Xa umtsha kwi-laser technology kwaye ucinge ngokuthenga umatshini wokusika i-laser, kufuneka kubekho imibuzo emininzi ofuna ukuyibuza.

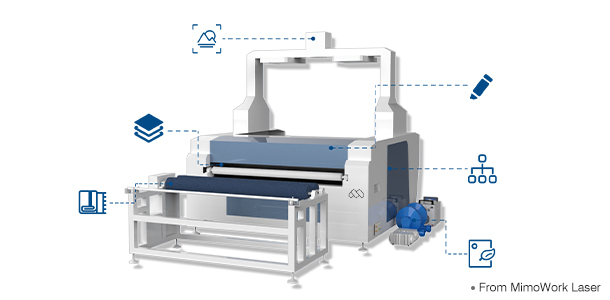

MimoWorkkuyavuya ukwabelana nawe ngolwazi oluthe kratya malunga noomatshini belaser be-CO2 kwaye ngethemba, ungasifumana isixhobo esikufanelekela ngokwenene, nokuba sivela kuthi okanye omnye umboneleli welaser.

Kule nqaku, siza kunika inkcazo emfutshane yokucwangciswa komatshini kwindawo eqhelekileyo kwaye senze uhlalutyo oluthelekisayo lwecandelo ngalinye. Ngokubanzi, inqaku liza kugubungela la manqaku angezantsi:

Ubuchwephesha bomatshini we-laser CO2

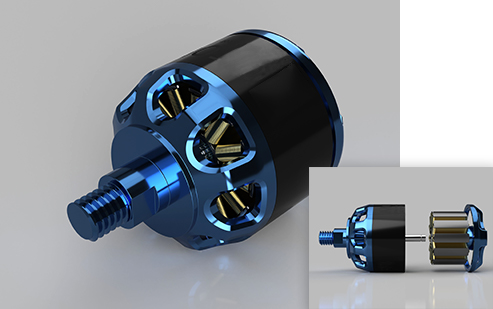

a. I-Brushless DC Motor, iServo Motor, iStep Motor

Brushless DC (ngqo ngqo) motor

I-Brushless DC motor inokubaleka kwi-RPM ephezulu (i-revolutions ngomzuzu). I-stator yemoto ye-DC ibonelela ngentsimi yamagnetic ejikelezayo eqhuba i-armature ukuba ijikeleze. Kuzo zonke iimoto, i-brushless dc motor inokubonelela ngeyona mandla ekinetic anamandla kwaye iqhube intloko ye-laser ukuba ihambe ngesantya esikhulu.Umatshini wokukrola we-laser we-MimoWork we-CO2 ixhotyiswe nge-brushless motor kwaye inokufikelela kwisantya esiphezulu sokukrola i-2000mm / s.I-brushless dc motor ayifane ibonwe kumatshini wokusika we-CO2 laser. Oku kungenxa yokuba isantya sokusika kwizinto eziphathekayo silinganiselwe ngobunzima bezinto eziphathekayo. Ngokuchasene noko, udinga kuphela amandla amancinci okukrola imizobo kwizinto zakho, Imoto engena brushless ixhotyiswe ngomkroli welaser iyanciphisa ixesha lakho lokukrola ngokuchaneka okukhulu.

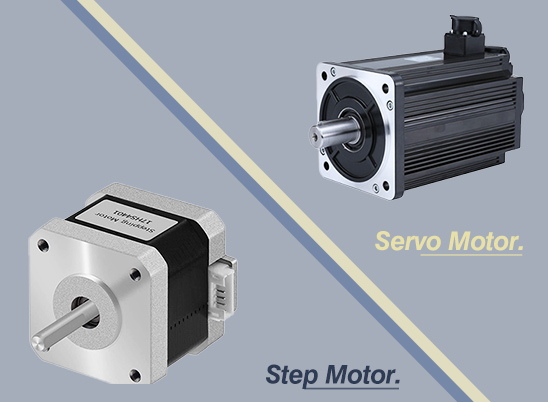

Servo motor & Inyathelo motor

Xa idityaniswe netafile ye-CO2 laser engraver, iimotor ze-servo zibonelela ngetorque ephezulu kunye nokuchaneka, ngakumbi kwimisebenzi yobugcisa efana nokusika ilaphu lokucoca okanye izigqubuthelo zokugquma. Ngelixa zibiza ngaphezulu kwaye zifuna ii-encoders kunye neebhokisi zegiya-ukwenza ukuseta kube nzima ngakumbi-zilungele ukufunwa kwezicelo. Oko kwathiwa, ukuba wenza izipho ezilula zobugcisa okanye imiqondiso, i-stepper motor kwitafile yakho yomkroli we-laser idla ngokwenza umsebenzi kakuhle.

Injini nganye ineenzuzo kunye neengxaki zayo. Eyona ikufaneleyo yeyona ilungileyo kuwe.

Ngokuqinisekileyo, iMimoWork inokubonelela ngeCO2 laser umkroli kunye nomsiki ngeentlobo ezintathu zeenjiningokusekelwe kwimfuno yakho kunye nohlahlo lwabiwo-mali.

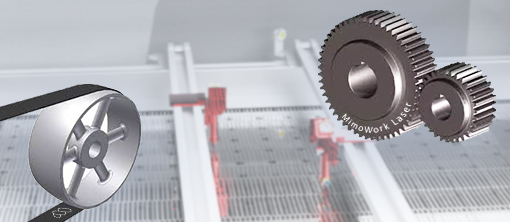

b. Bhanti Qhuba VS Gear Drive

Ukuqhuba ibhanti kusebenzisa ibhanti ukudibanisa amavili, ngelixa igiya idibanisa igiya ngokuthe ngqo ngamazinyo adibanayo. Kumatshini we-laser, zombini iinkqubo zinceda ukuhambisa i-gantry kwaye ichaphazele indlela echanekileyo ngayo umatshini.

Masithelekise ezi zimbini kunye nale theyibhile ilandelayo:

| Bhanti Qhuba | Gear Drive |

| Eyona nto iphambili iiPulleys kunye nebhanti | Iigiya ezingundoqo |

| Kufuneka indawo eninzi | Indawo encinci efunekayo, ngoko ke umatshini we-laser unokuyilwa ukuba ube mncinci |

| Ilahleko ephezulu yokukhuhlana, ngoko ke ukuhanjiswa okuphantsi kunye nokusebenza kancinci | Ilahleko yokukhuhlana okuphantsi, ngoko ke ukuhanjiswa okuphezulu kunye nokusebenza kakuhle |

| Ubomi obulindelekileyo obuphantsi kunokuqhuba kwegiya, ngokuqhelekileyo kutshintsha rhoqo emva kweminyaka emi-3 | Ubude bobomi obukhulu kakhulu kunokuqhuba ibhanti, ngokuqhelekileyo kutshintsha rhoqo kwiminyaka elishumi |

| Ifuna ukulungiswa okuthe chatha, kodwa iindleko zokuyilungisa zingabizi kakhulu kwaye ziluncedo | Ifuna ulondolozo oluncinci, kodwa iindleko zokugcinwa zincinci kwaye zinzima |

| Ukuthambisa akufuneki | Funa ukuthanjiswa rhoqo |

| Kuthe cwaka kakhulu ekusebenzeni | Ingxolo iyasebenza |

Zombini ii-gear drive kunye ne-belt drive systems ngokuqhelekileyo ziyilwe kumatshini wokusika we-laser kunye ne-pros and cons. Ngamafutshane,inkqubo yebhanti yokuqhuba inenzuzo ngakumbi kubungakanani obuncinci, iintlobo ze-flying-optical zoomatshini; ngenxa yosulelo oluphezulu kunye nokuqina,i-gear drive ifaneleke ngakumbi kwi-laser-format enkulu ye-laser cutter, ngesiqhelo ngoyilo lwe-hybrid optical.

c. Itheyibhile yokuSebenza eZimileyo VS iTheyibhile yokuSebenza yoMhambisi

Ukulungiswa kwe-laser processing, udinga ngaphezu kokunikezelwa kwe-laser ephezulu kunye nenkqubo ebalaseleyo yokuqhuba ukuhambisa intloko ye-laser, itafile efanelekileyo yokuxhasa izinto nayo iyafuneka. Itheyibhile esebenzayo eyenzelwe ukuhambelana nezinto okanye isicelo sithetha ukuba unokwandisa amandla omatshini wakho welaser.

Ngokubanzi, kukho iindidi ezimbini zamaqonga okusebenza: eZimileyo kunye neseSelula.

(Kwizicelo ezahlukeneyo, unokuphela usebenzisa zonke iintlobo zemathiriyeli, nokubaimpahla yeshiti okanye imathiriyeli ebhijelweyo)

○Itheyibhile yokuSebenza eZimileyoilungele ukubeka izinto zamaphepha njenge-acrylic, iinkuni, iphepha (ikhadibhodi).

• itafile strip yemela

• itafile yekama yobusi

○Itheyibhile yokuSebenza yeConveyorilungele ukubeka izinto zokuqengqeleka njengelaphu, ufele, ugwebu.

• itafile yemoto

• itheyibhile yokuthutha

Inzuzo yoyilo olufanelekileyo lwetafile yokusebenza

✔Ukutsalwa okugqwesileyo kokukhutshwa kokusika

✔Ukuzinzisa izinto eziphathekayo, akukho kususwa okwenzekayo xa usika

✔Ilungele ukulayisha kunye nokukhulula izixhobo zokusebenza

✔Esona sikhokhelo sigxininise enkosi kwimigangatho ethe tyaba

✔Ukunyamekela okulula kunye nokucoca

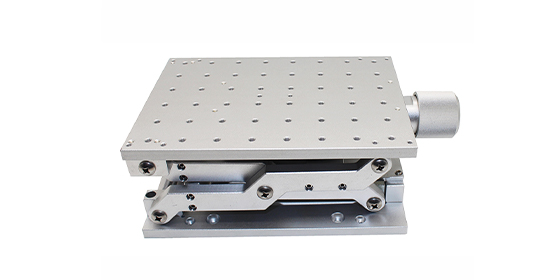

d. UkuPhakamisa okuSebenzayo kweVS Manual Lifting Platform

Xa ukrola izinto eziqinileyo, njengei-acrylic (PMMA)kwayeumthi (MDF), izixhobo ziyahluka ngobukhulu. Ubude obufanelekileyo bojoliso bunokwandisa umphumo wokukrola. Iqonga elihlengahlengiswayo lokusebenza liyimfuneko ukufumana eyona ndawo incinci yokugxila. Kumatshini wokukrola we-CO2 we-laser, ukuphakamisa ngokuzenzekelayo kunye namaqonga okuphakamisa okwenziwa ngesandla adla ngokuthelekiswa. Ukuba ibhajethi yakho yanele, yiya kwiiplatifti zokuphakamisa ngokuzenzekelayo.Ayipheleli nje ekuphuculeni ukusika kunye nokukrola ukuchaneka, kunokukugcina iitoni zexesha kunye nomgudu.

e. Phezulu, emacaleni kunye neNqanaba leNkqubo yokuPhumeza umoya

Inkqubo yokungenisa umoya esezantsi lolona khetho luqhelekileyo lomatshini we-CO2 we-laser, kodwa iMimoWork ikwanazo nezinye iintlobo zoyilo lokuqhubela phambili amava okusebenza kwelaser. Yeumatshini wokusika i-laser ngobukhulu obukhulu, iMimoWork iya kusebenzisa edibeneyoinkqubo yokudinwa ephezulu nasezantsiukunyusa isiphumo sokutsalwa ngelixa ugcina iziphumo ezikumgangatho ophezulu wokusika i-laser. Kuba uninzi lwethuumatshini wokumakisha wegalvo, siya kufaka iinkqubo yokungenisa umoya ecaleniukuphelisa umsi. Zonke iinkcukacha zomatshini kufuneka zijoliswe ngcono ekusombululeni iingxaki zeshishini ngalinye.

An inkqubo yotsaloiveliswa phantsi kwezinto ezenziwa ngoomatshini. Ayikokukhupha nje umsi owenziwe lunyango lwe-thermal kodwa ikwazinzisa imathiriyeli, ngakumbi ilaphu elinobunzima obulula. Inkulu inxenye yendawo yokulungisa egqunywe yimathiriyeli ecutshungulwayo, kokukhona isiphumo sokufunxa kunye nesiphumo sokufunxa ivacuum.

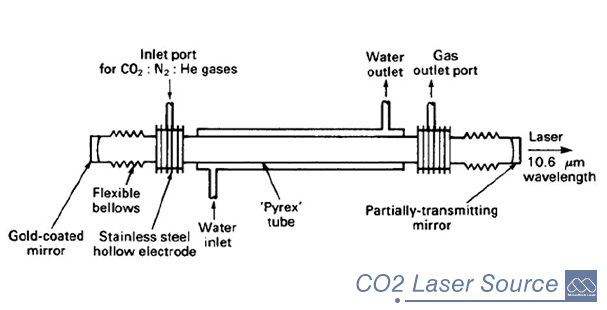

CO2 glass laser iityhubhu VS CO2 RF laser iityhubhu

a. Umgaqo wokuvuselela we-CO2 laser

Ilaser yekhabhon diokside yayiyenye yelaser yokuqala yerhasi eyaphuhliswa. Ngamashumi eminyaka yophuhliso, le teknoloji ikhulile kakhulu kwaye yanele kwizicelo ezininzi. Ityhubhu ye-CO2 ye-laser ivuyisa i-laser ngomgaqo weukukhutshwa okukhanyayokwayeiguqula amandla ombane abe ngamandla okukhanya agxininisiweyo. Ngokusebenzisa i-voltage ephezulu kwi-carbon dioxide (i-laser medium esebenzayo) kunye nenye igesi ngaphakathi kwi-tube ye-laser, igesi ivelisa ukukhutshwa okukhanyayo kwaye iqhubeka ivuya kwi-container phakathi kwezibuko ezibonisa izibuko apho izibuko zibekwe kumacala amabini omkhumbi ukuvelisa i-laser.

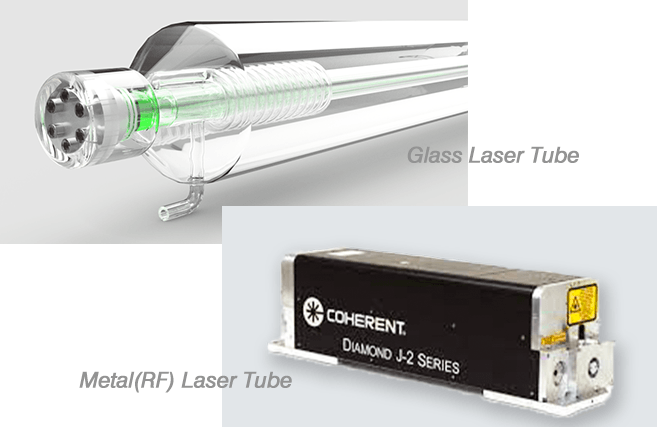

b. Umahluko we-CO2 yeglasi ye-laser tube & CO2 RF laser tube

Ukuba ufuna ukuqonda ngokubanzi umatshini we-laser CO2, kufuneka umbe kwiinkcukacha zeumthombo laser. Njengolona hlobo lufanelekileyo lwelaser ukucubungula imathiriyeli engeyiyo eyentsimbi, umthombo welaser CO2 unokwahlulwa ube ziitekhnoloji ezimbini eziphambili:Umbhobho weglasi weLaserkwayeRF Metal Laser Tube.

(Ngendlela, amandla aphezulu akhawulezayo-axial-flow CO2 laser kunye ne-slow-axial flow CO2 laser ayikho kumda wengxoxo yethu namhlanje)

| Imibhobho yeLaser yeglasi (DC). | Imibhobho yeLaser yesinyithi (RF) | |

| Umsebenzi wobomi | 2500-3500 iiyure | 20,000 iiyure |

| Uphawu | IsiTshayina | Iyahambelana |

| Indlela yokupholisa | Ukupholisa Amanzi | Ukupholisa Amanzi |

| Iyatshajwa kwakhona | Hayi, sebenzisa ixesha elinye kuphela | Ewe |

| Iwaranti | Iinyanga ezi-6 | Iinyanga ezili-12 |

Inkqubo yokulawula kunye neSoftware

Isoftware ye-CO2 ye-laser cutting machine isebenza njengengqondo yenkqubo, isebenzisa inkqubo ye-CNC ukukhokela ukunyakaza kwe-laser kunye nokulungelelanisa amanqanaba amandla. Inika amandla imveliso eguquguqukayo ngokukuvumela ukuba utshintshe uyilo ngokukhawuleza kwaye uphathe izinto ezahlukeneyo-nje ngokuguqula amandla e-laser kunye nesantya sokusika, akukho tshintsho lwesixhobo olufunekayo.

Abaninzi kwimarike baya kuthelekisa iteknoloji yesoftware yaseTshayina kunye neteknoloji yesoftware yeenkampani zaseYurophu kunye neMelika. Ngokusikwa ngokulula kwaye ukrole ipateni, ii-algorithms zesoftwares ezininzi kwimarike azahlukanga kakhulu. Ngeminyaka emininzi yengxelo yedatha evela kuninzi lwabavelisi, isoftware yethu ineempawu ezingezantsi:

1. Kulula ukuyisebenzisa

2. Ukusebenza okuzinzileyo nokukhuselekileyo kwixesha elide

3. Vavanya ixesha lokuvelisa ngokufanelekileyo

4. Inkxaso yeDXF, AI, PLT kunye nezinye iifayile ezininzi

5. Ngenisa iifayile ezininzi zokusika ngexesha elinye kunye namathuba okuguqulwa

6. Ukulungelelanisa ngokuzenzekelayo iipatheni zokusika kunye nemigqaliselo yeekholomu kunye nemigqa eneMimo-Nest

Ngaphandle kwesiseko sesoftware yokusika yesiqhelo, iUmbono Recognition Systeminokuphucula iqondo lokuzenzekelayo kwimveliso, ukunciphisa abasebenzi kunye nokuphucula ukuchaneka kokusika. Ngamagama alula, iKhamera yeCCD okanye iKhamera ye-HD efakwe kumatshini we-CO2 we-laser yenza njengamehlo omntu kwaye iyala umatshini we-laser apho unqunywe khona. Le teknoloji iqhele ukusetyenziswa kwizicelo zoshicilelo lwedijithali kunye namasimi e-embroidery, afana ne-dayi-sublimation sportwear, iiflegi zangaphandle, iipetshi ze-embroidery kunye nezinye ezininzi. Kukho iintlobo ezintathu zendlela yokuqaphela umbono iMimoWork enokubonelela ngayo:

▮ Uqwalaselo lweContour

Ushicilelo lwedijithali kunye ne-sublimation luyanda, ngakumbi kwiimveliso ezifana neempahla zemidlalo, iibhana, kunye neenyembezi. Ezi laphu ziprintiweyo azinakusikwa ngokuchanekileyo ngesikere okanye iiblades zemveli. Kulapho iinkqubo ze-laser esekwe kumbono zikhanya khona. Ukusebenzisa ikhamera enesisombululo esiphezulu, umatshini ubamba ipateni kwaye unqumle ngokuzenzekelayo kunye nolwandlalo lwalo-akukho fayile yokusika okanye i-trimming manual efunekayo. Oku akuphuculi nje ukuchaneka kodwa kwakhona kukhawulezisa imveliso.

Isikhokelo sokuSebenza:

1. Yondla iimveliso ezinepateni >

2. Thatha ifoto yepateni >

3. Qala ukusika i-contour laser >

4. Qokelela okugqityiweyo >

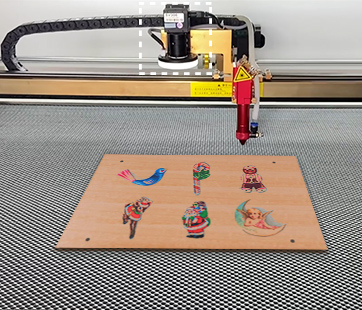

▮ Inqaku loBhaliso

Ikhamera yeCCDinokubona kwaye ifumane ipateni eprintiweyo kwibhodi yeenkuni ukunceda i-laser ngokusika ngokuchanekileyo. Iimpawu zokhuni, iiplakhi, umzobo kunye nefoto yokhuni eyenziwe ngomthi oprintiweyo inokucutshungulwa ngokulula.

Inyathelo loku-1.

>> Shicilela ipateni yakho ngokuthe ngqo kwibhodi yeenkuni

Inyathelo lesi-2.

>> Ikhamera yeCCD inceda i-laser ukusika uyilo lwakho

Inyathelo lesi-3.

>> Qokelela iziqwenga zakho ezigqityiweyo

▮ Ukuthelekisa itemplate

Kwezinye iipatches, iileyibhile, iifoyile eziprintiweyo ezinobukhulu obufanayo kunye nepateni, iSistim yeSibonelelo soMbono weSifanekiso esivela kwiMimoWork iya kuba luncedo olukhulu. Inkqubo ye-laser inokunqumla ngokuchanekileyo iphethini encinci ngokuqaphela kunye nokubeka i-template ebekiweyo eyifayile yokusika ukuyila ukufanisa inxalenye yecandelo leepatshi ezahlukeneyo. Nayiphi na ipateni, ilogo, umbhalo okanye enye inxalenye ebonakalayo ebonakalayo inokuba yinxalenye yefitsha.

Iinketho zeLaser

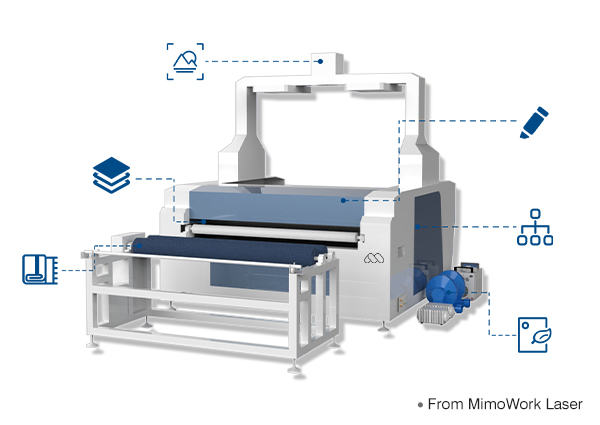

I-MimoWork ibonelela ngeendlela ezininzi ezongezelelekileyo kuzo zonke ii-laser cutters ezisisiseko ngokungqongqo ngokwesicelo ngasinye. Kwinkqubo yokuvelisa imihla ngemihla, ezi ziyilo ezenziwe ngokwezifiso kumatshini we-laser zijolise ekunyuseni umgangatho wemveliso kunye nokuguquguquka ngokweemfuno zemarike. Ikhonkco elibaluleke kakhulu kunxibelelwano lokuqala kunye nathi kukwazi imeko yakho yokuvelisa, zeziphi izixhobo ezisetyenziswa ngoku kwimveliso, kwaye zeziphi iingxaki ezidibana nazo kwimveliso. Ke makhe sazise isibini samalungu aqhelekileyo okhetho athandwayo.

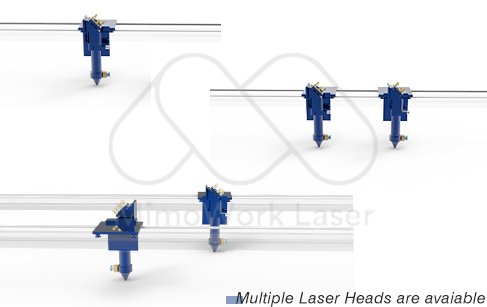

a. Iintloko ezininzi ze-laser ukuze ukhethe

Ukongeza iintloko ezininzi ze-laser kunye neetyhubhu kumatshini omnye yindlela elula kunye neendleko ezisebenzayo zokunyusa imveliso. Igcina zombini utyalo-mali kunye nendawo emgangathweni xa kuthelekiswa nokuthenga oomatshini abahlukeneyo. Kodwa ayisoloko ifanelekile. Kuya kufuneka uqwalasele ubungakanani betafile yakho yokusebenza kunye neepateni zokusika. Yiyo loo nto sihlala sicela abathengi ukuba babelane ngoyilo lwesampulu ngaphambi kokubeka iodolo.

Imibuzo engakumbi malunga nomatshini welaser okanye ukugcinwa kwelaser

Ixesha lokuposa: Oct-12-2021