I-Laser cutting acrylic inikeza indlela ephephile, ephumelelayo, nenembayo yokwenza imikhiqizo nemiklamo ehlukahlukene.Lo mhlahlandlela uhlolisisa ngokujulile izimiso, izinzuzo, izinselele, namasu asebenzayo we-laser cutting acrylic, esebenza njengesisetshenziswa esibalulekile sabaqalayo kanye nochwepheshe ngokufanayo.

Okuqukethwe

1. Isingeniso Se-Laser Cutting Of Acrylic

Yini ukusika i-acrylic

nge laser?

Ukusika i-acrylic nge-laserkuhilela ukusebenzisa i-laser enamandla amakhulu, eqondiswa ifayela le-CAD, ukusika noma ukuqopha imiklamo ethile ezintweni ze-acrylic.

Ngokungafani nezindlela zendabuko ezifana nokubhola noma ukusaha, le nqubo incike kubuchwepheshe be-laser obunembayo ukuze buhwamulise izinto ngokuhlanzekile nangempumelelo, kuncishiswe imfucuza kanye nokuletha imiphumela ephezulu.

Le ndlela ifaneleka ikakhulukazi ezimbonini ezifuna ukunemba okuphezulu, imininingwane eyinkimbinkimbi, kanye nokuphumayo okungaguquki, okwenza kube ukukhetha okuthandwayo kunezindlela ezijwayelekile zokusika.

▶ Kungani usike i-acrylic nge-laser?

Ubuchwepheshe be-Laser bunikeza izinzuzo ezingenakuqhathaniswa zokusika i-acrylic:

•Imiphetho ebushelelezi:Ikhiqiza imiphetho epholishwe ngamalangabi ku-acrylic extruded, inciphisa izidingo zangemuva kokucubungula.

•Izinketho Zokuqopha:Idala imibhalo eqoshiwe emhlophe eqhwele ku-acrylic ekhonjiwe yezinhlelo zokusebenza zokuhlobisa nezisebenzayo.

•Ukunemba Nokuphindaphinda:Iqinisekisa imiphumela efanayo yemiklamo eyinkimbinkimbi.

•Ukuhlukahluka:Ifanele kokubili amaphrojekthi ngokwezifiso asezingeni elincane kanye nokukhiqizwa ngobuningi.

I-LED Acrylic Stand White

▶ Izicelo Zomshini Wokusika we-Acrylic Laser

I-Laser-cut acrylic inezinhlobonhlobo zezinhlelo zokusebenza emikhakheni eminingi:

✔ Ukukhangisa:Izimpawu zangokwezifiso, amalogo akhanyayo, nezibonisi zokuphromotha.

✔ Architecture:Amamodeli wokwakha, amaphaneli okuhlobisa, nama-partitions asobala.

✔ Ezezimoto:Izingxenye zedeshibhodi, izembozo zamalambu, nama-windshields.

✔ Izinto Zasekhaya:Abahleli bekhishi, ama-coasters, nama-aquariums.

✔ Imiklomelo nokuhlonishwa:Ama-Trophies nama-plaque anemidwebo yomuntu siqu.

✔ Ubucwebe:Amacici anembe kakhulu, imihlobiso elengayo, nama-brooches.

✔ Ukupakishwa:Amabhokisi neziqukathi ezihlala isikhathi eside futhi ezijabulisa ngobuhle.

>> Bheka amavidiyo mayelana nokusika i-acrylic nge-laser

Noma yimiphi imibono mayelana nokusika kwe-laser kwe-acrylic?

▶ CO2 VS Fiber Laser: Iyiphi Efanele Ukusika I-Acrylic

Ukusika i-acrylic,i-CO2 Laser iyisinqumo esingcono kakhulungenxa yempahla yayo yemvelo ye-optical.

Njengoba ubona kuthebula, ama-laser e-CO2 ngokuvamile akhiqiza i-laser egxilile ebangeni elingama-micrometer angu-10.6, elimuncwa kalula i-acrylic. Kodwa-ke, ama-fiber lasers asebenza kubude begagasi obuzungeze i-micrometer engu-1, engamuncwe ngokuphelele ukhuni uma kuqhathaniswa namalaser e-CO2. Ngakho-ke uma ufuna ukusika noma ukumaka ensimbi, i-fiber laser yinhle. Kodwa kulezi ezingezona ezensimbi ezifana nezinkuni, i-acrylic, i-textile, i-CO2 laser cutting effect ayinakuqhathaniswa.

2. Izinzuzo kanye Nebubi Laser Cutting Of Acrylic

▶ Izinzuzo

✔ I-Smooth Cutting Edge:

Amandla e-laser anamandla anganqamula ishidi le-acrylic aqonde ngqo. Ukushisa kuvala futhi kupholishe unqenqema ukuze lushelele futhi luhlanzeke.

✔ Ukusika Okungeyena Othintwayo:

I-Laser cutter ifaka ukucubungula ngaphandle kokuthinta, ukususa ukukhathazeka mayelana nokuklwebheka kwezinto kanye nokuqhekeka ngoba akukho ukucindezela komshini. Asikho isidingo sokushintsha amathuluzi nezingcezu.

✔ Ukunemba okuphezulu:

Ukunemba okuphezulu kakhulu kwenza i-acrylic laser cutter ibe amaphethini ayinkimbinkimbi ngokuya ngefayela eliklanywe. Ifanele ukuhlobisa kwe-acrylic yangokwezifiso kanye nezinsiza zezimboni nezokwelapha.

✔ Isivinini nokusebenza kahle:

Amandla e-laser aqinile, akukho ukucindezeleka komshini, nokulawula okuzenzakalelayo kwedijithali, kwenyusa kakhulu isivinini sokusika kanye nokusebenza kahle konke kokukhiqiza.

✔ Ukuhlukahluka:

Ukusika kwe-laser ye-CO2 kunemisebenzi eminingi ukusika amashidi e-acrylic anobukhulu obuhlukahlukene. Ilungele kokubili izinto ze-acrylic ezincane neziwugqinsi, ezinikeza ukuguquguquka kwezicelo zephrojekthi.

✔ Ukulahlwa Kwezinto Ezincane:

I-beam egxilile ye-CO2 laser inciphisa udoti wezinto ezibonakalayo ngokudala ububanzi be-kerf obuncane. Uma usebenza ngokukhiqiza ngobuningi, isofthiwe ehlakaniphile yokwenza isidleke se-laser ingathuthukisa indlela yokusika, futhi yandise izinga lokusebenzisa impahla.

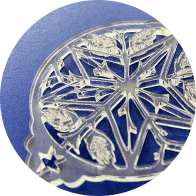

I-Crystal Clear Edge

Eyinkimbinkimbi Cut Iphethini

▶ Okubi

Izithombe Eziqoshiwe Ku-Acrylic

Nakuba izinzuzo zokusika i-acrylic nge-laser ziningi, kubalulekile ukucabangela izithiyo:

Amanani Okukhiqiza Aguquguqukayo:

Izinga lokukhiqiza lapho usika i-acrylic nge-laser ngezinye izikhathi lingase lingahambisani. Izinto ezifana nohlobo lwe-acrylic material, ukujiya kwayo, kanye nemingcele ethile yokusika i-laser idlala indima ekunqumeni ijubane nokufana kokukhiqiza. Lezi zinguquko zingathinta ukusebenza kahle okuphelele kwenqubo, ikakhulukazi emisebenzini emikhulu.

3. Inqubo yokusika i-acrylic nge-laser cutter

I-Laser cutting acrylic iyindlela eqondile nephumelelayo yokwakha imiklamo enemininingwane, kodwa ukuzuza imiphumela emihle kudinga ukuqonda izinto zokwakha kanye nenqubo. Kuye ngohlelo lwe-CNC kanye nezingxenye zomshini ezinembile, umshini wokusika we-laser we-acrylic uzenzakalela futhi kulula ukuwusebenzisa.

Udinga nje ukulayisha ifayela lokuklama kukhompyutha, futhi usethe imingcele ngokuya nezici ezibonakalayo kanye nezidingo zokusika.

Nansi inkomba yesinyathelo ngesinyathelo ehlanganisa ukucatshangelwa okubalulekile kokusebenza ngama-acrylics.

Isinyathelo 1. Lungisa Umshini Ne-Acrylic

Ukulungiswa kwe-Acrylic:gcina i-acrylic flat futhi ihlanzekile phezu kwetafula lokusebenza, futhi kangcono ukuhlola usebenzisa scrap ngaphambi real laser cutting.

Umshini we-Laser:thola usayizi we-acrylic, usayizi wephethini yokusika, nokuqina kwe-acrylic, ukukhetha umshini ofanele.

Isinyathelo 2. Setha Isofthiwe

Ifayela Lokuklama:ngenisa ifayela lokusika ku-software.

Isilungiselelo se-Laser:Khuluma nochwepheshe wethu we-laser ukuze uthole amapharamitha wokusika ajwayelekile. Kepha izinto ezahlukahlukene zinokujiya okuhlukile, ubumsulwa, kanye nokuminyana, ngakho-ke ukuhlola ngaphambili kuyisinqumo esingcono kakhulu.

Isinyathelo sesi-3. I-Laser Cut Acrylic

Qala ukusika i-Laser:I-laser izosika iphethini ngokuzenzakalelayo ngokwendlela enikeziwe. Khumbula ukuvula umoya ukuze ususe intuthu, futhi wehlise umoya ovunguzayo ukuze uqinisekise ukuthi unqenqema lubushelelezi.

Ngokulandela ngokucophelela lezi zinyathelo, ungafinyelela imiphumela enembile, yekhwalithi ephezulu lapho usika i-acrylic laser.

Ukulungiselela okufanele, ukusetha, kanye nezinyathelo zokuphepha kubalulekile empumelelweni, okukwenza ukwazi ukusebenzisa ngokugcwele izinzuzo zalobu buchwepheshe bokusika obuphambili.

Isifundo Sevidiyo: I-Laser Cutting & Engraving Acrylic

4. Izici EzinomthelelaUkusika i-Acrylic Nge-Laser

I-Laser cutting acrylic idinga ukunemba nokuqonda izici ezimbalwa ezithinta ikhwalithi nokusebenza kahle kwenqubo.Ngezansi, sihlolaizici ezibalulekile okufanele uzicabangele lapho usika i-acrylic.

▶ Izilungiselelo Zomshini Wokusika I-Laser

Ukumisa kahle izilungiselelo zomshini wakho wokusika i-laser kubalulekile ukuze uzuze imiphumela emihle.Imishini iza nezici ezihlukahlukene ezilungisekayo.kuthinte inqubo yokusika, kuhlanganise:

1. Amandla

• Umthetho ojwayelekile ukwaba10 watts (W)yamandla we-laser kuwo wonke umuntu1 mmubukhulu be-acrylic.

• Amandla aphezulu aphezulu avumela ukusika ngokushesha kwezinto ezincane futhi anikeze ikhwalithi engcono yokusika yezinto eziwugqinsi.

2. Imvamisa

Ithonya inani le-laser pulses ngomzuzwana, libe nomthelela ekunembeni kokusikwa.Imvamisa ye-laser elungile incike ohlotsheni lwe-acrylic kanye nekhwalithi yokusika efiswayo:

• I-Acrylic ye-Cast:Sebenzisa amafrikhwensi aphezulu(20–25 kHz)emiphethweni epholishe ngamalangabi.

• I-Acrylic Enwetshiwe:Amafrikhwensi aphansi(2–5 kHz)sebenza kangcono ukusikeka okuhlanzekile.

3.Isivinini

Ijubane elifanele liyahlukahluka ngokusekelwe kumandla e-laser nogqinsi lwempahla.Isivinini esisheshayo sinciphisa isikhathi sokusika kodwa singase sibeke engozini ukunemba kwezinto eziwugqinsi.

Amathebula achaza isivinini esikhulu nesilungile samaleveli wamandla ahlukene nogqinsi angasebenza njengezinkomba eziwusizo.

Ithebula 1: Ishadi lezilungiselelo ze-CO₂ Laser Cutting for Maximum Speed

Ikhredithi Yethebula:https://artizono.com/

Ithebula 2: Ishadi lezilungiselelo zokusika i-CO₂ Laser lesivinini esikhulu

Ikhredithi Yethebula:https://artizono.com/

▶Ubukhulu be-Acrylic

Ubukhulu beshidi le-acrylic buthinta ngokuqondile amandla e-laser adingekayo.Amashidi aminyene adinga amandla engeziwe ukuze athole ukusikwa okuhlanzekile.

• Njengomhlahlandlela ojwayelekile, cishe10 watts (W)kwamandla we-laser ayadingeka kuwo wonke umuntu1 mmubukhulu be-acrylic.

• Ngezinto ezisetshenziswayo ezizacile, ungasebenzisa izilungiselelo zamandla aphansi kanye nesivinini esinesivinini sokuqinisekisa ukufaka amandla anele okusika.

• Uma amandla ephansi kakhulu futhi engakwazi ukunxeshezelwa ngokunciphisa isivinini, ikhwalithi yokusika ingase yehlele izidingo zohlelo lokusebenza.

Ukuthuthukisa izilungiselelo zamandla ngokuya ngokujiya kwezinto kubalulekile ukuze uthole ukusikeka okubushelelezi, kwekhwalithi ephezulu.

Ngokucabangela lezi zici—izilungiselelo zomshini, isivinini, amandla, nokujiya kwezinto-Ungathuthukisa ukusebenza kahle nokunemba kokusika kwe-acrylic laser. Isici ngasinye sidlala indima ebalulekile ekuqinisekiseni impumelelo yephrojekthi yakho.

5. Kunconywa umshini wokusika we-Acrylic Laser

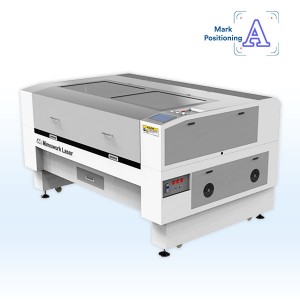

I-MimoWork Laser Series

▶ Izinhlobo ezidumile ze-Acrylic Laser Cutter

I-Acrylic Laser Cutter Ephrintiwe: Ukudala Okunamandla, Okushisiwe

Ukuze kuhlangatshezwane nezidingo zokusika i-acrylic ephrintiwe yi-UV, i-acrylic enephethini, iMimoWork idizayine umsiki we-laser we-acrylic ochwepheshile.Ifakwe ikhamera ye-CCD, ikhamera ye-laser cutter ingakwazi ukubona ngokunembile indawo yephethini futhi iqondise ikhanda le-laser ukuze lisike eduze kwekhonta ephrintiwe. Ikhamera ye-CCD laser cutter ilusizo olukhulu lwe-laser cut acrylic ephrintiwe, ikakhulukazi ngokusekelwa kwetafula lokusika le-laser ye-honey-comb, umklamo womshini wokudlula. Ukusuka Ezisekelweni Zokusebenza Ezenzeka Ngokwezifiso kuye Ezobuciko Obunhle Kakhulu, Umsiki Wethu We-Laser Cutting-Edge Weqa Imingcele. Iklanyelwe Ngokukhethekile Imboni Yezimpawu, imihlobiso, imisebenzi yezandla nezipho, Sebenzisa Amandla Obuchwepheshe Bekhamera Ye-CCD Ethuthukisiwe Ukusika Ngokuphelele Iphethini Ephrintiwe Ye-Acrylic. Ngokudluliswa kwe-Ball Screw Transmission kanye Nezinketho Zezimoto Ze-Servo Ezinemba Kakhulu, Gxila Ekunembeni Okungaqhathanisiwe Nokusebenzisa Okungenasici. Vumela Umcabango Wakho Unyukele Ekuphakameni Okusha njengoba Uchaza Kabusha Ubuhle Bobuciko Ngobuhlakani Obungenakuqhathaniswa.

I-Acrylic Sheet Laser Cutter, okungcono kakhulu kwakhoizimboni CNC laser cutting umshini

Ilungele ukusika i-laser usayizi omkhulu namashidi e-acrylic aminyene ukuze kuhlangatshezwane nezinhlelo zokusebenza ezihlukene zokukhangisa nezimboni.Ithebula lokusika i-laser engu-1300mm * 2500mm lakhiwe ngendlela enezindlela ezine. Okufakwe ngesivinini esikhulu, umshini wethu wokusika we-acrylic sheet laser ungafinyelela isivinini sokusika esingu-36,000mm ngomzuzu. Futhi isikulufu sebhola kanye nesistimu yokudlulisa imoto ye-servo iqinisekisa ukuzinza nokunemba kokuhamba ngesivinini esiphezulu kwe-gantry, okunomthelela ekusikeni kwe-laser izinto zefomethi enkulu kuyilapho kuqinisekiswa ukusebenza kahle kanye nekhwalithi. laser cutting acrylic sheets isetshenziswa kabanzi embonini yokukhanyisa & yezohwebo, inkambu yokwakha, imboni yamakhemikhali, kanye neminye imikhakha, nsuku zonke sivame kakhulu ekuhlobiseni ukukhangisa, amamodeli etafula lesihlabathi, namabhokisi okubonisa, njengezimpawu, amabhodi, iphaneli yebhokisi elikhanyayo, kanye nephaneli yezinhlamvu zesiNgisi.

(I-Plexiglass/PMMA) I-AcrylicI-Laser Cutter, okungcono kakhulu kwakhoizimboni CNC laser cutting umshini

Ilungele ukusika i-laser usayizi omkhulu namashidi e-acrylic aminyene ukuze kuhlangatshezwane nezinhlelo zokusebenza ezihlukene zokukhangisa nezimboni.Ithebula lokusika i-laser engu-1300mm * 2500mm lakhiwe ngendlela enezindlela ezine. Ifakwe ngesivinini esikhulu, umshini wethu wokusika i-acrylic laser ungafinyelela isivinini sokusika esingu-36,000mm ngomzuzu. Futhi isikulufu sebhola kanye nesistimu yokudlulisa imoto ye-servo iqinisekisa ukuzinza nokunemba kokuhamba ngesivinini esiphezulu kwe-gantry, okunomthelela ekusikeni kwe-laser izinto zefomethi enkulu kuyilapho kuqinisekiswa ukusebenza kahle kanye nekhwalithi. Akukhona lokho kuphela, i-acrylic ewugqinsi ingasikwa yishubhu ye-laser yamandla aphezulu yokuzikhethela okungu-300W no-500W. Umshini wokusika we-CO2 laser ungasika izinto eziqinile nezinkulu, njenge-acrylic nokhuni.

Thola Izeluleko Eziningi mayelana Nokuthenga Umshini Wokusika I-Acrylic Laser

6. Amathiphu jikelele wokusika i-acrylic nge-laser

Lapho usebenza nge-acrylic,kubalulekile ukulandela le mihlahlandlela ukuze uqinisekise ukuphepha futhi uthole imiphumela ehamba phambili:

1. Ungalokothi Ushiye Umshini Ungagadiwe

• I-Acrylic ivutha kakhulu uma ibhekene ne-laser cutting, okwenza ukugadwa okuqhubekayo kubalulekile.

• Njengomkhuba ojwayelekile wokuphepha, ungalokothi usebenzise i-laser cutter—kungakhathaliseki ukuthi iyiphi impahla—ngaphandle kokuba khona.

2. Khetha Uhlobo Olufanele Lwe-Acrylic

• Khetha uhlobo lwe-acrylic olufanele lohlelo lwakho lokusebenza oluthile:

o I-Acrylic ye-Cast: Ilungele ukuqoshwa ngenxa yokuqedwa kwayo okumhlophe okuyisithwathwa.

o I-Acrylic Enwetshiwe: Ifaneleka kangcono ukusika, ikhiqiza imiphetho ebushelelezi, epholishwe ngamalangabi.

3. Phakamisa i-Acrylic

• Sebenzisa izisekelo noma izikhala ukuze uphakamise i-acrylic esuka etafuleni lokusika.

• Ukuphakama kusiza ukuqeda ukubonakaliswa okungemuva, okungabangela amamaki angafuneki noma ukulimala kokusebenza.

I-Laser Cutting Acrylic Sheet

7. I-Laser Cutting ye-Acrylic FAQs

▶ Isebenza kanjani i-Laser Cutting Acrylic?

Ukusika i-laser kuhilela ukugxilisa i-laser beam enamandla phezu kwe-acrylic, ehwamulisa impahla endleleni emisiwe yokusika.

Le nqubo ibumba ishidi le-acrylic libe yifomu elifunayo. Ukwengeza, i-laser efanayo ingasetshenziselwa ukuqoshwa ngokulungisa izilungiselelo ukuze zihwamuke kuphela ungqimba oluncane olusuka endaweni ye-acrylic, kwakheka imiklamo yendawo enemininingwane.

▶ Iluphi Uhlobo Lwe-Laser Cutter Olungakwazi Ukusika I-Acrylic?

I-CO2 laser cutters iphumelela kakhulu ekusikeni i-acrylic.

Lezi zikhipha imishayo ye-laser endaweni ye-infrared, i-acrylic engakwazi ukumunca, kungakhathaliseki umbala.

Amalaser e-CO2 anamandla amakhulu angasika i-acrylic ngephasi eyodwa, kuye ngogqinsi.

▶ Kungani Khetha I-Laser Cutter ye-Acrylic

Esikhundleni Sezindlela Ezivamile?

Laser cutting okunikezwayoimiphetho eqondile, ebushelelezi, futhi ehlala njalo ngaphandle kokuthintana nempahla, enciphisa ukuphuka.

Ivumelana nezimo kakhulu, inciphisa udoti wezinto ezibonakalayo, futhi ayibangeli ukuguga kwamathuluzi.

Ukwengeza, ukusika nge-laser kungabandakanya ukulebula kanye nemininingwane emihle, okunikeza ikhwalithi ephezulu uma kuqhathaniswa nezindlela ezijwayelekile.

▶ Ngingakwazi Ukusika I-Acrylic Mina Nge-Laser?

Yebo, ungakwazilaser cut acrylic inqobo nje uma unezinto ezifanele, amathuluzi, kanye nekhono.

Kodwa-ke, ngemiphumela yekhwalithi yobungcweti, kuvame ukunconywa ukuqasha ochwepheshe abaqeqeshiwe noma izinkampani ezikhethekile.

Lawa mabhizinisi anemishini edingekayo kanye nabasebenzi abanamakhono ukuze baqinisekise imiphumela esezingeni eliphezulu.

▶ Yimuphi Usayizi Omkhulu We-Acrylic Lokho

Ingabe I-Laser Cut?

Usayizi we-acrylic ongasikwa uncike kusayizi wombhede womsiki we-laser.

Eminye imishini inosayizi abancane bemibhede, kanti eminye ingakwazi ukuhlalisa izingcezu ezinkulu, kuze kufike1200mm x 2400mmnoma ngisho nangaphezulu.

▶ Ingabe I-Acrylic Iyashisa Ngesikhathi Sokusika I-Laser?

Ukuthi i-acrylic iyasha yini ngesikhathi sokusika kuncike emandleni e-laser nezilungiselelo zesivinini.

Ngokuvamile, ukusha okuncane kwenzeka emaphethelweni, kodwa ngokulungiselela izilungiselelo zamandla, unganciphisa lokhu kusha futhi uqinisekise ukusikeka okuhlanzekile.

▶ Ingabe Yonke I-Acrylic Ifanele Ukusika I-Laser?

Izinhlobo eziningi ze-acrylic zifanele ukusika i-laser, kodwa ukuhlukahluka kombala nohlobo lwezinto ezibonakalayo kungathonya inqubo.

Kubalulekile ukuhlola i-acrylic ohlose ukuyisebenzisa ukuze uqiniseke ukuthi iyahambisana ne-laser cutter yakho futhi ikhiqiza imiphumela oyifunayo.

Qala I-Laser Consultant Manje!

> Yiluphi ulwazi okufanele ulunikeze?

| ✔ | Izinto Eziqondile (njenge-plywood, i-MDF) |

| ✔ | Usayizi Wempahla Nokuqina |

| ✔ | Yini Ofuna Ukwenza I-Laser? (sika, bhoboza, noma qopha) |

| ✔ | Ifomethi enkulu ezocutshungulwa |

> Imininingwane yethu yokuxhumana

Ungasithola nge-Facebook, YouTube, ne-Linkedin.

Dive Deeper ▷

Ungase ube nentshisekelo ku

# ibiza malini i-acrylic laser cutter?

# indlela yokukhetha ithebula lokusebenza le-laser cutting acrylic?

# indlela yokuthola ubude obuqondile bokugxila be-laser cutting acrylic?

# iyiphi enye impahla engasikwa nge-laser?

Noma yikuphi Ukudideka Noma Imibuzo Ye-Acrylic Laser Cutter, Vele Usibuze Noma Ngasiphi Isikhathi

Isikhathi sokuthumela: Jan-10-2025