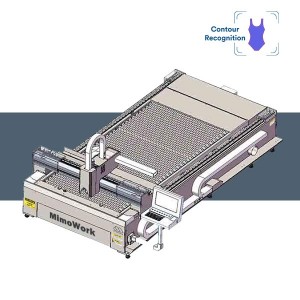

Embroidery Patch Laser Cutting Machine 60

Embroidery Laser Machine-Laser Cutting Embroidery Patches ngokulula

Idatha yoBugcisa

| Indawo yokusebenzela (W*L) | 600mm * 400mm (23.6” * 15.7”) |

| Ubungakanani bokuPakisha (W*L*H) | 1700mm * 1000mm * 850mm (66.9” * 39.3” * 33.4”) |

| Isoftware | Isoftware yeCCD |

| Amandla eLaser | 60W |

| Umthombo weLaser | CO2 Glass Laser Tube |

| Inkqubo yoLawulo loomatshini | Inyathelo leMoto yokuQhuba kunye noLawulo lwebhanti |

| Itheyibhile yokuSebenza | Itheyibhile eSebenzayo yeNkama yobusi |

| Isantya esiphezulu | 1~400mm/s |

| Isantya sokukhawulezisa | 1000~4000mm/s2 |

| Isixhobo sokupholisa | I-Chiller yamanzi |

| Ubonelelo ngoMbane | 220V/Isigaba esinye/60HZ |

(I-Laser yesiko esikwe kwi-Applique, ileyibhile, isincamathelisi, iipetshi eziprintiweyo)

I-Embroidery Patch Laser Cutting Machine 60 - IINKCAZELO EZIPHAKAMILEYO

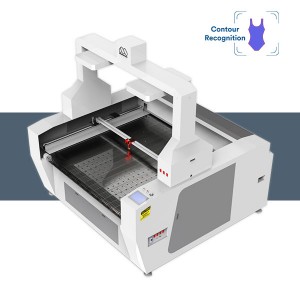

INkqubo yokuQatshelwa kwe-Optical

◾ Ikhamera yeCCD

IIkhamera yeCCDinokwazi kwaye ibeke ipateni kwisiqwenga, ileyibhile kunye nesincamathelisi, iyalele intloko ye-laser ukufezekisa ukusika okuchanekileyo ecaleni kwekhonto. Umgangatho ophezulu kunye nokusikwa okuguquguqukayo kwipateni eyenziwe ngokwezifiso kunye noyilo lwemilo njenge logo, kunye noonobumba. Kukho iindlela ezininzi zokuqaphela: indawo yokubeka uphawu, indawo yokubeka amanqaku, kunye nokutshatisa itemplate. I-MimoWork iya kunika isikhokelo malunga nendlela yokukhetha iindlela ezifanelekileyo zokuqaphela ukuba zilungele imveliso yakho.

◾ Ukubeka iliso ngexesha lokwenyani

Kanye kunye neKhamera yeCCD, inkqubo yokuqaphela ikhamera ehambelanayo ibonelela ngesibonisi sokuhlola ukujonga imeko yemveliso yexesha langempela kwikhompyuter. Oko kulungele ulawulo olukude kunye nokwenza uhlengahlengiso kwangexesha, ukugudisa ukuhamba komsebenzi wemveliso kunye nokuqinisekisa ukhuseleko.

Izinzile kunye neSakhiwo seLaser esiKhuselekileyo

◾ Uyilo loMzimba oManyanisiweyo womatshini

I-Contour laser cut patch machine ifana netafile yeofisi, engadingi indawo enkulu. Umatshini wokusika iileyibhile unokubekwa naphi na kwi-factory, kungakhathaliseki ukuba kwigumbi lokuvavanya okanye kwi-workshop. Incinci ngobukhulu kodwa ibonelela ngoncedo olukhulu.

◾ Ukuvuthela komoya

Uncedo lomoya lunokucoca umsi kunye namasuntswana awenziwe xa i-laser cut patch okanye i-patch ekroliweyo. Kwaye umoya ovuthuzayo unokunceda ekunciphiseni indawo echaphazelekayo yokushisa ekhokelela kumgca ococekileyo kunye nocwecwe ngaphandle kokunyibilika kwezinto ezongezelelweyo.

(* Ukuvuthela inkunkuma ngexesha elifanelekileyo kunokukhusela ilensi kumonakalo wokwandisa ubomi benkonzo.)

◾ Iqhosha likaNgxamiseko

Anukumisa ngexesha likaxakeka, ekwabizwa ngokuba yi-abulala utshintsho(E-stop), yindlela yokhuseleko esetyenziselwa ukuvala umatshini ngexesha likaxakeka xa ungenakuvalwa ngendlela eqhelekileyo. Ukumisa okungxamisekileyo kuqinisekisa ukhuseleko lwabaqhubi ngexesha lenkqubo yokuvelisa.

◾ ISekethe eKhuselekileyo

Ukusebenza okungenamagingxi-gingxi kwenza imfuno yesekethe ye-function-well, okhuseleko lwalo lusisiseko semveliso yokhuseleko.

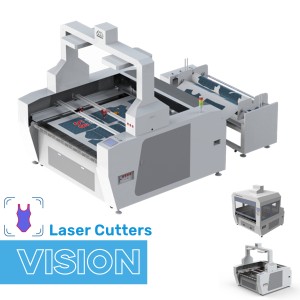

NgokuzikhethelaItafile yeShuttle, kuya kubakho iitafile ezimbini zokusebenza ezinokusebenza ngokutshintshanayo. Xa itafile enye yokusebenza igqiba umsebenzi wokusika, enye iya kuthatha indawo yayo. Ukuqokelela, ukubeka izinto kunye nokusika kunokuqhutywa ngexesha elifanayo ukuqinisekisa ukusebenza kakuhle kwemveliso.

Ubungakanani betafile yokusika i-laser kuxhomekeke kwifomathi yezinto eziphathekayo. IMimoWork ibonelela ngeendawo ezahlukeneyo zeetafile zokusebenza ukuba zikhethwe ngokwemfuno yakho yemveliso kunye nobukhulu bezinto eziphathekayo.

Iisixhobo sokukhupha umsi, kunye nefeni yokukhupha umoya, inokufunxa irhasi eyinkunkuma, ivumba elinukayo, kunye neentsalela ezihamba emoyeni. Kukho iintlobo ezahlukeneyo kunye neefomathi zokukhetha ngokwenyani yemveliso yesiqwenga. Ngakolunye uhlangothi, inkqubo yokucoca yokuzikhethela iqinisekisa indawo yokusebenza ecocekileyo, kwaye kwelinye imalunga nokukhuselwa kwendalo ngokucoca inkunkuma.

I-Embroidery Patch Laser Cutting ayizange ibe lula kwaye ineNzuzo

Kutheni Ndilindile? Qala Ngoku!

Embroidery Patch Laser Cutting-Imizekelo

Embroidery Patch Laser Ukusika

Iipetshi ze-Embroidery yindlela efanelekileyo yokongeza umnxeba wobuntu kunye nesitayela kuyo nayiphi na impahla okanye i-accessory. Nangona kunjalo, iindlela zemveli zokusika kunye nokuyila ezi ziqwengana zinokutya ixesha kwaye zidinwe. Kulapho ukusika kwe-laser kungena khona! Iipetshi zokuluka ezihonjisiweyo zeLaser ziyiguqule inkqubo yokwenza isiziba, zibonelela ngokukhawuleza, zichane ngakumbi, kunye nendlela esebenzayo yokudala iipetshi ezinoyilo kunye neemilo ezintsonkothileyo. Ngomatshini wokusika we-laser owenzelwe ngokukodwa ama-patches e-embroidery, unokufezekisa inqanaba lokuchaneka kunye neenkcukacha ezazingenakwenzeka ngaphambili.

Enye iPatch eqhelekileyo yokusika iLaser

Ukusika kwe-laser ye-patch kuthandwa kwifashoni, kwimpahla, nakwizixhobo zomkhosi ngenxa yomgangatho ophezulu kunye nokugcinwa okufanelekileyo ekusebenzeni kunye nokusebenza. Ukusika okushushu kwi-patch laser cutter kunokutywina udini ngelixa kusika i-patch, ekhokelela kumphetho ococekileyo nogudileyo obonisa imbonakalo entle kunye nokuqina. Ngenkxaso yenkqubo yokumisa ikhamera, kungakhathaliseki ukuba yintoni imveliso yobuninzi, i-laser cutting patch ihamba kakuhle ngenxa ye-template ekhawulezayo ehambelanayo kwi-patch kunye ne-automatic layout yendlela yokusika. Ukusebenza okuphezulu kunye nokusebenza okuncinci kwenza ukusika kwepetshi yanamhlanje kube bhetyebhetye kwaye ngokukhawuleza.

• Ipetshi yokuhombisa

• Isiqwenga seVinyl

• Ifilimu eprintiweyo

• Isiqwenga seflegi

• Ipetshi yamapolisa

• Isiqwenga sobuchule

• Iipatshi yesazisi

• Ipetshi ebonakalisayo

• Ipetshi yepleyiti yamagama

• Isiqwenga seVelcro

• Isiqwenga seCordura

• Isitika

• I-Applique

• Ileyibhile elukiweyo

• Umfuziselo (ibheji)

• Isiziba sesikhumba

▷ Umboniso Wevidiyo

NgeEmbroidery Patch Laser Cutting Machine 60

Usika njani iiPatches zokuhombisa-Ngamanyathelo

1. Ikhamera yeCCD iya kukhupha indawo ye-embroidery

2. Ngenisa ifayile yoyilo kunye nenkqubo ye-laser iya kubeka iphethini

3. Tshatisa i-embroidery kunye nefayile yetemplate kwaye ulingise indlela yokusika

4. Qala ukusika itemplate echanekileyo yodwa i-contour yepateni