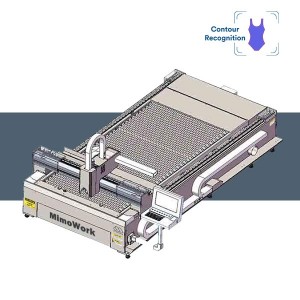

Umshini Wokusika I-Embroidery Patch Laser 60

Embroidery Laser Machine - Laser Cutting Embroidery Patches Kalula

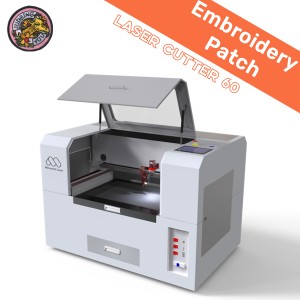

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W*L) | 600mm * 400mm (23.6” * 15.7”) |

| Usayizi Wokupakisha (W*L*H) | 1700mm * 1000mm * 850mm (66.9” * 39.3” * 33.4”) |

| Isoftware | Isoftware ye-CCD |

| Laser Amandla | 60W |

| Umthombo we-Laser | CO2 Glass Laser Tube |

| IMechanical Control System | Step Motor Drive & Belt Control |

| Ithebula Lokusebenza | I-Honey Comb Working Table |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

| Idivayisi yokupholisa | I-Chiller yamanzi |

| Ukunikezwa kukagesi | 220V/Isigaba Esisodwa/60HZ |

(I-Laser yangokwezifiso isike i-Applique, ilebula, Isitika, iziqephu eziphrintiwe)

Embroidery Patch Laser Cutting Machine 60 - OKUVELELE

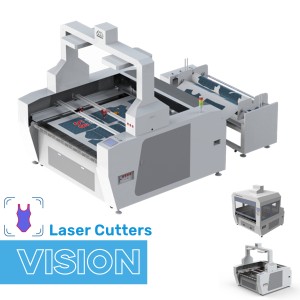

I-Optical Recognition System

◾ Ikhamera ye-CCD

IIkhamera ye-CCDiyakwazi ukubona futhi ibeke iphethini kupheshi, ilebula nesinamathiseli, iyalele ikhanda le-laser ukuze lifinyelele ukusika okunembile eduze kwekhonta. Ikhwalithi ephezulu enokusikwa okuguquguqukayo kwephethini eyenziwe ngokwezifiso kanye nomklamo womumo njengelogo, nezinhlamvu. Kunezindlela ezimbalwa zokuqaphela: ukuma kwendawo yesici, ukuma kwephoyinti lokumaka, nokumatanisa isifanekiso. I-MimoWork izohlinzeka ngomhlahlandlela wokuthi ungakhetha kanjani izindlela zokuqashelwa ezifanele ukuze zilingane nokukhiqiza kwakho.

◾ Ukuqapha Kwesikhathi Sangempela

Ngokuhambisana nekhamera ye-CCD, isistimu yokuqaphela ikhamera ehambisanayo inikeza isibonisi sokuqapha ukuze sihlole isimo sokukhiqiza sesikhathi sangempela kukhompuyutha. Lokho kulungele isilawuli kude futhi wenze ukulungiswa ngesikhathi, ukugeleza kokusebenza kokukhiqiza okushelelayo kanye nokuqinisekisa ukuphepha.

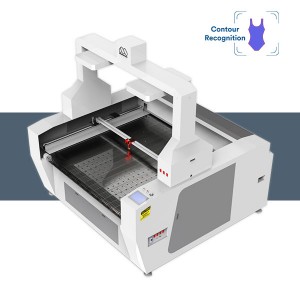

Isakhiwo Selaser Esizinzile Nephephile

◾ I-Compact Machine Body Design

I-Contour laser cut patch machine ifana netafula lasehhovisi, elingadingi indawo enkulu. Umshini wokusika ilebula ungabekwa noma kuphi efekthri, kungakhathaliseki ukuthi usendlini yokuhlola noma indawo yokusebenzela. Incane ngosayizi kodwa ikunikeza usizo olukhulu.

◾ Ukushaya komoya

Ukusiza komoya kungasusa intuthu nezinhlayiya ezikhiqizwe lapho i-laser cut patch noma iqopha ipheshi. Futhi umoya ovunguzayo ungasiza ekwehliseni indawo ethintekile ekushiseni okuholela emaphethelweni ahlanzekile futhi ayisicaba ngaphandle kokuncibilika kwempahla eyengeziwe.

(* Ukuphephuka kwemfucuza ngesikhathi kungavikela ilensi emonakalweni ukuze kunwetshwe impilo yesevisi.)

◾ Inkinobho Yesimo Esiphuthumayo

Anisitobhi esiphuthumayo, owaziwa nangokuthi abulala ukushintsha(I-E-stop), iyindlela yokuphepha esetshenziselwa ukuvala umshini esimweni esiphuthumayo lapho ungeke uvalwe ngendlela evamile. Isitobhi esiphuthumayo siqinisekisa ukuphepha kwabaqhubi ngesikhathi senqubo yokukhiqiza.

◾ Isekhethi ephephile

Ukusebenza okushelelayo kwenza imfuneko yesekethe yokusebenza kahle, ukuphepha kwayo okuyisisekelo sokukhiqizwa kokuphepha.

NgokuzithandelaIthebula leShuttle, kuzoba namatafula amabili asebenzayo angasebenza ngokushintshana. Lapho itafula elilodwa lokusebenza liqeda umsebenzi wokusika, elinye lizolishintsha. Ukuqoqa, ukubeka izinto kanye nokusika kungenziwa ngesikhathi esifanayo ukuqinisekisa ukusebenza kahle kokukhiqiza.

Ubukhulu betafula lokusika i-laser buncike kufomethi yezinto ezibonakalayo. I-MimoWork inikezela ngezindawo ezihlukene zamatafula okusebenza ukuze zikhethwe ngokuya ngesidingo sakho sokukhiqiza isichibi kanye nosayizi wezinto ezibonakalayo.

Ii-fume extractor, kanye nesiphephetha-moya se-exhaust, ingakwazi ukumunca igesi engcolile, iphunga elimnandi, nezinsalela eziphuma emoyeni. Kunezinhlobo ezahlukene namafomethi ongawakhetha ngokuya ngokukhiqizwa kwepheshi langempela. Ngakolunye uhlangothi, uhlelo lokuhlunga lokuzikhethela luqinisekisa indawo yokusebenza ehlanzekile, kanti ngakolunye imayelana nokuvikelwa kwemvelo ngokuhlanza imfucuza.

I-Embroidery Patch Laser Cutting Akukaze kube Lokhu Kulula futhi Kunenzuzo

Kungani Ulinda? Qala Manje!

I-Embroidery Patch Laser Cutting - Izibonelo

I-Embroidery Patch Laser Cutting

Ama-embroidery patches ayindlela enhle yokwengeza ukuthinta kobuntu nesitayela kunoma iyiphi impahla noma isisetshenziswa. Kodwa-ke, izindlela zendabuko zokusika nokuklama la ma-patches zingadla isikhathi futhi ziyisicefe. Yilapho i-laser cutting ingena khona! Amapheshana ahlotshisiwe okusika i-laser aguqule inqubo yokwenza iziqephu, ahlinzeke ngendlela esheshayo, enembe kakhudlwana, futhi ephumelelayo yokwakha amapheshana anemiklamo nemilo eyinkimbinkimbi. Ngomshini wokusika we-laser oklanyelwe ngokukhethekile ama-embroidery patches, ungafinyelela izinga lokunemba kanye nemininingwane eyayingenakwenzeka ngaphambili.

Okunye Okujwayelekile Kwe-Patch Laser Cutting

Ukusika i-patch laser kudumile kwezemfashini, izingubo, kanye namagiya ezempi ngenxa yekhwalithi ephezulu kanye nokunakekelwa okufanele ekusebenzeni nasekusebenzeni. Ukusika okushisayo okuvela kusikwa se-laser patch kungavala unqenqema ngenkathi kusika isichibi, okuholela emaphethelweni ahlanzekile futhi abushelelezi afaka ukubukeka okuhle kanye nokuqina. Ngokusekelwa kwesistimu yokumisa ikhamera, kungakhathaliseki ukukhiqizwa okukhulu, isiqephu sokusika i-laser sihamba kahle ngenxa yokumatanisa kwesifanekiso esisheshayo ku-patch kanye nesakhiwo esizenzakalelayo sendlela yokusika. Ukusebenza okuphezulu nokusebenza okuncane kwenza ukusika kwepheshi yesimanje kube nezimo futhi kusheshe.

• Isiqeshana se-Embroidery

• Isiqeshana sevinyl

• Ifilimu ephrintiwe

• Isiqeshana sefulegi

• Ipheshi lamaphoyisa

• Isiqeshana se-Tactical

• Isiqephu se-ID

• Isiqeshana esibonakalisayo

• Isiqeshana sepuleti yegama

• Isiqephu se-Velcro

• Isiqephu seCordura

• Isitika

• I-Applique

• Ilebula elukiwe

• Uphawu (ibheji)

• Ipheshi lesikhumba

▷ Umboniso Wevidiyo

NgeUmshini Wokusika I-Embroidery Patch Laser 60

Ungasika kanjani ama-Embroidery Patches - Ngezinyathelo

1. Ikhamera ye-CCD izokhipha isici se-embroidery

2. Ngenisa ifayela lokuklama kanye nesistimu ye-laser izobeka iphethini

3. Qondanisa i-embroidery nefayela lesifanekiso futhi ulingise indlela yokusika

4. Qala ukusika isifanekiso esinembile uwedwa umkhonto wephethini