Ukugcina umshini wakho wokusika i-laser kubalulekile, kungakhathaliseki ukuthi usuvele usebenzisa owodwa noma ucabanga ngokubeka izandla zakho komunye.

Akukhona nje ngokugcina umshini usebenza; kumayelana nokuzuza lokho kusikeka okuhlanzekile nokuqoshwa okubukhali okufisayo, ukuqinisekisa ukuthi umshini wakho usebenza njengephupho nsuku zonke.

Kungakhathaliseki ukuthi udala imiklamo enemininingwane noma ubhekana namaphrojekthi amakhulu, ukunakekelwa okufanele kwe-laser cutter yakho kuwusoso oyimfihlo wokuthola imiphumela ephezulu.

Kulesi sihloko, sizogxila kumishini yokusika nokuqopha i-CO2 laser, ukwabelana ngamathiphu nezindlela zokulungisa eziwusizo.

Izinto zokuqala kuqala: umshini ohlanzekile ungumshini Osebenzayo!

Cabanga ngelensi ye-laser cutter yakho nezibuko njengamehlo ayo. Uma zingcolile, ukusikeka kwakho ngeke kucace. Uthuli, imfucumfucu, nezinsalela kuvame ukunqwabelana kulezi zindawo, ezingangcolisa ngempela ukunemba kwakho kokusika.

Ukuze ugcine yonke into isebenza kahle, kwenze kube umkhuba ukuhlanza ilensi nezibuko njalo. Ngithembe, umshini wakho uzokubonga!

Indlela yokuhlanza i-lens yakho nezibuko? Izinyathelo ezintathu yilezi ezilandelayo:

Hlukanisa:Khumula izibuko bese uhlukanisa amakhanda e-laser ukuze ususe i-lens ngobumnene. Beka yonke into engutsheni ethambile, engena-lint.

Lungiselela Amathuluzi Akho:Thatha ithiphu ye-Q bese uyicwilisa kusixazululo sokuhlanza ilensi. Ukuhlanza njalo, amanzi ahlanzekile asebenza kahle, kodwa uma ubhekene nothuli olunenkani, isisombululo esisekelwe etshwaleni siwukubheja kwakho okuhle kakhulu.

Sula Phansi:Sebenzisa ngokucophelela ithiphu le-Q ukuze uhlanze indawo engaphezulu yelensi nezibuko. Ithiphu elisheshayo: gcina iminwe yakho kude namalensi—thinta imiphetho kuphela!

Futhi khumbula, uma izibuko zakho noma ilensi yonakele noma igugile,kungcono ukuthi esikhundleni sazo ufake ezintsha. Umshini wakho ufanelwe okungcono kakhulu!

Isifundo Sevidiyo: Uyihlanza Kanjani Futhi Ufake I-Laser Lens?

Uma kuziwa etafuleni lakho lokusika i-laser nendawo yokusebenza, ukuzigcina zingenabala ngemva komsebenzi ngamunye kubalulekile.

Ukusula izinto ezisele kanye nemfucumfucu kuqinisekisa ukuthi akukho lutho oluphazamisa i-laser beam, okuvumela ukusikeka okuhlanzekile, okunembayo njalo.

Ungakhohlwa mayelana nohlelo lokungenisa umoya, noma! Qiniseka ukuthi uhlanza lezo zihlungi namapayipi ukuze ugcine umoya ugeleza kanye nentuthu kude.

Ithiphu Kaseyili Ebushelelezi:Ukuhlola okuvamile kungase kuzwakale njengokuhlupheka, kodwa kukhokha isikhathi esiningi. Ukuhlola okusheshayo emshinini wakho kungasiza ukubamba izinkinga ezincane ngaphambi kokuba zibe yikhanda elibuhlungu emgwaqeni!

2. Ukugcinwa Kwesistimu Yokupholisa

Manje, ake sixoxe ngokugcina izinto zipholile—ngokoqobo!

I-water chiller ibalulekile ukuze ugcine ishubhu yakho yelaser isezingeni lokushisa elifanele.

Ukuhlola njalo izinga lamanzi kanye nekhwalithi kubalulekile.

Njalo khetha amanzi acwengekile ukuze ugweme amadiphozithi amaminerali ayingozi, futhi ungakhohlwa ukushintsha amanzi ngezikhathi ezithile ukuze uvimbele ulwelwe ukuthi lungangeni.

Njengomthetho ojwayelekile, kuwumqondo omuhle ukushintsha amanzi ku-chiller njalo ezinyangeni ezi-3 kuya kweziyisi-6.

Kodwa-ke, lo mugqa wesikhathi ungashintsha ngokuya ngekhwalithi yakho yamanzi nokuthi uwusebenzisa kangaki umshini wakho. Uma amanzi eqala ukubukeka engcolile noma enamafu, qhubeka futhi uwashintshe ngokushesha!

Ukukhathazeka Kwasebusika? Hhayi ngalawa Amathiphu!

Lapho izinga lokushisa lehla, kanjalo nengozi yokubanda kwakho kwamanzi iyancipha.Ukwengeza i-antifreeze ku-chiller kungayivikela ngalezo zinyanga ezibandayo.Vele uqiniseke ukuthi usebenzisa uhlobo olulungile lwe-antifreeze futhi ulandele imiyalelo yomkhiqizi ngesilinganiso esifanele.

Uma ufuna ukwazi mayelana nendlela yokwengeza i-antifreeze ku-chiller yamanzi ukuze uvikele umshini wakho emakhazeni. Bheka umhlahlandlela:Amathiphu ama-3 okuvikela umshini wakho wokuthobisa amanzi kanye nomshini we-laser

Futhi ungakhohlwa: ukugeleza kwamanzi okungaguquki kubalulekile. Qiniseka ukuthi iphampu isebenza kahle nokuthi akukho okuvimbekile. Ishubhu ye-laser eshisiwe ngokweqile ingaholela ekulungiseni okubizayo, ngakho ukunaka okuncane lapha kuhamba ibanga elide.

3. I-Laser Tube Maintenance

Ishubhu yakho ye-laser iyinhliziyo yomshini wakho wokusika i-laser.

Ukugcina ukuhleleka kwayo nokusebenza kahle kubalulekile ekuqinisekiseni amandla okusika nokunemba.

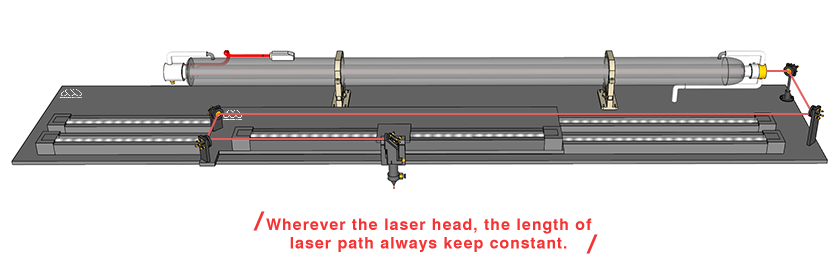

Kwenze umkhuba ukuhlola njalo ukuqondanisa.

Uma ubona noma yiziphi izimpawu zokungaqondani kahle—njengokusikeka okungahambisani noma ukuncishiswa kokuqina kwe-beam—qiniseka ukuthi ulungisa kabusha ishubhu ulandela imihlahlandlela yomkhiqizi.

Ukugcina konke kumugqa kuzogcina ukusikeka kwakho kubukhali!

Ithiphu ye-Pro: Ungaphusheli umshini wakho emikhawulweni yawo!

Ukusebenzisa i-laser ngamandla amakhulu isikhathi eside kunganciphisa impilo yeshubhu yakho. Kunalokho, lungisa izilungiselelo zamandla ngokuya ngezinto ozisikayo.

I-tube yakho izoyithokozela, futhi uzojabulela umshini ohlala isikhathi eside!

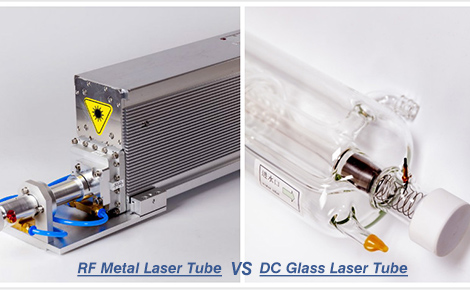

Kunezinhlobo ezimbili zamashubhu laser laser CO2: RF laser amashubhu kanye glass laser amashubhu.

I-RF Laser Tubes:

>> Amayunithi avaliwe adinga ukulungiswa okuncane.

>> Ivamise ukuhlala phakathi kwamahora angu-20,000 kuya kwangu-50,000 wokusebenza.

>> Imikhiqizo ephezulu ihlanganisa i-Coherent ne-Synrad.

Amashubhu e-Glass Laser:

>> Okuvame ukusetshenziswa futhi kuphathwe njengezimpahla ezidliwayo.

>> Ngokujwayelekile zidinga ukushintshwa njalo eminyakeni emibili.

>> Isilinganiso sempilo yesevisi singamahora angu-3,000, kodwa amashubhu asezingeni eliphansi angahlala amahora angu-1,000 kuya kwangu-2,000 kuphela.

>> Imikhiqizo ethembekile ihlanganisa i-RECI, i-Yongli Laser, ne-SPT Laser.

Lapho ukhetha umshini wokusika i-laser, thintana nochwepheshe babo ukuze uqonde izinhlobo zamashubhu e-laser abawanikezayo!

Uma ungaqiniseki ngokuthi ungawakhetha kanjani amashubhu e-laser omshini wakho, kungani kungenjalokhuluma nochwepheshe bethu be-laserukuba nengxoxo ejulile?

Xoxa Nethimba Lethu

I-MimoWork Laser

(Umkhiqizi womshini we-laser ochwepheshe)

4. Amathiphu Okugcina Ubusika

Ubusika bungaba nzima emshinini wakho, kodwa ngezinyathelo ezimbalwa ezengeziwe, ungawugcina usebenza kahle.

Uma i-laser cutter yakho isendaweni engashisi, cabanga ukuyiyisa endaweni efudumele.Amazinga okushisa abandayo angathinta ukusebenza kwezingxenye ze-elekthronikhi futhi aholele ekujikeni ngaphakathi komshini.Liyini izinga lokushisa elifanele lomshini we-laser?Bheka ikhasi ukuze uthole okwengeziwe.

Isiqalo Esifudumele:Ngaphambi kokusika, vumela umshini wakho ukuthi ufudumale. Lokhu kuvimbela ukuminyanisa ukuthi kungakheki kumalensi nasezibukweni, okungase kuphazamise umsebe we-laser.

Ngemuva kokuthi umshini usufudumala, wuhlole ukuthi awukho yini izimpawu zokufingqa. Uma ubona noma iyiphi, inike isikhathi sokuhwamuka ngaphambi kokuyisebenzisa. Sithembe, ukugwema ukujiya kuyisihluthulelo sokuvimbela ukuhamba kancane kanye nomunye umonakalo.

5. Ukugcotshwa Kwezingxenye Ezinyakazayo

Gcina izinto zihamba kahle ngokugcoba njalo ama-rails nama-bearings. Lezi zingxenye zibalulekile ukuze uvumele ikhanda le-laser ukuthi lintweza kalula kuyo yonke into.

Nakhu okumele ukwenze:

1. Faka I-Lubricant Ekhanyayo:Sebenzisa uwoyela womshini olula noma okokugcoba ukuvimbela ukugqwala nokuqinisekisa ukunyakaza koketshezi.

2. Sula Ukweqile:Ngemva kokufaka isicelo, qiniseka ukuthi usula noma yikuphi okokugcoba okweqile. Lokhu kusiza ukuvimbela uthuli nemfucumfucu ukuthi inganqwabelana.

3. Ukugcinwa njaloizogcina umshini wakho usebenza kahle futhi andise ubude bayo bempilo!

Shayela Amabhande, Futhi!Amabhande okushayela adlala indima ebalulekile ekuqinisekiseni ukuthi ikhanda le-laser lihamba ngokunembile. Zihlole njalo ukubona izimpawu zokuguga noma ukuxega, futhi uziqinise noma uzishintshe njengoba kudingeka.

Ukuxhunywa kukagesi emshinini wakho kufana nesistimu yayo yezinzwa.

1. Ukuhlola Njalo

>> Hlola Ukugqokwa: Bheka noma yiziphi izimpawu zokuguga, ukugqwala, noma ukuxega okuxhumekile.

>> Qinisa bese Ufaka Faka esikhundleni: Qinisa noma yikuphi ukuxhumana okuxekethile bese ubuyisela izintambo ezilimele ukuze ugcine yonke into isebenza kahle.

2. Hlala Uvuselelwe!

Ungakhohlwa ukugcina isofthiwe yomshini wakho kanye ne-firmware kusesikhathini samanje. Izibuyekezo ezivamile ngokuvamile zihlanganisa:

>> Ukuthuthukiswa Kokusebenza: Ukuthuthukiswa kokusebenza kahle.

>> Ukulungisa Iziphazamisi: Izixazululo ezindabeni ezikhona.

>> Izici Ezintsha: Amathuluzi angenza kube lula ukuhamba kwakho komsebenzi.

Ukuhlala njengamanje kuqinisekisa ukuhambisana okungcono nezinto ezintsha nemiklamo, okwenza umshini wakho usebenze kahle kakhulu!

Okokugcina, ukulinganisa okuvamile kuyisihluthulelo sokugcina ukunemba kokusika.

1. Nini Ukulinganisa Kabusha

>> Izinto Ezintsha: Ngaso sonke isikhathi uma ushintshela kokunye okuhlukile.

>> Ukwehla Kwekhwalithi: Uma ubona ukwehla kwekhwalithi yokusika, yisikhathi sokulungisa amapharamitha wokusika womshini wakho—njengejubane, amandla, nokugxila.

2. Shuna Kahle Ukuze Uphumelele

>> Lungisa Ilensi Yokugxila: Ukulungisa kahle lens yokugxila kuqinisekisa ukuthi i-laser beam ibukhali futhi igxile ngokunembile endaweni ebonakalayo.

>> Thola Ubude Bendawo: Thola ubude bokugxila obulungile bese ukala ibanga ukusuka ekugxilweni kuye endaweni ebonakalayo. Ibanga elifanele libalulekile ekusikeni nasekuqopheni ikhwalithi efanele.

Uma ungaqiniseki ngokugxila kwe-laser noma ukuthi ungathola kanjani ubude bokugxila obufanele, qiniseka ukuthi uhlola ividiyo engezansi!

Isifundo Sevidiyo: Ungabuthola Kanjani Ubude Bendawo Elungile?

Ukuze uthole izinyathelo ezinemininingwane yokusebenza, sicela uhlole ikhasi ukuze uthole okwengeziwe:I-CO2 Laser Lens Guide

Isiphetho: Umshini Wakho Ufanelwe Okungcono Kakhulu

Ngokulandela lawa macebiso okunakekela, awugcini nje ukwandisa impilo yomshini wakho wokusika i-CO2 laser—uqinisekisa nokuthi yonke iphrojekthi ihlangabezana nezindinganiso eziphakeme kakhulu zekhwalithi.

Ukunakekelwa okufanele kunciphisa isikhathi sokuphumula, kunciphisa izindleko zokulungisa, futhi kukhulisa umkhiqizo. Futhi khumbula, ubusika bubiza ukunakekelwa okukhethekile, njengokuthiukwengeza i-antifreeze ku-chiller yakho yamanzifuthi ufudumale umshini wakho ngaphambi kokuwusebenzisa.

Usulungele Okwengeziwe?

Uma ufuna abasiki be-laser be-top-notch nabaqophi, siyakumboza.

I-Mimowork inikeza uhla lwemishini eyenzelwe izinhlelo zokusebenza ezahlukahlukene:

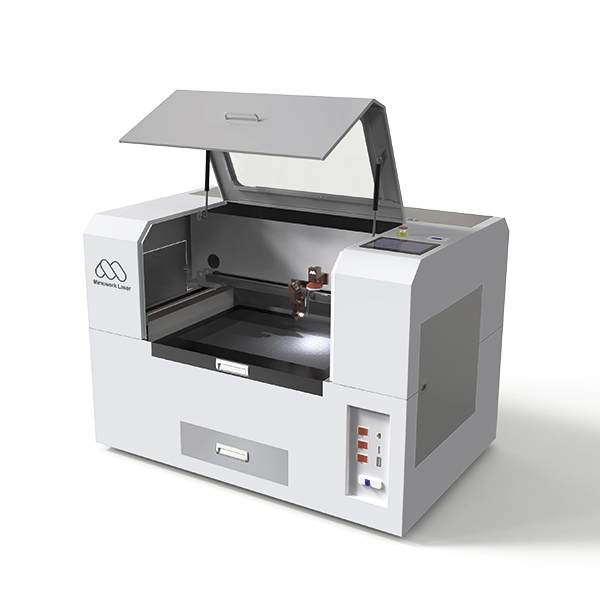

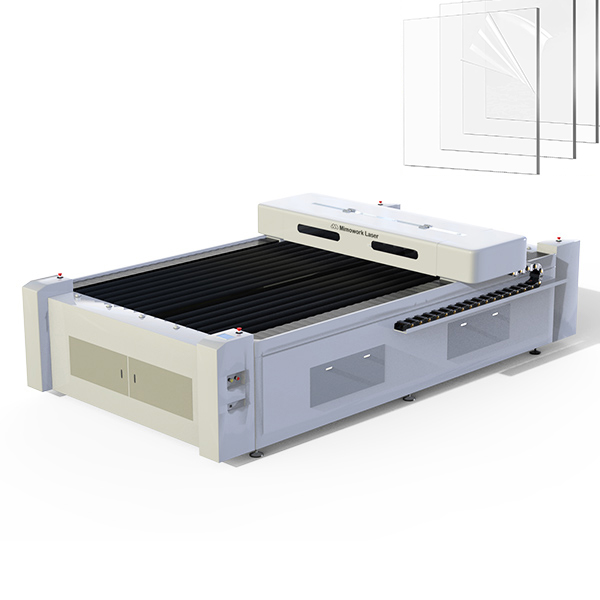

• I-Laser Cutter ne-Engraver ye-Acrylic & Wood:

Ilungele leyo miklamo eqoshiwe eyinkimbinkimbi kanye nokusikeka okunembile kuzo zombili izinto zokwakha.

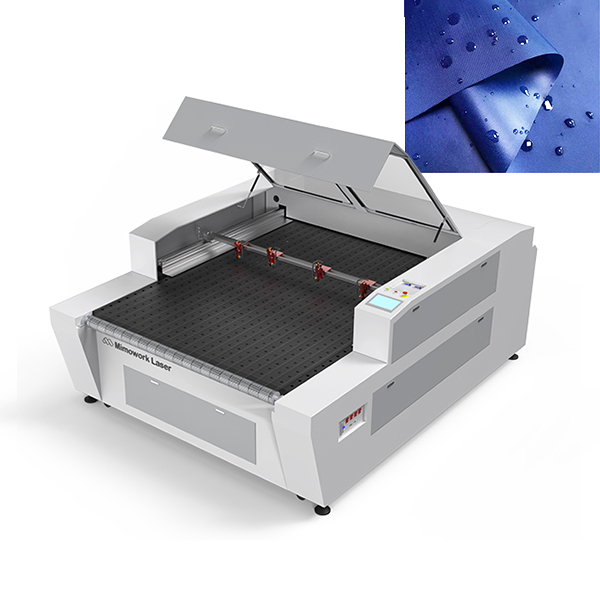

• Umshini Wokusika I-Laser Wendwangu Nesikhumba:

I-automation ephezulu, ilungele labo abasebenza ngezindwangu, eqinisekisa ukusikeka okubushelelezi, okuhlanzekile ngaso sonke isikhathi.

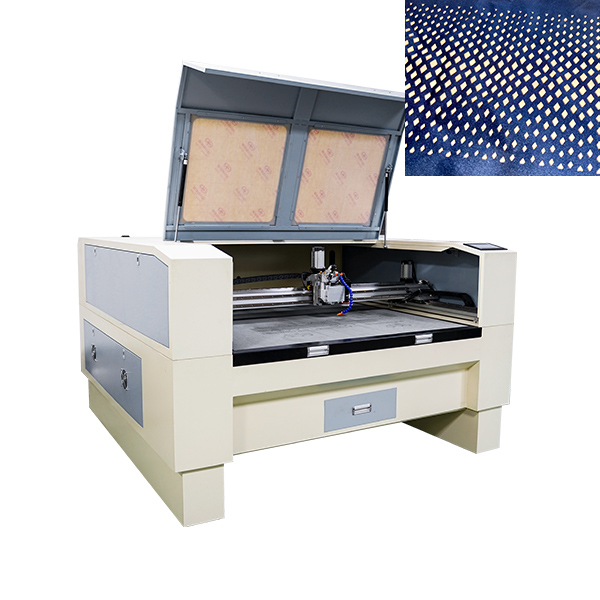

• Umshini Wokumaka we-Galvo Laser Wephepha, Idenim, Isikhumba:

Kuyashesha, kuyashesha, futhi kuphelele ekukhiqizeni ivolumu ephezulu ngemininingwane eqoshiwe yangokwezifiso kanye nezimpawu.

Funda kabanzi mayelana nomshini wokusika i-laser, umshini wokuqopha i-laser

Bheka Eqoqweni Lomshini Wethu

Singobani?

I-Mimowork ingumkhiqizi we-laser ogxile emiphumeleni, ozinze e-Shanghai nase-Dongguan, e-China. Ngaphezu kweminyaka engama-20 yobungcweti bokusebenza obujulile, sisebenza ngokukhethekile ekukhiqizeni amasistimu e-laser futhi sinikeza izixazululo eziphelele zokucubungula nokukhiqiza emabhizinisini amancane naphakathi nendawo (ama-SME) ezimbonini eziningi ezihlukahlukene.

Ulwazi lwethu olubanzi ekuxazululeni izixazululo ze-laser kokubili kokucutshungulwa kwezinto ezinsimbi nezingezona ezensimbi kusenze abalingani abathenjwayo emhlabeni wonke, ikakhulukazi emikhakheni yezokukhangisa, ezezimoto nezondiza, i-metalware, izicelo ze-sublimation kadayi, indwangu, nemboni yezindwangu.

Ngokungafani nabanye abaningi, silawula zonke izingxenye zochungechunge lokukhiqiza, siqinisekisa ukuthi imikhiqizo yethu iletha ukusebenza okuhle kakhulu ngokungaguquki. Kungani uvumela noma yini encane uma ungathembela esixazululweni esenziwe ngochwepheshe abaqonda izidingo zakho?

Ungase Unentshisekelo

Eminye Imibono Yamavidiyo >>

Uyigcina Kanjani Futhi Ufake Ishubhu Laser?

Indlela yokukhetha i-Laser Cutting Table?

Isebenza kanjani i-Laser Cutter?

SinguMkhiqizi Womshini Wokusika I-Laser Ochwepheshe,

Yini Okukukhathazayo, Siyakukhathalela!

Isikhathi sokuthumela: Aug-30-2024