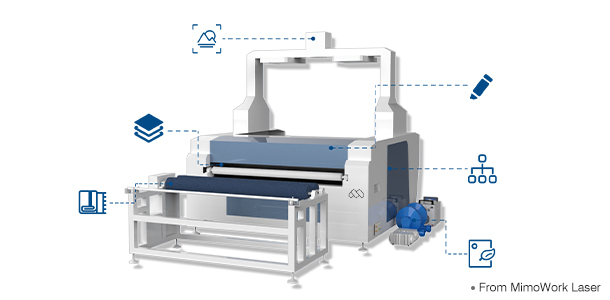

Ha o sa tsoa qala ho sebelisa theknoloji ea laser 'me u nahana ho reka mochini o sehang oa laser, ho tlameha hore ebe ho na le lipotso tse ngata tseo u batlang ho li botsa.

MimoWorke thabela ho arolelana le uena tlhahisoleseling e batsi ka mechini ea laser ea CO2 'me re tšepa hore u ka fumana sesebelisoa se u tšoanelang hantle, ebang ke sa rona kapa mofani e mong oa laser.

Sehloohong sena, re tla fana ka kakaretso e khutšoanyane ea tlhophiso ea mochini karolong e kholo le ho etsa tlhahlobo ea papiso ea karolo ka 'ngoe. Ka kakaretso, sehlooho se tla akaretsa lintlha tse latelang:

Mekaniki ea mochini oa laser oa CO2

a. Enjene ea DC e se nang borashe, Enjene ea Servo, Enjene ea Mohato

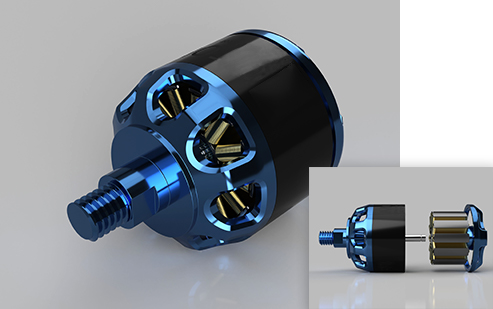

Enjene ea DC e se nang borashe (motlakase o tobileng)

Enjene ea DC e se nang borashe e ka sebetsa ka lebelo le phahameng la RPM (liphetoho ka motsotso). Stator ea enjene ea DC e fana ka matla a makenete a potolohang a khannang armature ho potoloha. Har'a lienjene tsohle, enjene ea DC e se nang borashe e ka fana ka matla a kinetic a matla ka ho fetisisa le ho khanna hlooho ea laser ho tsamaea ka lebelo le leholo.Mochini o motle ka ho fetisisa oa ho betla oa CO2 ka laser oa MimoWork e na le enjene e se nang borashe mme e ka fihlella lebelo le phahameng ka ho fetisisa la ho betla la 2000mm/s.Enjene ea dc e se nang borashe ha e fumanehe hangata mochining oa ho seha oa laser oa CO2. Lebaka ke hobane lebelo la ho seha thepa le lekanyelitsoe ke botenya ba thepa. Ho fapana le hoo, o hloka matla a manyane feela ho betla litšoantšo tsa thepa ea hau. Enjene e se nang borashe e nang le mochini oa ho betla oa laser e tlakhutsufatsa nako ea hau ea ho betla ka ho nepahala ho hoholo.

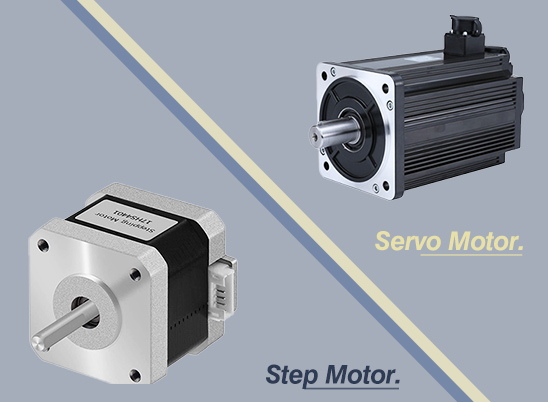

Enjene ea Servo le Enjene ea Mohato

Ha di kopantswe le tafole ya CO2 laser engraver, di-servo motor di fana ka torque e phahameng le ho nepahala, haholoholo bakeng sa mesebetsi ya botekgeniki jwalo ka ho seha lesela la sefe kapa dikoahelo tsa insulation. Le hoja di bitsa tjhelete e ngata mme di hloka di-encoder le di-gearbox—e leng se etsang hore setaele se be thata hanyane—di loketse ditshebediso tse boima. Leha ho le jwalo, haeba o etsa dimpho tse bonolo tsa mesebetsi ya matsoho kapa matshwao, enjene ya stepper tafoleng ya hao ya laser engraver hangata e etsa mosebetsi hantle.

Enjene e 'ngoe le e 'ngoe e na le melemo le mathata a eona. E u tšoanelang ke eona e molemohali bakeng sa hau.

Ka sebele, MimoWork e ka fana kaMoqapi le seha ka laser oa CO2 ka mefuta e meraro ea enjeneho latela tlhoko ea hau le tekanyetso ea hau.

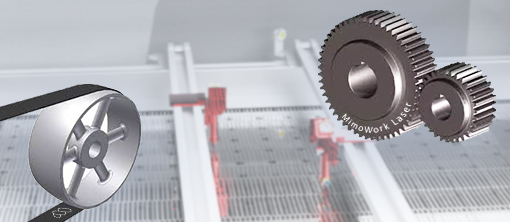

b. Lebanta la ho Kganna le la ho Kganna la Digiya

Lebanta le sebedisa lebanta ho hokahanya mabili, ha lebanta le sebedisang lebanta le hokahanya digiere ka ho toba ka meno a hokelanang. Mechining ya laser, ditsamaiso tsena ka bobedi di thusa ho tsamaisa gantry le ho ama hore na mochini o ka nepahala hakae.

A re bapiseng tse peli le tafole e latelang:

| Lebanta la ho khanna | Thepa ea ho khanna |

| Li-pulley le Lebanta la karolo e ka sehloohong | Li-Gear tsa karolo e ka sehloohong |

| Ho hlokahala sebaka se eketsehileng | Sebaka se fokolang se hlokahala, ka hona mochini oa laser o ka etsoa hore o be monyane |

| Tahlehelo e phahameng ea khohlano, ka hona phetiso e tlase le ts'ebetso e fokolang | Tahlehelo e tlase ea khohlano, ka hona phetiso e phahameng le katleho e eketsehileng |

| Tebello ea bophelo e tlase ho feta li-drive tsa gear, hangata lia fetoha lilemo tse ling le tse ling tse 3 | Tebello ea bophelo e kholo haholo ho feta li-drive tsa mabanta, hangata lia fetoha lilemo tse ling le tse ling tse leshome |

| E hloka tlhokomelo e eketsehileng, empa litšenyehelo tsa tlhokomelo li theko e tlase ebile li bonolo | E hloka tlhokomelo e nyane, empa litšenyehelo tsa tlhokomelo li theko e tlase haholo ebile li boima |

| Ha ho hlokahale setlolo | Hloka setlolo se tloaelehileng |

| Ho khutsitse haholo ha ho sebetsa | Ho na le lerata le sebetsang |

Mekhoa ea ho khanna li-gear le ea ho khanna lebanta hangata e entsoe ka mochini oa ho seha oa laser ka melemo le mathata. Ka bokhutšoanyane,Sistimi ea ho khanna lebanta e molemo haholo mefuteng ea mechini e menyenyane, e fofang-opticalka lebaka la phetiso e phahameng le ho tšoarella,drive ea gear e loketse haholoanyane sesebelisoa sa ho seha laser sa sebopeho se seholo, hangata se nang le moralo oa optical o kopaneng.

c. Tafole ea Mosebetsi e sa Feleng Vs Tafole ea Mosebetsi ea Conveyor

Bakeng sa ntlafatso ea ts'ebetso ea laser, o hloka ho feta phepelo ea laser ea boleng bo holimo le sistimi e ikhethang ea ho khanna ho tsamaisa hlooho ea laser, tafole e loketseng ea tšehetso ea thepa le eona ea hlokahala. Tafole e sebetsang e etselitsoeng ho lekana le thepa kapa ts'ebeliso e bolela hore o ka eketsa bokhoni ba mochini oa hau oa laser.

Ka kakaretso, ho na le mekhahlelo e 'meli ea liforomo tse sebetsang: tse sa sisinyeheng le tse tsamaeang.

(Bakeng sa lits'ebetso tse fapaneng, o ka qetella o sebelisitse mefuta eohle ea thepa, ebang kethepa ea lakane kapa thepa e kobehileng)

○Tafole ea ho Sebetsa e sa Felenge loketse ho beha thepa ea pampiri joalo ka acrylic, lehong, pampiri (khateboto).

• tafole ea thipa

• tafole ea mahe a linotši

○Tafole ea Mosebetsi oa Moqomoe loketse ho beha thepa ea ho rola joalo ka lesela, letlalo, foam.

• tafole ea seketsoana

• tafole ea phetisetso

Melemo ea moralo o loketseng oa tafole ea ho sebetsa

✔Ho ntša mesi e kotsi e khaotsoeng hantle haholo

✔Tsitsisa thepa, ha ho na ho falla ho etsahalang ha ho sehoa

✔Ho bonolo ho kenya le ho jarolla mesebetsi

✔Tataiso e ntle ea ho tsepamisa maikutlo ka lebaka la libaka tse bataletseng

✔Tlhokomelo le tlhoekiso e bonolo

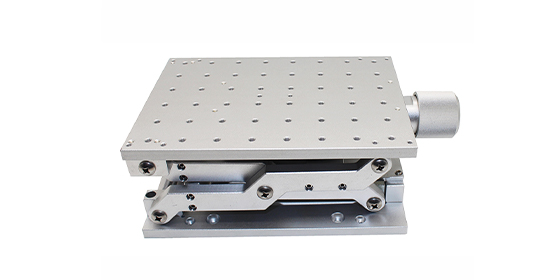

d. Sethala sa ho Phahamisa ka Bootho Vs sa ho Phahamisa ka Matsoho

Ha o betla thepa e tiileng, joalo kalesela la acrylic (PMMA)lelehong (MDF), thepa e fapana ka botenya. Bolelele bo loketseng ba ho tsepamisa maikutlo bo ka ntlafatsa phello ea ho betla. Sethala sa ho sebetsa se ka fetoloang sea hlokahala ho fumana ntlha e nyane ka ho fetisisa ea ho tsepamisa maikutlo. Bakeng sa mochini oa ho betla oa laser oa CO2, lithala tsa ho phahamisa ka boiketsetso le tsa ho phahamisa ka letsoho hangata li bapisoa. Haeba tekanyetso ea hau ea chelete e lekane, khetha lithala tsa ho phahamisa ka boiketsetso.Ha e ntlafatse feela ho nepahala ha ho seha le ho betla, empa e ka boela ea u bolokela nako le boiteko bo bongata.

e. Sistimi ea ho Phefumoloha e ka Holimo, e ka Lehlakoreng le e ka Tlase

Sistimi ea moea e ka tlase ke khetho e tloaelehileng haholo ea mochini oa laser oa CO2, empa MimoWork e boetse e na le mefuta e meng ea moralo ho ntšetsa pele phihlelo eohle ea ts'ebetso ea laser.mochini o moholo oa ho itšeha ka laser, MimoWork e tla sebelisasistimi e khathatsang e ka holimo le e ka tlaseho matlafatsa phello ea ho ntša ha ka nako e ts'oanang ho boloka liphetho tsa boleng bo holimo tsa ho seha ka laser. Bakeng sa boholo ba ronamochini oa ho tšoaea oa galvo, re tla kenyasistimi ea moea e lehlakorengho ntsha mosi. Dintlha tsohle tsa mochini di lokela ho shejwa hamolemo ho rarolla mathata a indasteri ka nngwe.

An sistimi ea ho ntšae hlahisoa tlas'a thepa e ntseng e etsoa ka mochini. Ha e ntše mosi o hlahisoang ke ho phekoloa ka mocheso feela empa hape e tsitsisa thepa, haholo-holo lesela le bobebe. Ha karolo ea bokaholimo ba ts'ebetso e koahetsoeng ke thepa e ntseng e sebetsoa e le kholoanyane, phello ea ho hula le vacuum e hlahisoang ke ho hula e ba holimo.

Liphaephe tsa laser tsa khalase tsa CO2 VS liphaephe tsa laser tsa CO2 RF

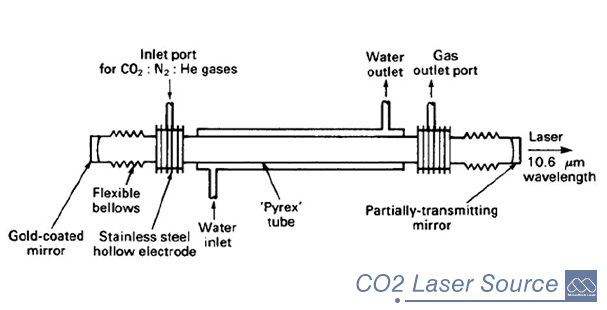

a. Molao-motheo oa ho hlohlelletsa oa laser ea CO2

Laser ea carbon dioxide e ne e le e 'ngoe ea li-laser tsa khase tsa pele ho ntlafatsoa. Ka lilemo tse mashome tsa nts'etsopele, theknoloji ena e se e hōlile haholo ebile e lekane bakeng sa lits'ebetso tse ngata. Tube ea laser ea CO2 e thabisa laser ka molao-motheo oaho ntša khanyalee fetola matla a motlakase hore e be matla a khanya a kopanengKa ho sebelisa motlakase o phahameng holim'a carbon dioxide (mochini o sebetsang oa laser) le khase e 'ngoe ka har'a tube ea laser, khase e hlahisa ho tsoa ha khanya 'me e lula e tsosoa ka har'a setshelo pakeng tsa liipone tse bonahatsang moo liipone li leng mahlakoreng a mabeli a sekepe ho hlahisa laser.

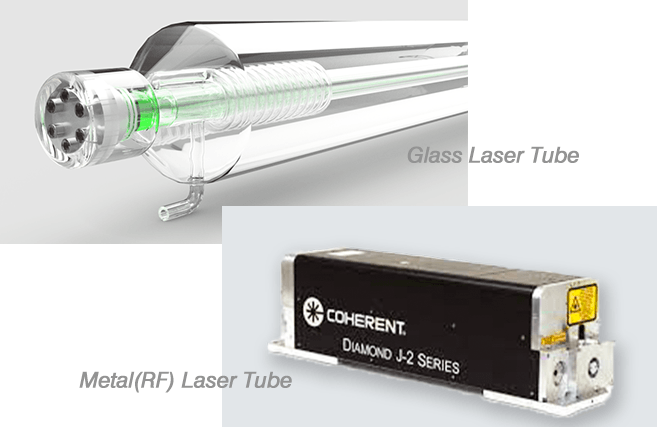

b. Phapang ea tube ea laser ea khalase ea CO2 le tube ea laser ea CO2 RF

Haeba o batla ho ba le kutlwisiso e batsi haholoanyane ka mochini oa laser oa CO2, o tlameha ho batlisisa lintlha tse qaqileng tsamohloli oa laserJwalo ka mofuta wa laser o loketseng ka ho fetisisa ho sebetsana le thepa e seng ya tshepe, mohlodi wa laser wa CO2 o ka arolwa ka mahlale a mabedi a maholo:Khalase ea Laser ea KhalaseleTube ea Laser ea Tšepe ea RF.

(Ha e le hantle, laser ea CO2 e phallang ka potlako e nang le matla a phahameng le laser ea CO2 e phallang butle ha li eo puisanong ea rona ea kajeno)

| Liphaephe tsa Laser tsa Khalase (DC) | Liphaephe tsa Laser tsa Tšepe (RF) | |

| Bolele ba bophelo | Lihora tse 2500-3500 | Lihora tse 20,000 |

| Letšoao | Sechaena | E lumellanang |

| Mokhoa oa ho Pholisa | Ho Pholisa Metsi | Ho Pholisa Metsi |

| E ka tjhajwa hape | Tjhe, e sebediswa hanngwe feela | E |

| Tiisetso | Likhoeli tse 6 | Likhoeli tse 12 |

Sistimi ea Taolo le Software

Software ea mochini oa ho seha laser oa CO2 e sebetsa e le boko ba sistimi, e sebelisa lenaneo la CNC ho tataisa motsamao oa laser le ho fetola maemo a matla. E nolofalletsa tlhahiso e tenyetsehang ka ho u lumella ho fetola meralo kapele le ho sebetsana le thepa e fapaneng - ka ho fetola matla a laser le lebelo la ho seha, ha ho hlokahale liphetoho tsa sesebelisoa.

Ba bangata 'marakeng ba tla bapisa theknoloji ea software ea Chaena le theknoloji ea software ea lik'hamphani tsa laser tsa Europe le Amerika. Bakeng sa mokhoa o sehiloeng le o ngoloang feela, li-algorithms tsa li-software tse ngata 'marakeng ha li fapane haholo. Ka lilemo tse ngata tsa maikutlo a data ho tsoa ho bahlahisi ba bangata, software ea rona e na le likarolo tse latelang:

1. Ho bonolo ho e sebelisa

2. Ts'ebetso e tsitsitseng le e bolokehileng nakong e telele

3. Lekola nako ea tlhahiso ka katleho

4. Tšehetsa DXF, AI, PLT le lifaele tse ling tse ngata

5. Kenya lifaele tse ngata tsa ho seha ka nako e le 'ngoe ka menyetla ea ho li fetola

6. Hlophisa dipaterone tsa ho seha ka bohona ka lihlopha tsa likholomo le mela e nang leSehlaha sa Mimo

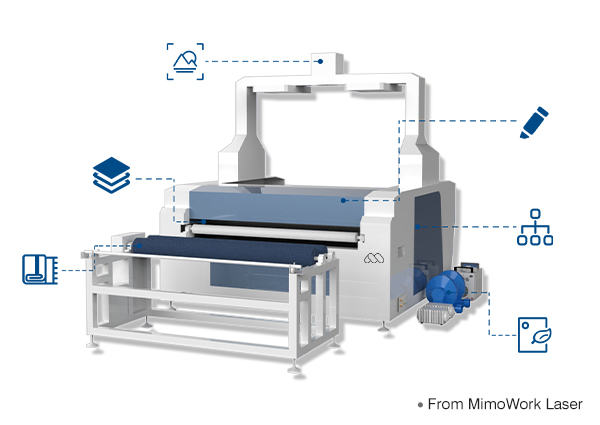

Ntle le motheo oa software e tloaelehileng ea ho seha,Sistimi ea ho Amohela Ponoe ka ntlafatsa tekanyo ea boiketsetso tlhahisong, ea fokotsa basebetsi le ho ntlafatsa ho nepahala ha ho seha. Ka mantsoe a bonolo, Khamera ea CCD kapa Khamera ea HD e kentsoeng mochining oa laser oa CO2 e sebetsa joaloka mahlo a motho 'me e laela mochini oa laser hore na o sehe hokae. Theknoloji ena e sebelisoa hangata lits'ebetsong tsa khatiso ea dijithale le masimong a ho roka, joalo ka liaparo tsa lipapali tsa dae-sublimation, lifolakha tsa kantle, li-patches tsa ho roka le tse ling tse ngata. Ho na le mefuta e meraro ea mekhoa ea ho lemoha pono eo MimoWork e ka fanang ka eona:

▮ Ho Tsebahatsa Meeli ea Lithaba

Khatiso ea dijithale le ea sublimation e ntse e eketseha, haholo-holo lihlahisoa tse kang liaparo tsa lipapali, lifolakha le marotholi a meokho. Masela ana a hatisitsoeng a ke ke a sehoa hantle ka sekere kapa mahare a setso. Ke moo litsamaiso tsa laser tse thehiloeng ponong li khanyang teng. Ka ho sebelisa khamera e nang le qeto e phahameng, mochini o hapa mohlala ebe o seha ka bohona ho latela moralo oa oona—ha ho hlokahale faele ea ho seha kapa ho kuta ka letsoho. Sena ha se ntlafatse ho nepahala feela empa se boetse se potlakisa tlhahiso.

Tataiso ea Ts'ebetso:

1. Fepa lihlahisoa tse nang le lipaterone >

2. Nka foto bakeng sa paterone >

3. Qala ho seha ka laser ea contour >

4. Bokella tse felileng >

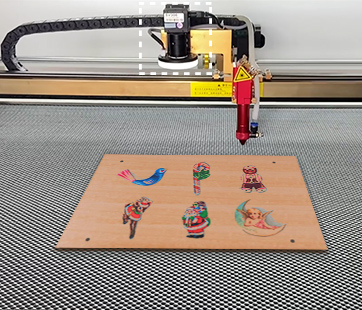

▮ Ntlha ea Letšoao la Ngoliso

Khamera ea CCDe ka lemoha le ho fumana paterone e hatisitsoeng botong ea lepolanka ho thusa laser ka ho seha ka nepo. Matšoao a lepolanka, li-plaque, litšoantšo le foto ea lepolanka e entsoeng ka lepolanka le hatisitsoeng li ka sebetsoa habonolo.

Mohato oa 1.

>> Printa paterone ea hau ka ho toba holim'a boto ea lehong

Mohato oa 2.

>> Khamera ea CCD e thusa laser ho seha moralo oa hau

Mohato oa 3.

>> Bokella likotoana tsa hau tse felileng

▮ Ho bapisa litempele

Bakeng sa dipetjhe tse ding, dilaebo, difoile tse hatisitsweng tse nang le boholo le paterone e tshwanang, Sistimi ya Pono ya ho Matching Template ho tswa ho MimoWork e tla ba thuso e kgolo. Sistimi ya laser e ka seha paterone e nyane ka nepo ka ho lemoha le ho beha template e setilweng e leng faele ya ho seha moralo ho lekana le karolo ya dipetjhe tse fapaneng. Paterone efe kapa efe, letshwao, mongolo kapa karolo e nngwe e bonahalang e ka ba karolo ya tšobotsi.

Likhetho tsa Laser

MimoWork e fana ka dikgetho tse ngata tse eketsehileng bakeng sa disehi tsohle tsa motheo tsa laser ka tieo ho latela ts'ebeliso e 'ngoe le e 'ngoe. Ts'ebetsong ea tlhahiso ea letsatsi le letsatsi, meralo ena e ikhethileng mochining oa laser e ikemiselitse ho eketsa boleng ba sehlahisoa le ho tenyetseha ho latela litlhoko tsa 'maraka. Khokahano ea bohlokoa ka ho fetisisa puisanong ea pele le rona ke ho tseba boemo ba hau ba tlhahiso, hore na ke lisebelisoa life tse sebelisoang hona joale tlhahisong, le hore na ke mathata afe a kopanang le tlhahiso. Kahoo ha re hlahiseng likarolo tse 'maloa tse tloaelehileng tse khethiloeng tse ratoang.

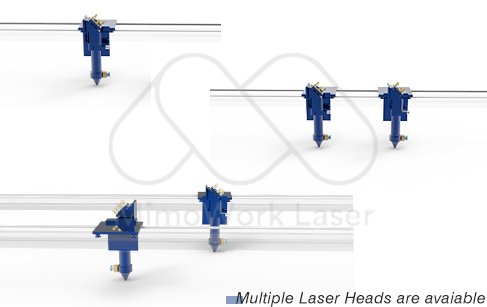

a. Lihlooho tse ngata tsa laser tseo u ka li khethang

Ho eketsa dihlooho le di-tube tse ngata tsa laser mochining o le mong ke tsela e bonolo le e theko e tlase ya ho eketsa tlhahiso. E boloka matsete le sebaka sa mokatong ha ho bapiswa le ho reka mechini e mmalwa e arohaneng. Empa ha se kamehla e leng yona e loketseng hantle. O tla hloka ho nahana ka boholo ba tafole ya hao ya ho sebetsa le dipaterone tsa ho seha. Ke ka lebaka leo hangata re kopang bareki ho arolelana meralo ya mehlala pele ba etsa odara.

Lipotso tse ling mabapi le tlhokomelo ea mochini oa laser kapa laser

Nako ea poso: Mphalane-12-2021