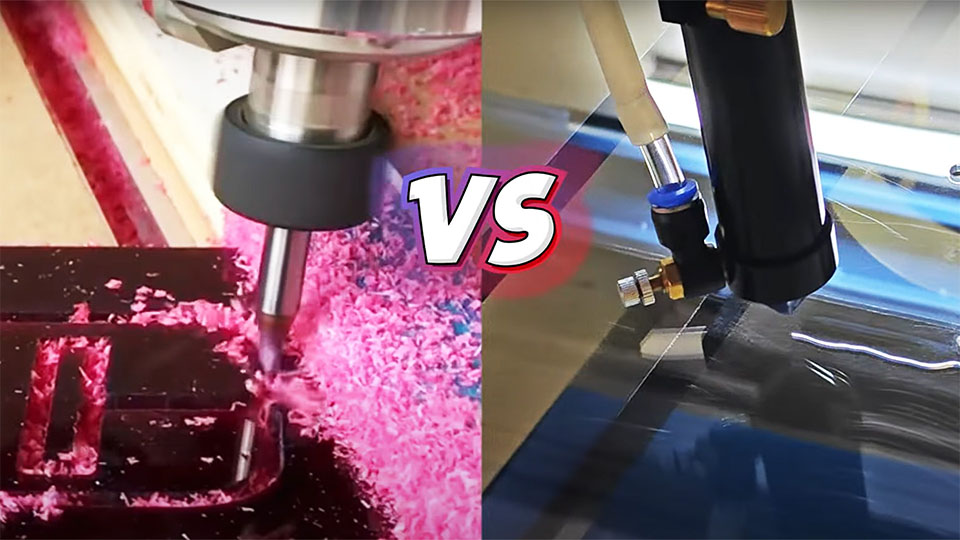

Marka ay timaaddo goynta akriliska iyo xaradhka, router-yada CNC iyo laser-ka ayaa inta badan la barbar dhigaa. Midkee wanaagsan? Runtu waxay tahay, way kala duwan yihiin laakiin way is dhammaystiraan iyagoo doorar gaar ah ka ciyaaraya meelo kala duwan. Waa maxay kala duwanaanshahan? Sideese tahay inaad doorato? Maqaalka ka gudub oo noo sheeg jawaabtaada.

Sidee U Shaqeeyaa? CNC Akril Goynta

CNC router waa qalab goynta dhaqameed oo si ballaaran loo isticmaalo. Qaybo kala duwan ayaa xamili kara jarista iyo xaradhka akril qoto dheer oo kala duwan. Routers CNC waxay gooyn karaan xaashida akril ilaa 50mm qaro weyn, taas oo u fiican xarfaha xayaysiinta iyo calaamadaha 3D. Si kastaba ha ahaatee, CNC-cut akril waxay u baahan tahay in la nadiifiyo ka dib. Sida mid ka mid ah khabiirada CNC uu yidhi, 'Hal daqiiqo in la gooyo, lix daqiiqo in la nadiifiyo.' Tani waa waqti-qaadasho. Waxaa dheer, beddelidda xoogaa yar iyo dejinta cabbirro kala duwan sida RPM, IPM, iyo heerka quudinta waxay kordhisaa waxbarashada iyo kharashka shaqada. Waxa ugu xun waa boodhka iyo qashinka meel kasta, kuwaas oo khatar gelin kara haddii la nuugo.

Taas bedelkeeda, akril goynta laysarka ayaa ka nadiifsan oo ka badbaadsan.

Sidee U Shaqeeyaa? Goynta Laser Acrylic

Goynta nadiifka ah iyo jawi shaqo oo badbaado leh ka sokow, gooyayaasha laysarka waxay bixiyaan goyn sare iyo saxnaanta xaradhka oo leh alwaax khafiif ah sida 0.3mm, kaas oo CNC aan la mid noqon karin. Looma baahna dhalaalid ama waxoogaa isbeddel ah, oo nadiifin yar, goynta laysarka waxay qaadataa 1/3 oo keliya wakhtiga wax-shiidka CNC. Si kastaba ha ahaatee, goynta laser waxay leedahay xaddidaadyo dhumucdiisuna. Guud ahaan, waxaan kugula talineynaa in la gooyo akril gudaha 20mm si loo gaaro tayada ugu fiican.

Haddaba, yaa dooranaya gooyaha laysarka? Oo yaa dooranaya CNC?

Yay tahay inay doortaan CNC router?

Geek makaanikada

Haddii aad khibrad u leedahay injineernimada farsamada oo aad xamili karto cabbirro adag sida RPM, heerka quudinta, biibiile, iyo qaababka caarada (cue animation of CNC router oo ay ku hareeraysan yihiin ereyo farsamo oo leh muuqaal 'maskax la shiilay'), router CNC waa doorasho weyn.

• Wixii Goynta Walxaha Dhumucsan

Waxay ku habboon tahay in la gooyo acrylic qaro weyn, in ka badan 20mm, taasoo ka dhigaysa mid ku habboon xarfaha 3D ama muraayadaha aquarium qaro weyn.

• Wax-qorista Qoto dheer

CNC router aad ayuu ugu fiican yahay hawlaha xaradhka qoto dheer, sida xaradhka shaambada, taas oo ay ugu wacan tahay mishiinkiisa xoogga badan.

Yaa Dooran Laydhka Router?

• Hawlaha Saxda ah

Ku habboon hawlaha u baahan saxnaanta sare. Looxyada dhinta acrylic, qaybaha caafimaadka, baabuurka iyo dashboard-yada diyaarada, iyo LGP, laysarka gooya wuxuu gaari karaa sax 0.3mm.

Daah-furnaan sare ayaa loo baahan yahay

Mashaariicda akril ee cad sida sanduuqyada nalka, muraayadaha soo bandhiga LED, iyo dashboards, layseryadu waxay xaqiijiyaan hufnaanta iyo hufnaanta aan isbarbar dhigin.

• Bilawga

Ganacsiyada diiradda saaraya alaabooyinka yaryar, qiimaha sarreeya sida dahabka, qaybaha farshaxanka, ama koobabka, gooyaha laysarka wuxuu bixiyaa fududaan iyo dabacsanaan u habeynta, abuurista tafaasiil qani ah oo wanaagsan.

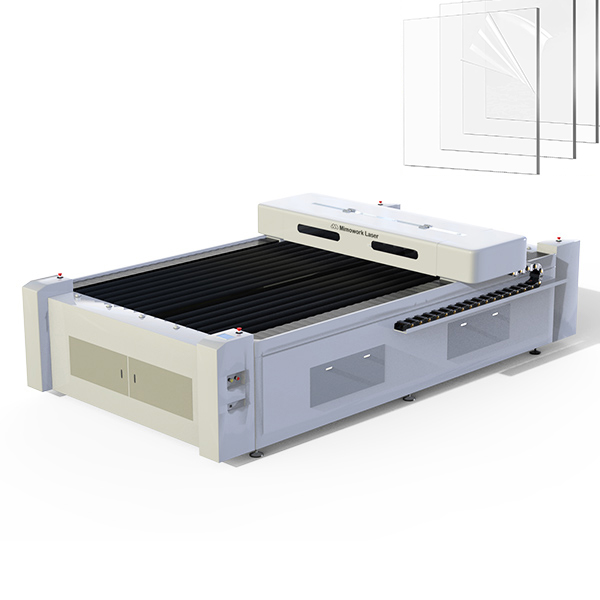

Waxaa jira laba mashiinada goynta laser caadiga ah adiga: Xardhayaasha laser yar yar (goynta iyo xardho) iyo qaab weyn oo xaashida goynta laysarka (kaas oo gooyn kara acrylic qaro weyn ilaa 20mm).

1. Gooyaha Laser-ka Yar ee Acrylic & Engaraver

• Goobta Shaqada (W * L): 1300mm * 900mm (51.2" * 35.4")

• Awoodda leysarka: 100W/150W/300W

Isha Laser: CO2 Glass Laser Tube ama CO2 RF Birta Laser Tube

Xawaaraha ugu badan ee goynta: 400mm/s

Xawaaraha ugu badan ee sawirida: 2000mm/s

TheGooyaha laser fidsan 130waxay ku fiican tahay goynta iyo xaradhka alaabta yaryar, sida silsiladda furaha, qurxinta. Way fududahay in la isticmaalo oo ku habboon naqshad qalafsan.

2. Goosha xaashida weyn ee akril

• Goobta Shaqada (W * L): 1300mm * 2500mm (51" * 98.4")

• Awoodda leysarka: 150W/300W/450W

Isha Laser: CO2 Glass Laser Tube ama CO2 RF Birta Laser Tube

Xawaaraha ugu badan ee goynta: 600mm/s

• Xaqiijinta booska: ≤±0.05mm

Thegooyaha laser fidsan 130Lwaxay ku fiican tahay qaabka weyn ee xaashida akril ama akril qaro weyn. Si fiican u maaraynta calaamadaha xayaysiisyada, bandhiga. Cabbir shaqo oo ka weyn, laakiin gooyn nadiif ah oo sax ah.

Haddii aad leedahay shuruudo gaar ah sida xaradhka alaabta cylindrical, jarista sprues, ama qaybaha baabuurta gaarka ah,nala tashadawaayo, talo laser xirfadeed. Waxaan halkaan u joognaa inaan ku caawinno!

Sharaxaada Fiidiyowga: CNC Router VS Laser Cutter

Marka la soo koobo, router-yada CNC waxay xamili karaan acrylic dhumuc weyn, ilaa 50mm, waxayna bixiyaan kala duwanaansho leh qaybo kala duwan laakiin waxay u baahan yihiin in la jaro ka dib oo ay soo saaraan boodh. Goynta laser-ku waxay bixiyaan nadiifin, goyn sax ah oo ka sii saxsan, looma baahna qalab beddela, iyo qalab la'aan. Laakiin, haddii aad u baahan tahay inaad gooyso acrylic ka sii dhumucdiisuna tahay 25mm, laysarka waxba kuma caawin doonaan.

Marka, CNC VS. Laser, kee baa u fiican wax soo saarka akrilkaaga? Aragtidaada nala wadaag!

1. Waa maxay farqiga u dhexeeya CNC acrylic iyo goynta laser?

Dariiqyada CNC waxay adeegsadaan aaladda goynta wareegta ah si ay jir ahaan uga saaraan walxaha, oo ku habboon akrilik dhumucdiisuna tahay (ilaa 50mm) laakiin badanaa waxay u baahan yihiin suuf. Qalab-jareyaasha laser-ka waxay isticmaalaan laambad layser ah si ay u dhalaaliyaan ama u soo saaraan walxaha, iyagoo siinaya saxan sare iyo cidhifyo nadiif ah iyada oo aan loo baahnayn suuf, ugu fiican akril khafiif ah (ilaa 20-25mm).

2. Goynta leysarka miyuu ka fiican yahay CNC?

Goynta laser-ka iyo router-yada CNC waxay ku fiican yihiin meelo kala duwan. Goynta laser-ku waxay bixiyaan goyn sax ah oo sarreeya, oo ku habboon naqshadaha qallafsan iyo faahfaahinta wanaagsan. Routers-yada CNC waxay xamili karaan agabka dhumuc weyn waxayna u fiican yihiin xaradhka qoto dheer iyo mashaariicda 3D. Doorashadaadu waxay ku xidhan tahay baahiyahaaga gaarka ah.

3. Maxay CNC uga dhigan tahay goynta laysarka?

Goynta laysarka, CNC waxay u taagan tahay "Xakamaynta Tirada Koombuyuutarka." Waxa loola jeedaa xakamaynta iswada ee gooyaha laysarka iyadoo la isticmaalayo kombuyuutar, kaas oo si sax ah u haga dhaqdhaqaaqa iyo hawlgalka laysarka si loo gooyo ama loo xardho agabka.

4. Sidee ugu dhakhsaha badan CNC marka la barbar dhigo laser?

Routers-yada CNC waxay caadi ahaan gooyaan alaabta ka dhumuc weyn marka loo eego kuwa wax gooya laser-ka. Si kastaba ha ahaatee, gooyayaasha laser-ka ayaa si degdeg ah u leh naqshado faahfaahsan oo adag oo ku saabsan alaabta khafiifka ah, maadaama aysan u baahnayn isbeddel qalab waxayna bixiyaan nadiifin nadiif ah oo leh hab-socodka ka dib.

5. Waa maxay sababta diode laser goyn karin akril?

Laysarada Diode waxay la halgami karaan akril sababtoo ah arrimaha hirarka, gaar ahaan walxo cad ama midab leh oo aan si fiican u nuugin iftiinka laysarka. Haddii aad isku daydo inaad gooyso ama ku xaradho akril leh leysarka diode, waxaa fiican inaad marka hore tijaabiso oo aad u diyaargarowdo fashilka iman kara, maadaama helitaanka goobaha saxda ah ay noqon karto mid adag. Xardho, waxaa laga yaabaa inaad isku daydo inaad ku buufiso lakabka rinjiga ama aad ku dhejiso filim dusha sare ee akril, laakiin guud ahaan, waxaan ku talinayaa inaad isticmaasho CO2 laser natiijooyinka ugu fiican.

Intaa waxaa dheer, laysarka diode-ku waxay gooyn karaan qaar mugdi ah oo akril ah. Si kastaba ha ahaatee, ma gooyn karaan ama ma xarri karaan akrilik cad sababtoo ah maaddadu si fiican uma nuugin iftiinka laysarka. Gaar ahaan, leysarka diode-ka buluuga ah ma jari karo ama ma xarri karo akril buluug ah isla sabab la mid ah: midabka ku habboon ayaa ka hortagaya nuugista saxda ah.

6. Layskee ugu fiican in la gooyo akril?

Laysarka ugu fiican ee lagu gooyo akril waa CO2 laser. Waxay bixisaa gooyn nadiif ah, sax ah waxayna awood u leedahay inay jarto dhumucyo kala duwan oo akril ah si wax ku ool ah. Laser-ka CO2 waa kuwo aad waxtar u leh oo ku habboon labadaba acrylic cad iyo midab leh, taas oo ka dhigaysa doorashada la doorbido ee xirfad-yaqaan iyo tayada sare leh ee goynta iyo xardho.

Dooro mashiinka ku habboon wax soo saarkaaga akril! Wixii su'aal ah, nala tasho!

Waqtiga boostada: Jul-27-2024