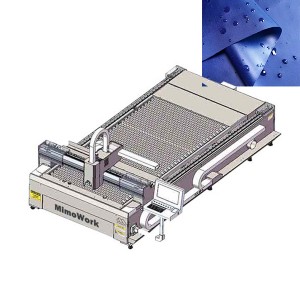

Alwaax iyo Akril Laser Engraver

• Nakhshad iftiin iyo cufan

• Fudud in lagu shaqeeyo bilowga

# Maxaa la ogaadaa ka hor goynta laysarka & alwaax xaradhka?

Waxaa muhiim ah in la ogaado in noocyada kala duwan ee alwaax ay leeyihiincufnaanta kala duwan iyo nuxurka qoyaanka, taas oo saameyn karta habka laser-goynta. Qoryaha qaar ayaa laga yaabaa inay u baahdaan hagaajinta goobaha goynta laysarka si loo gaaro natiijooyinka ugu fiican. Intaa waxaa dheer, marka laser-goynta alwaax, hawo habboon iyohababka qiiqawaxay lagama maarmaan u yihiin in meesha laga saaro qiiqa iyo qiiqa ka dhashay hawsha.

# Intee qaro weyn oo alwaax ah ayaa gooyn kara laysarka?

Qalabka laser CO2, dhumucda alwaax ee si wax ku ool ah loo jari karo waxay kuxirantahay awooda laysarka iyo nooca alwaax ee loo isticmaalo. Waa muhiim in maskaxda lagu hayo taasdhumucda goyntu way kala duwanaan kartaaiyada oo ku xidhan goynta laser CO2 gaar ah iyo soo saarka korontada. Qaar ka mid ah qalabka korontada ku shaqeeya ee CO2 laser ayaa laga yaabaa inay awoodaan inay gooyaan alaabta dhumuc weyn leh, laakiin waa lagama maarmaan in la tixraaco qeexida gooyaha laser gaarka ah ee loo isticmaalo awoodaha goynta saxda ah. Intaa waxaa dheer, alaabta dhumuc weyn ayaa laga yaabaa inay u baahdaanxawaaraha goynta oo gaabis ah iyo baas badansi loo gaaro goyn nadiif ah oo sax ah.

# Mashiinka laysarka ma jari karaa qoryo nooc kasta ah?

Haa, laser CO2 wuxuu gooyn karaa oo xarri karaa alwaax nooc kasta ah, oo ay ku jiraan bjørk, maple,alwaax, MDF, cherry, mahogany, alder, poplar, geed, iyo bamboo. Alwaax aad u cufan ama adag sida geedka geedka ama ebony wuxuu u baahan yahay awood sare oo leysarka si loo farsameeyo. Si kastaba ha ahaatee, dhammaan noocyada alwaax warshadaysan, iyo chipboard,iyadoo ay ugu wacan tahay nuxurka wasakhda sare leh, laguma talinayo in la isticmaalo farsamaynta laysarka

# Suurtagal ma tahay in alwaax jarista laysarka uu waxyeeleeyo alwaaxyada uu ku shaqaynayo?

Si loo ilaaliyo daacadnimada alwaaxda ku wareegsan mashruuca goynta ama xoqidda, waxaa muhiim ah in la hubiyo in habayntu ay yihiinsi habboon loo habeeyey. Si aad u hesho hagitaan faahfaahsan oo ku saabsan habaynta saxda ah, la tasho buug-gacmeedka MimoWork Wood Laser Engraving Machine ama sahamin agabka taageerada dheeraadka ah ee laga heli karo mareegahayaga.

Markaad garaacdo goobaha saxda ah, waxaad ku kalsoonaan kartaa inuu jirokhatar uma laha waxyeeloalwaax ku dheggan xadhkaha goosan ee mashruucaaga. Tani waa halka ay ka soo ifbaxdo kartida gaarka ah ee mashiinnada laser CO2 - saxnimadooda gaarka ah ayaa ka soocaya agabka caadiga ah sida miinshaarta duubka iyo miisyada.