I-Laser Welding vs TIG Welding: Yini Eshintshile ngo-2024

Iyini i-Handheld Laser Welding?

I-Handheld Laser Welding Stainless Steel

I-laser welding ephathwa ngesandlaisebenzisa idivayisi ye-laser ephathekayo ukuhlanganisa izinto, ngokuvamile izinsimbi.

I-laser welding ephathwa ngesandla ivumelaokukhuluukunemba nokunemba,

Futhi ikhiqiza i-weld yekhwalithi ephezulu, ehlanzekile ngeokuncaneokokufaka ukushisa,

Ukunciphisaukuhlanekezela kanye nesidingo sokucutshungulwa okubanzi kwe-post-weld.

Ama-Opharetha angakwazi ukulungisa kalula amandla nesivinini se-laser,

Inika amandlaizilungiselelo ezenzelwe wenaizinto ezahlukene kanye ukujiya.

Uhlu Lokuqukethwe:

Iyini i-Laser Weld Cleaning?

Ukubaluleka Kwenhlanzeko Ekushiseleni

Ukuhlanza Kwangaphambi Kokushisela Kwe-TIG Welding

Uma kuziwa ekushiseleni,

Inhlanzeko idlala indima ebalulekile ekuzuzeniikhwalithi ephezuluimiphumela.

Lesi simiso sisebenza kukho kokubili ukushisela kwe-TIG kanye ne-laser welding ephathwayo,

Kodwa izindlela zokulungiselela indaba zihluke kakhulu.

Kunoma iyiphi inqubo yokushisela,

Ukuba khona kokungcola okufana nokugqwala, upende, namafutha

Angakwaziukuyekethisa kakhuluubuqotho be-weld.

Lokhu kungcola kungaholela emalungeni abuthakathaka, i-porosity, nokunye ukukhubazeka

Lokho kwehlisa amandla omkhiqizo wokugcina.

Nansi indlela wenaKUFANELEBhekana nalokhu Okungcolisa:I-Laser Weld Cleaning.

I-Laser Welding vs TIG Welding: I-Laser Weld Cleaning

Indawo Ehlanzekile Ikhiqiza Ukushisela Kwekhwalithi Ephezulu

I-Laser Weld Cleaning ye-Handheld Laser Cleaning

Ngenkathi ukushisela kwe-TIG kuncikeimanuwaliizindlela zokuhlanza njengokugaya i-engeli kanye nokusula i-acetone,

I-laser welding ephathwa ngesandla inikeza okwengeziweelulaokunye okuhlanganisa amakhono ayo okuhlanza.

Lokhu okusha akugcini nje ngokuthuthukisa ukusebenza kahle

Kodwa futhi iqinisekisa ukuthi inqubo yokushisela iyasebenza ngangokunokwenzeka,

Ekugcineni okuholela emiphumeleni engcono.

Ukulungiselela i-TIG Welding:

Ku-TIG (I-Tungsten Inert Gas) ukushisela, ukulungiselela ngokucophelela kubalulekile.

Ngaphambi kokuqala inqubo yokushisela,

Kuyinto evamile ukusebenzisaama-angle grindersukususa ukugqwala noma ukunamathela ebusweni bento.

Lokhu kuhlanza ngomshini kusiza ukuqinisekisa ukuthi indawo engaphezulu ayinakho ukungcola.

Ngemva kwalokhu, sula ngokuphelele ngei-acetonekuyenziwa ngokuvamile.

I-acetone iyi-solvent enamandla leyoisusa ngempumelelonoma yimaphi amafutha asele noma ukungcola,

Ukushiya indawo ehlanzekile yokushisela.

Le nqubo yokuhlanza enezinyathelo ezimbili ingadla isikhathi,

Kodwa kubalulekile ekuzuzeni i-weld eqinile futhi ehlala isikhathi eside.

Ephathwayo Laser Welding Ukulungiselela

Ngokuphambene, ukunikezwa kwe-laser welding ephathwayo

Okunyeindlela elulaukulungiswa kwendawo.

Nge3-ku-1laser welder, inqubo iba lula kakhulu.

Le mishini ethuthukisiwe ngokuvamile ifika ifakweimibhobho eshintshashintshayo

Lokho kuvumela ukuhlanzwa kwendawo ngaphambi nje kokushisela.

Ngokungafani nezindlela zendabuko, lapho kudingeka khona amathuluzi ahlukene nama-ejenti okuhlanza,

Ama-laser welder angakwazi ukuhlanza kalula indawo nge-laser beam egxilile.

Lokhu akugcini nje konga isikhathi kodwa futhi kunciphisainani lemishiniedingekayo esizeni.

I-Laser Welding vs TIG Welding ishintshile ngo-2024

Xhumana nathi ukuze uthole okwengeziwe mayelana ne-Handheld Laser Welding System

Kungani Kufanele Usebenzise I-Shielding Gas in Welding?

Ukukhetha Igesi Yokuvikela Kudlala Indima Ebalulekile

I-Shielding Gas ye-TIG Welding: Argon

Uma kuziwa ekushiseleni,

Ukukhethwa kwegesi yokuvikela kubalulekile ekuqinisekiseni imiphumela yekhwalithi ephezulu.

Ikakhulukazi, i-TIG welding kanye ne-handheld laser welding inezidingo nezinketho ezahlukene

Uma kuziwa ekuvikeleni amagesi, okunomthelela kokubili ukusebenza nezindleko.

I-Shielding Gas inI-TIG Welding

Ku-TIG (Tungsten Inert Gas) yokushisela,

Igesi yokuvikela eyinhloko esetshenziswayoubumsulwa obuphezului-argon.

Le gesi ehloniphekile ikhethwa ngenxa yekhono layo elihle kakhulu lokuvikela i-weld pool

Kusukela ekungcoleni komoya, ikakhulukazi i-oxidation.

I-oxidation ingaholelaamaphuthaku-weld, njenge-porosity namalunga abuthakathaka,

Yikuphiukuyekethisaubuqotho obuphelele bensimbi.

Ngenxa yokuphumelela kwayo,

I-TIG welding ngokuvamile idinga aokuqhubekayoukunikezwa kwe-argon kuyo yonke inqubo yokushisela.

Nokho, i-argon ingaba eqolo, okuholela ezindlekweni zokusebenza eziphakeme,

Ikakhulukazi kumaphrojekthi adinga i-welding ebanzi.

I-Shielding Gas inI-Handheld Laser Welding

I-Alternative Shielding Gas Ye-Laser Welding: I-Nitrogen

Ngakolunye uhlangothi, i-laser welding ephathwa ngesandla ngokuvamile isebenzisa i-nitrogen njengegesi evikelayo.

I-nitrogen ayigcini njengempumeleloekuvimbeleni i-oxidation

Kodwa futhi ngokuphawulekayo ngaphezulukuqiza kahlekune-argon.

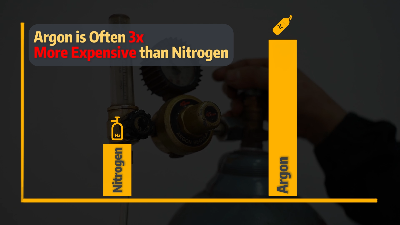

Umehluko wamanani ungaba mkhulu;

I-nitrogen ingaba cishekathathuishibhile kune-argon yokuhlanzeka okuphezulu.

Lokhu kwenza i-nitrogen ibe yindlela ekhangayo kumabhizinisi afuna ukunciphisa izindlekongaphandle kokudelaizinga.

I-TIG vs Laser Welding: Izinketho Zokuvikela Igesi

Zuza Ukonga Ngenkathi Ugcina Ikhwalithi

Ukuqhathaniswa Kwamanani Phakathi kwe-Argon neNitrojeni

Ukushintshela ku-nitrogen ekunikezelweni kwe-laser welding ephathwayoezininganaizinzuzo

Ukonga Izindleko:

Ngeokubalulekileumehluko wentengo phakathi kwe-argon ne-nitrogen,

Ukusebenzisa i-nitrogen kungaholela ekongeni okukhulu ngokuhamba kwesikhathi.

Lokhukuzuzisa ngokukhethekileamaphrojekthi amakhulu noma amabhizinisi

Lokho kwenza imisebenzi yokushisela njalo.

Ukuvikelwa Okuphumelelayo:

I-nitrogen ihlinzekaisivikelo esanelengokumelene ne-oxidation,

Ukuqinisekisa ukuthi i-weld ihlalaihlanzekile futhi inamandla.

Ngenkathi i-argon yaziwa ngokuvikela kwayo okuphezulu,

I-nitrogen isekhonainketho esebenzayolokho kuhlangabezana ngokuphumelelayo nezidingo zezinhlelo zokusebenza eziningi zokushisela.

Qhathanisa Inqubo Yokushisela: I-Laser vs TIG Welding

Ukunakisisa Icebo Lizuza Imiphumela Emihle Kakhulu

I-engeli elungile ye-Laser Welding: 45 Degree

Uma igesi elivikelayo seligeleza kahle,

Isikhathi sokugxila kunqubo ye-welding yangempela.

Kokubili i-TIG (Tungsten Inert Gas) yokushisela kanye ne-laser ephathwayo ngesandla

Dingaamasu anembeukuthola imiphumela yekhwalithi ephezulu,

Nokho, ziyehluka ngezidingo nezindlela zazo ezithile.

I-TIG WeldingIcebo

Khomba ukugcina i-electrode endaweniibanga elilungile nesivininiukwakha nokuhola i-weld pool.

Leli banga lingahluka kuye ngokuthi impahla kanye ukushuba kokuba ashiselwe.

Ukugcina i-engeli efanele, ngokuvamile nxazonke15-20 degrees,

Isiza ekufinyeleleni ukushisela okungaguquki nokuhlanzekile.

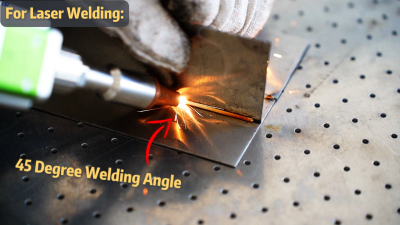

I-Handheld Laser WeldingIcebo

Enye yezinzuzo ze-laser welding yikhono lokusetha i-engeli engaguquki

Ngokujwayelekile nxazonke45 degrees, okuvumela ukuphathwa kalula kwenqubo yokushisela.

Uma i-engeli isethiwe, igcinaisivinini esingaguqukiukhiye.

I-laser welding ephathwa ngesandla ngokuvamile ikhiqizaukushisa okuncaneuma kuqhathaniswa nokushisela kwe-TIG.

Lokhu kusho ukuthi kukhonaingozi encane yokuphazamiseka noma ukuhlanekezela,

Ukuyenza ifanelekele ukusebenza ngokunemba ezintweni ezizacile.

I-Laser Weld Strength vs TIG: I-Debunking Myths

Imibono Eyiphutha Evamile Mayelana Ne-Laser Welding

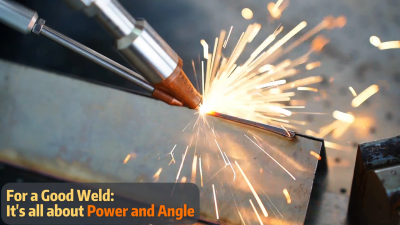

Ukuze Kuhle Handheld Laser Welding: Amandla & Angle

Enye yezinzuzo ezibalulekile ze-laser welding ephathwayo yikhono layo lokuletha amandla agxililengokuqondilelapho idingeka khona.

Ngeizilungiselelo zamandla angakwesokudlakanye nei-angle efanele

Ngokujwayelekile nxazonke45 degrees, i-laser welding ingafinyelela ukungena namandla okuhle kakhulu.

Okokukhipha Amandla Okulungile

Ukusetha amandla we-laser welder kubalulekile.

Ukukhipha amandla amancane kakhulu kungaholela ekutheniukungena okwanele, okuholela ekushiseleleni okubuthakathaka.

Ngokuphambene, izinga elifanele lamandla livumela i-laser ukuthi incibilikise izinto ngokuphumelelayo, idale amalunga aqinile.

Ukusebenzisa imishini enamandla angaphansi ngeke kuveze imiphumela oyifunayo.

Kokubili i-TIG kanye ne-Handheld Laser Welding ziyasebenza

Uyafuna Ukufunda Kabanzi Nge-Handheld Laser Welding?

I-Handheld Laser Welding: Indlela Yokugcina Imishini

Ukunakekela Okufanelekile Nokunaka Imininingwane Kuzoqinisekisa Ukukhiqiza Nokwethembeka

Ubuwazi ukuthi kokubili ukushisela kwe-TIG (Tungsten Inert Gas) kanye nokushiswa kwe-laser ephathwayo kuhlukaniswa ngokuthi

Izindlela zokushisela ezingasebenziseki?

Lokhu kusho ukuthi, ngaphansi kwezimo ezifanele kanye nokunakekelwa okufanele,

Izingxenye ezibalulekile ezisetshenziswa kulezi zinqubo zingahlala isikhathi eside

Ngaphandle kokudinga ukushintshwa njalo.

Izingxenye Ezingasebenziseki

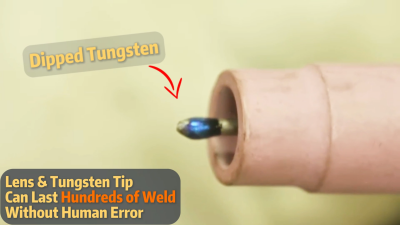

Iphutha le-Tungsten elicwilisiwe le-TIG Welding

I-electrode ye-tungsten iyisici esibalulekile ekushiseleni kwe-TIG.

Ngokungafani nama-electrode asebenzisekayo asetshenziswa kwezinye izindlela zokushisela,

njenge-MIG welding, i-electrode ye-tungstenayincibilikingesikhathi se-welding.

Kunalokho, igcina ubuqotho bayo, ivumela ukusetshenziswa isikhathi eside.

Kodwa-ke, i-electrode ingangcoliswa noma "ifakwe" uma itholaeduze kakhulu nedamu lokushisela elincibilikisiwe.

Ezimweni ezinjalo, kufanele inqanyulwe futhi iphansi ukuze ibuyisele iphuzu layo elibukhali nokusebenza okuphumelelayo.

Ukugcinwa njaloye-electrode ye-tungsten ibalulekile ekuzuzeni ukushisela okuhlanzekile, okuphezulu.

Ephathwayo Laser Welding Ukulungiselela

I-Laser Lens Ye-Handheld Laser Welding Maintenance

Ekushiseleni i-laser ephathwayo, ilensi ye-laser isebenza njengendawo okugxilwe kuyo ye-laser beam.

Ilensi ebekwe kahle ingahlala isikhathi eside, inikeze ukusebenza okungaguquki.

Kodwa-ke, uma ilensi iqhekeka ngenxa yokuma okungafanele noma ukuchayeka ekushiseni okukhulu

Izodinga ukushintshwa.

Ukugcina i-lens isesimweni esihle kubalulekile,

Njengoba ngisho nomonakalo omncane ungathinta ukunemba nokusebenza kwe-laser, okuholela ekushiseleni okungaphansi.

Ufuna Umhlahlandlela Ophelele Wereferensi we-Handheld Laser Welding?

I-laser welding ephathwa ngesandla inikeza izinzuzo eziningi,

Kodwa futhi kudinga ukunakwa okucophelelayo kumaphrothokholi okuphepha.

Lesi sihloko sizohlola ukucatshangelwa okubalulekile kokuphepha kwe-laser welding ephathwayo.

Kanye nokuhlinzeka ngezincomo zokuvikela ukukhethwa kwegesi kanye nokukhetha kwezintambo zokugcwalisa zezinhlobo zensimbi ezivamile.

Ingabe i-Laser Welding iqine njenge-TIG Welding?

I-laser weldingkanye nokushisela kwe-TIG (Tungsten Inert Gas) kokubili kwaziwa ngokunemba kanye nekhwalithi yokuhlanganisa insimbi.

Kodwa bahlangana kanjani ngokwamandla?

Kule vidiyo, sizongena ezinhlobonhlobo eziyinhlokoukusebenza kwe-weld,ukuhambisana kwezinto ezibonakalayo, futhiukuqina okuphelelephakathi kwe-laser ne-TIG welding.

I-Handheld Fiber Laser Welding (I-Handheld Laser Weld)

Isengezo Esibalulekile ku-Handheld Laser Weld Landscape

I-Laser Welder Encane Yenza Ukushisela Kungabizi futhi Kuthengeke

Ngokubukeka komshini ohlangene futhi omncane.

Umshini we-laser welder ophathwayo ufakwe isibhamu esiphathwa ngesandla se-laser welder esinyakazayoengasindi.

Futhi elungele izicelo zokushisela ama-laser amaningi kunoma iyiphi i-engelifuthiphezulu.

Izinhlobo ezihlukahlukene zokuzikhethela ze-laser welder nozzles.

Uhlelo lokuphakela izintambo oluzenzakalelayo lokuzikhethela lwenza ukusebenza kwe-laser welding kube lula futhi lokho kube nobungane kwabaqalayo.

Izinto Ezi-5 Mayelana Ne-Laser Welding (Okuphuthele)

Uma uyijabulele le vidiyo, kungani ungacabangiubhalisela Isiteshi sethu se-YouTube?

Izicelo Ezihlobene Ongase Uzithande:

I-Handheld Laser Weld iyisinqumo esihle kakhulu seMisebenzi Yezandla Yokushisela

Futhi Ikusasa Liqala Ngawe!

Isikhathi sokuthumela: Sep-14-2024