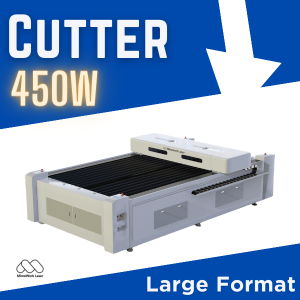

I-CO2 Laser Cutting Machine ye-Acrylic Sheet

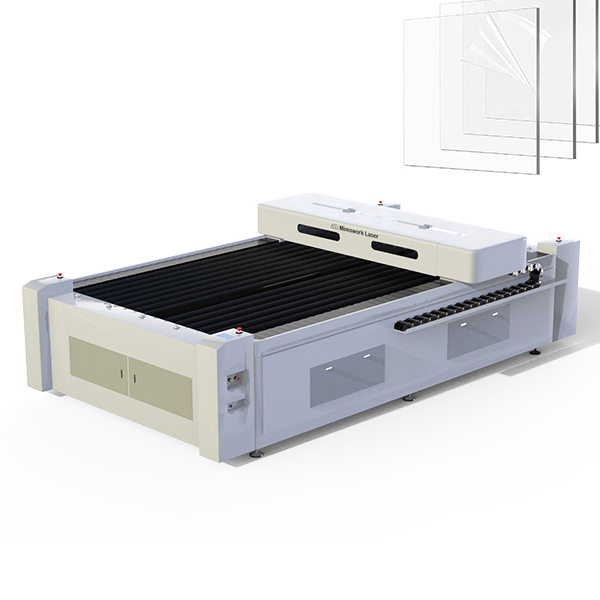

▶ acrylic sheet laser cutting machine

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W * L) | 1300mm * 2500mm (51” * 98.4”) |

| Isoftware | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 150W/300W/450W |

| Umthombo we-Laser | CO2 Glass Laser Tube |

| IMechanical Control System | I-Ball Screw ne-Servo Motor Drive |

| Ithebula Lokusebenza | I-Knife Blade noma Ithebula Lokusebenza Lekhekheba Lezinyosi |

| Isivinini esikhulu | 1~600mm/s |

| Isivinini Sokusheshisa | 1000~3000mm/s2 |

| Ukunemba Kwesikhundla | ≤±0.05mm |

| Usayizi Womshini | 3800 * 1960 * 1210mm |

| I-Voltage yokusebenza | AC110-220V±10%,50-60HZ |

| Imodi Yokupholisa | Uhlelo Lokupholisa Amanzi Nokuvikela |

| Indawo Yokusebenzela | Izinga lokushisa:0—45℃ Ukuswakama:5%—95% |

| Usayizi Wephakheji | 3850 * 2050 * 1270mm |

| Isisindo | 1000kg |

▷Izici ze-1325 Laser Cutter

Ukugxuma Okukhulu Ekukhiqizeni

◾ Ikhwalithi Ezinzile Nenhle Kakhulu Yokusika

I-Constant Optical Path Design

Ngobude bendlela ye-optical ephumayo efanele, i-laser beam engaguquki kunoma iyiphi indawo ebangeni letafula lokusika ingaholela ekusikeni okulinganayo kuyo yonke into, kungakhathaliseki ukuthi ugqinsi lungakanani. Ngenxa yalokho, ungathola umphumela ongcono wokusika we-acrylic noma ukhuni kunendlela ye-laser endizayo uhhafu.

◾ Ukusebenza Okuphezulu Nokunemba

Uhlelo Lokudlulisa Olusebenzayo

Imojuli yesikulufu sokunemba kwe-X-axis, isikulufu sebhola se-Y-axis unilateral sinikeza ukuzinza nokunemba okuhle kakhulu kokuhamba ngesivinini esiphezulu kwe-gantry. Ihlanganiswe ne-servo motor, uhlelo lokudlulisela ludala ukusebenza kahle kokukhiqiza okuphezulu.

◾ Impilo Eqinile Neyinde Yesevisi

Isakhiwo esiqinile semishini

Umzimba womshini ushiselwe ngeshubhu lesikwele esingu-100mm futhi uyaguga ngokudlidliza kanye nokwelashwa kokuguga kwemvelo. I-Gantry kanye nekhanda lokusika lisebenzisa i-aluminium ehlanganisiwe. Ukucushwa kukonke kuqinisekisa isimo sokusebenza esizinzile.

◾ High Speed Processing

Isivinini esikhulu sokusika nokuqopha

I-laser cutter yethu engu-1300*2500mm ingafinyelela isivinini sokuqopha esingu-1-60,000mm/min kanye nesivinini sokusika esingu-1-36,000mm/min.

Ngesikhathi esifanayo, ukunemba kwesikhundla nakho kuqinisekisiwe ngaphakathi kuka-0.05mm, ukuze ikwazi ukusika futhi iqophe izinombolo noma izinhlamvu ezingu-1x1mm, akunankinga nhlobo.

DIY amaphrojekthi akho e-acrylic laser cut

Amandla Amakhulu: I-Acrylic Laser Cutter Enkulu

Izimpawu Ezinkulu | Indlela yokusika Ishidi le-Acrylic Laser?

Umshini wethu wokusika i-laser ongu-300W unesakhiwo sokudlulisa esizinzile - igiya & iphinikhodi kanye nedivayisi yokushayela enembe kakhulu ye-servo motor, eqinisekisa yonke i-plexiglass yokusika i-laser enekhwalithi ephezulu eqhubekayo nokusebenza kahle. Sinamandla aphezulu angu-150W, 300W, 450W, 600W ebhizinisi lakho le-laser cutting machine acrylic sheet.

Yimuphi Usayizi Weshidi Lakho Le-Acrylic?

Sazise izidingo zakho futhi sikunikeze iseluleko!

I-Acrylic Eminyene | I-Laser Cut Acrylic Board

Ishidi le-acrylic eliwugqinsi kusuka ku-10mm kuya ku-30mmingasikwa i-laser nge-Flatbed Laser Cutter 130250 ngamandla we-laser ozikhethela (150W, 300W, 500W).

Ezinye izinto ezicatshangelwayo ngesikhathi sokusika:

1. Lungisa i-air assist ukuze wehlise ukushaywa komoya nokucindezela ukuqinisekisa ukuthi i-acrylic ingaphola kancane

2. Khetha ilensi efanele: Uma i-material ijiya, ubude belensi buba bude

3. Amandla e-laser aphakeme anconyelwa i-acrylic ewugqinsi (icala ngalinye ngezidingo ezahlukahlukene)

Thola amavidiyo amaningi mayelana nama-laser cutters ethuIgalari Yamavidiyo

I-Laser Cutting Acrylic: Isivinini

Uma kuziwa ekusikeni i-acrylic, indlela ephumelela kakhulu ngokuvamile ihilela ukusebenzisa isivinini sokusika esihamba kancane esihlanganiswe namandla aphezulu e-laser. Le nqubo ethile yokusika yenza i-laser beam ukuthi incibilike imiphetho ye-acrylic, okuholela kulokho okungachazwa njengonqenqema olupholishelwe ilangabi.

I-Laser Cutting Acrylic: Ishadi Lejubane

Emakethe yanamuhla, abakhiqizi abaningi be-acrylic bahlinzeka ngezinhlobonhlobo zezinhlobo zama-acrylic, okuhlanganisa kokubili okuhlukile kwe-cast kanye ne-extruded, etholakala ngemibala ehlukahlukene, ukwakheka, namaphethini. Ngohlu oluhlukahlukene kangaka lwezinketho, akumangazi ukuthi i-acrylic isibe yisinqumo esithandwa kakhulu sokusika nokuqoshwa kwe-laser. Ukuguquguquka nokuhlukahluka kwe-acrylic kuyenza ibe yinto ethandwayo yamaphrojekthi e-laser okudala.

Nawa Amanye Amathiphu Okucubungula I-Laser Okujwayelekile Okusebenza nge-Acrylic:

1. Ukugada Kungukhiye:

Ungalokothi ushiye umshini wakho we-laser ungagadiwe lapho usebenza nge-acrylic. Nakuba izinto eziningi zingase zibe lula ekuthungeleni, i-acrylic, ngazo zonke izinhlobo zayo ezihlukahlukene, ibonise ubungozi obuphezulu bokuvutha lapho isikwa nge-laser. Njengomthetho oyisisekelo wokuphepha, ungawusebenzisi umshini wakho we-laser - kungakhathaliseki ukuthi usetshenziswa yiphi impahla - ngaphandle kwakho.

2. Khetha i-Acrylic Elungile:

Khetha uhlobo olufanele lwe-acrylic kuhlelo lwakho lokusebenza oluthile. Khumbula ukuthi i-acrylic eyi-cast ifaneleka kangcono imisebenzi yokuqopha, kuyilapho i-acrylic ekhishwe ifaneleka kakhulu ngezinjongo zokusika i-laser.

3. Phakamisa i-Acrylic:

Ukuze unciphise ukubonakala kwengemuva futhi uthuthukise ikhwalithi yokusika, cabanga ukuphakamisa i-acrylic ngaphezu kwendawo yetafula lokusika. Izinsiza ezifana ne-Epilog's Pin Table noma ezinye izinhlelo zokusekela zingasetshenziselwa le njongo.

Ukuqedwa kwe-Acrylic of laser cutting

• Izibonisi Zokukhangisa

• Imodeli Yezakhiwo

• Ubakaki

• Ilogo Yenkampani

• Ifenisha Yesimanje

• Izincwadi

• Amabhodi okukhangisa angaphandle

• Isitendi Somkhiqizo

• Ukuthenga ezitolo

• Izimpawu Zomdayisi

• Indondo

(Amacici e-acrylic laser cut, izimpawu ze-acrylic laser cut, ubucwebe be-acrylic laser cut, izinhlamvu ze-acrylic laser cut…)

Thuthukisa Izinketho ze-Laser ongakhetha kuzo

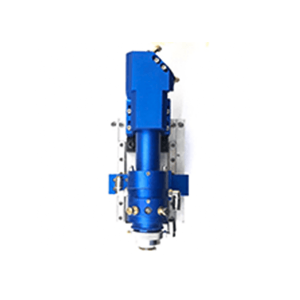

I-Mix Laser Head

I-Auto Focus

IIkhamera ye-CCDingabona futhi ibeke iphethini ku-acrylic ephrintiwe, isize i-laser cutter ukuthi ibone ukusika okunembile ngekhwalithi ephezulu. Noma yimuphi umdwebo owenziwe ngezifiso ophrintiwe ungacutshungulwa kalula ngohlaka ngesistimu yokubona, ubambe iqhaza elibalulekile kwezokukhangisa nakweminye imboni.

Okuhlobene Acrylic Sheet Laser Cutter

ukusika i-acrylic ne-laser yokhuni

• Ukuqoshwa okusheshayo nokunembayo kwezinto eziqinile

• Idizayini yokungena yezindlela ezimbili ivumela izinto ezinde kakhulu ezibekwe futhi zisikwe

nge-acrylic ne-laser yokhuni eqoshiwe

• Idizayini elula futhi ehlangene

• Kulula ukusebenza kwabaqalayo