Uyini umshini we-Galvo Laser?

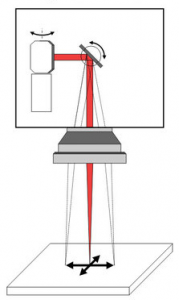

Ilaser ye-Galvo, evame ukubizwa ngokuthi i-Galvanometer laser, iwuhlobo lwesistimu ye-laser esebenzisa izikena ze-galvanometer ukulawula ukunyakaza nokuqondiswa kwe-laser.

Lobu buchwepheshe buvumela ukuma kwe-laser okunembe nokusheshayo, kuyenze ifanelekele izinhlelo zokusebenza ezahlukahlukene, okuhlanganisa ukumaka nge-laser, ukuqopha, ukusika, nokunye.

Igama elithi "Galvo" lisuselwa ku-"galvanometer," okuyithuluzi elisetshenziselwa ukulinganisa nokubona amaza kagesi amancane. Ngomongo wezinhlelo ze-laser, izikena ze-Galvo zisetshenziselwa ukukhombisa kanye nokukhohlisa i-laser beam.

Lezi zikena zihlanganisa izibuko ezimbili ezifakwe kumamotha e-galvanometer, ezingalungisa ngokushesha i-engeli yezibuko ukuze zilawule ukuma kwe-laser beam.

Izimpawu Ezisemqoka ze-Galvo Laser Systems zihlanganisa:

1. Umthombo we-Laser

2. Laser Beam Emission

3. Izikena ze-Galvanometer

4. Ukuchezuka kweBeam

5. I-Focusing Optics

6. Ukusebenzisana Okubalulekile

7. Ukuskena Okusheshayo

8. Ukulawula Ikhompyutha

9. Ukupholisa kanye Nokuphepha

10. Ukuphatha I-Exhaust kanye Nemfucuza

Indlela yokwenza: I-Galvo Laser Engraving Paper

Ingabe unemibuzo mayelana ne-Galvo Laser? Kungani Ungaxhumani Nathi?

1. Isicelo sakho:

Chaza ngokucacile inhloso yelaser yakho. Ingabe uyasika, uyamaka, noma uyaqopha? Izobeka amandla e-laser nobude begagasi obudingekayo.

3. Amandla eLaser:

Khetha amandla e-laser afanele ngokusekelwe kuhlelo lwakho lokusebenza. Ama-laser amandla aphezulu afanele ukusika, kuyilapho ama-laser amandla aphansi asetshenziselwa ukumaka nokuqopha.

5. Umthombo weLaser:

Khetha phakathi kwe-CO2, i-fiber, noma ezinye izinhlobo zemithombo ye-laser. Amalaser e-CO2 avame ukusetshenziselwa ukuqopha nokusika izinto eziphilayo.

7. Isofthiwe nokulawula:

Isofthiwe esebenziseka kalula enamakhono okwenza ngokwezifiso ibalulekile ekulungiseni kahle imingcele ye-laser nokuthuthukisa ukusebenza kahle.

9. Isondlo Nokwesekwa:

Cabangela izidingo zokunakekela kanye nokutholakala kokusekelwa kwamakhasimende. Ukufinyelela osizweni lobuchwepheshe nezingxenye ezishintshayo lapho kudingeka.

11. Isabelomali Nokuhlanganiswa:

Nquma isabelomali sakho sohlelo lwe-Galvo laser. Khumbula ukuthi amasistimu ekhwalithi ephezulu anezici ezithuthukile angase eze ngezindleko eziphezulu. Uma uhlela ukuhlanganisa isistimu ye-laser ye-Galvo emugqeni wokukhiqiza okhona, qiniseka ukuthi iyahambisana nezinhlelo zakho ezizenzakalelayo nokulawula.

2. Ukuhambelana Kwezinto:

Qinisekisa ukuthi isistimu ye-laser ye-Galvo iyahambisana nezinto ozosebenza ngazo. Izinto ezihlukile zingadinga ubude beza be-laser noma amazinga wamandla.

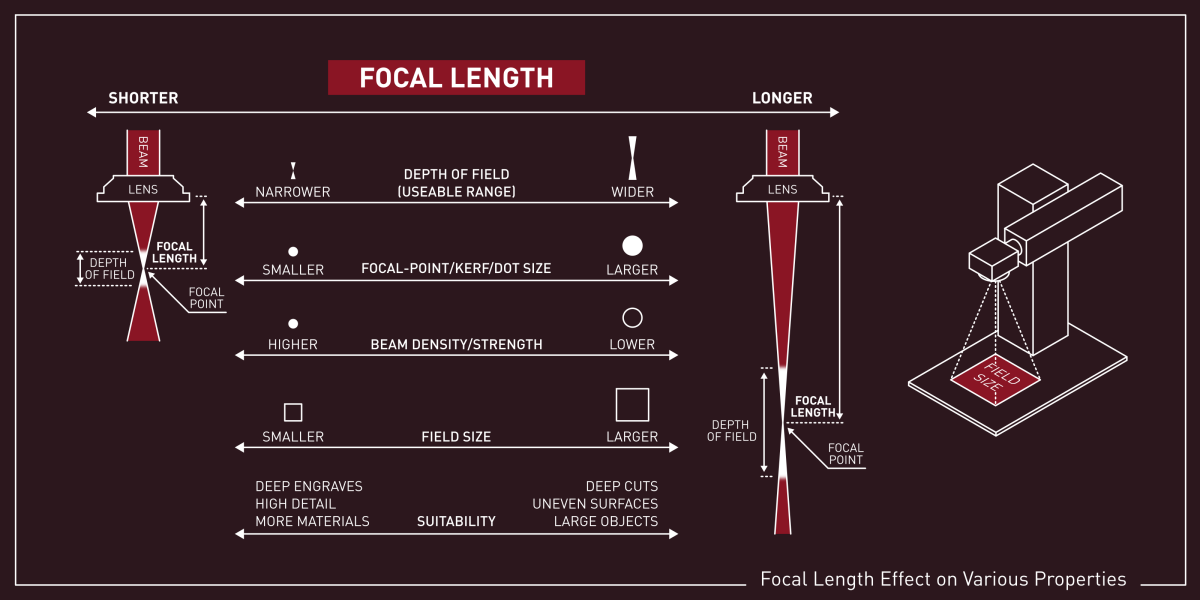

4. Isivinini se-Galvo Scanner:

Cabangela isivinini sokuskena sesithwebuli se-Galvo. Izikena ezisheshayo zilungele izinhlelo zokusebenza eziphuma phambili, kuyilapho izikena ezihamba kancane zinganemba kakhulu ngomsebenzi onemininingwane.

6. Usayizi Wendawo Yokusebenzela:

Nquma usayizi wendawo yokusebenza edingekayo kuhlelo lwakho lokusebenza. Qinisekisa ukuthi isistimu ye-laser ye-Galvo ingakwazi ukuhambisana nobukhulu bezinto zakho zokusebenza.

8. Uhlelo Lokupholisa:

Qinisekisa ukusebenza kahle kwesistimu yokupholisa. Isistimu yokupholisa ethembekile ibalulekile ukuze kugcinwe ukusebenza kwe-laser nokwelula impilo yesisetshenziswa.

10. Izici zokuphepha:

Beka kuqala izici zokuphepha ezifana nezikhiya, izihlangu eziwugqinsi, nezinkinobho zokumisa izimo eziphuthumayo ukuze uvikele abaqhubi futhi ugweme izingozi.

12. Ukwandiswa Okuzayo Nokubuyekeza:

Cabanga ngezidingo ezingase zibe khona esikhathini esizayo. Isistimu ye-laser ye-Galvo enwebekayo ikuvumela ukuthi wandise amakhono akho njengoba ibhizinisi lakho likhula. Cwaninga futhi ufune izincomo kontanga yemboni noma ochwepheshe ukuze uthole imininingwane ngamasistimu we-laser we-Galvo afaneleka kakhulu.

13. Ukwenza ngokwezifiso:

Cabangela ukuthi ingabe udinga isistimu engekho eshalofini noma isixazululo esenziwe ngokwezifiso esifanelana nesicelo sakho esithile.

Ngokuhlola ngokucophelela lezi zici, ungakhetha isistimu ye-laser ye-Galvo efanele ehambisana nemigomo yebhizinisi lakho, ethuthukisa izinqubo zakho zokukhiqiza, futhi iqinisekise ukusebenza okuphelele kanye nekhwalithi ezinhlelweni zakho zokusebenza.

Umbukiso Wevidiyo: Ungawukhetha Kanjani Umshini Wokumaka we-Laser?

I-MimoWork Laser Series

▶ Kungani Ungaqali Ngalezi Zinketho Ezinhle?

Usayizi Wethebula Lokusebenza:400mm * 400mm (15.7” * 15.7”)

Izinketho zamandla e-Laser:180W/250W/500W

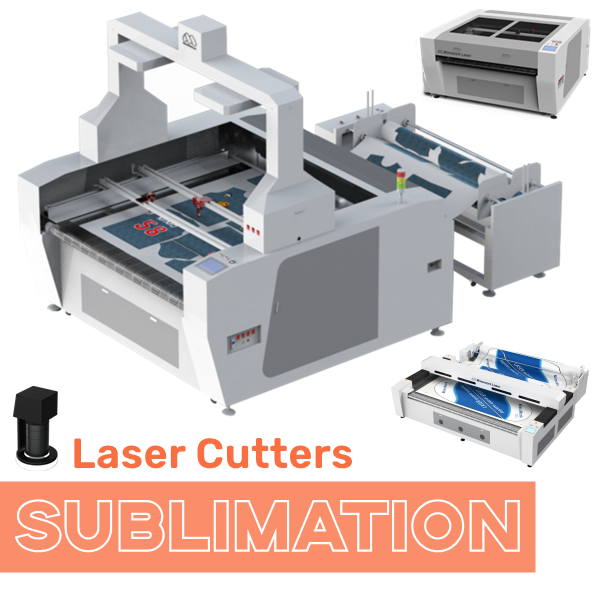

Uhlolojikelele lweGalvo Laser Engraver & Marker 40

Ukubuka okuphezulu kokusebenza kwalolu hlelo lwe-Galvo laser kungafinyelela ku-400mm * 400 mm. Ikhanda le-GALVO lingalungiswa liqonde phezulu ukuze uzuze osayizi abahlukahlukene be-laser beam ngokuya ngosayizi wempahla yakho. Ngisho nasendaweni yokusebenza ephezulu kakhulu, usengathola i-laser beam ehamba phambili ukuya ku-0.15 mm ukuze uthole umdwebo we-laser ongcono kakhulu kanye nokusebenza kokumaka. Njengezinketho ze-laser ye-MimoWork, i-Red-Light Indication System kanye ne-CCD Positioning System zisebenzisana ukuze kulungiswe isikhungo sendlela yokusebenza siye endaweni yangempela yocezu ngesikhathi sokusebenza kwe-galvo laser. Ngaphezu kwalokho, inguqulo yomklamo Ovalelwe Ngokugcwele ingacelwa ukuthi ihlangabezane nezinga lokuvikeleka lesigaba 1 somqophi we-galvo laser.

Usayizi Wethebula Lokusebenza:1600mm * Infinity (62.9" * Infinity)

Izinketho zamandla e-Laser:350W

Ukubuka konke kwe-Galvo Laser Engraver

Umqophi we-laser wefomethi enkulu uyi-R&D yosayizi omkhulu wokuqoshwa kwe-laser nokumaka nge-laser. Ngesistimu yokuthutha, umqophi we-galvo laser angaqopha futhi amake ezindwangu ezigoqekayo (izindwangu). Lokho kulungele lezi zinto zefomethi ye-ultra-long ukucubungula okuqoshiwe kwe-laser okuqhubekayo nokuguquguqukayo kuwina kokubili ukusebenza kahle okuphezulu kanye nekhwalithi ephezulu ekukhiqizeni okungokoqobo.

Usayizi Wethebula Lokusebenza:70*70mm, 110*110mm, 175*175mm, 200*200mm (Okungenziwa ngokwezifiso)

Izinketho zamandla e-Laser:20W/30W/50W

Uhlolojikelele lomshini wokumaka we-Fiber Galvo Laser

Umshini wokumaka we-fiber laser usebenzisa imishayo ye-laser ukwenza amamaki angapheli ebusweni bezinto ezihlukahlukene. Ngokuhwamuka noma ukushiswa ebusweni bezinto ezisetshenziswayo ngamandla okukhanya, ungqimba olujulile lwembula khona-ke ungathola umphumela oqoshiwe emikhiqizweni yakho. Kungakhathaliseki ukuthi iyinkimbinkimbi kangakanani iphethini, umbhalo, ibhakhodi, noma ezinye izithombe, umshini wokumaka we-MimoWork Fiber Laser ungawanamathisela emikhiqizweni yakho ukuze uhlangabezane nezidingo zakho zokwenza ngendlela oyifisayo.

Thumela Izidingo Zakho Kithi, Sizokunikeza Isixazululo Esisebenzayo SeLaser

Qala I-Laser Consultant Manje!

> Yiluphi ulwazi okufanele ulunikeze?

> Imininingwane yethu yokuxhumana

Imibuzo Evamile Mayelana ne-Galvo Laser

Uma isetshenziswa ngendlela efanele nangezinyathelo zokuphepha ezifanele, amasistimu we-laser we-Galvo aphephile. Kufanele bafake izici zokuphepha ezifana nezingidi ezihlanganayo nezihlangu ze-beam. Hlala ulandela imihlahlandlela yokuphepha futhi unikeze ukuqeqeshwa komsebenzisi ukuze uqinisekise ukusetshenziswa okuphephile.

Yebo, izinhlelo eziningi ze-laser ze-Galvo zenzelwe ukuhlanganiswa ezindaweni zokukhiqiza ezizenzakalelayo. Qinisekisa ukuhambisana nezinhlelo zakho zokulawula ezikhona kanye nemishini ezishintshayo.

Izidingo zokunakekela ziyahlukahluka kumkhiqizi kanye nemodeli. Ukunakekela okuvamile kungase kuhlanganise ukuhlanza okokusebenza, ukuhlola izibuko, nokuqinisekisa ukuthi isistimu yokupholisa isebenza ngendlela efanele. Kubalulekile ukulandela izincomo zesondlo zomkhiqizi.

Yebo, izinhlelo ze-laser ze-Galvo ziyakwazi ukudala imiphumela ye-3D ngokushintsha amandla e-laser kanye nemvamisa. Lokhu kungasetshenziselwa ukuthumela umbhalo kanye nokwengeza ukujula endaweni.

Ukuphila kwesistimu ye-laser ye-Galvo kuncike ekusetshenzisweni, ekugcinweni kwayo, nakwikhwalithi. Amasistimu ekhwalithi ephezulu angahlala amashumi ezinkulungwane zamahora okusebenza, inqobo nje uma egcinwa kahle.

Nakuba izinhlelo ze-Galvo zihamba phambili ekuphawuleni nasekuqopheni, zingasetshenziselwa futhi ukusika izinto ezincane njengephepha, amapulasitiki, nezindwangu. Amandla okusika ancike emthonjeni we-laser namandla.

Amasistimu we-laser we-Galvo abhekwa njengobungani bemvelo kunezindlela zendabuko zokumaka. Zikhiqiza udoti omncane futhi azidingi izinto ezisetshenziswayo ezifana noyinki noma odayi.

Amanye amasistimu we-laser we-Galvo angaguqulelwa izinhlelo zokusebenza zokuhlanza i-laser, awenze abe ngamathuluzi aguquguqukayo emisebenzi eyahlukene.

Yebo, izinhlelo ze-laser ze-Galvo zingacubungula zombili ihluzo ze-vector ne-raster, zikwazi ukwenza imisebenzi eminingi ngemiklamo namaphethini ayinkimbinkimbi.

Ungalungiseleli Noma Yini Engaphansi Kokukhethekile

Invest in the Best

Isikhathi sokuthumela: Nov-09-2023