Wholesale Die Board Cutting Machine Quotes - Cordura Fabric Laser Cutter – MimoWork Laser

Wholesale Die Board Cutting Machine Quotes - Cordura Fabric Laser Cutter – MimoWork Laser Detail:

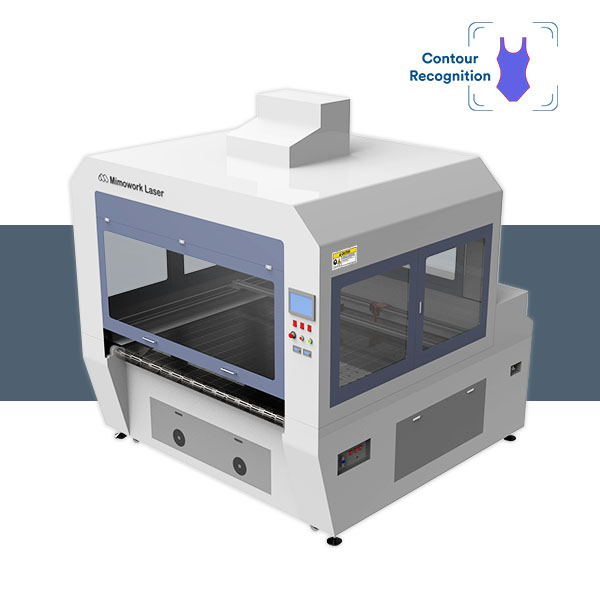

▶ Cordura Laser Cutter 160

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Servo Motor Upgrade Available

Features of Cordura Laser Cutter

Swift and powerful cutting

Huge energy from the laser source can be turned into heat when contacting the Cordura fabric. That will instantly cut through (just to say melt through) the synthetic fabric, and seal the edge in virtue of the heat from laser cutting.

High speed & high efficiency

According to the powerful laser beam, the laser head can be contact-less to the material. The force-free processing greatly improves the cutting speed whilst ensuring no any damage and fray for the Cordura fabric. Plus with the CNC system and auto conveyor system, laser cutter enhances the efficiency to realize the smooth and continuous cutting. Precision and high efficiency coexists side by side.

Flexible cutting as design pattern

Just import the cutting file, the laser system will auto treat the image and convey the instruction to the laser head. Fully in accordance with your design pattern, fine laser beam without any shape limitation can draw the cutting trace on the Cordura. Flexible curving cutting gives great freedom on the design pattern. Customized working table allows different formats of Cordura.

Mechanical Structure

Automation Components

Safe & Stable Structure

R&D for Flexible Material Cutting

Nesting Software

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further manual intervention.

Auto Feeding System

The Auto Feeder combined with the Conveyor Table is the ideal solution for series and mass production. It transports the flexible material (fabric most of the time) from the roll to the cutting process on the laser system. With stress-free material feeding, there is no material distortion while contactless cutting with laser ensures outstanding results.

Marker Pen Module

You can use the marker pen to make the marks on the cutting pieces, enabling the workers to sew easily. You can also use it to make special marks such as the serial number of the product, the size of the product, the manufacture date of the product, etc.

Ink-jet Print Module

It is widely used commercially for marking and coding products and packages. A high-pressure pump directs liquid ink from a reservoir through a gun body and a microscopic nozzle, creating a continuous stream of ink droplets via the Plateau-Rayleigh instability. Different inks are optional for specific fabrics.

Samples of laser cutting fabric

Video Display

Find more videos about our laser cutters at our Video Gallery

Cordura® Cutting Test

1050D Cordura® fabric is tested that has an excellent laser cutting ability

◆ No pull deformation with contactless processing

◆ Crisp & clean edge without burr

◆ Flexible cutting for any shapes and sizes

<a href="https://www.mimowork.com/laser-cutting-cordura/" title=" >> Learn more about Cordura laser cutting” target=”_blank”>

>> Learn more about Cordura laser cutting

Pictures Browse

Related Fabric Cutter Laser

Cordura Industrial Laser Cutter

• Laser Power: 150W/300W/500W

• Working Area (W *L): 1600mm * 3000mm

Textile laser cutting machine (fabric)

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1800mm * 1000mm

Laser Cutter for Cloth

• Laser Power: 100W / 150W / 300W

• Working Area (W *L): 1600mm * 1000mm

• Collecting Area (W *L): 1600mm * 500mm

How to cut Cordura fabric with laser cutter?

MimoWork offer professional laser advice for you!

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for Wholesale Die Board Cutting Machine Quotes - Cordura Fabric Laser Cutter – MimoWork Laser , The product will supply to all over the world, such as: New Orleans , Indonesia , Thailand , With the development of the society and economy, our company will continue the "loyalty, dedication, efficiency, innovation" spirit of enterprise, and we will always adhere to the management idea of "would rather lose gold, do not lose customers heart". We will serve the domestic and foreign businessmen with sincere dedication, and let us create bright future together with you!

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!