Yintoni iGalvo Laser Machine?

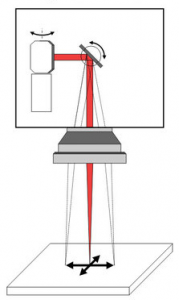

I-laser ye-Galvo, edla ngokubizwa ngokuba yi-laser ye-Galvanometer, luhlobo lwenkqubo ye-laser esebenzisa izikena ze-galvanometer ukulawula ukuhamba kunye nolwalathiso lwe-laser beam.

Le teknoloji yenza ukuba i-laser beam ibekwe ngokuthe ngqo kwaye ikhawuleze, iyenze ifaneleke kwizicelo ezahlukeneyo, kubandakanya ukumakisha kwelaser, ukukrola, ukusika, nokunye.

Igama elithi "Galvo" lithatyathwe kwi "galvanometer," isixhobo esisetyenziselwa ukulinganisa kunye nokubona imisinga yombane emincinci. Kumxholo weenkqubo ze-laser, iiskena ze-Galvo zisetyenziselwa ukubonakalisa kunye nokuxhaphaza i-laser beam.

Ezi scanner ziquka izibuko ezibini ezifakwe kwi-galvanometer motors, ezinokulungisa ngokukhawuleza i-angle yezibuko ukulawula indawo ye-laser beam.

Iimpawu eziphambili zeGalvo Laser Systems zibandakanya:

1. Umthombo weLaser

2. Laser Beam Emission

3. I-Galvanometer Scanners

4. Ukuphambuka kweBeam

5. Ii-Optics zokuJonga

6. Ukusebenzisana kwezinto

7. Ukuskena ngokukhawuleza

8. Ulawulo lweKhompyutha

9. Ukupholisa noKhuseleko

10. Ulawulo lokukhupha neNkunkuma

Indlela: Galvo Laser Engraving Paper

Ngaba unemibuzo malunga neGalvo Laser? Kutheni Ungadibani Nathi?

1. Isicelo sakho:

Cacisa ngokucacileyo injongo yelaser yakho. Ngaba uyasika, uyamakisha, okanye uyakrola? Iya kuyalela amandla e-laser kunye nobude obufunekayo.

3. Amandla eLaser:

Khetha amandla e-laser afanelekileyo ngokusekwe kwisicelo sakho. Iilaser zamandla aphezulu zifanelekile ukusika, ngelixa iilaser zamandla aphantsi zisetyenziselwa ukumakisha kunye nokukrola.

5. Umthombo weLaser:

Khetha phakathi kweCO2, ifayibha, okanye ezinye iintlobo zemithombo yelaser. Iilaser ze-CO2 zihlala zisetyenziselwa ukukrola kunye nokusika izinto eziphilayo.

7. Isoftware noLawulo:

Isoftware esebenziseka lula kunye nesakhono sokwenza ngokwezifiso ibalulekile kuhlengahlengiso lweeparamitha zelaser kunye nokwenza ngcono ukusebenza.

9. Ukugcinwa kunye neNkxaso:

Qwalasela iimfuno zokugcina kunye nokufumaneka kwenkxaso yabathengi. Ukufikelela kuncedo lobuchwephesha kunye namalungu okutshintshwa xa kufuneka.

11. Uhlahlo lwabiwo-mali noManyano:

Qinisekisa uhlahlo lwabiwo-mali lwakho lwenkqubo ye-laser ye-Galvo. Gcina ukhumbula ukuba iinkqubo ezikumgangatho ophezulu ezineempawu eziphambili zinokuza ngexabiso eliphezulu. Ukuba uceba ukudibanisa inkqubo ye-laser ye-Galvo kumgca wokuvelisa okhoyo, qinisekisa ukuba iyahambelana ne-automation yakho kunye neenkqubo zokulawula.

2. Ukuhambelana kwezinto:

Qinisekisa ukuba inkqubo ye-laser ye-Galvo iyahambelana nezixhobo oza kusebenza ngazo. Izixhobo ezahlukeneyo zinokufuna ubude obuthile belaser okanye amanqanaba amandla.

4. Isantya seSkena seGalvo:

Qwalasela isantya sokuskena se-Galvo scanner. Izikena ezikhawulezayo zifanelekile kusetyenziso oluphezulu, ngelixa izikena ezicothayo zinokuchaneka ngakumbi kumsebenzi oneenkcukacha.

6. Ubungakanani beNdawo yoMsebenzi:

Qinisekisa ubungakanani bendawo yokusebenza efunekayo kwisicelo sakho. Qinisekisa ukuba inkqubo ye-laser ye-Galvo inokusingatha imilinganiselo yemathiriyeli yakho.

8. Inkqubo yokupholisa:

Qinisekisa ukusebenza kakuhle kwenkqubo yokupholisa. Inkqubo yokupholisa ethembekileyo ibalulekile ukugcina ukusebenza kwelaser nokwandisa ubomi besixhobo.

10. Iimpawu zoKhuseleko:

Beka phambili izinto zokhuseleko ezinje ngee-interlocks, amakhaka omthi, kunye namaqhosha okumisa okungxamisekileyo ukukhusela abasebenzi kunye nokuthintela iingozi.

12. Ulwandiso lwexesha elizayo kunye noPhononongo:

Cinga ngeemfuno ezinokubakho kwixesha elizayo. Inkqubo yelaser yeGalvo eyoyikisayo ikuvumela ukuba wandise amandla akho njengoko ishishini lakho likhula. Phanda kwaye ufune iingcebiso kubalingane boshishino okanye iingcali zokufumana ukuqonda kwiinkqubo ze-laser zeGalvo ezifanelekileyo.

13. Ukwenza ngokwezifiso:

Qwalasela ukuba ngaba ufuna isixokelelwano esisezantsi-kwishelufu okanye isisombululo esilungiselelwe ngokwesicelo sakho esithile.

Ngokuphonononga ngononophelo ezi zinto, unokukhetha inkqubo eyiyo yeGalvo laser ehambelana neenjongo zakho zoshishino, iphucula iinkqubo zakho zokuvelisa, kwaye iqinisekise ukusebenza okugqwesileyo kunye nomgangatho kwizicelo zakho.

Umboniso weVidiyo: Ungawukhetha njani uMatshini wokuMakisha iLaser?

MimoWork Laser Series

▶ Kutheni Ungaqali Ngezi Zikhetho Zilungileyo?

Ubungakanani beTheyibhile yokuSebenza:400mm * 400mm (15.7” * 15.7”)

Ukhetho lwamandla eLaser:180W/250W/500W

Isishwankathelo seGalvo Laser Engraver kunye neMarker 40

Umbono ophezulu wokusebenza wale nkqubo ye-laser ye-Galvo inokufikelela kwi-400mm * 400 mm. Intloko ye-GALVO inokulungelelaniswa ngokuthe nkqo ukuze ufezekise ubungakanani obuhlukeneyo be-laser beam ngokobungakanani bezinto zakho. Nakweyona ndawo iphezulu yokusebenza, usenokufumana eyona beam yelaser igqwesileyo ukuya kwi-0.15 mm kowona mfanekiso ubalaseleyo welaser kunye nokumakisha ukusebenza. Njengokhetho lwe-laser ye-MimoWork, i-Red-Light Indication System kunye ne-CCD ye-Positioning System isebenza kunye ukulungisa umbindi wendlela yokusebenza kwindawo yokwenyani yesiqhekeza ngexesha lokusebenza kwe-galvo laser. Ngaphezu koko, uguqulelo loyilo oluVikelwe ngokupheleleyo lunokucelwa ukuba luhlangabezane nomgangatho woku-1 wokhuseleko wokhuseleko we-galvo laser engraver.

Ubungakanani beTheyibhile yokuSebenza:1600mm * Infinity (62.9" * Infinity)

Ukhetho lwamandla eLaser:350W

Isishwankathelo seGalvo Laser Engraver

Umkroli wefomathi enkulu yelaser yiR&D yobukhulu obukhulu bezixhobo zokukrola ngelaser kunye nokumakishwa kwelaser. Ngenkqubo yokuhambisa, umkroli we-galvo laser unokukrola kwaye uphawule kumalaphu aqengqelekayo (amalaphu). Oko kulungele ezi zinto zokwenziwa kwefomati ye-ultra-long Eqhubekayo kwaye eguquguqukayo yokukrola i-laser iphumelela zombini ukusebenza okuphezulu kunye nomgangatho ophezulu kwimveliso ephathekayo.

Ubungakanani beTheyibhile yokuSebenza:70*70mm, 110*110mm, 175*175mm, 200*200mm (Inokwenzeka ngokwezifiso)

Ukhetho lwamandla eLaser:20W/30W/50W

Isishwankathelo seFiber Galvo Laser yokuMakisha uMshini

Umatshini wokumakisha we-fiber laser usebenzisa imiqadi yelaser ukwenza amanqaku asisigxina kumphezulu wezinto ezahlukeneyo. Ngokuphuphuma komphunga okanye ukutshisa umphezulu wezinto kunye namandla okukhanya, umaleko onzulu ubonisa ngoko unokufumana umphumo wokukrola kwiimveliso zakho. Nokuba ipateni entsonkothe kangakanani na, iteksti, ikhowudi yebha, okanye enye imizobo, iMimoWork Fiber Fiber Laser Marking Machine unokuzifakela kwiimveliso zakho ukuze uhlangabezane neemfuno zakho zokwenza ngokwezifiso.

Thumela iimfuno zakho kuthi, siya kubonelela ngesisombululo seLaser yobuchwephesha

Qala uMcebisi weLaser ngoku!

> Loluphi ulwazi ekufuneka ulunikeze?

> Iinkcukacha zethu zoqhagamshelwano

Imibuzo eqhelekileyo Malunga Galvo Laser

Xa zisebenza ngokuchanekileyo kunye namanyathelo okhuseleko afanelekileyo, iinkqubo ze-laser ze-Galvo zikhuselekile. Kufuneka zibandakanye iimpawu zokhuseleko ezifana nezikhuselo zentsimbi kunye nezikhuselo zentsimbi. Ngalo lonke ixesha ulandela izikhokelo zokhuseleko kwaye unike uqeqesho lwabaqhubi ukuqinisekisa ukusetyenziswa okukhuselekileyo.

Ewe, iinkqubo ezininzi ze-laser zeGalvo ziyilelwe ukudityaniswa kwindawo yemveliso ezenzekelayo. Qinisekisa ukuhambelana neenkqubo zakho zolawulo ezikhoyo kunye nezixhobo ezizenzekelayo.

Iimfuno zokugcina ziyahluka ngokomvelisi kunye nemodeli. Ukugcinwa rhoqo kunokubandakanya ukucoca ii-optics, ukutshekisha izipili, nokuqinisekisa ukuba isixokelelwano sokupholisa sisebenza ngokuchanekileyo. Kubalulekile ukulandela iingcebiso zolondolozo lomenzi.

Ewe, iinkqubo ze-laser ze-Galvo ziyakwazi ukwenza iziphumo ze-3D ngokutshintsha amandla e-laser kunye nobuninzi. Oku kungasetyenziselwa ukubhala kunye nokongeza ubunzulu kwimigangatho.

Ubomi benkqubo ye-laser ye-Galvo buxhomekeke ekusebenziseni, ukugcinwa, kunye nomgangatho. Iinkqubo ezikumgangatho ophezulu zingahlala amashumi amawaka eeyure zokusebenza, ngaphandle kokuba zigcinwe kakuhle.

Ngelixa iinkqubo zeGalvo zigqwesa ekuphawuleni nasekukroleni, zisenokusetyenziswa ukusika izinto ezibhityileyo njengephepha, iiplastiki, kunye nelaphu. Ikhono lokusika lixhomekeke kumthombo we-laser kunye namandla.

Iinkqubo ze-laser ze-Galvo zithathwa ngokuba zinobuhlobo ngakumbi kwendalo kuneendlela zokumakisha zemveli. Zivelisa inkunkuma encinci kwaye azifuni izinto ezisetyenziswayo njengeinki okanye idayi.

Ezinye iisistim ze-laser zeGalvo zinokuhlengahlengiswa kwizicelo zokucoca ngelaser, zizenze izixhobo eziguquguqukayo zemisebenzi eyahlukeneyo.

Ewe, iisistim ze-laser zeGalvo zinokusebenza zombini iVector kunye nemizobo yeraster, ibenza bakwazi ukwenza uluhlu olubanzi lwemisebenzi ngoyilo oluntsonkothileyo kunye neepateni.

SukuLungiselela Nantoni na eNgaphantsi kuneNjalo

Tyala kweyona ilungileyo

Ixesha lokuposa: Nov-09-2023