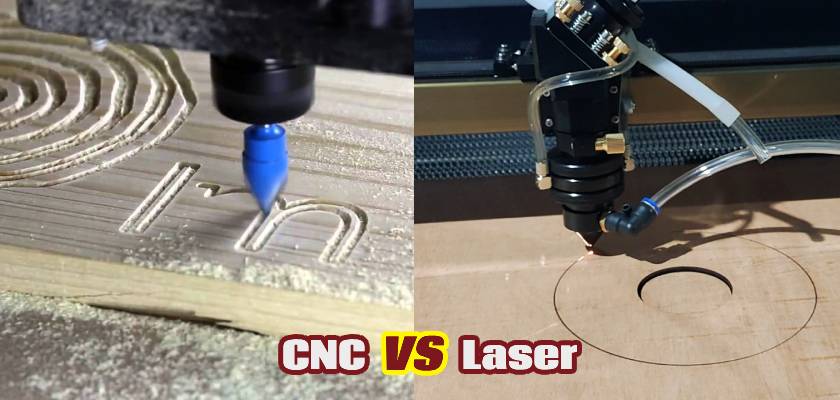

Uyini umehluko phakathi kwe-cnc router kanye ne-laser cutter? Ngokusika nokuqopha ukhuni, abathanda izinkuni kanye nezingcweti ngokufanayo bavame ukubhekana nenkinga yokukhetha ithuluzi elifanele lamaphrojekthi abo. Izinketho ezimbili ezidumile amarutha e-CNC (Computer Numerical Control) nemishini ye-laser ye-CO2, ngayinye inesethi yayo eyingqayizivele yezinzuzo nezinhlelo zokusebenza. Kulesi sihloko, sizohlola umehluko phakathi kwalawa mathuluzi futhi sikusize wenze ukukhetha unolwazi ngezidingo zakho zokhuni.

Thatha Ngokushesha >>

Amaphuzu Abalulekile:

I-CNC Routers

Izinzuzo:

• Zuza ukujula okunembile kokusika ngokulawula kwe-axis engu-Z.

• Isebenza kahle ekuphatheni amajika kancane kancane nokubaza okuyinkimbinkimbi.

• Ifanele i-3D woodworking kanye nemiklamo enemininingwane.

Ububi:

• Ukunemba okulinganiselwe ekuphatheni ama-engeli acijile ngenxa yobubanzi bebhithi yokusika.

• Idinga i-anchoring evikelekile, engabangela ukungezwani kwezinye izimo.

Ama-Laser Cutters

Izinzuzo:

• Ukusika okungathintekiyo ngokushisa okukhulu.

• Ukunemba okukhethekile kokusikeka okuyinkimbinkimbi nemiphetho ebukhali.

• Amaphethelo okuvalwa ukuze kuncishiswe ukwanda nokuncipha kwezinkuni.

Ububi:

• Kungase kubangele ukushintsha kombala kokhuni, kodwa kugwenywe ngezinyathelo ezifanele.

• Ayisebenzi kahle kumajika ahamba kancane namaphethelo ayindilinga.

Isinyathelo ngesinyathelo Ukuhlukaniswa >>

Incazelo yalo lonke:

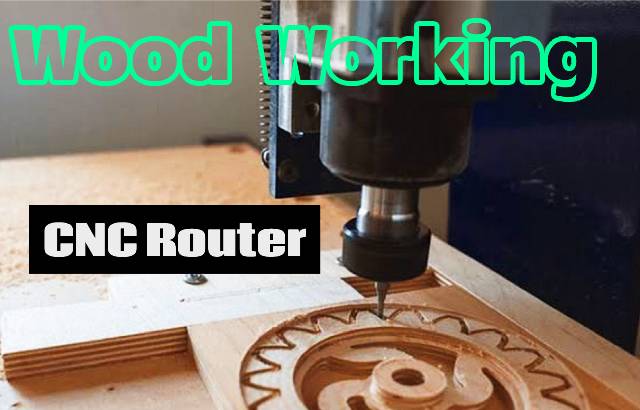

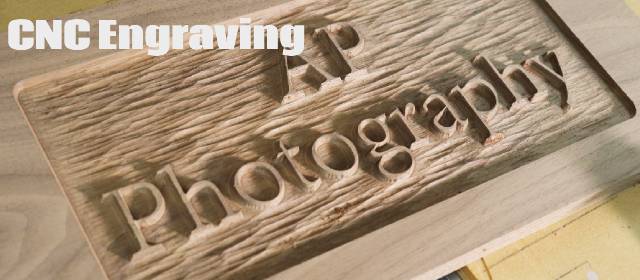

1. Iyini i-CNC Router yokhuni?

Irutha ye-CNC (Computer Numerical Control) iyithuluzi lokusebenza ngokhuni eliguquguqukayo eliguqule umhlaba wobungcweti nokusebenza kwezinkuni ngokunemba. Elawulwa izinhlelo zekhompyutha, amarutha e-CNC asebenza ngokunemba okukhethekile futhi angakhiqiza imiklamo eyinkimbinkimbi nokusikeka ngokhuni. Basebenzisa ucezu oluphothayo ukuze basuse izinto ezibonakalayo kucezu lokusebenza, bazenze zifanelekele imisebenzi eyahlukene, kusukela ekuqoshweni okuningiliziwe nokusebenza ngokhuni kwe-3D kuya kumaphrofayili asemaphethelweni anembile, ngisho nokuqoshwa. Kulesi sihloko, sizohlola amakhono kanye nezinzuzo zamarutha e-CNC kumongo womsebenzi wokhuni, sikusize uqonde ukuthi lobu buchwepheshe buye baba kanjani ithuluzi elibalulekile labathandi bezinkuni kanye nezingcweti.

2. Iyini i-Laser Cutter yezinkuni?

Ama-Laser cutters, anikwe amandla yimishayo yokukhanya enamandla amakhulu, avele njengethuluzi loguquko emkhakheni wokwenza izinkuni. Le mishini isebenzisa ukunemba kwama-laser ukuze yenze ukusikeka okuyinkimbinkimbi nokunembe kakhulu, kanye nokuqoshwa kwezinto ezihlukahlukene, kuhlanganise nokhuni. Ngekhono lokudala imiphetho emihle necijile ngokumangalisayo, abasiki be-laser bathole ukuduma ngenxa yokunemba okukhethekile nekhono lokusika eliyinkimbinkimbi ekusebenzeni ngokhuni, kungakhathaliseki ukuthi okokwakha, ukubumba, noma ukuqopha izindawo zokhuni. Kulesi sihloko, sizophenya emhlabeni wabasiki be-laser be-CO2 futhi sihlole izinhlelo zabo zokusebenza emsebenzini wokhuni, sikusize uqonde ukuthi lobu buchwepheshe obusezingeni eliphezulu buyichaze kanjani kabusha imingcele yokudala kanye nobuciko.

3. Umehluko: CNC VS. I-Laser Cutter

◼ Ngena Ujule Emisweni Yokusebenza - Isebenza kanjani?

I-CNC Routers

Irutha ye-CNC isebenza ngomgomo wokukhiqiza okhiphayo. Empeleni umshini wokusika olawulwa ngekhompuyutha osebenzisa ithuluzi lokusika eliphothayo, njenge-router bit noma isigayo sokugcina, ukuze ukhiphe okubalulekile kucezu lokusebenza. I-router bit izungeza ngesivinini esiphezulu futhi ihlanganiswa nento, okungaba ukhuni, ipulasitiki, noma amanye ama-substrates. Njengoba i-bit yenza ukuthintana, kancane kancane isusa izinto, idale izimo, amaphethini, nemiklamo.

Ukunyakaza kwe-router kulawulwa ngokunembile ngezinhlangothi ezintathu (X, Y, no-Z) ngohlelo lwekhompyutha. Lokhu kuvumela ukulawula okunembile endaweni nokujula kwethuluzi. Amarutha e-CNC ahamba phambili ekusikeni, ekubumbeni, ekuqopheni, nasekukhipheni impahla. Ziyifanele kakhulu imisebenzi edinga umsebenzi oyinkimbinkimbi, we-3D, noma onemininingwane eminingi, futhi zingasetshenziselwa ukuqoshwa ngokulawula ngokucophelela ukujula nesivinini somsiki.

Ama-Lase Cutters

Abasiki be-laser basebenza ngomgomo ohlukile owaziwa ngokuthi ukukhiqiza izithombe ezikhiphayo. Esikhundleni sokuthintana ngokomzimba nempahla, basebenzisa i-laser enamandla amakhulu ukuze bancibilike, bahwamuke, noma bashise izinto eziphuma kucezu lokusebenza. Abasiki be-laser bavame ukuqashwa ngezinto ezihlukahlukene, kuhlanganise nokhuni, futhi bangasika ngokunemba. Futhi banekhono lokuqopha, bakha imiklamo eyinkimbinkimbi ngokushintsha ukuqina nobude be-laser beam.

Uhlelo olulawulwa ngekhompuyutha lomsiki we-laser luqondisa ugongolo lwe-laser ukuba lulandele izindlela ezithile, ludale ukusikeka okuyinkimbinkimbi nemifanekiso. Umehluko obalulekile lapha ukuthi iyindlela yokungaxhumani nayo. I-laser inembe ngendlela emangalisayo futhi ingadala imininingwane emihle kakhulu nemiphetho ebukhali. Isebenza kahle kakhulu ekusikeni nasekuqopheni ukhuni, amapulasitiki, nezinye izinto lapho kudingeka khona ukunemba nokususwa kwezinto ezincane.

◼ Uma Ugawula Izinkuni:

I-CNC Routers

Amarutha e-CNC angamahhashi okusebenza ngokhuni agujwa ngekhono lawo lokuhlanganisa ngaphandle komthungo ikhono lokusika nokulawula ukujula. Le mishini iguquguquka, iyenza ibe ilungele ukwenza imiklamo eyinkimbinkimbi, ukubaza, nokubumba ukhuni. Okubenza bahluke ukunemba kwabo ekufinyeleleni ukujula okuhlukahlukene. Ngokulawula kwe-Z-axis, unamandla okulungisa kahle ukujula kokusikwa. Noma ngabe ukuqoshwa okuningiliziwe, ukwenza ngokhuni kwe-3D, noma ukukhiqiza amaphrofayli onqenqema ayinkimbinkimbi, amarutha e-CNC anikezela ngezinto eziningi okungenzeka. Ukujula kokusika kunqunywa ubude bethuluzi lokusika namandla we-Z-axis.

Ama-Lase Cutters

Abasiki be-laser, ngenkathi baziswa ngokunemba kwabo kokusika, basebenza ngendlela ehlukile uma kuziwa ekujuleni. Bahamba phambili ekudaleni ukusika okunembayo, okungashoni kanye nokuqoshwa kwezinga eliphezulu, okugcizelela ukucoliseka ngaphezu kokujula. Le mishini ingochwepheshe ekukhiqizeni amaphethini ayinkimbinkimbi, imininingwane emihle, namaphethelo acijile. Nakuba zikwazi ukugawula ukhuni, okugxilwe kakhulu kukhwalithi yendawo kunokususwa kwezinto ezibonakalayo. Abasiki be-laser bangompetha bokunemba, benza imiklamo eyinkimbinkimbi ezindaweni zokhuni. Ukulawula ukujula, nokho, kunomkhawulo uma kuqhathaniswa namarutha e-CNC, ngokuvamile afana nogqinsi lwento abasebenza ngayo.

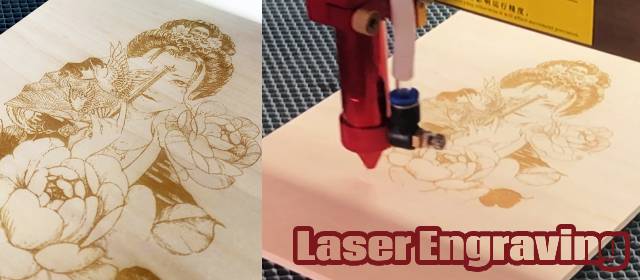

◼ Uma Usebenza Ngokuqopha Ukhuni:

I-Laser engraving izinkuniempeleni iphakeme kakhulu ekudaleni ukuqoshwa okuningiliziwe, ikakhulukazi uma kuziwa ekuqoshweni kwe-raster, okubandakanya ukuthungatha noma ukujula okuqoshiwe okuhlukahlukene ukuze kukhiqizwe amaphethini noma izithombe eziyinkimbinkimbi. Ukunemba nokungathinteki kwemvelo yama-lasers iwenza afanelekele ukuzuza imiklamo emihle, enemininingwane ezintweni ezihlukahlukene, okuhlanganisa ukhuni.

Ngakolunye uhlangothi, amarutha e-CNC afaneleka kakhulu imisebenzi edinga ukuqoshwa okuyinkimbinkimbi, ukubunjwa, kanye nokusebenza ngokhuni kwe-3D kodwa angeke aphumelele ekukhiqizeni izinga elifanayo lemininingwane ekuqoshweni njengabasiki be-laser. Amarutha e-CNC abalulekile ekudaleni izindawo ezithungwe kanye namaphrofayili onqenqema ayinkimbinkimbi, okuwenza abe ngamathuluzi ahlukahlukene ekusebenzeni ngokhuni.

Ezinye Iziphakamiso:

Abasiki be-laser bangcono kakhulu ekudaleni ukuqoshwa okuningiliziwe, ikakhulukazi uma kukhulunywa ngokuqoshwa kwe-raster, okubandakanya ukuthungatha noma ukujula okuqoshiwe okuhlukahlukene ukukhiqiza amaphethini noma izithombe eziyinkimbinkimbi. Ukunemba nokungathinteki kwemvelo yama-lasers iwenza afanelekele ukuzuza imiklamo emihle, enemininingwane ezintweni ezihlukahlukene, kuhlanganisa nokhuni.

◼ Cabangela Ukusebenza Nekushesha kokusebenza ngokhuni

Lapho ukhetha phakathi kwamarutha e-CNC nabasiki belaser bephrojekthi yakho yokwenza ukhuni, ukuqonda isivinini sabo sokusika nokuqopha kubalulekile. Amarutha e-CNC asebenza ngokuthinta ngokoqobo okokusebenza, okwethula ukungqubuzana okuthile futhi kungase kubangele izikhathi zokusika ezinde. Kwezinye izimo, kungase kudingeke amaphasi amaningi ukuze kuqedelwe ukusika. Ngokuphambene, abasiki be-laser baziwa ngesivinini sabo nokusebenza kahle. Bangakwazi ukunqamula ngokushesha ezintweni, ngokuvamile baqedele imisebenzi ngephasi eyodwa.

Isibonelo, ukusika i-MDF engu-6mm, umzila we-cnc unganqamula ngesivinini esingu-25mm ngomzuzwana, kodwa i-laser iyashesha, ingafinyelela umsebenzi wokusika ngo-50mm ngomzuzwana we-laser engu-300W. Kodwa-ke, kubalulekile ukuqaphela ukuthi njengoba ubukhulu bezinto ezibonakalayo bukhula, ijubane nokusebenza kahle kokusika kwe-laser kungase kwehle. Ngokhuni oluhle oluwugqinsi, irutha ye-cnc inamandla ukuyiphatha. Kodwa uma isivinini kanye nemininingwane eyinkimbinkimbi kuyizidingo zakho eziyinhloko, i-laser cutter ingaba ukukhetha kwakho okuthandayo. Imininingwane enemininingwane kusibuze >>

UMA unezidingo ezikhethekile zokuklama ukhuni ngokwezifiso,

ukuya ukuthola iseluleko nochwepheshe laser!

◼ Ukusebenza kulula noma cha?

Lapho ukhetha phakathi kwamarutha e-CNC nabasiki belaser bephrojekthi yakho yokwenza ukhuni, ukuqonda isivinini sabo sokusika nokuqopha kubalulekile. Amarutha e-CNC asebenza ngokuthinta ngokoqobo okokusebenza, okwethula ukungqubuzana okuthile futhi kungase kubangele izikhathi zokusika ezinde. Kwezinye izimo, kungase kudingeke amaphasi amaningi ukuze kuqedelwe ukusika. Ngokuphambene, abasiki be-laser baziwa ngesivinini sabo nokusebenza kahle. Bangakwazi ukunqamula ngokushesha ezintweni, ngokuvamile baqedele imisebenzi ngephasi eyodwa.

Ngokuphambene kakhulu, imishini ye-CNC ihlanganisa ijika lokufunda eliyinkimbinkimbi. Ukuze uziqonde kahle, kufanele uhlole ubunkimbinkimbi, okuhlanganisa ukuqonda amabhithi e-router ahlukahlukene kanye nokusetshenziswa kwawo okuthile, kanye nokulungisa uhla lwamapharamitha ukuze uthole imiphumela emihle. Uma ucabanga ngomshini we-CNC, lindela ijika lokufunda eliningi, elidinga ukutshalwa kwezimali okubalulekile kwesikhathi ukuze ubambe ithuluzi nemininingwane yalo eyinkimbinkimbi.

◼ Iyiphi evumelana nemvelo?

• Umsindo

Irutha ye-CNC:

Amarutha e-CNC ngokuvamile akhiqiza umsindo owengeziwe uma kuqhathaniswa nabasiki be-laser. Izinga lomsindo lingahluka kuye ngohlobo lwerutha, ithuluzi lokusika, nezinto ezicutshungulwayo. Ngokuvamile kuyalulekwa ukusebenzisa ukuvikela ukuzwa lapho usebenzisa irutha ye-CNC, ikakhulukazi isikhathi eside.

I-Laser Cutter:

Ama-Laser cutter athule uma esebenza. Ngenkathi enza umsindo, ngokuvamile usezingeni eliphansi le-decibel kunamarutha e-CNC. Kodwa-ke, kubalulekile ukuqaphela ukuthi amafeni akhipha umoya kanye nezinhlelo zokuhlunga komoya, ezivame ukusetshenziswa nezinqamuleli ze-laser ukuze zisuse umusi, zingaba nomthelela ezingeni lilonke lomsindo.

• Ukuphepha

Irutha ye-CNC:

Amarutha e-CNC abhekwa njengephephile ngokwemibandela yokunciphisa ingozi yokuhogela intuthu noma uthuli olukhiqizwa ngesikhathi sokusika. Kodwa-ke, izinyathelo zokuphepha kufanele zisasebenza, njengezinhlelo zokuqoqa uthuli kanye nokukhipha umoya ngendlela efanele, ukuze kuncishiswe izingozi zezempilo ezihlobene nothuli lwezinkuni.

I-Laser Cutter:

Abasiki be-laser bangabangela ukukhathazeka ngokuphepha ngenxa yokukhishwa kwentuthu engaba khona kanye nezinhlayiya lapho besika noma beqopha ukhuni. Izinto ezifana ne-MDF kanye ne-plywood zingakhiqiza igesi eyingozi, futhi umoya ofanele kanye nezinhlelo zokukhipha umoya kubalulekile ukugcina indawo yokusebenza ephephile. Imihlahlandlela yokuphepha ye-laser kufanele ilandelwe ngokuqinile ukuze kuvikelwe emisebeni ye-laser.

4. Ungakhetha kanjani i-CNC noma i-Laser?

Cabangela Izidingo Zakho Zephrojekthi:

Ngokuqoshwa okuyinkimbinkimbi, ukwenza ngokhuni kwe-3D, nemisebenzi yokubumba, amarutha e-CNC ayisinqumo esiqinile.

Uma ukunemba, imininingwane emihle, kanye nokuqoshwa okuyinkimbinkimbi kuyizinto eziza kuqala kuwe, khetha isisiki nge-laser.

Isivinini nokusebenza kahle:

Amarutha e-CNC ahamba phambili ekususeni impahla nasekubumbeni imisebenzi, ayenza isheshe kule misebenzi.

Abasiki be-laser bayashesha futhi basebenza kahle kakhulu uma kuziwa ekusikeni okunembayo nemisebenzi eyinkimbinkimbi.

Umsindo nokuphepha:

Amarutha e-CNC anomsindo kakhulu ngesikhathi sokusebenza, ngakho-ke cabangela ukubekezelela umsindo futhi usebenzise ukuvikela ukuzwa.

Abasiki be-laser bathule kancane kodwa badinga izinyathelo zokuphepha eziqinile ngenxa yentuthu engaba khona kanye nemisebe ye-laser.

Ijika lokufunda:

Amarutha e-CNC anejika lokufunda elishubile, elidinga ukuqonda okujulile kwamathuluzi namapharamitha.

Abasiki be-laser banikeza ijika lokufunda elisheshayo kulabo abafuna ukuzizwisa 'kwe-plug-and-play'.

Ukususwa Kwezinto Ezibalulekile vs. Imininingwane:

Amarutha e-CNC angcono ekususeni izinto ezibonakalayo nokudala izindawo ezithungwe.

Ama-Laser cutters alungele ukunemba kanye nemininingwane emihle endaweni yezinto ezibonakalayo.

Ubukhulu Bezinto:

Amarutha e-CNC angakwazi ukuphatha izinto eziwugqinsi kangcono ngenxa yekhono lawo lokusika ngokujulile.

Abasiki be-laser bafaneleka kakhulu ezintweni ezizacile ngokugxila kukhwalithi engaphezulu.

Unezinkinga mayelana ne-cnc vs laser kuze kube manje? Kungani ungasibuzi izimpendulo!

Uma uthanda izinkuni laser cutter

Bheka umshini ohlobene >>

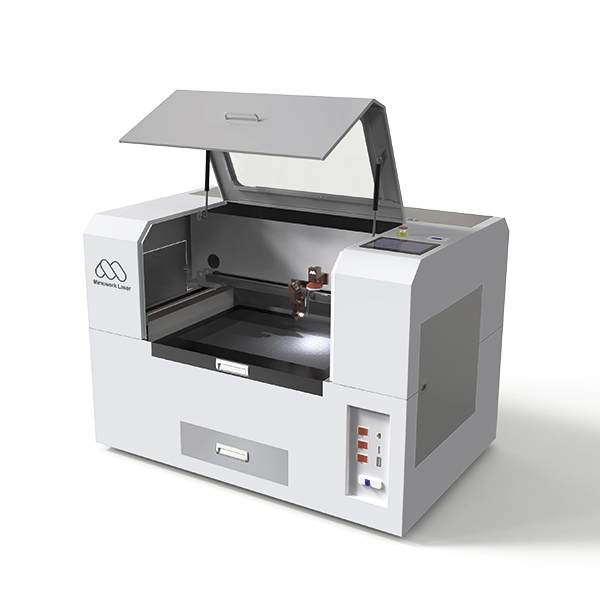

Usayizi Wethebula Lokusebenza:600mm * 400mm (23.6” * 15.7”)

Izinketho zamandla e-Laser:65W

Uhlolojikelele lwe-Desktop Laser Cutter 60

I-Flatbed Laser Cutter 60 iyimodeli yedeskithophu. Ukwakheka kwayo okuhlangene kunciphisa izidingo zesikhala zekamelo lakho. Ungakwazi ukuyibeka etafuleni ukuze isetshenziswe, okuyenza ibe inketho yezinga lokungena ezinhle kakhulu zokuqalisa ezisebenzelana nemikhiqizo emincane yangokwezifiso.

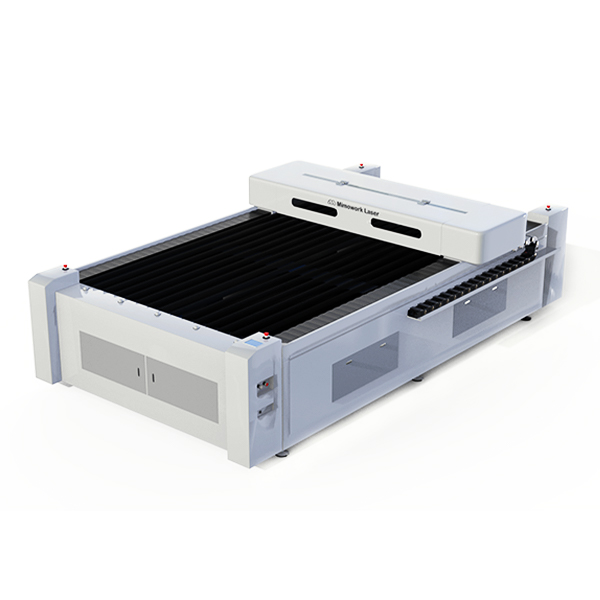

Usayizi Wethebula Lokusebenza:1300mm * 900mm (51.2” * 35.4 ”)

Izinketho zamandla e-Laser:100W/150W/300W

Uhlolojikelele lwe-Flatbed Laser Cutter 130

I-Flatbed Laser Cutter 130 iyisinqumo esithandwa kakhulu sokusika izinkuni. I-front-to-back through-type yayo yetafula lomsebenzi ikwenza ukwazi ukusika amabhodi amade kunendawo yokusebenza. Ngaphezu kwalokho, inikeza ukuguquguquka ngokufaka amashubhu e-laser anoma yisiphi isilinganiso samandla ukuze kuhlangatshezwane nezidingo zokusika izinkuni ezinobukhulu obuhlukahlukene.

Usayizi Wethebula Lokusebenza:1300mm * 2500mm (51.2” * 98.4”)

Izinketho zamandla e-Laser:150W/300W/500W

Uhlolojikelele lwe-Flatbed Laser Cutter 130L

I-Flatbed Laser Cutter 130L ingumshini onefomethi enkulu. Ilungele ukusika amabhodi amakhulu okhuni, njengamabhodi avame ukutholakala 4ft x 8ft emakethe. Ibhekelela kakhulu imikhiqizo emikhulu, okwenza kube ukukhetha okuthandwayo ezimbonini ezifana nokukhangisa nefenisha.

Ingabe ufuna ukuqala i-Laser Cutting / Laser Engraving Business yakho?

▶I-Sidenote: Ngaphandle izinkuni, materials likeipulangwefuthiAmapaneli e-MDFnazo zivame ukusetshenziswa embonini.

Isikhathi sokuthumela: Oct-18-2023