Nadiifinta laysarka warshaduhu waa habka toogashada laydhka laysarka ee dusha adag si loo nadiifiyo laysarka loogana saaro walaxda aan loo baahnayn. Tan iyo qiimaha ilaha laser fiber ayaa si weyn hoos ugu dhacay dhowrkii sano ee la soo dhaafay, nadiifiyeyaasha laser-loogu talagalay in lagu caawiyo dadka isticmaala inay nadiifiyaan laser si hufan - waxay buuxiyaan baahiyo badan oo suuq ah iyo rajooyin la dabaqay, sida nadiifinta hababka qaabeynta duritaanka, ka saarida filimada khafiifka ah ama dusha sare sida saliidda, iyo dufanka, iyo qaar kaloo badan. Maqaalkan, waxaan kaga hadli doonaa mowduucyada soo socda:

Liiska nuxurka(guji si aad dhakhso u hesho ⇩)

Waa maxay Nadiifinta Laser?

Dhaqan ahaan, si looga saaro miridhku, rinjiga, oksaydhka, iyo wasakhda kale ee dusha birta ah, nadiifinta farsamada, nadiifinta kiimikada, ama nadiifinta ultrasonic ayaa laga yaabaa in lagu dabaqo. Codsiga hababkani waa mid aad u xaddidan marka loo eego deegaanka iyo shuruudaha saxda ah ee sarreeya.

Habka Nadiifinta Laser

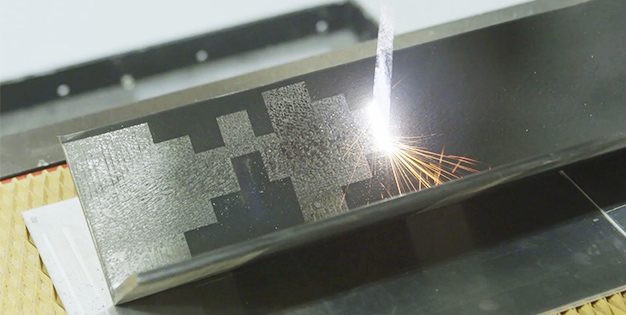

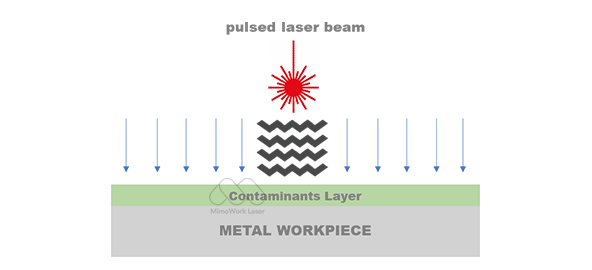

Sannadihii 80aadkii, saynisyahannadu waxay ogaadeen in marka la iftiiminayo dusha daxalsan ee birta tamarta leysarka ee xoogga badan, walaxda la shiiday waxay martaa falcelin isku dhafan oo jireed iyo kiimiko ah sida gariir, dhalaalid, sublimation, iyo gubasho. Natiijadu waxay tahay, wasakhda ayaa laga saaraa oogada maaddada. Habkan fudud ee waxtarka leh ee nadiifinta waa nadiifinta laysarka, kaas oo si tartiib tartiib ah u beddelay hababka nadiifinta dhaqameed ee meelo badan oo leh faa'iidooyin badan oo u gaar ah, oo muujinaya rajooyin ballaaran oo mustaqbalka ah.

Sidee bay u shaqeeyaan Nadiifiyeyaasha Laser?

Mashiinka Nadiifinta Laser

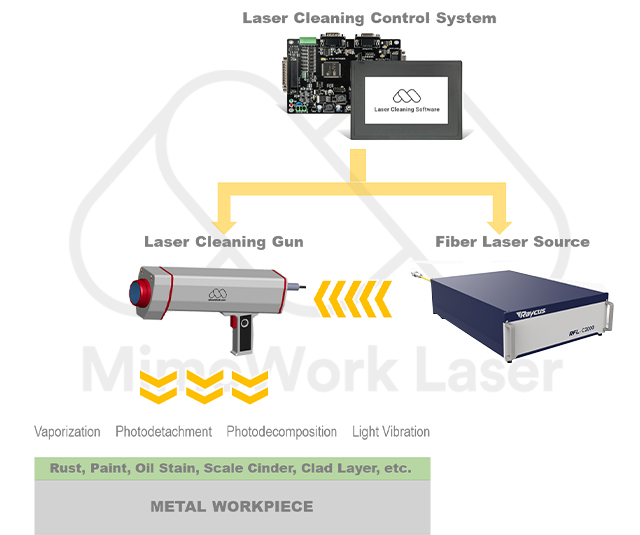

Nadiifiyeyaasha laysarka waxay ka kooban yihiin afar qaybood:Isha laser fiber (laser joogto ah ama garaaca wadnaha), guddiga kantaroolka, qoriga laser gacanta, iyo qaboojiyaha heerkulka joogtada ah ee biyaha. Guddiga xakamaynta nadiifinta laysarka wuxuu u shaqeeyaa sida maskaxda mashiinka oo dhan wuxuuna siinayaa amarka koronto-dhaliyaha laysarka fiber-ka iyo qoriga laysarka gacanta lagu qaato.

Koronto-dhaliyaha laysarka fiber-ku waxa uu soo saaraa nal leyser ah oo xoog badan kaas oo la sii dhex mariyo Fiber dhexdhexaad ah oo loo gudbiyo qoriga laysarka ee gacanta lagu qaato. Galvanometer-ka iskaanka, mid uniaxial ama biaxial, oo lagu ururiyay gudaha qoriga laysarka ayaa ka tarjumaysa tamarta iftiinka lakabka wasakhda ah ee shaqada. Marka la isku daro falcelinta jirka iyo kiimikaad, miridhka, rinjiga, wasakhda dufanka leh, lakabka dahaarka, iyo wasakhda kale ayaa si fudud looga saaraa.

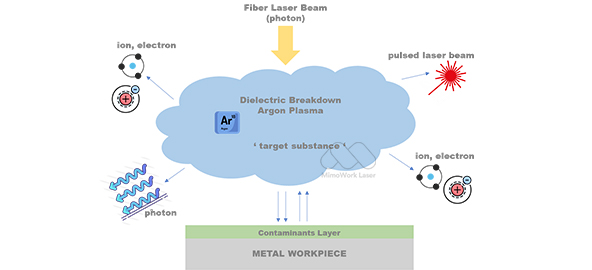

Aynu si faahfaahsan u sii wadno habkan. Dareen-celinta adag ee ku lug leh isticmaalkagariir garaaca wadnaha laser, ballaarinta kulaylkaQaybaha shucaaca ah,sawir-qaboojin molecularisbedelka wajiga, amafalkooda isku dhafansi looga adkaado xoogga isku xiran ee u dhexeeya wasakhda iyo dusha sare ee shaqada. Maaddada bartilmaameedka ah (lakabka dusha sare ee la saarayo) ayaa si degdeg ah loo kululeeyaa iyada oo la nuugayo tamarta laydhka laysarka oo buuxiya shuruudaha sublimation si wasakhda dusha sare u baaba'o si loo gaaro natiijada nadiifinta. Sababtaas awgeed, dusha sare ee substrate-ku wuxuu nuugaa tamarta ZERO, ama tamar aad u yar, iftiinka laysarka fiberku waxba ma yeeli doono.

Baro wax badan oo ku saabsan Qaab-dhismeedka iyo Mabaadi'da Nadiifiyaha Laser-gacanta

Saddex falcelin oo Nadiifinta Laser-ka

1. Sublimation

Halabuurka kiimikaad ee maaddada salka iyo wasakhdu way kala duwan tahay, sidaas oo kale waa heerka nuugista laysarka. Substrate-ka salku waxa uu ka tarjumayaa in ka badan 95% iftiinka laysarka iyada oo aan wax dhaawac ahi soo gaadhin, halka wasakhdu ay nuugto inta badan tamarta laysarka oo ay gaadho heerkulka sublimation.

Sawirka Habka Nadiifinta Laser

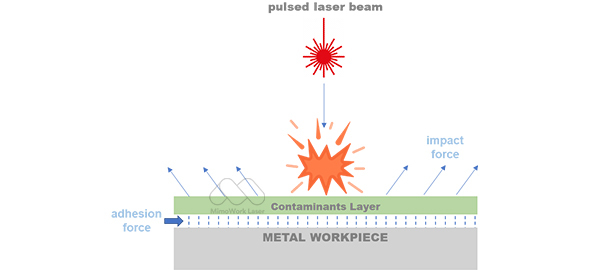

2. Balaadhinta kulaylka

Qaybaha wasakhaysan waxay nuugaan tamarta kulaylka waxayna si degdeg ah u fidaan ilaa heer dilaac ah. Saamaynta qaraxu waxa ay ka gudubtaa xoogga adhesion (xoogga soo jiidashada ee u dhexeeya walxaha kala duwan), sidaas awgeed qaybaha wasakhaysan ayaa ka go'ay dusha sare ee birta. Sababtoo ah wakhtiga shucaaca laysarka waa mid aad u gaaban, waxay isla markiiba soo saari kartaa dardargelinta weyn ee xoogga saameynta qarxa, oo ku filan si ay u bixiso dardargelin ku filan oo ah qaybo ganaax ah si ay uga guurto adhesion alaabta saldhigga.

Jaantuska is dhexgalka Ciidanka Nadiifinta Laser Pulsed

3. Gariirka garaaca Laser-ka

Balaadhka garaaca wadnaha ee laydhka laysarka ayaa ah mid cidhiidhi ah, sidaa darteed ficilka soo noqnoqda ee garaaca wadnaha ayaa abuuri doona gariir ultrasonic si loo nadiifiyo qaybta shaqada, iyo hirarka naxdinta leh ayaa burburin doona qaybaha wasakhaysan.

Farsamaynta Nadiifinta Beam Laser Pulsed

Faa'iidooyinka Mashiinka Nadiifinta Fiber Laser

Sababtoo ah nadiifinta laysarka uma baahna wax kiimiko ah ama wax kale oo la isticmaalo, waa deegaan saaxiibtinimo, badbaado leh in la shaqeeyo, waxayna leedahay faa'iidooyin badan:

✔Budada adagi inta badan waa qashinka ka dib nadiifinta, mugga yar, wayna fududahay in la ururiyo oo dib loo warshadeeyo

✔Qiiqa iyo dambaska uu dhaliyo laser-ka fiber-ku waa ay fududahay in uu daajiyo qiiqa soo saara, oo aan ku adkeyn caafimaadka aadanaha

✔Nadiifinta aan lala xiriirin, ma jirto warbaahin haraaga ah, ma jirto wasakh kale

✔Kaliya nadiifinta bartilmaameedka ( miridhku, saliidda, rinjiga, dahaarka), ma dhaawici doonto dusha sare ee substrate

✔Korontadu waa isticmaalka kaliya, kharash yar oo socda, iyo kharashka dayactirka

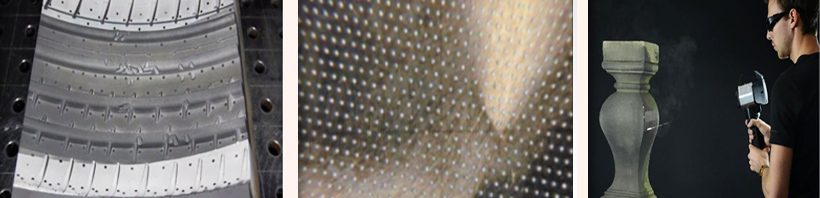

✔Ku haboon meelaha ay adagtahay in la gaadho iyo qaabdhismeedka artifact kakan

✔Robot si toos ah loo nadiifiyo laser waa ikhtiyaari, beddelaya macmal

Si looga saaro wasakhda sida miridhku, caaryada, rinjiga, waraaqaha waraaqaha, polymers, balaastikada, ama shay kasta oo dusha sare ah, hababka dhaqanka - qarxinta warbaahinta iyo etching kiimikaad - waxay u baahan yihiin maarayn gaar ah iyo tuurista warbaahinta waxayna si cajiib ah khatar ugu noqon kartaa deegaanka iyo hawl-wadeenada mararka qaarkood. Shaxda hoose ayaa taxaysa farqiga u dhexeeya nadiifinta laysarka iyo hababka kale ee nadiifinta warshadaha

| Nadiifinta Laser | Nadiifinta Kiimikada | Farsamaynta farsamada | Nadiifinta barafka qalalan | Nadiifinta Ultrasonic | |

| Habka Nadiifinta | Laser, aan lala xidhiidhin | Walxaha kiimikada, xiriir toos ah | Warqad xoqan, xiriir toos ah | Baraf qallalan, aan lala xiriirin | Saabuunta, si toos ah ula xiriir |

| Waxyeelada alaabta | No | Haa, laakiin waa dhif | Haa | No | No |

| Waxtarka Nadiifinta | Sare | Hoose | Hoose | Dhexdhexaad | Dhexdhexaad |

| Isticmaalka | Korontada | Walxaha Kiimikada | Waraaqda Xadhkaha Leh/ Garaashka Xadhkaha Leh | Baraf qallalan | Daawada dareeraha ah |

| Natiijada Nadiifinta | baro la'aan | joogto ah | joogto ah | heer sare ah | heer sare ah |

| Waxyeelada deegaanka | Saaxiibtinimada deegaanka | wasakhaysan | wasakhaysan | Saaxiibtinimada deegaanka | Saaxiibtinimada deegaanka |

| Hawlgalka | Fudud oo sahlan in la barto | Nidaam adag, hawlwadeen xirfad leh ayaa loo baahan yahay | shaqaale xirfad leh ayaa loo baahan yahay | Fudud oo sahlan in la barto | Fudud oo sahlan in la barto |

Raadinta Habka ugu Wanaagsan ee Looga Saaro Wasakhowga iyadoon Waxyeeleyn Substrate-ka

▷ Mashiinka Nadiifinta Laser

Hababka Nadiifinta Laser

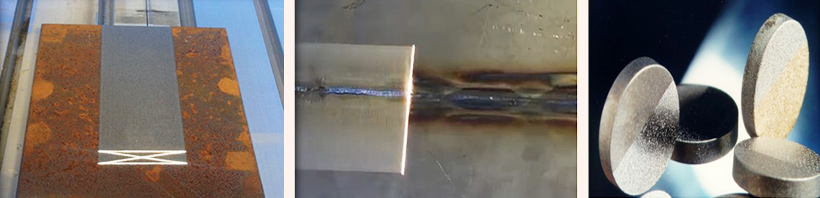

• caaryada duritaanka nadiifinta laysarka

• qallafsanaanta dusha laysarka

• Qalabka nadiifinta laysarka

• Ka saarida rinjiga laysarka

Nadiifinta Laser-ka ee Isticmaalka Dhabta ah

FAQS

Haa, gabi ahaanba waa ammaan. Furaha ayaa ku jira heerarka nuugista laysarka ee kala duwan: maaddada salka ayaa ka tarjumaysa in ka badan 95% tamarta laysarka, oo nuugta wax yar oo kuleyl ah. Wasakhowga ( miridhku, rinjiga) waxay nuugaan tamarta inteeda badan. Iyadoo lagu taageerayo kontoroolka saxda ah ee garaaca wadnaha, geeddi-socodku wuxuu kaliya bartilmaameedsadaa walxaha aan loo baahnayn, isaga oo iska ilaalinaya waxyeello kasta oo ku timaada qaabka substrate-ka ama tayada dusha sare.

Waxay si hufan u maareysaa noocyo kala duwan oo wasakhda warshadaha ah.

- miridhku, oksaydhyada, iyo daxalka dusha birta ah.

- Rinjiyeynta, dahaarka, iyo filimaanta khafiifka ah ee laga sameeyay qaybaha shaqada.

- Saliid, dufan, iyo wasakh ku jira hababka qaabaynta duritaanka.

- Hadhaaga alxanka iyo burooyinka yaryar ee alxanka ka hor.

- Kuma koobna biraha-sidoo kale waxay ka shaqeysaa sagxadaha aan biraha ahayn qaarkood ee wasakhda iftiinka.

Aad bay uga fiican tahay deegaanka marka loo eego kiimikaad ama nadiifinta farsamada.

- Ma jiro dareere kiimiko ah (oo ka ilaaliya wasakhowga ciidda/biyaha) ama waxyaabaha wasakhaysan (yareeya qashinka).

- Qashinku inta badan waa budo adag ama qiiq yar, kaas oo ay fududahay in lagu ururiyo qiiqa soo saara.

- Kaliya waxay isticmaashaa koronto-ma jirto baahiyo qashin oo halis ah, iyadoo u hogaansanta heerarka deegaanka ee warshadaha adag.

Waqtiga boostada: Jul-08-2022