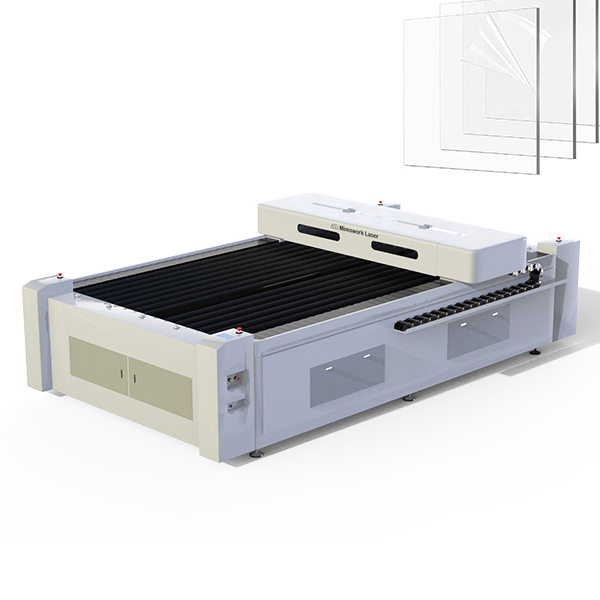

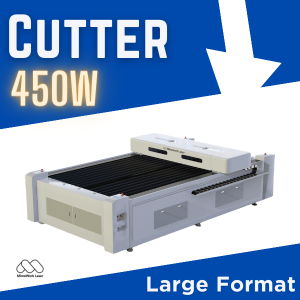

CO2 Mashiinka Goynta Laser-ka ee Sheet Acrylic

▶ mashiinka goynta xaashida akril

Xogta Farsamada

| Goobta Shaqada (W * L) | 1300mm * 2500mm (51" * 98.4") |

| Software | Software-ka khadka tooska ah |

| Awoodda leysarka | 150W/300W/450W |

| Isha Laser | CO2 Tube Laser Glass |

| Nidaamka Xakamaynta Makaanikada | Kubbada Screw & Servo Motor Drive |

| Shaxda Shaqada | Middida Midiyaha ama Miiska Shaqada Malabka |

| Xawaaraha ugu badan | 1 ~ 600mm/s |

| Xawaaraha Dardargelinta | 1000 ~ 3000mm/s2 |

| Xaqiijinta booska | ≤±0.05mm |

| Cabirka Mashiinka | 3800 * 1960 * 1210mm |

| Ku shaqaynta Voltage | AC110-220V± 10%,50-60HZ |

| Qaabka qaboojinta | Nidaamka qaboojinta iyo ilaalinta biyaha |

| Deegaanka shaqada | Heerkulka:0-45℃ Qoyaanka:5%-95% |

| Cabbirka Xidhmada | 3850 * 2050 * 1270mm |

| Miisaanka | 1000kg |

▷Astaamaha 1325 Laser Cutter

Wax-soo-saarka aadka u wayn

◾ Xasillooni & Tayo Goyn heer sare ah

Naqshadaynta Jidka indhaha ee Joogtada ah

Iyada oo dhererka jidka indhaha ee wax soo saarka ugu fiican, laydhka laysarka ee joogtada ah ee meel kasta oo ka mid ah miiska goynta wuxuu keeni karaa in xitaa la gooyo dhammaan walxaha, iyadoon loo eegin dhumucda. Waad ku mahadsan tahay taas, waxaad ka heli kartaa saameyn goynta ka wanaagsan akril ama alwaax marka loo eego dariiqa laysarka ee nuska duulaya.

◾ Waxtarka sare iyo saxnaanta

Nidaamka Gudbinta Waxtarka leh

Qalabka saxda ah ee dhidibka-X-axis, dhidibka Y-dhidibka kubbadda hal dhinac ayaa siinaya xasillooni aad u fiican iyo saxnaanta dhaqdhaqaaqa xawaaraha sare ee gantry. Marka lagu daro mashiinka servo, nidaamka gudbinta wuxuu abuuraa waxtarka wax soo saarka si cadaalad ah.

◾ Cimri waarta oo dheer

Qaab dhismeedka farsamaysan ee deggan

Jirka mishiinka waxa lagu alxanayaa tuubo labajibbaaran oo 100mm ah waxaana la mariyaa gabownimada gariir iyo daawaynta gabowga dabiiciga ah. Gantry iyo madax goynta waxay isticmaalaan aluminium isku dhafan. Qaabaynta guud waxay xaqiijinaysaa xaalad shaqo oo deggan.

◾ Habaynta Xawaaraha Sare

Xawaaraha sare ee jarista iyo xaradhka

Gooyaha laser-ka 1300 * 2500mm wuxuu gaari karaa 1-60,000mm / min xawaaraha xarashka iyo 1-36,000mm / min xawaaraha goynta.

Isla mar ahaantaana, saxnaanta booska ayaa sidoo kale lagu dammaanad qaaday gudaha 0.05mm, si ay u gooyso oo u xardho tirooyinka ama xarfaha 1x1mm, gabi ahaanba dhib ma leh.

DIY mashaariicda goynta laser-ka

Awoodda Sare: Gooyaha Laser-ka Weyn

Calaamadaha La Weyn | Sidee loo gooyaa xaashida akril ee laser?

Mashiinka goynta laser-ka 300W wuxuu leeyahay qaab-dhismeedka gudbinta xasilloon - gear & pinion iyo aaladda wadista servo ee saxda ah ee saxda ah, hubinta dhammaan goynta laser-ka plexiglass oo leh tayo sare oo joogto ah iyo hufnaan. Waxaan leenahay awood sare 150W,300W, 450W, 600W aad mashiinka goynta laysarka acrylic ganacsiga xaashida.

Intee le'eg yahay xaashida akriliga?

Aan ogaano shuruudahaaga oo aan ku siino talo!

Akril qaro weyn | Laser Cut Acrylic Board

xaashi akrilik badan oo dhumucdiisuna waxay ka bilaabataa 10mm ilaa 30mmwaxaa lagu gooyn karaa laser Flatbed Laser Cutter 130250 oo leh awood laser ikhtiyaar ah (150W, 300W, 500W).

Tixgelinta Qaar ka mid ah Xilliga Goynta:

1. Hagaajin caawinta hawada si aad hoos ugu dhigto garaaca hawada iyo cadaadiska si aad u hubiso in akrilku uu si tartiib ah u qaboojin karo

2. Dooro muraayadda saxda ah: Mar kasta oo maadadu sii dhumucdo, ayaa sii dheeraynaysa dhererka isha ee muraayadda

3. Awood sare oo laser ah ayaa lagula talinayaa akril qaro weyn (xaaladba xaalad shuruudo kala duwan)

Ka hel fiidiyowyo badan oo ku saabsan qalabkayaga laysarkayagaMuuqaalka Muuqaalka

Laser Goynta Acrylic: Xawaaraha

Marka ay timaado goynta akril, habka ugu waxtarka badan ayaa inta badan ku lug leh isticmaalka xawaare goyn ah oo gaabis ah oo lagu lamaaniyay koronto sare. Habkan gaarka ah ee goynta ayaa awood u siinaya laydhka laysarka inuu dhalaaliyo cidhifyada akril, taasoo keentay waxa lagu tilmaami karo cidhif ololaysa.

Laser Goynta Acrylic: Jaantuska Xawaaraha

Suuqa maanta, warshado badan oo akrilik ah ayaa bixiya noocyo kala duwan oo akrilik ah, oo ay ku jiraan labbada iyo noocyada kala duwanaanshiyaha, oo lagu heli karo midabyo kala duwan, textures, iyo qaabab. Iyada oo noocyo kala duwan oo ikhtiyaari ah, la yaab maaha in acrylic uu noqday doorasho aad caan u ah goynta laysarka iyo xaradhka. Kala duwanaanshaha iyo kala duwanaanta acrylic waxay ka dhigtaa wax la doorbido mashaariicda laser-ka hal-abuurka ah.

Waa kuwan qaar ka mid ah talooyinka habaynta laser-ka guud ee la shaqaynta akril:

1. Kormeerku waa furaha:

Weligaa ha ka tagin mishiinka laysarka adigoon cidina ilaalin markaad ku shaqaynayso akril. In kasta oo maaddooyin badan ay u nugul yihiin shilalka, acrylic, dhammaan noocyadeeda kala duwan, waxay muujiyeen khatar sare oo gubasho ah marka la gooyo laser. Sida qaanuunka badbaadada aasaasiga ah, ha ku shaqayn mashiinka laysarka - iyadoon loo eegin walxaha la isticmaalayo - la'aanteed joogitaan.

2. Dooro akril sax ah:

Dooro nooca akril ee ku habboon codsigaaga gaarka ah. Maskaxda ku hay in acrylic kabka ay ku habboon tahay xaradhka hawlaha, halka akriliga la saaray uu aad ugu habboon yahay ujeedooyinka goynta laysarka.

3. Kor u qaad akriliga:

Si loo yareeyo milicsiga dhinaca dambe oo kor loogu qaado tayada goynta, ka fiirso sare u qaadida acrylic ee ka sarreeya dusha miiska goynta. Agabka sida Epilog's Pin Table ama hababka kale ee taageerada ayaa loo isticmaali karaa ujeedadan.

Dhamaystirka acrylic goynta laysarka

Bandhigyada Xayeysiiska

• Qaab-dhismeedka

• Bracket

Astaanta Shirkadda

• Alaabooyinka Casriga ah

• Warqado

• Boodhadhka bannaanka

• Meesha alaabta

• Dukaamada ku habboon

• Calaamadaha tafaariiqda

• Koob

(dhegaha goynta leysarka akrilik, calamadaha goynta laser-ka, dahabka goynta leysarka akriliga, xarfaha goynta leysarka…)

cusboonaysii Ikhtiyaarada Laser si aad u doorato

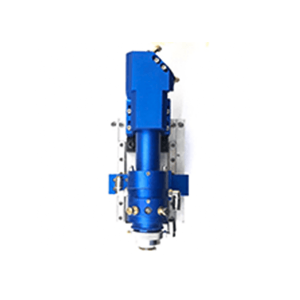

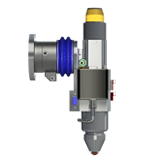

Isku-dhafka Laser Head

Diirada tooska ah

TheKaamirada CCDaqoonsan karaa oo meelayn karaa qaabka on akril daabacan, caawinta gooyaha laser si ay u ogaadaan goynta saxda ah oo tayo sare leh. Naqshad kasta oo garaafyo ah oo la daabaco ayaa si dabacsan loogu habayn karaa iyada oo la raacayo habka indhaha, iyada oo qayb muhiim ah ka ciyaaraysa xayaysiinta iyo warshadaha kale.

Gooyaha xaashida acrylic ee la xidhiidha

goynta laysarka alwaax iyo akril

• Xarigga degdegga ah ee saxda ah ee alaabta adag

• Nakhshad laba-geesood ah oo gelitaanka ayaa u oggolaanaysa in la dhigo oo la gooyo agab aad u dheer

loogu talagalay xaradhka laysarka alwaax iyo akril

• Nakhshad iftiin iyo cufan

• Fudud in lagu shaqeeyo bilowga