I-CO2 Galvo Laser Umzobi woMzobo wesikhumba kunye nokuGqiba

▶ Umatshini wokukrola wesikhumba welaser wokwenza ngokwezifiso kunye nokuveliswa kwebhetshi

Idatha yoBugcisa

| Indawo yokusebenzela (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Ukuhanjiswa kweBeam | 3D Galvanometer |

| Amandla eLaser | 180W/250W/500W |

| Umthombo weLaser | CO2 RF Metal Laser Tube |

| Inkqubo yoomatshini | I-Servo iqhutywa, ibhanti liqhutywa |

| Itheyibhile yokuSebenza | Itheyibhile eSebenzayo yeNkama yobusi |

| Isantya esiphezulu sokusika | 1~1000mm/s |

| Isantya esiphezulu sokuMakisha | 1~10,000mm/s |

Iimpawu zesakhiwo - Umzobi we-Leather Laser

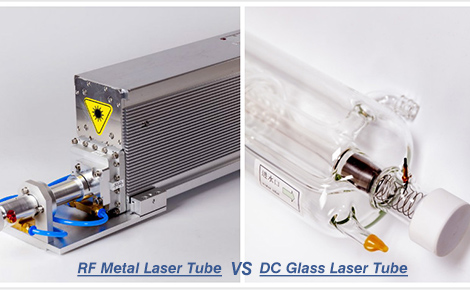

RF Metal Laser Tube

I-Galvo Laser Marker ithatha i-RF (iRadio Frequency) ityhubhu ye-laser yesinyithi ukuhlangabezana nomzobo ophezulu kunye nokumakisha ngokuchanekileyo. Ngobukhulu obuncinci bendawo yelaser, ukukrolwa kwepateni entsonkothileyo eneenkcukacha ezithe kratya, kunye nemingxunya ecolekileyo yokugqobhoza inokuqondwa ngokulula kwiimveliso zesikhumba ngelixa ikhawulezayo ukusebenza kakuhle. Umgangatho ophezulu kunye nobomi benkonzo ende zizinto eziphawulekayo zetyhubhu ye-laser yensimbi. Ngaphandle koko, iMimoWork ibonelela ityhubhu yelaser yeglasi yeDC (ngokuthe ngqo) ukukhetha malunga ne-10% yexabiso le-RF laser tube. Thatha ulungelelwaniso lwakho olufanelekileyo njengemfuno zemveliso.

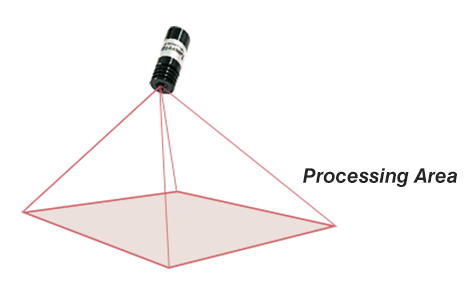

Red-light inkomba System

chonga indawo yokulungisa

Ilensi yeGalvo Laser

Intloko yeGalvo Laser

Ukusebenza okuphezulu - isantya esikhawulezayo

Icwecwe elijikelezayo

Itafile eshukumayo ye-XY

Nayiphi na imibuzo malunga neGalvo Laser Engraver Configurations?

(Usetyenziso olwahlukeneyo lwesikhumba sokukrola iLaser)

Iisampulu ezisuka kuMkrolo weLaser yesikhumba

Unokukhetha njani izixhobo zokukrola zobugcisa besikhumba?

Ukusuka kwisitampu sesikhumba sevini kunye nokukrolwa kwesikhumba ukuya kwindlela entsha yetekhnoloji: umzobo we-laser wesikhumba, uhlala ukonwabela ukwenza ufele kunye nokuzama into entsha ukuze utyebe kwaye ucokise umsebenzi wakho wesikhumba. Vula ubuchule bakho bokuyila, vumela iimbono zobuchwephesha besikhumba ziqhubele phambili, kunye nomzekelo woyilo lwakho.

I-DIY ezinye iiprojekthi zesikhumba ezifana nezipaji zesikhumba, imihombiso ejingayo yesikhumba, kunye nezacholo zesikhumba, kwaye kwinqanaba eliphezulu, ungasebenzisa izixhobo zokusebenza zesikhumba njenge-laser engraver, i-die cutter, kunye ne-laser cutter ukuqala ishishini lakho lobuchwephesha besikhumba. Kubalulekile ukuphucula iindlela zakho zokusetyenzwa.

UBUKWENZI LWESIKHUMBA: Isikhumba sokukrola iLaser!

Umboniso wevidiyo: uMzobo weLaser kunye nokusika izihlangu zesikhumba

Ngaba unokukrola iLaser kwisikhumba?

Ukumakishwa kweLaser kwithwathwa yinkqubo echanekileyo neguquguqukayo esetyenziswa ukwenza amanqaku asisigxina, iilogo, uyilo, kunye neenombolo zesiriyali kwiimpahla zethwathwa ezifana nezipaji, amabhanti, iibhegi kunye nezihlangu.

Ukumakishwa kweLaser kubonelela ngekhwalithi ephezulu, entsonkothileyo, kunye neziphumo ezihlala ixesha elide kunye nokugqwethwa okuncinci kwemathiriyeli. Isetyenziswa kakhulu kwifashoni, kwimizi-mveliso yeemoto, nakwimizi-mveliso yokwenziwa ngokwezifiso kunye neenjongo zokuthengisa, ukuphucula ixabiso lemveliso kunye nobuhle.

Ukukwazi kwelaser ukufezekisa iinkcukacha ezintle kunye neziphumo ezihambelanayo zenza kube lukhetho oluhle kakhulu lwezicelo zokumakisha ngesikhumba. Isikhumba esilungele ukukrolwa kwelaser sibandakanya iindidi ezahlukeneyo zofele lwenyani kunye nendalo, kunye nezinye iindlela zokwenziwa zesikhumba.

Ezona ntlobo zolusu zoMzobo weLaser zibandakanya:

1. Isikhumba esisukiweyo semifuno:

Isikhumba esifakwe kwimifuno sithwathwa sendalo kwaye esinganyangekiyo esikrola kakuhle ngeelaser. Ivelisa umzobo ococekileyo kunye nochanekileyo, okwenza ukuba ulungele uluhlu olubanzi lwezicelo.

2. Ufele:

Isikhumba esipheleleyo siyaziwa ngokutya okuziinkozo kunye nokuthungwa, okunokongeza umlingiswa kuyilo olukroliweyo lwelaser. Ikrola kakuhle, ngakumbi xa iqaqambisa iinkozo.

3. Ufele:

Isikhumba se-top-grain, esihlala sisetyenziswa kwiimveliso zesikhumba eziphezulu, nazo zibhala kakuhle. Igudile kwaye ifana ngakumbi kunesikhumba esigcweleyo, ibonelela ngobuhle obahlukileyo.

4. Isikhumba sika-Aniline:

Isikhumba seAniline, esidayiwe kodwa singagqunywanga, sikulungele ukukrolwa ngelaser. Igcina imvakalelo ethambileyo neyendalo emva kokukrola.

5. Nubuck kunye neSuede:

Ezi zikhumba zinokwakheka okuyingqayizivele, kwaye i-laser engraving inokudala umahluko onomdla kunye neziphumo ezibonakalayo.

6. Ufele:

Ezinye izinto zesikhumba zokwenziwa, ezifana ne-polyurethane (PU) okanye i-polyvinyl chloride (PVC), nazo zinokukrolwa nge-laser, nangona iziphumo zinokwahluka ngokuxhomekeke kwizinto ezithile.

Xa ukhetha ufele lokukrola i-laser, kubalulekile ukuqwalasela izinto ezinje ngokutyeba kwesikhumba, ukugqiba, kunye nesicelo esicetywayo. Ukongeza, ukwenza imizobo yovavanyo kwisampulu yesikhumba esithile oceba ukusisebenzisa kunokunceda ukumisela useto lwelaser olufanelekileyo kwiziphumo ezifunwayo.

Kutheni Khetha iGalvo Laser ukuze ukrole ufele

▶ Isantya esiphezulu

Ukumakishwa okubhabhayo ukusuka kwisibuko esiguqukayo sokuphambuka kuphumelela kwisantya sokusebenza xa kuthelekiswa nomatshini we-flatbed lase. Akukho ntshukumo yomatshini ngexesha lokucubungula (ngaphandle kwezibuko), i-laser beam inokukhokelwa phezu kwendawo yokusebenza ngesantya esiphezulu kakhulu.

▶ Ukumakisha ngendlela entsonkothileyo

Ubukhulu bendawo yelaser buncinci, ukuchaneka okuphezulu kokukrolwa kwelaser kunye nokumakishwa. Umkrolo wesikhumba we-laser kwizipho ezithile zesikhumba, izipaji, ubugcisa bunokuqondwa ngomatshini weglavo laser.

▶ Iinjongo ezininzi kwinyathelo elinye

Ukukrolwa kwe-laser okuqhubekayo kunye nokusika, okanye ukugqobhoza kunye nokusika kwinqanaba elinye gcina ixesha lokucubungula kunye nokuphelisa ukutshintshwa kwesixhobo esingeyomfuneko. Ngesiphumo sokusetyenzwa kweprimiyamu, unokukhetha amandla ahlukeneyo e-laser ukuhlangabezana neteknoloji ethile yokucwangcisa. Sibuze ngayo nayiphi na imibuzo.

Yintoni iGalvo Laser? Ingaba isebenza kanjani?

Kwi-galvo scanner laser engraver, imfihlelo yokukrola ngokukhawuleza, ukumakisha, kunye nokugqobhoza ilele kwintloko ye-galvo laser. Uyakwazi ukubona izibuko ezibini eziguquguqukayo ezilawulwa ziinjini ezimbini, uyilo olukrelekrele lunokuhambisa imiqadi yelaser ngelixa ulawula ukuhamba kokukhanya kwelaser. Kule mihla kukho i-auto egxile kwi-galvo master laser, isantya sayo esikhawulezayo kunye ne-automation iya kwandisa kakhulu umthamo wakho wemveliso.

Ngesikhumba Laser uMzobo isindululo Machine

• Amandla eLaser: 75W/100W

• Indawo yokusebenzela: 400mm * 400mm

• Amandla eLaser: 100W/150W/300W

• Indawo yokusebenza: 1600mm * 1000mm

![Uthotho lweLaser ye3D [Yomkrolo weLaser ongaphantsi komhlaba]](https://cdnus.globalso.com/mimowork/3d-laser-series-high-end-1-300x300.png)