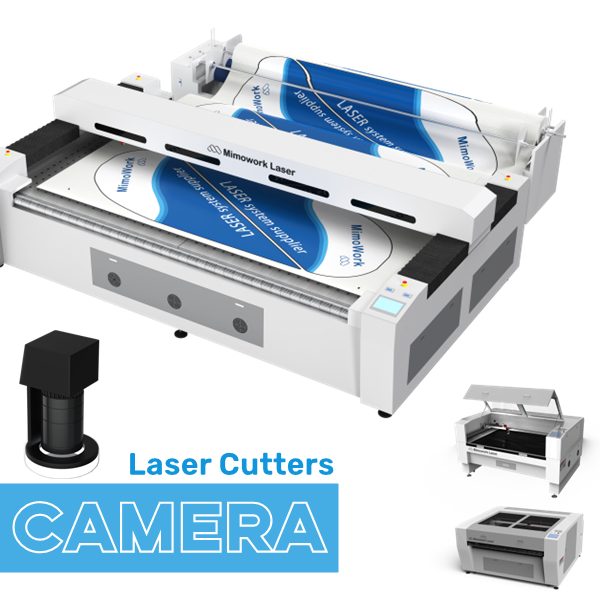

Wholesale Laser Cutting Acrylic Die Board - Camera Laser Cutting Machine – MimoWork Laser

Wholesale Laser Cutting Acrylic Die Board - Camera Laser Cutting Machine – MimoWork Laser Detail:

Technical Data

of Camera Laser Cutter 130 – Standard but Capable

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

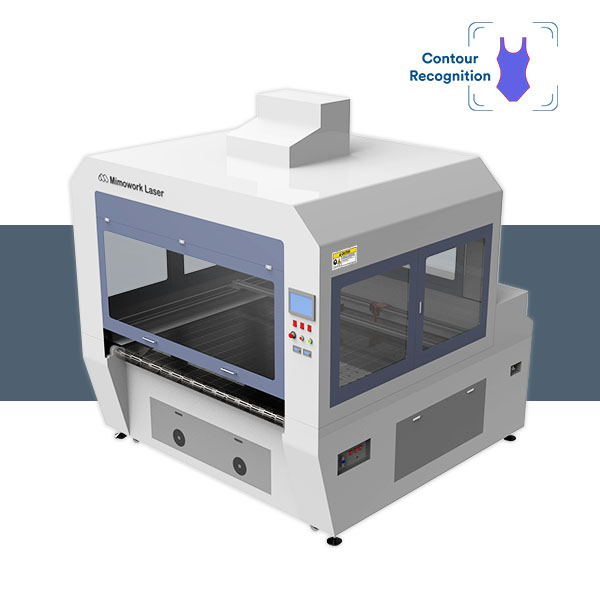

of Camera Laser Cutter 160 – Upgraded Working Area for Productivity Improvement

| Working Area (W *L) | 1600mm * 1,000mm (62.9’’ * 39.3’’) |

| Software | CCD Registration Software |

| Laser Power | 100W / 150W / 300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Drive & Belt Control |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

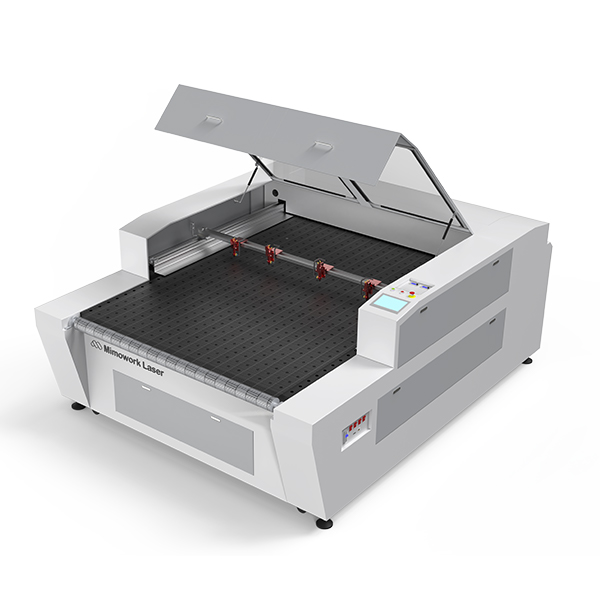

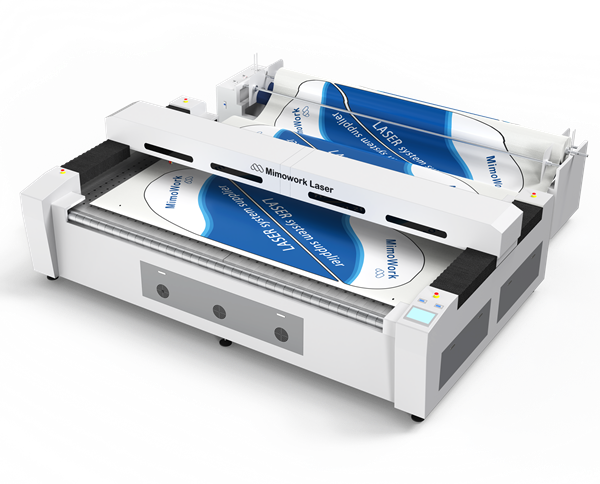

of Camera Laser Cutter 320 – The Latest of Industrial Preformance

| Working Area (W * L) | 3200mm * 1400mm (125.9’’ *55.1’’) |

| Max Material Width | 3200mm (125.9’’) |

| Software | Offline Software |

| Laser Power | 130W |

| Laser Source | CO2 Glass Laser Tube |

| Mechanical Control System | Rack & Pinion Transmission and Step Motor Driven |

| Working Table | Conveyor Working Table |

| Cooling Mode | Constant Temperature Water Cooling |

| Electricity Supply | 220V/50HZ/single phase |

Advantages of Laser Cutter with Camera – The Next Step of Progression

Laser Cutting Was Never This Easy

◼ Specific for cutting digitally printed solid materials (Printed acrylic, wood, plastic, etc) AND Sublimation laser cutting for flexible materials (Sublimation Fabric & Garment Accessories)

◼ High laser power option to 300W for cutting thick material

◼ Precise CCD Camera Recognition System ensures tolerance within 0.05mm

◼ Optional servo motor for extremely high speed cutting

◼ Flexible pattern cutting along the contour as your different design files

◼ Enhanced two laser heads, greatly increase your productivity (Optional)

◼ CNC (Computer Numerical Control) and computer data support high automation processing and constant stable high-quality output

◼ MimoWork Smart Vision Laser Cutter Software automatically corrects deformation and deviation

◼ Auto-feeder provides automatic & fast feeding, allowing unattended operation which saves your labor cost, and lower rejection rate (Optional)

Multifunction Provided by R&D

CCD Camera

The CCD Camera equipped next to the laser head can detect feature marks to locate the printed, embroidered, or woven patterns and the software will apply the cutting file to the actual pattern with 0.001mm accuracy to ensure the highest precious cutting result.

Conveyor Working Table

Stainless steel web will be suitable for flexible materials like direct injection and digitally printed fabrics. With the Conveyor Table, continuously process can be easily realized, greatly increasing your productivity.

Auto Feeder

Auto Feeder is a feeding unit that runs synchronously with the laser cutting machine. Coordinated with conveyor table, the auto feeder can convey the roll materials to the cutting table after you put the rolls on the feeder. To match the wide format materials, MimoWork recommends the widened auto-feeder which is able to carry a bit of heavy load with large format, as well as ensure feeding smoothly. Feeding speed can be set according to your cutting speed. A sensor is equipped to ensure perfect material positioning and minimize errors. The feeder is able to attach different shaft diameters of rolls. The pneumatic roller can adapt textiles with various tension and thickness. This unit helps you to realize a completely automatic cutting process.

Knife Stripe Working Table

Besides laser honeycomb bed, MimoWork provides the knife stripe working table to suit solid materials cutting. The gap between the stripes makes it not easy to accumulate waste and much easier to clean after processing.

<a href="https://www.mimowork.com/working-table/" title=">> Optional Laser Cutter Tables” target=”_blank”>

>> Optional Laser Cutter Tables

Optional Lifting Working Table

The working table can be moved up and down on Z-axis when cutting products with different thickness, which makes the processing more extensive.

Optional Servo Motor

Servo motor motion system can be selected to provide a higher cutting speed. Servo motor will improve the stable performance of C160 when cutting complex outer contour graphics.

Pass-through Design

The front and back pass-through design unfreezes the limitation of processing longer materials that exceeds the working table. No need to cut down the materials to adaptive the working table length in advance.

Y-axis Gear & X-axis Belt Drive

The camera laser cutting machine features a Y-axis rack & pinion Drive and X-axis belt transmission. The design offers a perfect remedy between a large format working area and smooth transmission. Y-axis rack & pinion is a type of linear actuator that comprises a circular gear (the pinion) engaging a linear gear (the rack), which operates to translate rotational motion into linear motion. The rack and the pinion drive each other spontaneously. Straight and helical gears are available for the rack & pinion. X-axis belt transmission provides a smooth and steady transmission to the laser head. High-speed and high precision laser cutting can be completed.

Vacuum Suction

The Vacuum Suction lies under the cutting table. Through the small and intensive holes on the surface of the cutting table, the air ‘fastens’ the material on the table. The vacuum table does not get in the way of the laser beam while cutting. On the contrary, together with the powerful exhaust fan, it enhances the effect of smoke & dust prevention during cutting.

Video Demos of Camera Laser Cutting Machine

of Laser Cutting Printed Acrylic

of How to Make Laser Cut Label (Printed Film)?

of How to Contour Laser Cut with CCD Camera

of Embroidery Patch Laser Cutting with CCD Camera

Find more videos about our laser cutters at our Video Gallery

Having any Question about How the CCD Camera Laser Cutter Works?

Fields of Application

for CCD Camera Laser Cutting Machine

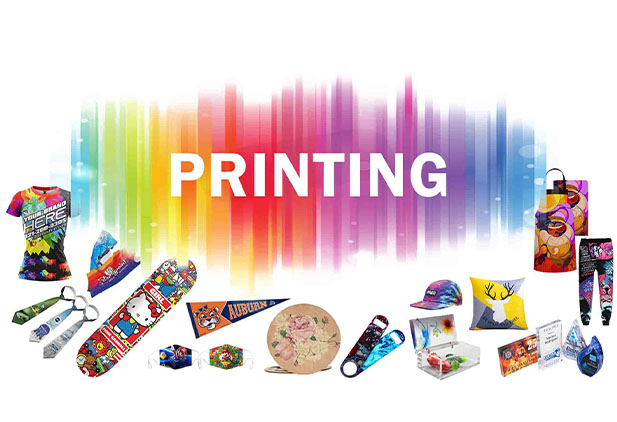

Digital Printing

Clean and Smooth Edge with Thermal Treatment

✔ Bringing about more economical and environment-friendly manufacturing process

✔ Customized working tables meet requirements for varieties of materials formats

✔ Quick response to market from samples to large-lot production

Large Advertising

Excellent Cutting Quality in Laser Cutting Signs, Flag, Banner

✔ Flexible and efficient production solution for laser cutting outdoor advertising

✔ Benefiting from no limitation on shape, size, and pattern, customized design can be fast realized

✔ Quick response to market from samples to large-lot production

Sublimation Apparel

Polished Edge and Accurate Contour Cutting

✔ The CCD Camera accurately locate the registration marks

✔ Optional dual laser heads can greatly increase the output and efficiency

✔ Clean and accurate cutting edge without post-trimming

Sublimation Accessories

Precision and Flexibility

✔ Cut along the press contours after detecting the mark points

✔ Laser cutting machine is suitable for both short-run production and mass production orders

✔ High Precision within 0.1 mm error range

Common Materials and Applications

of Camera Laser Cutter 130

Materials: Acrylic, Plastic, Wood, Glass, Laminates, Leather

Applications: Signs, Signage, Abs, Display, Key chain, Arts, Crafts, Awards, Trophies, Gifts, etc.

of Camera Laser Cutter 160

Materials: Twill, Velvet, Velcro, Nylon, Polyester, Film, Foil, and other patterned materials

Applications: Apparel, Clothing Accessories, Lace, Home Textiles, Photo Frame, Labels, Sticker, Applique

of Camera Laser Cutter 320

Materials: Sublimation Fabric, Polyester, Spandex Fabric, Nylon, Canvas Fabric, Coated Fabric, Silk, Taffeta Fabric, and other printed fabrics.

Applications: Print Advertising, Banner, Signage, Teardrop Flag, Exhibition Display, Billboard, Sublimation Clothing, Home Textiles, Wall Cloth, Outdoor Equipment, Tent, Parachute, Paragliding, Kiteboard, Sail, etc.

Learn more about CCD Camera Laser Cutting Machine,

MimoWork is here to support you!

Product detail pictures:

Related Product Guide:

It adheres on the tenet Honest, industrious, enterprising, innovative to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for Wholesale Laser Cutting Acrylic Die Board - Camera Laser Cutting Machine – MimoWork Laser , The product will supply to all over the world, such as: Manila , Liberia , Nigeria , Many kinds of different solutions are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions with us!!

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.