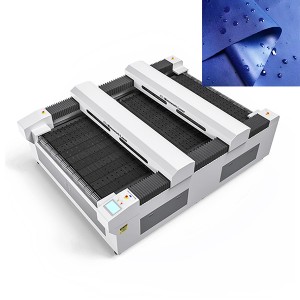

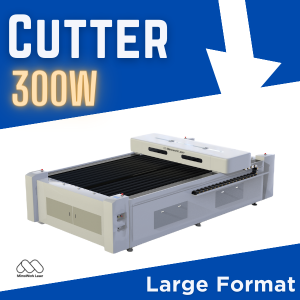

I-Industrial Wood Laser Cutter Yokhuni Olukhulu Nolugqinsi (Kufika ku-30mm)

▶ Umsiki we-laser wesakhiwo esikhulu sokhuni

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W * L) | 1300mm * 2500mm (51” * 98.4”) |

| Isoftware | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 150W/300W/450W |

| Umthombo we-Laser | CO2 Glass Laser Tube |

| IMechanical Control System | I-Ball Screw ne-Servo Motor Drive |

| Ithebula Lokusebenza | I-Knife Blade noma Ithebula Lokusebenza Lekhekheba Lezinyosi |

| Isivinini esikhulu | 1~600mm/s |

| Isivinini Sokusheshisa | 1000~3000mm/s2 |

| Ukunemba Kwesikhundla | ≤±0.05mm |

| Usayizi Womshini | 3800 * 1960 * 1210mm |

| I-Voltage yokusebenza | AC110-220V±10%,50-60HZ |

| Imodi Yokupholisa | Uhlelo Lokupholisa Amanzi Nokuvikela |

| Indawo Yokusebenzela | Izinga lokushisa:0—45℃ Ukuswakama:5%—95% |

| Usayizi Wephakheji | 3850mm * 2050mm * 1270mm |

| Isisindo | 1000kg |

▷Izici ze-1325 Laser Cutter

Ukugxuma Okukhulu Ekukhiqizeni

◾ Ikhwalithi Ezinzile Nenhle Kakhulu Yokusika

I-Constant Optical Path Design

Ngobude bendlela ye-optical ephumayo efanele, i-laser beam engaguquki kunoma iyiphi indawo ebangeni letafula lokusika ingaholela ekusikeni okulinganayo kuyo yonke into, kungakhathaliseki ukuthi ugqinsi lungakanani. Ngenxa yalokho, ungathola umphumela ongcono wokusika we-acrylic noma ukhuni kunendlela ye-laser endizayo uhhafu.

◾ Ukusebenza Okuphezulu Nokunemba

Uhlelo Lokudlulisa Olusebenzayo

Imojuli yesikulufu sokunemba kwe-X-axis, isikulufu sebhola se-Y-axis unilateral sinikeza ukuzinza nokunemba okuhle kakhulu kokuhamba ngesivinini esiphezulu kwe-gantry. Ihlanganiswe ne-servo motor, uhlelo lokudlulisela ludala ukusebenza kahle kokukhiqiza okuphezulu.

◾ Impilo Eqinile Neyinde Yesevisi

Isakhiwo sikaMechanical Esizinzile

Umzimba womshini ushiselwe ngeshubhu lesikwele esingu-100mm futhi uyaguga ngokudlidliza kanye nokwelashwa kokuguga kwemvelo. I-Gantry kanye nekhanda lokusika lisebenzisa i-aluminium ehlanganisiwe. Ukucushwa kukonke kuqinisekisa isimo sokusebenza esizinzile.

◾ High Speed Processing

Isivinini esikhulu sokusika nokuqopha

I-laser cutter yethu engu-1300*2500mm ingafinyelela isivinini sokuqopha esingu-1-60,000mm/min kanye nesivinini sokusika esingu-1-36,000mm/min.

Ngesikhathi esifanayo, ukunemba kwesikhundla nakho kuqinisekisiwe ngaphakathi kuka-0.05mm, ukuze ikwazi ukusika futhi iqophe izinombolo noma izinhlamvu ezingu-1x1mm, akunankinga nhlobo.

Kungani ukhethe i-MimoWork Laser

130250 imininingwane yomshini we-laser ukuqhathanisa

|

| Ezabanye umkhiqizi | Umshini we-laser we-MimoWork |

| Ukusika isivinini | 1-15,000mm/min | 1-36,000mm/min |

| Ukunemba kwesikhundla | ≤±0.2mm | ≤±0.05mm |

| Amandla e-laser | 80W/100W/130W/150W | 100W/130W/150W/300W/500W |

| Indlela ye-Laser | Indlela ye-laser ye-half fly | Indlela yokubona njalo |

| Isistimu yokudlulisela | Ibhande lokudlulisela | I-Servo motor + isikulufu sebhola |

| Isistimu yokushayela | Umshayeli wesinyathelo | I-Servo motor |

| Isistimu yokulawula | Isistimu endala, ayithengiswa | Uhlelo olusha oludumile lokulawula i-RDC |

| Umklamo kagesi ozikhethela wona | No | I-CE/UL/CSA |

| Umzimba oyinhloko | Traditional welding fuselage | Umbhede oqinisiwe, isakhiwo sonke sishiselwe ngeshubhu lesikwele esingu-100mm, futhi siguga ngokudlikiza kanye nokwelashwa kokuguga kwemvelo. |

Amasampula Avela Ku-Wood Laser Cutter

Izinto zokhuni ezifanele

I-MDF, Basswood, White Pine, Alder, Cherry, Oak, Baltic Birch Plywood, Balsa, Cork, Cedar, Balsa, Solid Wood, Plywood, Timber, Teak, Veneers, Walnut, Hardwood, Laminated Wood kanye neMultiplex

Izicelo ezibanzi

Amavidiyo | Yini engakwenzela yona umsiki we-laser?

I-Laser Engraving Photo on Wood

Thola I-Wood Laser Cutter ukuze Uthuthukise Ibhizinisi Lakho

Jabulela fun laser izinkuni!

▶ Umsiki we-laser wesakhiwo esikhulu sokhuni

Thuthukisa Izinketho ongakhetha kuzo

I-Mix Laser Head

I-Auto Focus

IIkhamera ye-CCDingabona futhi ibeke iphethini ku-acrylic ephrintiwe, isize i-laser cutter ukuthi ibone ukusika okunembile ngekhwalithi ephezulu. Noma yimuphi umdwebo owenziwe ngezifiso ophrintiwe ungacutshungulwa kalula ngohlaka ngesistimu yokubona, ubambe iqhaza elibalulekile kwezokukhangisa nakweminye imboni.

Imibuzo Ehlobene: Ungase Ube Nentshisekelo Kuyo

1. Ngingasebenzisa noma yiluphi uhlobo lwezinkuni ukusika i-laser, noma kukhona izinhlobo ezithile zezinkuni ezisebenza kangcono?

2. Yikuphi ukushuba kwezinkuni umshini wokusika we-CO2 laser ongawuphatha ngokuphumelelayo?

Yebo, ukuphepha kubaluleke kakhulu uma usebenza ngamalaser. Qinisekisa ukungena komoya ngendlela efanele endaweni yakho yokusebenza ukuze ukhiphe intuthu ekhiqizwe ngesikhathi sokusika. Njalo gqoka izinto zokuzivikela ezifanele (i-PPE), okuhlanganisa nezibuko zokuphepha. Ukwengeza, qiniseka ukuthi ukhuni alunawo ama-coatings, ama-finish, noma amakhemikhali angase akhiqize intuthu eyingozi lapho evezwe ku-laser.

Ukusika Izinkuni: I-CNC Routers VS Laser

1. Izinzuzo CNC Routers

Ngokomlando, enye yezinzuzo eziyinhloko zokukhetha irutha ngokuphambene ne-laser kwakuwukukwazi kwayo ukuzuza ukujula okunembile kokusika. Irutha ye-CNC inikeza lula ukulungiswa okuqondile (ku-axis Z), okuvumela ukulawula okuqondile phezu kokujula kokusikwa. Ngamagama alula, ungalungisa ukuphakama komsiki ukuze ukhethe ngokukhetha ingxenye yendawo yokhuni.

2. Ukungalungi kwama-CNC Routers

Ama-routers ahamba phambili ekuphatheni amajika kancane kancane kodwa anemikhawulo uma kukhulunywa ngawoama-engeli abukhali. Ukunemba abakunikezayo kuvinjelwa irediyasi yebhithi yokusika. Ngamagama alula,ububanzi bokusika buhambisana nobukhulu bebhithi ngokwayo. Amabhithi erutha amancane ngokuvamile anendawo engaba cishe1 mm.

Njengoba ama-routers enqamula ukungqubuzana, kubalulekile ukunamathisela ngokuvikelekile okokusebenza endaweni yokusika. Ngaphandle kokulungiswa okufanele, i-torque ye-router ingaholela ekujikelezeni noma ekushintsheni kungazelelwe. Ngokuvamile, izinkuni ziboshelwa endaweni kusetshenziswa ama-clamp. Kodwa-ke, lapho ibhithi yerutha enesivinini esikhulu isetshenziswa ezintweni eziboshwe ngokuqinile, kukhiqizwa ukungezwani okukhulu. Lokhu kushuba kunamandla okusonta noma ukulimaza izinkuni, ukwethula izinselele lapho usika izinto ezithambile kakhulu noma ezithambile.

3. Izinzuzo & Nebubi Laser

Ngokufanayo namarutha azishintshayo, abasiki belaser balawulwa uhlelo lwe-CNC (Computer Numerical Control). Nokho, umehluko oyinhloko usendleleni yabo yokusika. Ama-Laser cuttersunganciki ekungqubuzaneni; esikhundleni salokho, basika ngokusebenzisa izinto zokwakhaukushisa okukhulu. Isibani sokukhanya esinamandla aphezulu sivutha ngokuphumelelayo ngokhuni, ngokuphambene nenqubo evamile yokuqopha noma yokwenza imishini.

Njengoba kuphawuliwe ngaphambili, ububanzi bokusikwa bunqunywa ubukhulu bethuluzi lokusika. Nakuba izingcezu zerutha ezincane kakhulu zinerediyasi engaphansi kancane kuno-1 mm, i-laser beam ingalungiswa ukuze ibe nerediyasi encane njenge0.1 mm. Leli khono livumela ukudala ukusikeka okuyinkimbinkimbi kakhuluukunemba okumangalisayo.

Ngenxa yokuthi abasiki be-laser basebenzisa inqubo yokuvutha ukuze bagawule ukhuni, bayakhiqizaimiphetho ebukhali kakhulu futhi ebukhali. Nakuba lokhu kushiswa kungaholela ekuguquguqukeni okuthile, izinyathelo zingasetshenziswa ukuvimbela izimpawu zokusha ezingafunwa. Ukwengeza, isenzo esivuthayo sivala imiphetho, ngaleyo ndlelaukunciphisa ukunwetshwa nokunciphazokhuni ezisikiwe.

Ehlobene Laser Machine

ngokhuni kanye ne-acrylic laser cutting

• Ukuqoshwa okusheshayo nokunembayo kwezinto eziqinile

• Idizayini yokungena yezindlela ezimbili ivumela izinto ezinde kakhulu ezibekwe futhi zisikwe

ngokhuni kanye ne-acrylic laser engraving

• Idizayini elula futhi ehlangene

• Kulula ukusebenza kwabaqalayo