I-Crystal ye-scintillation

(I-Sub Surface Laser Engraving)

Ama-detectors asekelwe ku-scintillation, kusetshenziswa ama-pixelated crystal scintillator, kukhonaesetshenziswa kabanzi ukuthola izinhlayiyana nemisebe, kufaka phakathiIzikena ze-positron emission tomography (PET)..

Ngokungeza izici eziqondisa ukukhanya kukristalu, ukulungiswa kwendawo komtshinaingathuthukiswa ibe yi-millimeter esikalini, ithuthukise ukucaca okuphelele kwe-tomograph.

Nokho, indlela yendabuko yepixelating ngokomzimbaamakristalu ainqubo eyinkimbinkimbi, ebizayo, futhi ekhandlayo. Ukwengeza, ingxenye yokupakisha nokuzwela komtshinakungaba sengoziningenxa yeizinto ezibonakalayo ezingabonakali ezisetshenziswayo.

Ungabuka Iphepha Locwaningo Loqobo Lapha. (Kusuka ku-ResearchGate)

I-Subsurface Laser Engraving yeI-Crystal ye-scintillation

Enye indlela ukusebenzisai-subsurface laser engraving (SSLE) amasuamakristalu e-scintillator.

Ngokugxilisa i-laser ngaphakathi kwekristalu, ukushisa kukhiqizweingakha iphethini elawulwayo yama-microcrackslokhosebenza njengezakhiwo ezikhanyayo, ukudala ngempumeleloamaphikseli aqondisa ukukhanyangaphandle kwesidingo sokuhlukana ngokomzimba.

1. Akukho pixelation ebonakalayo yekristalu edingekayo,ukunciphisa ubunzima kanye nezindleko.

2. Izici ze-optical kanye nejometri yezakhiwo ezikhanyayo zingabakulawulwa ngokunembile, okuvumela ukuklanywa komumo nosayizi bephikseli ngokwezifiso.

3. Ukufunda kanye nesakhiwo somtshinahlala ufana nowokuhlelwa kwe-pixelated okujwayelekile.

I-Laser Engraving Process (SSLE) ye-Scintillator Crystal

Inqubo yokuqopha ye-SSLE ibandakanyaizinyathelo ezilandelayo:

1. Umklamo:

Ukulingisa kanye nomklamo wei-pixel architecture oyifunayo, kuhlanganiseizilinganisofuthiizici ze-optical.

2. Imodeli ye-CAD:

Ukudalwa kwe-aimodeli enemininingwane ye-CADukusabalalisa kwe-microcrack,ngokusekelwe emiphumeleni yokulingisafuthilaser engraving imininingwane.

3. Qala Ukuqopha:

Ukuqoshwa kwangempela kwekristalu ye-LYSO kusetshenziswa uhlelo lwe-laser,iqondiswa imodeli ye-CAD.

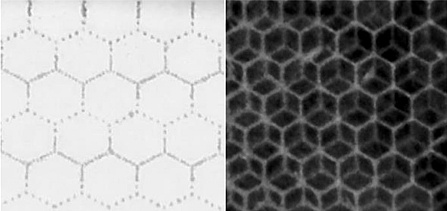

Inqubo Yokuthuthukisa I-SSLE: (A)Imodeli Yokulingisa, (B)Imodeli ye-CAD, (C) Eqoshwe i-LYSO, (D)Umdwebo Wesikhukhula sasensimini

4. Ukuhlolwa Kwemiphumela:

Ukuhlolwa kokusebenza kwekristalu eqoshiwe kusetshenziswa aisithombe senkundla yezikhukhulafuthiUkulinganisa kwe-Gaussianukuhlola ikhwalithi ye-pixel nokulungiswa kwendawo.

I-Subsurface Laser Engraving ICHAZWE emizuzwini emi-2

Isubsurface laser engraving inquboamakristalu e-scintillator anikeza aindlela yokuguqulaekufanekisweni kwalezi zinto zokwakha.

Ngokunikeza ukulawula okunembile phezu kwezici ze-optical kanye nejometri yezakhiwo ezikhanyayo, le ndlelainika amandla ukuthuthukiswa kwezakhiwo zomtshina ezintshangeukulungiswa kwendawo nokusebenza okuthuthukisiwe, konkengaphandleisidingo se-pixelation ebonakalayo eyinkimbinkimbi futhi ebizayo.

Ufuna ukwazi okwengeziwe mayelana:

I-Subsurface Laser Engraving Scintillation Crystal?

Okutholakele kwe-SSLE Scintillation Crystal

1. Ukukhiqiza Okukhanyayo Okuthuthukisiwe

Kwesokunxele: Ukubuka Konke Kwe-Surface Reflectivity Asymmetry DoI.

Kwesokudla: I-Pixel Displacement DoI.

Ukuqhathaniswa kwama-pulses phakathii-subsurface laser eqoshiwe (SSLE) arraysfuthiama-array ajwayelekileukhombisa aisivuno esingcono kakhulu sokukhanya se-SSLE.

Lokhu kungenzeka ngenxa ye-ukungabi khona kwezibonisi zepulasitikiphakathi kwamaphikseli, okungabangela ukungafani kokubona nokulahlekelwa kwesithombe.

Isivuno sokukhanya esithuthukisiwe sishoukukhanya okwengeziwe kwamapulses wamandla afanayo, ukwenza i-SSLE isici esifiselekayo.

2. Ukuziphatha Kwesikhathi Okuthuthukisiwe

Isithombe se-Scintillation Crystal

Ubude bekristalu buno-aumthelela omubi ngesikhathi, okubalulekile ezinhlelweni zokusebenza ze-Positron Emission Tomography (PET).

Nokho, iukuzwela okuphezulu kwamakristalu e-SSLEivumela ukusetshenziswa kweamakristalu amafushane, okungabathuthukisa ukuziphatha kwesikhathi kwesistimu.

Ukulingisa kuphinde kwaphakamisa ukuthi umumo wephikseli ohlukile, njenge-hexagonal noma i-dodecagonal, kungenzekakuholela ekusebenzeni okungcono kokuqondisa ukukhanya nokusebenza kwesikhathi, efana nemigomo ye-optical fibers.

3. Izinzuzo Ezingabizi

Isithombe seScintillator Crystal

Uma kuqhathaniswa namabhulokhi e-monolithic, intengo yamakristalu e-SSLEkungaba ngaphansi njengobaingxenye yesithathuwezindlekoyamalungu afanayo amaphikiseli, kuye ngobukhulu bephikseli.

Ngaphezu kwalokho, i-ukuzwela okuphezulu kwamakristalu e-SSLEivumelaukusetshenziswa kwamakristalu amafushane, ngokuqhubekayo ukunciphisa izindleko zizonke.

Indlela ye-SSLE idinga amandla e-laser aphansi uma kuqhathaniswa nokusika kwe-laser, ukuvumelaamasistimu e-SSLE angabizi kakhuluuma kuqhathaniswa nezindawo zokuncibilika kwe-laser noma zokusika.

Iutshalomali lokuqala kwingqalasizinda nokuqeqeshwaye-SSLE nayo iphansi kakhulukunezindleko zokuthuthukisa umtshina we-PET.

4. Design Ukuvumelana nezimo kanye ngokwezifiso

Inqubo yokuqopha amakristalu e-SSLEakudli isikhathi, ngokulinganisaImizuzu engu-15okudingekayo ukuze kuqoshwe 12.8x12.8x12 mm, 3-crystal array.

Iimvelo eguquguqukayo, ukuphumelela kwezindleko, futhilula ukulungisa amakristalu e-SSLE, kanye naboingxenyana yokupakisha ephezulu, nxephezela iukulungiswa kwendawo okungaphansi kancaneuma kuqhathaniswa namalungu afanayo amaphikiseli ajwayelekile.

I-Non-Conventional Pixel Geometries

I-SSLE ivumela ukuhlolwa kweamajiyometri wephikseli angajwayelekile, okwenza amaphikseli acwebezelayo abeifaniswe ngokunembile nezidingo ezithile zohlelo lokusebenza ngalunye, njengama-collimator noma ubukhulu bamaphikseli e-silicon photomultiplier.

Ukwabelana Ngokukhanya Okulawulwayo

Ukwabelana ngokukhanya okulawulwayo kungafinyelelwa ngokuguqulwa okunembile kwezici ze-optical yezindawo eziqoshiwe,ukwenza kube lula ukwenziwa kancane kancane kwezitholi ze-gamma.

Imiklamo Engavamile

Imiklamo engavamile, njenge-Voronoi tessellations, ingabaaqoshwe kalula ngaphakathi kwamakristalu e-monolithic. Ngaphezu kwalokho, ukusatshalaliswa okungahleliwe kosayizi wamaphikseli kunganika amandla ukwethulwa kwamasu okuzwa acindezelwe, kusizakala ngokwabelana ngokukhanya okubanzi.

Imishini ye-Subsurface Laser Engraving

Inhliziyo yokudalwa kwe-Subsurface Laser ilele emshinini wokuqopha nge-laser. Le mishini iyasebenzai-laser eluhlaza enamandla amakhulu, eyenzelwe ngokukhethekilesubsurface laser engraving in crystal.

IOne & Only Solutionuyoke udinge i-Subsurface Laser Engraving.

Isekela6 Ukucushwa Okuhlukene

KusukaI-Hobbyist Encane Encane to Ukukhiqiza Okukhulu

Ukunemba Kwendawo Okuphindaphindiwe at <10μm

Ukunemba Kokuhlinzwaye-3D Laser Carving

3D Crystal Laser Engraving Machine(SSLE)

Nge-Subsurface Laser Engraving,ukunemba kubalulekilengokudala ukuqoshwa okuningiliziwe nokuyinkimbinkimbi. I-laser's focused beamisebenzisana ngokuqondilengesakhiwo sangaphakathi sekristalu,ukudala isithombe se-3D.

Iyaphatheka, Inembile futhi Ithuthukile

Umzimba we-Laser Compactokwe-SSLE

Ubufakazi bokwethuka&Iphephe Kwabaqalayo

Fast Crystal Engravingkufika ku-3600 amaphuzu/ngesekhondi

Ukuhambisana Okukhuluku-Design