Laser Cutting Tulle Fabric

Introduction

What is Tulle Fabric?

Tulle is a fine, mesh-like fabric characterized by its hexagonal weave. It is lightweight, airy, and available in various colors and stiffness levels.

Commonly used in veils, tutus, and event decor, tulle combines elegance with versatility.

Tulle Features

Sheerness and Flexibility: Tulle’s open weave allows for breathability and draping, ideal for layered designs.

Lightweight: Easy to handle and ideal for voluminous applications.

Decorative Appeal: Adds texture and dimension to garments and decor.

Delicate Structure: Requires careful handling to avoid snags or tears.

Pink Tulle Bow

Types

Nylon Tulle: Soft, flexible, and widely used in bridal wear.

Polyester Tulle: More durable and cost-effective, suitable for decorations.

Silk Tulle: Luxurious and delicate, preferred for high-end fashion.

Material Comparison

Tulle Applications

Tulle Backdrop

Tulle Floral Arrangements On Ground

Tulle Table Runner

1. Fashion & Apparel

Bridal Veils & Dresses: Adds ethereal layers with lightweight elegance, perfect for delicate bridal designs.

Costumes & Tutus: Creates dramatic volume and structured silhouettes for theatrical and dance performances.

2. Decorations

Event Backdrops & Table Runners: Enhances ambiance with subtle, airy textures for weddings and themed events.

Gift Wrapping & Bows: Provides a refined finishing touch with intricate laser-cut patterns for luxury packaging.

3. Crafts

Embroidery Embellishments: Enables precise lace-like detailing for textile art and mixed-media projects.

Floral Arrangements: Secures stems elegantly while maintaining aesthetics in bouquets and decorative displays.

Functional Characteristics

Layering: Tulle is ideal for layering over other fabrics to add depth and texture.

Volume: Its lightweight nature allows it to be used in multiple layers to create volume without adding significant weight.

Structure: Tulle can be stiffened for more structured creations, such as tutus and decorative items.

Dyeability: Tulle is easy to dye and comes in a wide range of colors and finishes.

Breathability: The open weave makes it breathable, suitable for various applications.

Tulle Dress

Tulle Embroidery Design

Mechanical Properties

Tensile Strength: Tulle has moderate tensile strength, which varies depending on the fiber used. Nylon tulle, for example, is stronger than polyester tulle.

Elongation: Tulle has limited elongation, meaning it does not stretch much, except for some types that incorporate elastane.

Tear Strength: Tulle has moderate tear strength, but it can be prone to snagging and tearing if not handled carefully.

Flexibility: The fabric is flexible and can be gathered, shaped, and layered easily.

How to Cut Tulle?

CO2 laser cutting is ideal for tulle due to its precision, speed, and edge-sealing properties.

It cleanly cuts intricate patterns without fraying, works efficiently for large batches, and seals edges to prevent unraveling.

This makes it a superior choice for delicate fabrics like tulle.

Detailed Process

1. Preparation: Lay the fabric flat on the laser cutting table to ensure that the fabric does not move

2. Setup: Test settings on scrap fabric to avoid scorching, and import vector files for precise cuts.

3. Cutting: Ensure proper ventilation to dissipate fumes and monitor the process for consistent results.

4. Post-Processing: Remove debris with compressed air and trim minor imperfections with fine scissors.

Tulle Bridal Vells

Related Videos

How to Create Amazing Designs with Laser Cutting

Unlock your creativity with our advanced Auto Feeding CO2 Laser Cutting Machine! In this video, we demonstrate the remarkable versatility of this fabric laser machine, which effortlessly handles a wide range of materials.

Learn how to cut long fabrics straight or work with rolled fabrics using our 1610 CO2 laser cutter. Stay tuned for future videos where we'll share expert tips and tricks to optimize your cutting and engraving settings.

Don't miss your chance to elevate your fabric projects to new heights with cutting-edge laser technology!

Laser Cutting Fabric | Full Process!

This video captures the entire laser cutting process of fabric, showcasing the machine's contactless cutting, automatic edge sealing, and energy-efficient speed.

Watch as the laser precisely cuts intricate patterns in real-time, highlighting the advantages of advanced fabric cutting technology.

Any Question to Laser Cutting Tulle Fabric?

Let Us Know and Offer Further Advice and Solutions for You!

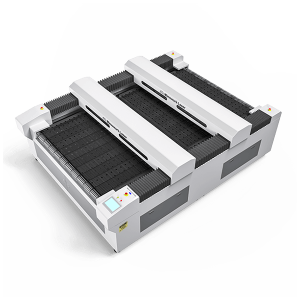

Recommended Tulle Laser Cutting Machine

At MimoWork, we specialize in cutting-edge laser cutting technology for textile production, with a particular focus on pioneering innovations in Tulle solutions.

Our advanced techniques tackle common industry challenges, ensuring impeccable outcomes for clients across the globe.

Laser Power: 100W/150W/300W

Working Area (W * L):1600mm * 1000mm (62.9” * 39.3 ”)

Laser Power: 100W/150W/300W

Working Area (W * L): 1800mm * 1000mm (70.9” * 39.3 ”)

Laser Power: 150W/300W/450W

Working Area (W * L): 1600mm * 3000mm (62.9’’ *118’’)

FAQs

Tulle's delicate, airy texture makes it an excellent choice for garments requiring a soft, flowy quality.

Its lightweight nature allows it to be used in multiple layers to produce volume while remaining lightweight, making it especially useful in formal wear and costumes.

Hand wash or use a gentle cycle with cold water and mild detergent. Air dry flat; avoid dryers to prevent damage.

Nylon tulle can withstand moderate heat but should be treated carefully; excessive heat can cause melting or deformation.

Tulle can be made from a variety of natural and synthetic fibers, including silk, nylon, rayon, or cotton.