Waa maxay Mashiinka Laser-ka Galvo?

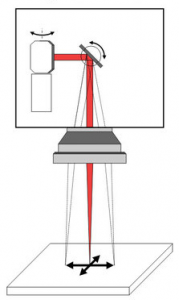

Laser-ka Galvo, oo inta badan loo yaqaan 'Galvanometer laser', waa nooc ka mid ah nidaamka laysarka ee isticmaala sawir-qaadayaasha galvanometer si loo xakameeyo dhaqdhaqaaqa laydhka laysarka iyo jihada.

Farsamadani waxay awood u siinaysaa meelaynta laydhka leysarka saxda ah oo degdeg ah, taasoo ka dhigaysa mid ku haboon codsiyada kala duwan, oo ay ku jiraan calaamadaynta laysarka, xaradhka, jarista, iyo in ka badan.

Erayga "Galvo" waxa uu ka yimid "galvanometer" oo ah qalab loo isticmaalo in lagu cabbiro laguna ogaado qulqulka korontada yar yar. Marka la eego nidaamka laysarka, sawir-qaadayaasha Galvo waxaa loo isticmaalaa in lagu milicsado oo lagu maamulo laydhka laysarka.

Sawir-qaadayaashani waxay ka kooban yihiin laba muraayadood oo ku rakiban matoorada galvanometer, kuwaas oo si dhakhso ah u hagaajin kara xagasha muraayadaha si loo xakameeyo booska laydhka laysarka.

Astaamaha Muhiimka ah ee Nidaamyada Laser-ka Galvo waxaa ka mid ah:

1. Isha Laser

2. Laysarka Beam Emission

3. Sawir-qaadayaasha Galvanometer

4. Beam leexashada

5. Focusing Optics

6. Isdhexgalka Maaddada

7. Baadhitaanka degdega ah

8. Xakamaynta Kumbuyuutarka

9. Qaboojinta iyo Badbaadada

10. Qashinka iyo Maareynta Qashinka

Sida loo: Galvo Laser Graving Paper

Ma haysaa su'aalo ku saabsan Galvo Laser? Waa maxay sababta aan nala tashan karin?

1. Codsigaaga:

Si cad u qeex ujeedada laysarkaaga. Miyaad gooynaysaa, calaamadaynaysaa, mise wax xardhaysa? Waxay tilmaami doontaa awoodda laysarka iyo dhererka loo baahan yahay.

3. Awoodda laser:

Dooro awooda laysarka habboon ee ku salaysan codsigaaga. Laysarka awoodda sare waxay ku habboon yihiin in la gooyo, halka laydhka awoodda hoose loo isticmaalo calaamadaynta iyo xarrigga.

5. Isha Laser:

Kala dooro CO2, fiber, ama noocyada kale ee ilaha laysarka. Laser-ka CO2 ayaa inta badan loo isticmaalaa xaradhka iyo jarista alaabta dabiiciga ah.

7. Software and Control:

Software-ku-saaxiibtinimo leh oo leh karti-is-beddelid ayaa lagama maarmaan u ah hagaajinta cabbirrada laser-ka iyo hagaajinta waxqabadka.

9. Dayactirka iyo Taageerada:

Tixgeli shuruudaha dayactirka iyo helitaanka taageerada macaamiisha. Helitaanka kaalmada farsamada iyo qaybaha beddelka marka loo baahdo.

11. Miisaaniyadda & Is-dhexgalka:

Go'aami miisaaniyadaada nidaamka laysarka Galvo. Maskaxda ku hay in nidaamyada tayada sare leh ee leh sifooyin horumarsan ay ku iman karaan kharash sare. Haddii aad qorsheyneyso inaad ku dhex-gasho nidaamka laser-ka Galvo khadka wax soo saarka ee jira, hubi inuu ku habboon yahay qalabkaaga iyo nidaamyada xakamaynta.

2. Waafaqsanaanta Shayga:

Hubi in nidaamka laysarka Galvo uu ku habboon yahay alaabta aad ku shaqayn doonto. Qalab kala duwan ayaa laga yaabaa inay u baahdaan mawjadaha dhererka leysarka gaar ah ama heerar koronto.

4. Xawaaraha Sawirka Galvo:

Tixgeli xawaaraha iskaanka ee Galvo. Sawir-qaadayaasha degdega ah waxay ku habboon yihiin codsiyada wax-soo-saarka sare leh, halka sawir-qaadayaasha gaabinaya laga yaabo inay aad ugu saxsan yihiin shaqada faahfaahsan.

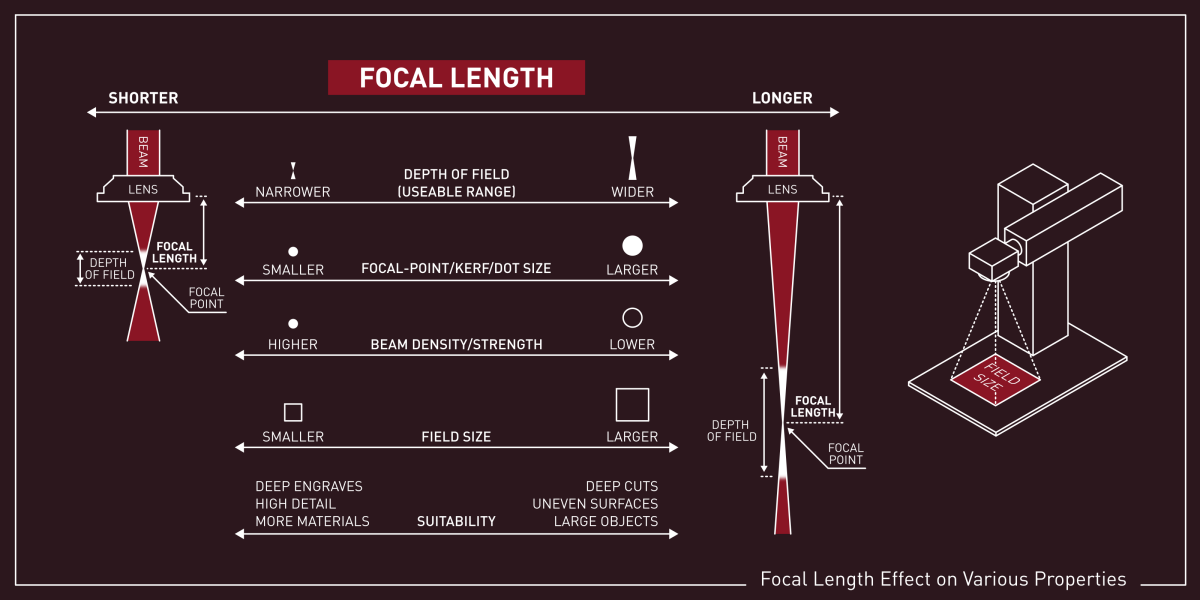

6. Cabbirka Goobta Shaqada:

Go'aami xajmiga goobta shaqada ee looga baahan yahay codsigaaga. Hubi in nidaamka laysarka Galvo uu qaadi karo cabbirrada alaabtaada.

8. Nidaamka qaboojinta:

Xaqiiji waxtarka nidaamka qaboojinta. Nidaam qaboojin la isku halayn karo ayaa lagama maarmaan u ah in la ilaaliyo waxqabadka laysarka oo loo dheereeyo cimriga qalabka.

10. Astaamaha Badbaadada:

Mudnaanta sii sifooyinka badbaadada sida isgoysyada, gaashaanka alwaaxa, iyo badhamada joogsiga degdega ah si loo ilaaliyo hawlwadeenada loogana hortago shilalka

12. Balaadhinta Mustaqbalka & Faallooyin:

Ka fakar baahiyaha mustaqbalka. Nidaamka leysarka Galvo ee la miisaami karo wuxuu kuu oggolaanayaa inaad ballaariso awooddaada marka ganacsigaagu uu korayo. Cilmi baaris oo raadso talooyinka asxaabta warshadaha ama khubarada si aad fikrado uga hesho hababka laser-ka Galvo ee ugu habboon.

13. Habaynta:

Tixgeli haddii aad u baahan tahay nidaam caadi ah oo ka baxsan shelf ama xal la habeeyey oo ku habboon codsigaaga gaarka ah.

Markaad si taxadar leh u qiimeyso arrimahan, waxaad dooran kartaa nidaamka saxda ah ee Galvo laser kaas oo ku habboon yoolalkaaga ganacsiga, kor u qaadaya hababka wax soo saarkaaga, oo hubiya waxqabadka ugu fiican iyo tayada codsiyadaada.

Bandhigga Fiidiyowga: Sidee loo Doortaa Mashiinka Calaamadaynta Laser?

Taxanaha MimoWork Laser

▶ Waa maxay sababta aanad uga bilaabin doorashooyinkan waaweyn?

Cabbirka Miiska Shaqada:400mm * 400mm (15.7" * 15.7")

Ikhtiyaarada Laydhka:180W/250W/500W

Dulmarka Galvo Laser Engraver & Sumadeeyaha 40

Aragtida ugu badan ee shaqada ee nidaamka laser Galvo wuxuu gaari karaa 400mm * 400 mm. Madaxa GALVO waxaa lagu hagaajin karaa si toos ah si aad u gaarto cabbirrada laydhka leysarka ee kala duwan iyadoo loo eegayo cabbirka alaabtaada. Xataa meesha ugu badan ee shaqada, waxaad weli heli kartaa laydhka ugu fiican ilaa 0.15 mm xaradhka laser-ka ugu fiican iyo waxqabadka calaamadaynta. Sida xulashooyinka laser-ka MimoWork, Nidaamka Tilmaanta Iftiinka-Casaha iyo Nidaamka Meelaynta CCD waxay wada shaqeeyaan si loo saxo bartamaha waddada shaqada ee booska dhabta ah ee gabal inta lagu jiro galvo laser. Waxaa intaa dheer, nooca nakhshad buuxda oo kuxiran waxaa la codsan karaa si uu u buuxiyo heerka ilaalinta badbaadada fasalka 1 ee xardha laysarka galvo.

Cabbirka Miiska Shaqada:1600mm * Infinity (62.9 "* Infinity)

Ikhtiyaarada Laydhka:350W

Dulmarka Galvo Laser Engraver

Qaabka weyn ee xaradhka laysarka ayaa ah R&D oo loogu talagalay qalabka cabbirka weyn ee xaradhka laysarka & calaamadaynta laysarka. Habka gudbinta, xardh-xeerka laysarka galvo wuxuu qori karaa oo ku calaamadin karaa maryaha duuban. Taasi waxay ku habboon tahay qalabkan qaabaysan ee aadka u dheer ee farsamaynta xaradhka leysarka joogtada ah iyo dabacsanaanta labadaba waxay ku guulaystaan waxtarka sare iyo tayada sare ee wax soo saarka la taaban karo.

Cabbirka Miiska Shaqada:70*70mm, 110*110mm, 175*175mm, 200*200mm (La beddeli karo)

Ikhtiyaarada Laydhka:20W/30W/50W

Guudmarka Mashiinka Calaamadaynta Fiber Galvo Laser

Mashiinka calaamadaynta laysarka fiber-ku wuxuu isticmaalaa laydhka laysarka si uu calaamado joogto ah ugu sameeyo dusha walxaha kala duwan. Adigoo uumi baxayo ama gubaya dusha walxaha leh tamar iftiin leh, lakabka qoto dheer ayaa muujinaya markaa waxaad heli kartaa saameyn xardho alaabtaada. Haddi ay u adag tahay qaabka, qoraalka, koodhka bar ama garaafyada kale, MimoWork Fiber Laser Marking Machine ayaa ku dhejin kara alaabtaada si ay u daboolaan baahiyahaaga habaynta.

Nooga soo dir shuruudahaaga, waxaanu ku siin doonaa xalinta leeser-yaqaanka ah

Hadda Bilow La-taliye Laser ah!

Waa maxay macluumaadka aad u baahan tahay inaad bixiso?

> Macluumaadka xiriirkayaga

Su'aalaha Caadiga ah ee ku saabsan Galvo Laser

Marka si sax ah loo shaqeeyo oo la raacayo tallaabooyinka badbaadada ee habboon, nidaamyada laysarka Galvo waa badbaado. Waa inay ku jiraan sifooyinka badbaadada sida qufulyada iyo gaashaanka alwaaxyada. Had iyo jeer raac tilmaamaha badbaadada oo bixi tababbarka hawlwadeenka si loo hubiyo isticmaalka badbaadada leh.

Haa, nidaamyo laser badan oo Galvo ah ayaa loogu talagalay is dhexgalka deegaan wax soo saar otomaatig ah. Hubi in ay waafaqsan yihiin nidaamyadaada gacanta ee jira iyo qalabka otomaatiga ah.

Shuruudaha dayactirku way ku kala duwan yihiin soo saaraha iyo qaabka. Dayactirka joogtada ah waxaa ku jiri kara nadiifinta muraayadaha indhaha, hubinta muraayadaha, iyo hubinta in habka qaboojinta uu si sax ah u shaqeeyo. Waa lama huraan in la raaco talooyinka dayactirka ee soo saaraha.

Haa, nidaamyada laysarka Galvo waxay awood u leeyihiin inay abuuraan saamaynta 3D iyagoo kala duwanaya awoodda laysarka iyo inta jeer. Tan waxaa loo isticmaali karaa qoraalka iyo ku darida qoto dheer ee dusha sare.

Cimrada habka laysarka Galvo waxay ku xidhan tahay isticmaalka, dayactirka, iyo tayada. Nidaamyada tayada sare leh waxay socon karaan tobanaan kun oo saacadood oo hawlgal ah, waase haddii si wanaagsan loo ilaaliyo.

In kasta oo nidaamyada Galvo ay aad ugu sarreeyaan calaamadaynta iyo xaradhka, waxa kale oo loo isticmaali karaa jarista walxaha khafiifka ah sida waraaqaha, balaastikada, iyo dunta. Awoodda goynta waxay kuxirantahay isha laysarka iyo awooda.

Nidaamyada laser-ka Galvo waxaa loo arkaa inay ka wanaagsan yihiin deegaan ahaan marka loo eego hababka calaamadaynta dhaqameed. Waxay soo saaraan qashin yar oo uma baahna waxyaabaha la isticmaalo sida khadadka ama midabaynta.

Qaar ka mid ah hababka laser-ka Galvo ayaa loo habeyn karaa codsiyada nadiifinta laysarka, iyaga oo ka dhigaya qalab kala duwan oo loogu talagalay hawlo kala duwan.

Haa, nidaamyada Laser-ka Galvo waxay farsamayn karaan sawirada vector iyo raster labadaba, taas oo awood u siinaysa inay qabtaan hawlo badan oo kala duwan oo leh naqshado iyo qaabab qalafsan.

Ha u degin wax ka yar wax aan caadi ahayn

Maalgelinta ugu Wanaagsan

Waqtiga boostada: Nov-09-2023