Umatshini wokukrola we-CO2 weLaser woMthi (Plywood, MDF)

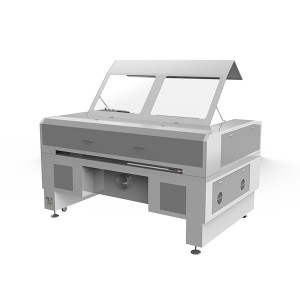

▶ Umzobi weLaser woMthi (Umzobi weLaser osebenza ngamaplanga)

Idatha yoBugcisa

| Indawo yokusebenzela (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Isoftware | Isoftware engasebenziyo |

| Amandla eLaser | 100W/150W/300W |

| Umthombo weLaser | CO2 Glass Laser Tube okanye CO2 RF Metal Laser Tube |

| Inkqubo yoLawulo loomatshini | Inyathelo Motor Belt Control |

| Itheyibhile yokuSebenza | Itheyibhile eSebenzayo yoBusi okanye iThayibhile yokuSebenza yeKnife Strip |

| Isantya esiphezulu | 1~400mm/s |

| Isantya sokukhawulezisa | 1000~4000mm/s2 |

| Ubungakanani bepakethi | 2050mm * 1650mm * 1270mm (80.7'' * 64.9'' * 50.0'') |

| Ubunzima | 620kg |

Uphuculo oluKhethayo: Umboniso we-CO2 RF Metal Laser Tube Showcase

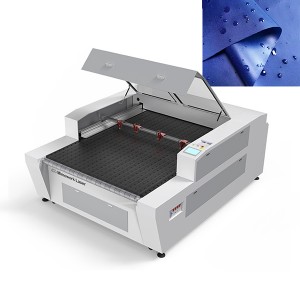

Imisebenzi emininzi kwi-Wood Laser Engraver

Uyilo lokuNgena oluneendlela ezimbini

Ulwakhiwo oluZinzileyo noluKhuselekileyo

◾ Ukukhanya koMqondiso

Ukukhanya komqondiso kunokubonisa imeko yokusebenza kunye nemisebenzi eyenziwa ngumatshini we-laser, kukunceda wenze isigwebo esifanelekileyo kunye nokusebenza.

◾ Iqhosha likaNgxamiseko

Yenzeka kwimeko ethile ngequbuliso kwaye engalindelekanga, iqhosha likaxakeka liya kuba sisiqinisekiso sakho sokhuseleko ngokumisa umatshini kwangoko.

◾ ISekethe eKhuselekileyo

Ukusebenza okungenamagingxi-gingxi kwenza imfuno yesekethe ye-function-well, okhuseleko lwalo lusisiseko semveliso yokhuseleko.

◾ Isiqinisekiso seCE

Ukuba nelungelo elisemthethweni lokuthengisa nokusasaza, uMshini weLaser weMimoWork uzingca ngomgangatho oqinileyo nothembekileyo.

◾ Uncedo lomoya olulungiselelwayo

Uncedo lomoya lunokuvuthela inkunkuma kunye namaqhekeza ukusuka kumphezulu womthi okroliweyo, kwaye unike inqanaba lesiqinisekiso sothintelo lokutsha kweenkuni. Umoya oxinzelelweyo ovela kwimpompo yomoya unikezelwa kwimigca eqingqiweyo ngokusebenzisa umbhobho, ukucima ubushushu obongezelelweyo obuqokelelwe kubunzulu. Ukuba ufuna ukufezekisa umbono ovuthayo kunye nobumnyama, lungisa uxinzelelo kunye nobungakanani bokuhamba komoya ngomnqweno wakho. Nayiphi na imibuzo ukudibana nathi ukuba ubhidekile ngaloo nto.

Nyusela nge

Ikhamera yeCCD yokhuni oluprintiweyo

Ikhamera yeCCD inokubona kwaye ifumane ipateni eprintiweyo kwibhodi yeenkuni ukuncedisa i-laser ngokusika ngokuchanekileyo. Iimpawu zokhuni, iiplakhi, umzobo kunye nefoto yokhuni eyenziwe ngomthi oprintiweyo inokucutshungulwa ngokulula.

Inkqubo yeMveliso

Inyathelo loku-1.

>> Shicilela ipateni yakho ngokuthe ngqo kwibhodi yeenkuni

Inyathelo lesi-3.

>> Qokelela iziqwenga zakho ezigqityiweyo

(Umzobi weLaser yamaplanga kunye neCutter yonyusa iMveliso yakho)

Olunye ukhetho lokuphucula ukuba ukhethe

Iimoto zeServo

DC Brushless Motors

Intloko yeLaser exutyiweyo

Ugxininiso oluzenzekelayo

Ibhola kunye neScrew

Iisampulu zoMkrolo weLaser yoMthi

Loluphi uhlobo lweProjekthi yokhuni endinokuthi ndisebenze kuyo nge-CO2 yam yeLaser Engraver?

• Iimpawu eziqhelekileyo

• Iitreyi zomthi, iiCoasters, kunye neePlacemats

•Isihombiso saseKhaya (Ubugcisa baseDongeni, iiwotshi, izibane zezibane)

•Iipuzzle kunye neebhloko zeAlfabhethi

• Imifuziselo yoYilo/iiPrototypes

Umboniso weevidiyo

Ifoto yeLaser ekroliweyo yeenkuni

✔Uyilo oluguquguqukayo olulungiselelweyo kunye nokusikwa

✔Iipateni zokukrola ezicocekileyo nezintsonkothileyo

✔Isiphumo sesithathu-ntathu esinamandla ahlengahlengiswayo

Izixhobo eziqhelekileyo

- ukusika i-laser kunye nokukrola iinkuni (MDF)

IBamboo, iBalsa Wood, Beech, Cherry, Chipboard, Cork, Hardwood, Wood Laminated, MDF, Multiplex, Natural Wood, Oak, Plywood, Solid Wood, Timber, Teak, Veneers, Walnut...

Vector Laser uMzobo Wood

Umkrolo weVector laser emthini ubhekisa ekusebenziseni isisiki selaser ukukrola okanye ukukrola uyilo, iipateni, okanye isicatshulwa kumphezulu womthi. Ngokungafaniyo nokukrolwa kwe-raster, okubandakanya ukutshisa iipikseli ukwenza umfanekiso ofunekayo, ukukrolwa kwevektha kusebenzisa iindlela ezichazwe yiequation zemathematika ukuvelisa imigca echanekileyo necocekileyo. Le ndlela ivumela imizobo ebukhali kwaye eneenkcukacha ngakumbi emthini, njengoko i-laser ilandela iindlela ze-vector ukwenza uyilo.

Nayiphi na imibuzo emalunga nendlela yeLaser yokuBeka iinkuni?

Related Wood Laser Machine

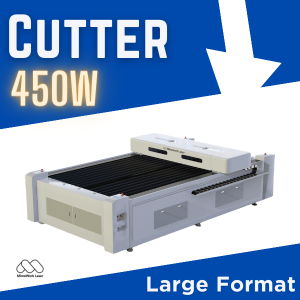

Iinkuni kunye ne-Acrylic Laser Cutter

• Ifanele ifomathi enkulu imathiriyeli eqinileyo

• Ukusika ukutyeba okuninzi ngamandla okuzikhethela we-laser tube

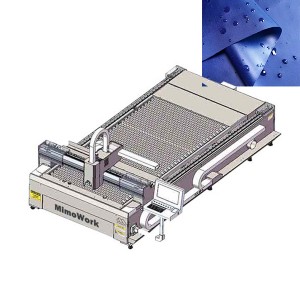

Iinkuni kunye ne-Acrylic Laser uMzobi

• Ukukhanya kunye noyilo oludibeneyo

• Kulula ukusebenza kwabaqalayo

# Yintoni omele uyiqaphele ngaphambi kokusika i-laser kunye nokukrola iinkuni?

Kubalulekile ukuqaphela ukuba iintlobo ezahlukeneyo zomthi zineukuxinana okwahlukeneyo kunye nomxholo wokufuma, enokuchaphazela inkqubo yokusika i-laser. Ezinye iinkuni zinokufuna uhlengahlengiso kwiisetingi ze-laser cutter ukufezekisa iziphumo ezilungileyo. Ukongeza, xa laser-ukusika iinkuni, umoya ofanelekileyo kunyeiinkqubo zokukhuphazibalulekile ukususa umsi kunye nomsi owenziwe ngexesha lenkqubo.

# Umsiki welaser unokuwusika kangakanani umthi?

Nge-CO2 laser cutter, ubukhulu bomthi obunokuthi bunqunywe ngokufanelekileyo buxhomekeke kumandla e-laser kunye nohlobo lomthi osetyenziswayo. Kubalulekile ukukhumbula ukubaubukhulu bokusika bunokwahlukakuxhomekeke kwi-CO2 laser cutter ethile kunye nemveliso yamandla. Abanye abasiki belaser beCO2 abanamandla aphezulu banokukwazi ukusika izinto zomthi ezityebileyo, kodwa kubalulekile ukubhekisa kwiinkcukacha zesisiki selaser esisetyenziselwa ukusika okuchanekileyo. Ukongeza, izinto zokhuni ezityebileyo zinokufunaisantya esicothayo sokusika kunye nokupasa okuninziukufezekisa ukusika okucocekileyo kunye nokuchanekileyo.

# Ngaba umatshini welaser unokugawula iinkuni zazo zonke iintlobo?

Ewe, i-CO2 laser inokusika kwaye ikrole iinkuni zazo zonke iintlobo, kubandakanya ibhirch, imaple,iplywood, MDF, icherry, imahogany, ialder, ipoplar, ipayina, noqalo. Iinkuni ezixinene kakhulu okanye eziqinileyo njenge-oki okanye i-ebony zifuna amandla aphezulu e-laser ukusetyenzwa. Nangona kunjalo, phakathi kwazo zonke iintlobo zokhuni ezilungisiweyo, kunye ne-chipboard,ngenxa yokungcola okuphezulu, akukhuthazwa ukusebenzisa i-laser processing

# Ngaba inokwenzeka into yokuba umgawuli wemithi ngelaser uwonakalisa umthi esisebenza kuwo?

Ukukhusela ingqibelelo yomthi ojikeleze iprojekthi yakho yokusika okanye yokufaka, kubalulekile ukuqinisekisa ukuba useto lukhona.iqwalaselwe ngokufanelekileyo. Ukufumana isikhokelo esineenkcukacha malunga nokuseta okufanelekileyo, jonga iMimoWork Wood Laser Engraving Machine manual okanye ujonge izibonelelo zenkxaso ezongezelelweyo ezikhoyo kwiwebhusayithi yethu.

Nje ukuba ucofe useto oluchanekileyo, ungaqiniseka ukuba lukhonaakukho mngcipheko wokonakalisaukhuni olusecaleni kweprojekthi yakho yokusikwa okanye imigca ye-etch. Apha kulapho isakhono esahlukileyo soomatshini belaser be-CO2 bukhanya khona - ukuchaneka kwabo okungaqhelekanga kubenza bahluke kwizixhobo eziqhelekileyo ezifana neesarha zokuskrola kunye neesarha zetafile.