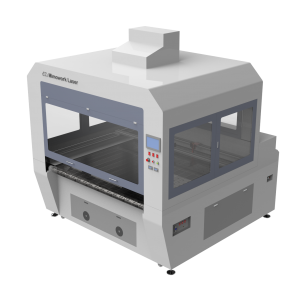

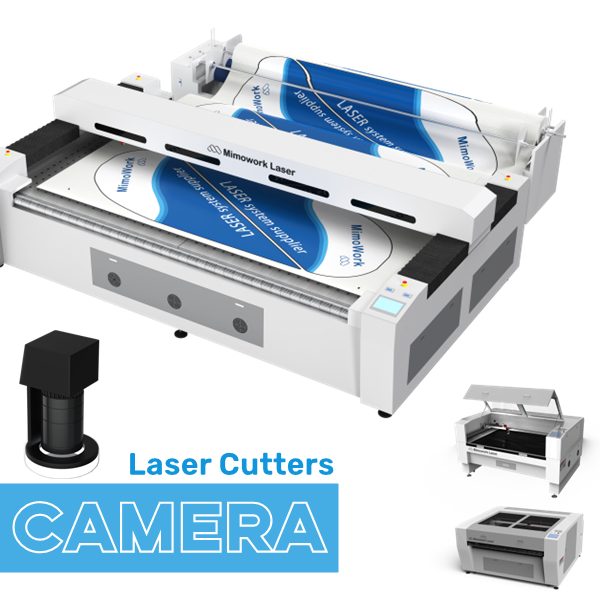

Lace Laser Cutting Machine le High Precision

| Sebaka sa Mosebetsi (W *L) | 1600mm * 1,000mm (62.9"39.3") - E tloaelehileng |

| 1600mm * 1200mm (62.9” * 47.2”) - E atolositsoe | |

| Software | CCD Software Ngoliso |

| Matla a Laser | 100W / 150W / 300W |

| Mohloli oa Laser | CO2 Glass Laser Tube kapa CO2 RF Metal Laser Tube |

| Sistimi ea Taolo ea Mechini | Step Motor Drive & Belt Control |

| Tafole ea Mosebetsi | Tafole ea Ts'ebetso ea Conveyor e bonolo |

| Lebelo le Leholo | 1 ~ 400mm/s |

| Ho Potlakisa Lebelo | 1000 ~ 4000mm/s2 |

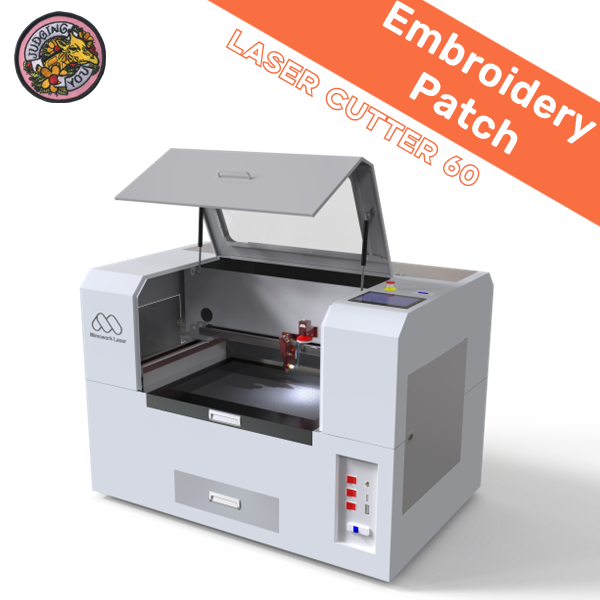

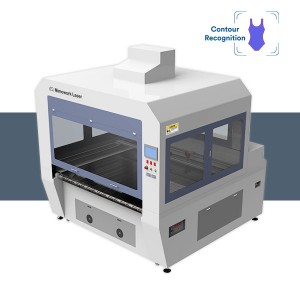

Lace Laser Cutter (E Koaletsoe ka ho Feletseng)

| Sebaka sa Mosebetsi (W *L) | 1800mm * 1300mm (70.87'' * 51.18'') |

| Max Thepa Width | 1800mm (70.87'') |

| Matla a Laser | 100W / 130W / 150W / 300W |

| Mohloli oa Laser | CO2 Glass Laser Tube / RF Metal Tube |

| Sistimi ea Taolo ea Mechini | Phetiso ea Belt & Servo Motor Drive |

| Tafole ea Mosebetsi | Tafole ea Ts'ebetso ea Conveyor e bonolo |

| Lebelo le Leholo | 1 ~ 400mm/s |

| Ho Potlakisa Lebelo | 1000 ~ 4000mm/s2 |

Tlosa bonono: Precision e kopana le Elegance

Bakeng sa Lace Laser Cutter 160 & 160L (E Tloaelehileng & E Atolositsoe):

◉Sublimation laser itšeha bakeng sa thepa tenyetsehang joalokaLacele Tse dingLisebelisoa tsa Moaparo

◉ Lihlooho tse peli tsa laser tse ntlafalitsoeng, e eketsa tlhahiso ea hau haholo (Lintlafatso tsa Boikhethelo)

◉CNC (Computer Numerical Control) le data ea khomphutha e ts'ehetsa ts'ebetso e phahameng ea boiketsetso le tlhahiso e tsitsitseng ea boleng bo holimo.

◉MimoWork SmartPono ea Laser Cutter Softwaree lokisa deformation le ho kgeloha ka boyona

◉Wide dikopo liindasteri tse kangKhatiso ea Dijithale, Lisebelisoa tse Kopantsoeng, Liaparo le Masela a Lehae

◉ Theknoloji e bonolo le e potlakileng ea MimoWork laser cutting e thusa lihlahisoa tsa hau kapele ho arabela litlhoko tsa 'maraka

◉ Auto-feedere fana kaho fepa ka boiketsetso, e lumellang ts'ebetso e sa lebelloang e bolokang litšenyehelo tsa basebetsi, le sekhahla se tlase sa ho hana (Lintlafatso tsa Boikhethelo)

Bakeng sa Sekhabiso sa Lace Laser (E Koaletsoe ka Botlalo):

◉Lisebelisoa tse pharalletseng liindastering tse joalo ka khatiso ea dijithale, lisebelisoa tse kopaneng, liaparo le masela a lapeng

◉ E tenyetseha ebile e potlakileTheknoloji ea MimoWork laser cutting e thusa lihlahisoa tsa hau ho arabela ka potlako litlhoko tsa 'maraka

◉EvolutionaryTheknoloji ea ho Tseba ka Ponole software e matla e fana ka boleng bo holimo le ts'epahalo bakeng sa khoebo ea hau.

◉ Ho fepa ka boiketsetsoe lumella ts'ebetso e sa lebelloang e bolokang litšenyehelo tsa basebetsi le ho theola sekhahla sa ho hana (ho ikhethela)

◉TheSebopeho se Koaletsoeng ka Botlaloe eketsoa Mochini o tloaelehileng oa Pono ea Laser ea ho Seha.

Ho na le3likarolo tsa ntlafatso ts'ebetsong ea "contour laser cutter":

1. Tšireletseho ea Opereishene

2. Sebaka sa ho sebetsa se hloekileng le phello e ntle ea ho qeta lerōle

3. Bokhoni bo botle ba ho lemoha ha optical

Lintlha-khōlō tsa Mechini ea ho Seha Lace Laser

TheKhamera ea CCDe hlomelloa haufi le hlooho ea laser e khona ho bona matšoao a likarolo ho fumana lipaterone tse hatisitsoeng, tse khabisitsoeng kapa tse lohiloeng mme software e tla sebelisa faele ea ho itšeha ho paterone ea 'nete ka ho nepahala ha 0.001mm ho netefatsa sephetho sa bohlokoa ka ho fetisisa sa ho itšeha.

TheContour Recognition Systeme lemoha khouto ho latela phapang ea mebala lipakeng tsa moralo oa khatiso le bokamorao ba lintho. Ha ho hlokahale ho sebelisa mekhoa ea pele kapa lifaele. Ka mor'a ho fepa ka mokhoa o itekanetseng, masela a hatisitsoeng a tla fumanoa ka ho toba. Ena ke ts'ebetso e ikemetseng ka botlalo ntle le ho kenella ha motho. Ho feta moo, khamera e tla nka lifoto ka mor'a hore lesela le feptjoe sebakeng sa ho itšeha. Contour ea ho itšeha e tla fetoloa ho felisa ho kheloha, ho kheloha le ho potoloha, ka hona, qetellong o ka fihlela sephetho se nepahetseng haholo sa ho itšeha.

Ha u leka ho khaola li-contours tse sothehileng haholo kapa ho phehella li-patches le li-logos tse hlakileng haholo,Template Matching Systeme loketse ho feta sehiloeng sa contour. Ka ho bapisa litempele tsa moralo oa hau oa mantlha le linepe tse nkuoeng ke kh'amera ea HD, u ka fumana sebopeho se tšoanang le seo u batlang ho se khaola habonolo. Hape, o ka beha bohole ba ho kheloha ho latela litlhoko tsa hau.

Lihlooho tse Ikemetseng tse peli - Ntlafatso ea Boikhethelo

Bakeng sa mochine oa ho itšeha oa lihlooho tse peli tsa laser, lihlooho tse peli tsa laser li behiloe holim'a gantry e le 'ngoe, kahoo li ke ke tsa khaola mekhoa e fapaneng ka nako e le' ngoe. Leha ho le joalo, bakeng sa liindasteri tse ngata tsa feshene tse kang liaparo tsa dae sublimation, mohlala, li ka 'na tsa e-ba le ka pele, ka morao, le matsoho a jeresi ho khaola. Nakong ena, lihlooho tse peli tse ikemetseng li ka sebetsana le likotoana tsa mekhoa e fapaneng ka nako e le 'ngoe. Khetho ena e matlafatsa ts'ebetso ea ho itšeha le ho fetoha ha maemo ho isa tekanyong e kholo. Sephetho se ka eketsoa ho tloha ho 30% ho isa ho 50%.

Auto Feederke setsi sa ho fepa se tsamaeang ka mokhoa o ts'oanang le mochini oa ho itšeha oa laser. E hokahane letafole ea conveyor, "Auto feeder" e ka fetisetsa lisebelisoa tsa moqolo tafoleng ea ho itšeha ka mor'a hore u behe lirolo holim'a sesebelisoa. Ho tsamaisana le lisebelisoa tsa sebopeho se pharaletseng, MimoWork e khothaletsa mochini o fepang likoloi o atolositsoeng o khonang ho jara moroalo o boima ka sebopeho se seholo, hammoho le ho netefatsa ho fepa hantle. Lebelo la ho fepa le ka behoa ho latela lebelo la ho itšeha. Sensor e hlomelloa ho netefatsa boemo bo phethahetseng ba thepa le ho fokotsa liphoso. Feeder e khona ho hokela li-diameter tse fapaneng tsa meqolo. Rolara ea pneumatic e khona ho ikamahanya le masela ka likhohlano tse fapaneng le botenya. Sehlopha sena se u thusa ho hlokomela mokhoa oa ho itšeha ka ho feletseng.

Y-axis Gear & X-axis Belt Drive

Mochini oa ho itšeha oa laser oa k'hamera o na le rack ea Y-axis & pinion Drive le phetiso ea lebanta la X-axis. Moralo o fana ka pheko e phethahetseng pakeng tsa sebaka se seholo sa ho sebetsa sa sebopeho le phetiso e boreleli. Y-axis rack & pinion ke mofuta oa actuator ea mela e nang le giya e chitja (pinion) e kenyang lisebelisoa tse melang (rack), e sebetsang ho fetolela motsamao o potolohang hore e be motsamao oa mola. Raka le pinion li khannana ka boithatelo. Li-gear tse otlolohileng le tsa helical lia fumaneha bakeng sa rack & pinion. Phetiso ea lebanta la X-axis e fana ka phetiso e boreleli le e tsitsitseng ho hlooho ea laser. Ho ka phethoa ho itšeha ka laser ea lebelo le holimo le e nepahetseng haholo.

Khetho ea Servo Motor

Notlolla lebelo la ho itšeha ka lebelo le potlakileng ka sistimi e matla ea servo motor. Phahamisa ts'ebetso ea Mechini ea Laser Cutter ea Sublimation ho fihla bophahamong bo bocha ha e ntse e betla lits'oants'o tse rarahaneng tsa kantle ho naha ka nepo e sa sisinyeheng. Amohela matla a servo 'me u be le botsitso bo ke keng ba lekanngoa le lebelo.

TheHo hula ka Hloekilenge robala ka tlas'a tafole ea ho itšeha. Ka likoti tse nyenyane le tse matla tse holim'a tafole ea ho itšeha, moea o "fastens" thepa e holim'a tafole. Tafole ea vacuum ha e kene tseleng ea beam ea laser ha e ntse e khaola. Ho fapana le hoo, hammoho le fene e matla ea ho tima, e ntlafatsa phello ea mosi le thibelo ea lerōle nakong ea ho itšeha.

Moralo oa Kakaretso ka Botlalo - Ntlafatso ea Boikhethelo

Ka moralo o khethehileng oa monyako o koetsoeng ka botlalo, theE kentsoeng Contour Laser Cuttere ka etsa bonnete ba ho khathala ho molemo le ho ntlafatsa ka ho eketsehileng phello ea ho lemoha ea khamera ea HD ho qoba vignetting e amang tlhokomelo ea contour tabeng ea maemo a mabe a mabone. Monyako ka mahlakoreng 'ohle a mane a mochine o ka buloa, o ke keng oa ama tlhokomelo ea letsatsi le letsatsi le ho hloekisa.

Laser Cutting Lace Fabric (Applique, Embroidery)

Moralo o katiloeng ka ho Feletseng - Pontšo

Fumana livideo tse ling mabapi le li-cutter tsa rona tsa laser ho ronaKhale ea Lifitio

Libaka tsa Kopo

bakeng sa Mechini ea ho Seha Lace Laser

Amohela Bokhabane, Precision e Kopana le Boqhetseke

✔ Khamera ea CCD e beha matšoao a ngoliso ka nepo

✔ Lihlooho tse peli tsa laser tse ikhethileng li ka eketsa tlhahiso le katleho haholo

✔ Hloekisa le ho nepahala ho itšeha ntle le ho kuta ka morao

✔ Seha li-contours tsa khatiso ka mor'a ho fumana lintlha tsa matšoao

✔ Phapang e Phahameng ka har'a mefuta ea liphoso tsa 0.1 mm

✔ Mochini oa ho itšeha oa Laser o loketse bakeng sa tlhahiso ea nakoana le litaelo tsa tlhahiso ea bongata

✔ Notlolla liphiri tsa ho itšeha ka laser bakeng sa Lisebelisoa tsa Lace le ho hlahisa lefatše la menyetla

✔ Eba le ho nepahala ho se nang sekoli, meralo e rarahaneng, bokhabane bo matla, le ho itloaetsa ho se nang moeli.

✔ Phahamisa lintho tseo u li qapileng ho ea holimo ka bokhabane le bokhoni ba theknoloji ea laser-cutting

✔ Kena ka bokamoso ba tlhahiso ea Lace Accessory 'me u shebelle boqapi ba hau bo phela ka lintlha tse makatsang

Phethahatso e se nang sekoli e nang le Boqapi bo sa Lekanyetsoang

E Phethahetseng, Nako le nako: Finyella likhahla tse tsitsitseng, tse hlophisitsoeng tse netefatsang ho lekana hantle, ho matlafatsa matšeliso le kholiseho liaparong tsa lace.

Khokahano e se nang Seam, Phallo ea Mosebetsi e Nolofalitsoeng: Kopanya ka mokhoa o sa reroang thekenoloji ea ho itšeha laser ka mekhoa ea tlhahiso bakeng sa katleho e eketsehileng le tlhahiso.

Phahamisa Boqapi, Lintlha Tse Ntle: Phahamisa bonono ba ho etsa lileisi ka mokhoa o nepahetseng oa laser, ho totobatsa lintlha tse rarahaneng le ho ntlafatsa boqapi ka kakaretso.

Tlosa Monyetla oa Lace: Amohela matla a phetoho a ho itšeha ka laser, ho sututsa meeli ea boqapi ba lace le ho theha meralo e sa lebaleheng, e tsotehang.

Tlhahiso e Sebetsang, Bokhabane bo sa Feleng: Boloka nako le lisebelisoa ha u ntse u boloka bokhabane bo sa feleng ka mokhoa o potlakileng, o sebetsang oa ho itšeha ka laser bakeng sa lisebelisoa tsa lace.

ea Sublimation Laser Cutting Machines

Lisebelisoa:

Twill,Velvet, Velcro, Nylonpolyester,Filimi, Foil, le Lisebelisoa tse ling tse entsoeng ka Paterone

Lesela la Polyester,Spandex,Nylon,Silika,Velvet e hatisitsoeng,K'hothone, le tse lingSublimation Textiles

Lisebelisoa:

Liaparo,Lisebelisoa tsa Liaparo, Lace, Lisebelisoa tsa Lehae, Foreimi ya Senepe, Dileibole, Sticker, Applique

Liaparo tse Mahlahahlaha, Liaparo tsa Lipapali (Liaparo tsa Libaesekele, Lijesi tsa Hockey, Lijesi tsa Baseball, Lijesi tsa Basketball, Lijesi tsa Soccer, Lijesi tsa Volleyball, Lacrosse Jerseys, Ringette Jerseys)

Unifomo, Liaparo tsa ho sesa,Leggings,Lisebelisoa tsa Sublimation(Sekoahelo sa Matsoho, Lilefi tsa Leoto, Bandanna, Letlapa la hlooho, Sekoahelo sa Sefahleho, Limasi)