Uyenza njani i-Laser Weld Aluminium Alloys

I-Aluminiyam ye-Welding ingaba yinkohliso

I-alloys ye-aluminiyam yahlulahlulwe ngokwezintlu ezisekelwe kwizinto eziphambili zokudibanisa.

Uthotho ngalunye luneepropati ezizodwa ezichaphazela ukuwelda kwayo, ngakumbi xa usebenzisa i-laser welding ephathwayo.

Ngezantsi umboniso wechungechunge oluqhelekileyo lwe-aluminium alloy, iimpawu zabo, iigesi ezifanelekileyo zokukhusela, iingcingo ezifanelekileyo zokuzalisa, kunye neengcebiso zokuphumeza i-welds ephezulu.

Isiqulatho:

1. Iingxube zeAluminiyam eziqhelekileyo zeLaser Welding

Inyathelo lokuqala lokufumana iWeld elungileyo: Ukuqonda

1000 Series Aluminiyam Alloys

Ukuqulunqwa:Iqulethe 99.00% aluminiyam okanye ngaphezulu.

Iinkcazelo ngeempawu:Ikhaphukhaphu kunye ne-ductile ephezulu, eyenza kube lula ukusebenza nayo.

Irhasi yokuKhusela:I-100% yeArgon iyacetyiswa ukukhusela i-oxidation.

iFiller Wire:Sebenzisa i-4047 okanye i-4045 yocingo lokuzalisa ukuhambelana okungcono.

Iingcebiso zokuwelda:Qinisekisa ukuba umphezulu womhlaba ucocekile kwaye awunazo iioksidi. Ukufudumala ngokuqhelekileyo akuyimfuneko ngenxa ye-ductility ephezulu.

2000 Series Aluminiyam Alloys

Ukuqulunqwa:I-alloyed ngokuyinhloko ngobhedu (2-10%).

Iinkcazelo ngeempawu:Amandla aphezulu kodwa i-ductility ephantsi; ithanda ukuqhekeka ngexesha le-welding.

Irhasi yokuKhusela:IArgon enepesenti encinci yeHelium inokunceda ukuphucula ukungena.

iFiller Wire:Sebenzisa i-4047 okanye i-2319 yocingo yokuzalisa, eyenzelwe i-alloys enobhedu.

Iingcebiso zokuwelda:Ukufudumala izinto eziphathekayo ukunciphisa umngcipheko wokuqhekeka. Lawula igalelo lobushushu ngononophelo ukuthintela uxinzelelo olugqithisileyo lobushushu.

3000 Series Aluminiyam Alloys

Ukuqulunqwa:Ifakwe kwi-manganese.

Iinkcazelo ngeempawu:Ukumelana nokugqwesa okulungileyo kunye namandla; igcina amandla kumaqondo obushushu aphakamileyo.

Irhasi yokuKhusela:I-100% iArgon iyasebenza.

iFiller Wire:I-4045 okanye i-4047 ucingo lokuzalisa lufanelekile.

Iingcebiso zokuwelda:Coca umphezulu ngokucokisekileyo ukuze ususe naziphi na izinto ezingcolisayo. Gcina isantya sohambo esizinzileyo ukuze uqinisekise ukusasazeka kobushushu.

4000 Series Aluminiyam Alloys

Ukuqulunqwa:Iqulethe i-silicon, ehlisa indawo yokunyibilika.

Iinkcazelo ngeempawu:Ukunyuka kwe-ductility kunye nokugqwesileyo kwi-die-casting; enganyangekiyo ubushushu.

Irhasi yokuKhusela:Argon ikhethwayo.

iFiller Wire:Sebenzisa 4047 ucingo lokuzalisa ngeziphumo ezizezona.

Iingcebiso zokuwelda:Ukushisa kwangaphambili kunokunceda ngokungena. Lawula igalelo lobushushu ngokusondeleyo ukunqanda ukulwa.

5000 Series Aluminiyam Alloys

Ukuqulunqwa:Ifakwe kwi-magnesium.

Iinkcazelo ngeempawu:Amandla aphezulu kunye nokumelana nokugqwesa okugqwesileyo; alungele amaphepha kunye neepleyiti.

Irhasi yokuKhusela:100% Argon iyacetyiswa.

iFiller Wire:Sebenzisa i-5356 yocingo lokuzalisa ukuhambelana ngcono.

Iingcebiso zokuwelda:Ukufudumala kwangaphambili kunenzuzo kumacandelo atyebileyo. Sebenzisa ubuchule bokutyhala ukuphucula isenzo sokucoca kunye nokunciphisa ungcoliseko.

6000 Series Aluminiyam Alloys

Ukuqulunqwa:Iqulethe zombini i-magnesium kunye ne-silicon.

Iinkcazelo ngeempawu:I-ductility elungileyo kunye nokunyangwa kobushushu; ilungele i-extrusions.

Irhasi yokuKhusela:Argon okanye umxube Argon kunye Helium.

iFiller Wire:I-4045 okanye i-5356 yocingo yokuzalisa ifanelekile.

Iingcebiso zokuwelda:Qinisekisa ukucocwa okufanelekileyo komphezulu. Sebenzisa isantya esiphezulu sokuhamba ukunqanda ukutshisa.

7000 Series Aluminiyam Alloys

Ukuqulunqwa:Ngokuqhelekileyo idibene ne-zinc.

Iinkcazelo ngeempawu:Amandla aphezulu kodwa ayifanelekanga ngokubanzi i-fusion welding ngenxa yemicimbi yokuqhekeka.

Irhasi yokuKhusela:IArgon eneHelium inokuba luncedo.

iFiller Wire:Sebenzisa i-7072 okanye i-7005 yocingo lokuzalisa.

Iingcebiso zokuwelda:Ukushisa kwangaphambili kubalulekile ukunciphisa umngcipheko wokuqhekeka. Sebenzisa igalelo lobushushu elilawulwayo kwaye uthintele isantya sohambo esigqithisileyo.

NgokuPhucula iTekhnoloji yale mihla

Ixabiso leLaser Welding Machine alizange libe lifikelelekayo!

2. Iingcebiso eziqhelekileyo ze-Laser Welding Aluminium

Ukufezekisa iziphumo eziLungileyo zeWelding, Nanga amanye amanqaku aphambili:

Ukulungiswa komphezulu

Hlala ucoce umphezulu we-aluminiyam ukususa ii-oksidi kunye nezingcoliso.

Ukulawula Ubushushu

Lawula igalelo lobushushu ngononophelo ukunqanda ukulwa kunye nokugqwetheka, ngakumbi kwizinto ezibhityileyo.

Isantya sokuhamba

Lungisa isantya sokuhamba ngokobunzima bezinto eziphathekayo ukulinganisa ukungena kunye negalelo lobushushu.

Uhlengahlengiso lweNdawo ekugxilwe kuyo

Gxininisa i-laser kancinane ngaphantsi komphezulu wokungena okungcono kunye nokunciphisa ukubonakaliswa.

Ukukhetha phakathi kweentlobo ezahlukeneyo zeLaser Welding Machine?

Singakwazi ukuNceda ukwenza iSigqibo esiLungileyo ngokuSekwe kwizicelo

3. Ukufikelela njani kwiWeld elungileyo ngeAluminiyam Alloys

Ukuqonda iMaterial yakho yiHalf Way apho

Ukuqonda uthotho oluqhelekileyo lwe-aluminium alloy kubalulekile ekufezekiseni i-weld elungileyo kunye ne-laser welder ephathwayo ngenxa yezizathu ezininzi:

Iimpahla zeMathiriyeli

Uluhlu ngalunye lwe-aluminium alloy lunezinto ezizodwa, kubandakanya amandla, i-ductility, kunye nendawo yokunyibilika.

Ukwazi ezi zakhiwo kunceda ekukhetheni iiparamitha ezifanelekileyo ze-welding, ezifana nezicwangciso zamandla kunye nesantya sokuhamba, ukuqinisekisa i-weld enamandla, esebenzayo.

Imingeni yeWelding

Iintlobo ezahlukeneyo ze-alloy zinika imingeni ethile ngexesha lokutshisa.

Umzekelo, ama-alloys angama-2000 athanda ukuqhekeka, ngelixa ama-alloys angama-4000 angahamba ngokulula kakhulu.

Ukuqonda le mingeni kunceda abashiseli ukuba basebenzise ubuchule bokunciphisa imiba, njengokushisa kwangaphambili okanye ukulungelelanisa izinto zokuzalisa.

Ukuhambelana kwezinto zokugcwalisa

Ii-alloys ezahlukeneyo ze-aluminiyam zifuna izixhobo zokuzalisa ezihambelanayo zokuqinisekisa ibhondi eyomeleleyo.

Ngokomzekelo, ukusebenzisa ucingo olufanelekileyo lokuzalisa kunokuthintela imiba efana ne-porosity okanye ukudibanisa okungonelanga.

Ulwazi loluhlu lwe-alloy lunceda ekukhetheni ucingo oluchanekileyo lokuzalisa ukunyusa umgangatho we-weld.

UKhetho lweGesi yokuKhusela

Ukukhethwa kwegesi yokukhusela kunokuchaphazela kakhulu umgangatho we-weld.

Uluhlu lwe-alloy ngalunye lunokufuna iigesi ezithile zokukhusela ukukhusela i-oxidation kunye nokuphucula ukungena.

Ukuqonda ukubunjwa kwe-alloy kunceda abashicileli bakhethe igesi ekhuselayo yokukhusela iziphumo ezilungileyo.

Ulawulo lobushushu

Ii-alloys ezahlukeneyo zisabela ngokuhlukileyo kubushushu.

Abanye banokufuna ukufudumeza okanye unyango lwe-post-weld ukukhulula uxinzelelo.

Ukuqonda uchungechunge lwe-alloy luvumela i-welders ukulawula igalelo lokushisa ngokufanelekileyo, ukunciphisa umngcipheko wokulwa okanye ukuqhekeka.

Ukufaneleka kwesicelo

Ezinye iialloyi ze-aluminiyam zifaneleka ngakumbi kwizicelo ezithile, ezifana ne-aerospace okanye i-automotive.

Ukwazi iimpawu zochungechunge ngalunye kunceda ekukhetheni i-alloy efanelekileyo yomsebenzi, ukuqinisekisa ukuba imveliso yokugqibela ihlangabezana nemigangatho yokusebenza kunye nokhuseleko.

UkuSebenza kweendleko

Ukusebenzisa i-alloy efanelekileyo kunye ne-welding parameters kunokukhokelela kwiinkqubo ze-welding ezisebenzayo, ukunciphisa inkunkuma yezinto eziphathekayo kunye nokusebenza kwakhona.

Ukuqonda iipropati ze-alloy kuncedisa ekucwangcisweni okungcono kunye nokusetyenziswa, ekugqibeleni konga ixesha kunye neendleko.

Ukuqinisekisa umgangatho

Ukuqonda uluhlu oluhlukeneyo lwe-aluminium lunceda ekusekeni imilinganiselo yokulawula umgangatho.

I-Welders inokwamkela ubuchule obuthile kunye nemigangatho esekelwe kuhlobo lwe-alloy, ekhokelela kwi-welds ehambelanayo kunye nekhwalithi ephezulu.

I-Aluminiyam yokuwelda inzima kunye ne-Welding yesiNtu

Laser Welding Lula le Nkqubo

Ngaba uyafuna ukwazi ngakumbi malunga ne-Laser Welding Aluminium?

I-Aluminiyam ye-Welding yi-Tricker kune-Welding ezinye izinto.

Ke ngoko sabhala iNqaku malunga nendlela yokuPhumelela iiWelds ezilungileyo ngeAluminiyam.

Ukusuka kwiSetingi ukuya kuNjani.

Ngeevidiyo kunye nolunye ulwazi.

Unomdla kwi-Laser Welding ezinye izinto?

Ngaba uyafuna ukuqalisa kwi-Laser Welding Fast?

Ngaba uyafuna ukuhlaziya ulwazi lwakho lweLaser Welding?

Esi Sikhokelo esiGqibeleleyo seReference silungiselelwe wena!

Umthamo oPhezulu kunye nokuWattage kwizicelo ezahlukeneyo zeWelding

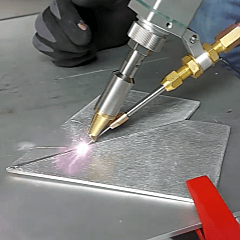

Umatshini wokuwelda we-laser we-2000W ubonakaliswe ngobungakanani bomatshini omncinci kodwa umgangatho we-welding omenyezelayo.

Umthombo we-fiber laser ozinzileyo kunye nentambo yefayibha edibeneyo inika ukuhanjiswa kwe-laser beam ekhuselekileyo kwaye ezinzileyo.

Ngamandla aphezulu, i-laser welding keyhole igqibelele kwaye yenza ukuba i-welding joint firmer iqine nakwintsimbi eshinyeneyo.

Ukuphatheka ngokuguquguquka

Ngokubonakala komatshini odibeneyo kunye nomncinci, umatshini we-laser welder ophathwayo uxhotyiswe ngompu we-laser welder oshukumayo olula kwaye ulungele ukusetyenziswa kwe-laser welding kwi-angle kunye nomphezulu.

Ukuzikhethela iintlobo ezahlukeneyo zemilomo ye-laser welder kunye neenkqubo zokutyisa ucingo oluzenzekelayo zenza umsebenzi we-laser welding lula kwaye inobubele kubaqalayo.

Isantya esiphezulu se-laser welding yonyusa kakhulu ukusebenza kwakho kwemveliso kunye nemveliso ngelixa uvumela isiphumo esihle kakhulu selaser.

Izinto ekufuneka uzazi malunga: Handheld Laser Welding

Ukuba uyonwabele le vidiyo, kutheni ungacingiubhalisela kwisiteshi sethu seYouTube?

Izicelo Eziyeleleneyo Unokuba Nomdla:

Yonke into eThengiweyo kufuneka yaziswe kakuhle

Singakwazi ukuNceda ngolwazi oluneenkcukacha kunye noBonwano!

Ixesha lokuposa: Dec-20-2024