I-Laser Welding vs TIG Welding: Yintoni etshintshileyo ngo-2024

Yintoni i-Handheld Laser Welding?

Handheld Laser Welding Steel Stainless

Ukuwelda kwelaser ngesandlaisebenzisa isixhobo esiphathwayo selaser ukudibanisa imathiriyeli, ngokwesiqhelo iintsimbi.

Ukuwelda kwe-laser ngesandla kuyakuvumelamkhuluukusebenza kunye nokuchaneka,

Kwaye ivelisa umgangatho ophezulu, i-weld ecocekileyo ngeencinciigalelo lobushushu,

Ukunciphisaukugqwetheka kunye nesidingo sokulungiswa okubanzi kwe-post-weld.

Abaqhubi banokuhlengahlengisa ngokulula amandla kunye nesantya selaser,

Iyanika amandlaizicwangciso ezilungiselelweyokwizinto ezahlukeneyo kunye nobukhulu.

Isiqulatho:

Yintoni iLaser Weld Cleaning?

Ukubaluleka kococeko kwiWelding

Ukucocwa kwangaphambili kwe-Weld ye-TIG Welding

Xa kuziwa kwi-welding,

Ucoceko ludlala indima ebalulekileyo ekuphumezeni okoumgangatho ophezuluiziphumo.

Lo mgaqo usebenza kuzo zombini i-TIG welding kunye ne-laser welding ephathwayo,

Kodwa iindlela zokulungiselela izinto zihluke kakhulu.

Kuyo nayiphi na inkqubo yokuwelda,

Ubukho bezinto ezingcolisayo ezifana nomhlwa, ipeyinti, kunye negrisi

Ngabaukulalanisa kakhuluingqibelelo ye weld.

Oku kungcola kunokukhokelela kumalungu abuthathaka, i-porosity, kunye nezinye iziphene

Oko kujongela phantsi amandla emveliso yokugqibela.

Nantsi indlela wenaKUFUNEKAJongana nezi Ngcolisi:Laser Weld Cleaning.

Laser Welding vs TIG Welding: Laser Weld Cleaning

Imihlaba eCociweyo Ivelisa iiWelds ezikwiMgangatho ophezulu

Laser Weld Cleaning for Handheld Laser Cleaning

Ngelixa i-TIG welding ithembeleincwadi yesandlaiindlela zokucoca ezifana nokusila i-engile kunye nokusula i-acetone,

Ukuwelda ngesandla kwelaser kubonelela ngakumbieluncedoenye indlela kunye nezakhono zayo zokucoca ezihlanganisiweyo.

Olu tshintsho aluphuculi nje ukusebenza kakuhle

Kodwa kwakhona iqinisekisa ukuba inkqubo yokuwelda iyasebenza kangangoko kunokwenzeka,

Ekugqibeleni kukhokelela kwiziphumo ezingcono.

ULungiselelo lwe-TIG ye-Welding:

Kwi-TIG (Igesi yeTungsten Inert) ukuwelda, ukulungiselela ngononophelo kubalulekile.

Ngaphambi kokuba uqale inkqubo ye-welding,

Kuqhelekile ukusetyenziswaii-angle grindersukususa umhlwa okanye iingubo ukusuka kumphezulu wezinto eziphathekayo.

Oku kucocwa komatshini kunceda ukuqinisekisa ukuba umphezulu ukhululekile kwizinto ezingcolileyo.

Ukulandela oku, sula ngokucokisekileyo ngeiacetoneiyenziwa ngokwesiqhelo.

I-acetone sisinyibilikisi esinamandla esoisusa ngempumelelonayiphi na igrisi eseleyo okanye izinto ezingcolisayo,

Ukushiya indawo ecocekileyo ye-weld.

Le nkqubo yokucoca ngamanyathelo amabini inokutya ixesha,

Kodwa kubalulekile ukufezekisa i-weld eyomeleleyo kwaye ehlala ixesha elide.

Ukulungiselela ukuwelda kweLaser ngesandla

Ngokwahlukileyo, i-laser welding ephathwayo inikezela

A ngakumbiindlela elungelelanisiweyoukulungisa umphezulu.

Nge3-in-1laser welder, inkqubo iba lula kakhulu.

Aba matshini baphucukileyo badla ngokuxhotyiswaimilomo etshintshanayo

Oko kuvumela ukucocwa komphezulu kanye phambi kwe-welding.

Ngokungafaniyo neendlela zemveli, apho kufuneka izixhobo ezahlukeneyo kunye neearhente zokucoca,

Iintsimbi zeLaser zinokucoca ngaphandle komphezulu ngomqadi welaser ogxilileyo.

Oku akugcini nje ixesha kodwa kunciphisaubungakanani bezixhoboefunekayo kwindawo.

I-Laser Welding vs TIG Welding itshintshile ngo-2024

Qhagamshelana nathi ngakumbi malunga ne-Handheld Laser Welding System

Kutheni Usebenzisa iGesi yokuKhusela kwi-Welding?

UKhetho lokuKhusela iGasi ludlala indima ebalulekileyo

IGesi yokuKhusela kwi-TIG Welding: Argon

Xa kuziwa kwi-welding,

Ukukhethwa kwegesi yokukhusela kubalulekile ekuqinisekiseni iziphumo eziphezulu.

Ngokukodwa, ukuwelda kwe-TIG kunye ne-laser welding ephathwayo ineemfuno ezahlukeneyo kunye nokhetho

Xa kuziwa ekukhuseleni iigesi, okuchaphazela zombini ukusebenza kunye neendleko.

Ukukhusela igesi ngaphakathiTIG Welding

Kwi-TIG (Tungsten Inert Gas) ukuwelda,

Irhasi yokukhusela eyona nto isetyenziswayo yileubunyulu obuphezuluiargon.

Le gesi ehloniphekileyo ikhethwa ngenxa yokukwazi kwayo okugqwesileyokhusela i-weld pool

Ukusuka kungcoliseko lwe-atmospheric, ngakumbi i-oxidation.

I-oxidation inokukhokelela kwiiziphenekwi-weld, njenge-porosity kunye namalungu abuthathaka,

Yiyiphiukuvumelanaingqibelelo iyonke yesinyithi.

Ngenxa yokusebenza kwayo,

Ukuwelda kwe-TIG kaninzi kufuna angokuqhubekayounikezelo lwe-argon kuyo yonke inkqubo ye-welding.

Nangona kunjalo, i-argon inokubiza kakhulu, okukhokelela kwiindleko eziphezulu zokusebenza,

Ngokukodwa kwiiprojekthi ezifuna i-welding ebanzi.

Ukukhusela igesi ngaphakathiUkuwelda kweLaser ngesandla

Enye iGesi yokuKhusela i-Laser Welding: iNitrogen

Kwelinye icala, i-laser welding ephathwa ngesandla ihlala isebenzisa initrogen njengerhasi ekhuselayo.

Nitrogen ayikho kuphelaesebenzayoekuthinteleni i-oxidation

Kodwa kwakhona ngokuphawulekayo ngakumbiisebenza kakuhle emaliningaphezu kwe-argon.

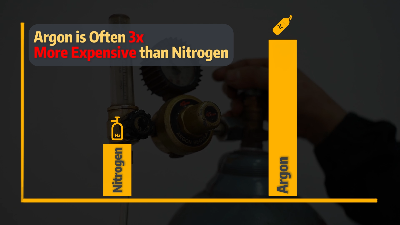

Umahluko wamaxabiso unokuba mkhulu;

Nitrogen ingaba phantseamaxa amathathuzitshiphu kune-argon yococeko oluphezulu.

Oku kwenza initrogen ibe yindlela enomtsalane kumashishini ajonge ukunciphisa iindlekongaphandle kokubingelelaumgangatho.

I-TIG vs i-Laser Welding: Iinketho zokuKhusela iGesi

Ukuzuza Ugcino Ngelixa Ugcina Umgangatho

Ukuthelekiswa kwexabiso phakathi kweArgon kunye neNitrogen

Ukutshintshela kwi-nitrogen ekunikezelweni kwe-laser welding ephathwayoezininziiingenelo

Ugcino lweendleko:

Neebalulekileyoumahluko wexabiso phakathi kweargon kunye nenitrogen,

Ukusebenzisa initrogen kunokukhokelela kulondolozo olukhulu ngokuhamba kwexesha.

Yi leluncedo ngakumbikwiiprojekthi ezinkulu okanye amashishini

Oko kwenza imisebenzi ye-welding rhoqo.

Ukhuseleko olusebenzayo:

Nitrogen ibonelelaukhuselo olwaneleyongokuchasene ne-oxidation,

Ukuqinisekisa ukuba i-weld ihlalaicocekile kwaye yomelele.

Ngoxa i-argon iyaziwa ngokukhusela kwayo okuphezulu,

I-nitrogen isekhoukhetho olusebenzayoehlangabezana ngokufanelekileyo neemfuno zezicelo ezininzi ze-welding.

Thelekisa iNkqubo yokuWelding: Laser vs TIG Welding

Ingqalelo ngononophelo kubuChwephesha buPhumelela ezona ziphumo zilungileyo

I-Engile eLungileyo ye-Laser Welding: i-45 Degree

Nje ukuba igesi ekhuselayo ihamba kakuhle,

Lixesha lokugxila kweyona nkqubo yewelding.

Zombini i-TIG (i-Tungsten Inert Gas) i-welding kunye ne-laser welding ephathwayo

Funaubuchule obuchanekileyoukufumana iziphumo ezikumgangatho ophezulu,

Nangona kunjalo, ziyahluka kwiimfuno kunye neendlela zabo ezithile.

TIG WeldingUbuchwephesha

Injongo yokugcina i-electrode kwindawoowona mgama kunye nesantyaukwenza kunye nokukhokela i-weld pool.

Lo mgama unokwahluka ngokuxhomekeke kwizinto kunye nobukhulu obudityanisiweyo.

Ukugcina i-engile echanekileyo, ngokuqhelekileyo ngeenxa zonke15 ukuya kuma-20 degrees,

Inceda ekufezekiseni i-weld engaguqukiyo kwaye ecocekileyo.

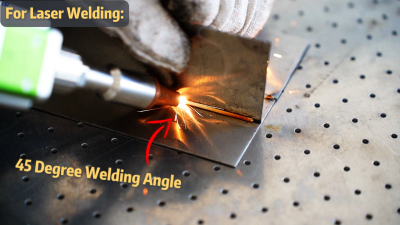

Ukuwelda kweLaser ngesandlaUbuchwephesha

Enye yeenzuzo ze-laser welding kukukwazi ukuseta i-angle engaguqukiyo

Ngokuqhelekileyo ngeenxa zonke45 degrees, ukuvumela ukuba kube lula ukulawula inkqubo ye-welding.

Emva kokuba i-angle iseti, ukugcinaisantya esizinzileyongundoqo.

Ukuwelda kwelaser ngesandla ngokuqhelekileyo kuyavelisaubushushu obuncincixa kuthelekiswa ne-TIG welding.

Oku kuthetha ukuba kukhoumngcipheko omncinci wokuphazamiseka okanye ukuphazamiseka,

Ukuyenza ilungele umsebenzi ochanekileyo kwizinto ezibhityileyo.

Laser Weld Amandla vs TIG: Debunking Myths

Iimbono ezingezizo eziqhelekileyo ngokumalunga ne-Laser Welding

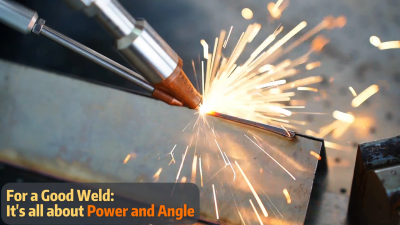

Kwi-Handheld Laser Welding: Amandla kunye neAngle

Enye yeenzuzo eziphambili ze-laser welding ephathwayo kukukwazi kwayo ukuhambisa amandla axinanisiweyongokuchanekileyoapho ifuneka khona.

Neizicwangciso zamandla zasekunenekunye neeyona engile

Ngokuqhelekileyo ngeenxa zonke45 degrees, i-laser welding inokufikelela ekungeneni okugqwesileyo kunye namandla.

IsiPhumo saMandla esiLungileyo

Ukusetwa kwamandla e-laser welder kubalulekile.

Ukuphantsi kakhulu kwemveliso yamandla kunokubangelaukungena ngokwaneleyo, ekhokelela kwii-welds ezibuthathaka.

Ngokwahlukileyo, inqanaba lamandla elifanelekileyo livumela i-laser ukuba inyibilikise izinto eziphathekayo ngokufanelekileyo, idale amajoyina anamandla.

Ukusebenzisa izixhobo ezingenamandla angaphantsi akuzuzisa iziphumo ezinqwenelekayo.

Zombini i-TIG kunye ne-Handheld Laser Welding ziyasebenza

Ngaba uyafuna ukufunda ngakumbi malunga ne-Handheld Laser Welding?

I-Handheld Laser Welding: Indlela Yokugcina Isixhobo

Ukhathalelo olululo kunye nokuqwalaselwa kweNkcukacha kuya kuqinisekisa imveliso kunye nokuthembeka

Ngaba ubusazi ukuba zombini i-TIG (i-Tungsten Inert Gas) yokuwelda kunye ne-laser ephathwayo ihlelwa njenge

Iindlela ze-welding ezingasetyenziswayo?

Oku kuthetha ukuba, phantsi kweemeko ezifanelekileyo kunye nokhathalelo olufanelekileyo,

Amacandelo aphambili asetyenziswa kwezi nkqubo anokuhlala ixesha elide

Ngaphandle kokufuna ukutshintshwa rhoqo.

Amacandelo angasetyenziswayo

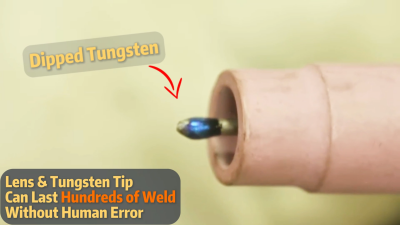

Imposiso eDitshiweyo yeTungsten ye-TIG Welding

I-electrode ye-tungsten yinto ebalulekileyo kwi-TIG welding.

Ngokungafaniyo nee-electrode ezisetyenziswayo kwezinye iindlela zokuwelda,

njenge-MIG welding, i-electrode ye-tungstenayinyibilikingexesha lenkqubo ye-welding.

Kunoko, igcina ingqibelelo yayo, ivumela ukusetyenziswa ixesha elide.

Nangona kunjalo, i-electrode inokungcoliseka okanye "ifakwe" ukuba ifumenekufutshane kakhulu kwi-weld pool etyhidiweyo.

Kwiimeko ezinjalo, kufuneka inqunyulwe emva kunye nomhlaba ukubuyisela inqaku layo elibukhali kunye nokusebenza okusebenzayo.

Ukugcinwa rhoqoI-electrode ye-tungsten ibalulekile ekufezekiseni ukucoceka okucocekileyo, umgangatho ophezulu we-welds.

Ukulungiselela ukuwelda kweLaser ngesandla

I-Laser Lens ye-Handheld Laser Welding Maintenance

Kwiwelding yelaser ephathwayo, ilensi yelaser isebenza njengendawo ekugxilwe kuyo kumqadi welaser.

I-lens ebekwe ngokufanelekileyo inokuhlala ixesha elide, ibonelela ngokusebenza okuhambelanayo.

Nangona kunjalo, ukuba i-lens iyaqhekeka ngenxa yendawo engafanelekanga okanye ukuvezwa kubushushu obugqithisileyo

Kuya kufuneka kutshintshwe.

Ukugcina ilensi ikwimeko entle kubalulekile,

Njengoko nomonakalo omncinci unokuchaphazela ukuchaneka kunye nokusebenza kwelaser, ekhokelela kwi-welds engaphantsi.

Ngaba uyafuna iSikhokelo esiGqibeleleyo seReferensi ye-Handheld Laser Welding?

Ukuwelda ngesandla kwelaser kubonelela ngeenzuzo ezininzi,

Kodwa ikwafuna ingqwalasela engqongqo kwiiprothokholi zokhuseleko.

Eli nqaku liza kuphonononga ezona ngqwalasela zingundoqo zokhuseleko kwi-handheld laser welding.

Kanye nokubonelela ngeengcebiso ekukhuseleni ukhetho lwegesi kunye nokukhetha kocingo lokuzalisa kwiintlobo zetsimbi eziqhelekileyo.

Ngaba i-Laser Welding yomelele njenge-TIG Welding?

Ukuwelda kweLaserkunye ne-TIG (i-Tungsten Inert Gas) i-welding zombini idume ngokuchaneka kunye nomgangatho wokujoyina isinyithi.

Kodwa badibana njani ngokwamandla?

Kule vidiyo, siza kuntywila kumahluko aphambili kuwoukusebenza weld,ukuhambelana kwezinto, kwayeukuqina ngokubanziphakathi kwe-laser kunye ne-TIG welding.

I-Handheld Fiber Laser Welding (Handheld Laser Weld)

Ukongezwa okuBalulekileyo kwi-Handheld Laser Weld Landscape

I-Laser Welder encinci yenza i-Welding ibe yindleko kwaye ifikeleleke

Ngokubonakala komatshini odibeneyo kunye nomncinci.

Umatshini we-laser welder ophathwayo uxhotyiswe ngompu we-laser welder ophathwayo ophathwayoilula.

Kwaye ilungele izicelo ze-welding ezininzi ze-laser kwinayiphi na i-engilekwayeumphezulu.

Ukuzikhethela iintlobo ezahlukeneyo zemilomo ye-laser welder.

Inkqubo yokutya okuzenzekelayo ngocingo yenza umsebenzi we-laser welding lula kwaye inobubele kubaqalayo.

Izinto ezi-5 malunga ne-Laser Welding (ezokuba uziphosile)

Ukuba uyonwabele le vidiyo, kutheni ungacingiubhalisela kwisiteshi sethu seYouTube?

Izicelo Eziyeleleneyo Unokuba Nomdla:

I-Handheld Laser Weld luKhetho olugqwesileyo lweMisebenzi ye-Welding Manual

Kwaye ikamva liqala ngawe!

Ixesha lokuposa: Sep-14-2024