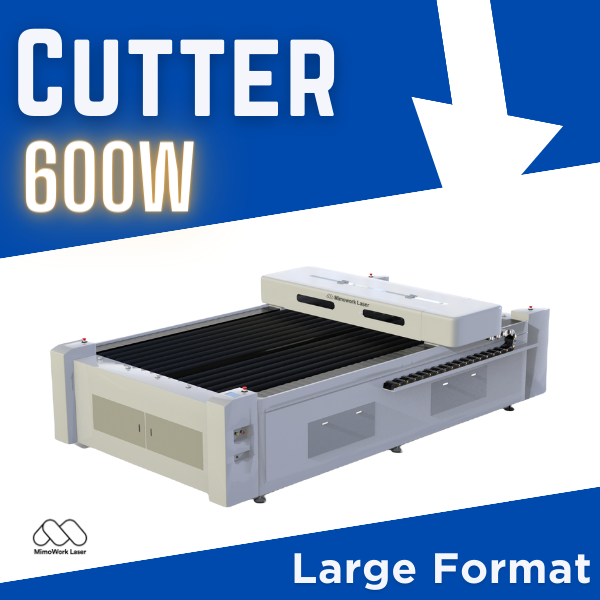

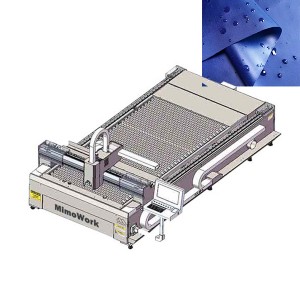

I-600W Laser Cutter (Ifomethi Enkulu)

▶ Umshini Wokusika I-Laser ongu-600W (Ifomethi Enkulu)

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W * L) | 1300mm * 2500mm (51” * 98.4”) |

| Isoftware | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 600W |

| Umthombo we-Laser | CO2 Glass Laser Tube |

| IMechanical Control System | I-Ball Screw ne-Servo Motor Drive |

| Ithebula Lokusebenza | I-Knife Blade noma Ithebula Lokusebenza Lekhekheba Lezinyosi |

| Isivinini esikhulu | 1~600mm/s |

| Isivinini Sokusheshisa | 1000~3000mm/s2 |

| Ukunemba Kwesikhundla | ≤±0.05mm |

| Usayizi Womshini | 3800 * 1960 * 1210mm |

| I-Voltage yokusebenza | AC110-220V±10%,50-60HZ |

| Imodi Yokupholisa | Uhlelo Lokupholisa Amanzi Nokuvikela |

| Indawo Yokusebenzela | Izinga lokushisa:0—45℃ Ukuswakama:5%—95% |

| Usayizi Wephakheji | 3850 * 2050 * 1270mm |

| Isisindo | 1000kg |

Okugqamile Kwedizayini Ye-600W Yefomethi Enkulu Yokusisika I-Laser

Ukweqa Okukhulu Ekukhiqizeni

◾ Ikhwalithi Ezinzile Nenhle Kakhulu Yokusika

I-Constant Optical Path Design

Ngobude bendlela ye-optical ephumayo efanele, i-laser beam engaguquki kunoma iyiphi indawo ebangeni letafula lokusika ingaholela ekusikeni okulinganayo kuyo yonke into, kungakhathaliseki ukuthi ugqinsi lungakanani. Ngenxa yalokho, ungathola umphumela ongcono wokusika we-acrylic noma ukhuni kunendlela ye-laser endizayo uhhafu.

◾ Ukusebenza Okuphezulu Nokunemba

Uhlelo Lokudlulisa Olusebenzayo

Imojuli yesikulufu sokunemba kwe-X-axis, nesikulufu sebhola se-Y-axis unilateral inikeza ukuzinza nokunemba okuhle kakhulu kokunyakaza kwesivinini esikhulu se-gantry. Ihlanganiswe ne-servo motor, uhlelo lokudlulisela ludala ukusebenza kahle kokukhiqiza okuphezulu.

◾ Impilo Eqinile Neyinde Yesevisi

Isakhiwo sikaMechanical Esizinzile

Umzimba womshini ushiselwe ngeshubhu lesikwele esingu-100mm futhi uyaguga ngokudlidliza kanye nokwelashwa kokuguga kwemvelo. I-Gantry kanye nekhanda lokusika lisebenzisa i-aluminium ehlanganisiwe. Ukucushwa kukonke kuqinisekisa isimo sokusebenza esizinzile.

◾ High Speed Processing

Isivinini esikhulu sokusika nokuqopha

I-laser cutter yethu engu-1300*2500mm ingafinyelela isivinini sokuqopha esingu-1-60,000mm/min kanye nesivinini sokusika esingu-1-36,000mm/min.

Ngesikhathi esifanayo, ukunemba kwesikhundla nakho kuqinisekisiwe ngaphakathi kuka-0.05mm, ukuze ikwazi ukusika futhi iqophe izinombolo noma izinhlamvu ezingu-1x1mm, akunankinga nhlobo.

Letha Imiklamo Yakho Nezimfanelo Ezizofana

I-Acrylic Eminyene | I-Laser Cut Acrylic Sheet

Thola amavidiyo amaningi mayelana nama-laser cutters ethuIgalari Yamavidiyo

Amashidi e-acrylic anogqinsi kusuka ku-10mm kuya ku-30mmingasikwa nge-laser ngomshini wokusika we-laser wefomethi engu-600W.

Ezinye izinto ezicatshangelwayo ngesikhathi sokusika:

1. lungisa i-air assist ukuze wehlise ukushaywa komoya nokucindezela ukuze uqinisekise ukuthi i-acrylic ingaphola kancane

2. khetha ilensi efanele: jiya i-material, ubude bokugxila bude belensi

3. Amandla e-laser aphakeme anconyelwa ama-acrylic aminyene (icala ngalinye ngezidingo ezahlukahlukene)

I-Laser Cutting Acrylic - Izicelo

• Izibonisi Zokukhangisa

• Imodeli Yezakhiwo

• Ubakaki

• Ilogo Yenkampani

• Ifenisha Yesimanje

• Izincwadi

• Amabhodi okukhangisa angaphandle

• Isitendi Somkhiqizo

• Ukuthenga ezitolo

• Izimpawu Zomdayisi

• Indondo

(Amacici e-acrylic laser cut, izimpawu ze-acrylic laser cut, ubucwebe be-acrylic laser cut, izinhlamvu ze-acrylic laser cut…)

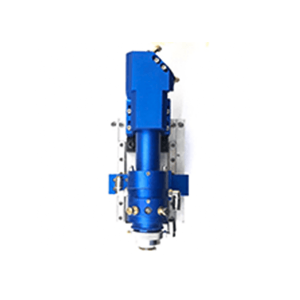

Izinketho Ezithuthukiswayo - Vula Amandla Aphelele

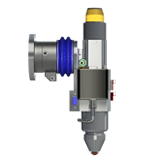

I-Mix Laser Head

I-Auto Focus

IIkhamera ye-CCDingabona futhi ibeke iphethini ku-acrylic ephrintiwe, isize i-laser cutter ukuthi ibone ukusika okunembile ngekhwalithi ephezulu. Noma yimuphi umdwebo owenziwe ngezifiso ophrintiwe ungacutshungulwa kalula ngohlaka ngesistimu yokubona, ubambe iqhaza elibalulekile kwezokukhangisa nakweminye imboni.