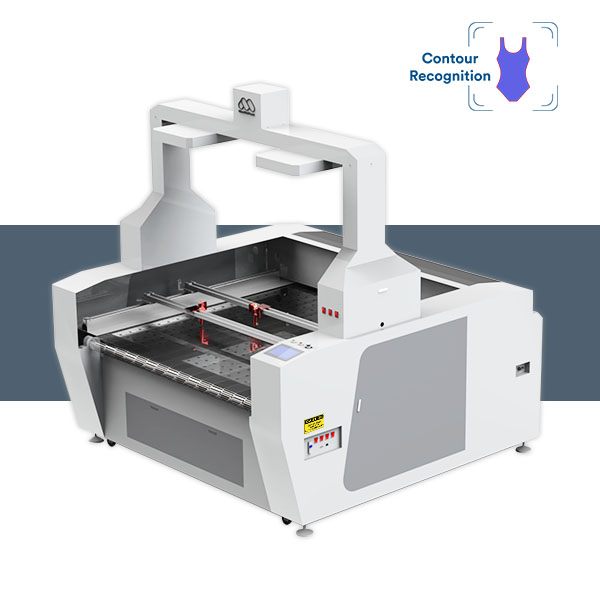

China Wholesale Laser Cut Camping Sleeping Bags Quotes Pricelist - Laser Cut Sportswear Machine (180L) – MimoWork Laser

China Wholesale Laser Cut Camping Sleeping Bags Quotes Pricelist - Laser Cut Sportswear Machine (180L) – MimoWork Laser Detail:

Technical Data

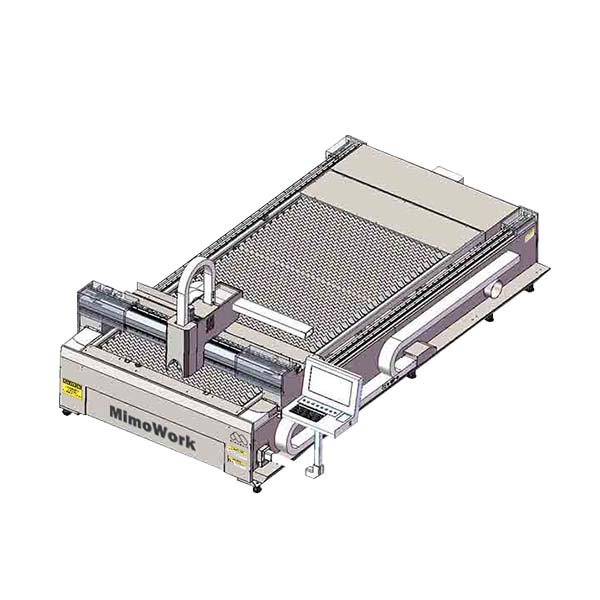

| Working Area (W *L) | 1800mm * 1300mm (70.87’’ * 51.18’’) |

| Max Material Width | 1800mm / 70.87’’ |

| Laser Power | 100W/ 130W/ 300W |

| Laser Source | CO2 Glass Laser Tube / RF Metal Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

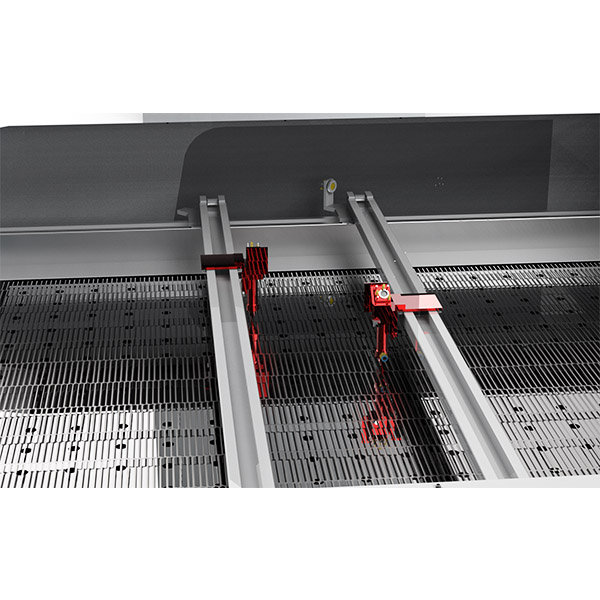

* Dual-Laser-Heads option is avaliable

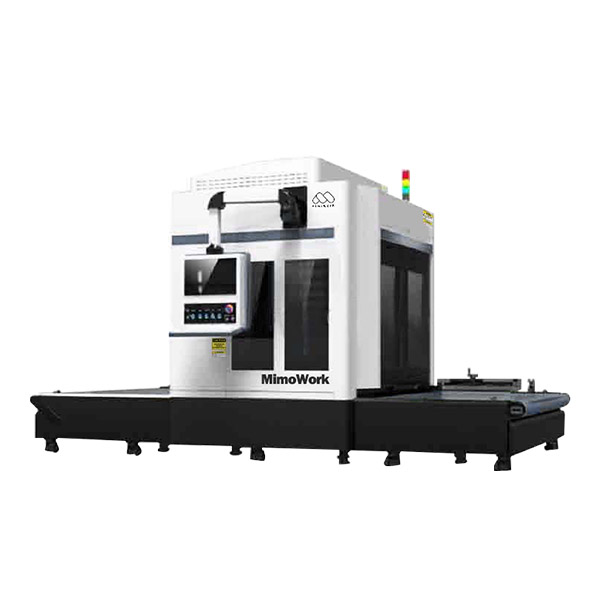

A Giant Leap from Digital Sublimation Laser Cutting Machine

Best choice for cutting large-format printed fabrics

▶ Widely used in digital printing products like advertising banners, clothing and home textiles and other industries

▶ Thanks to MimoWork latest innovative technology, our customers can realize efficient production with fast & accurate laser cutting of dye sublimation textiles

▶ Advanced visual recognition technology and powerful software provide higher quality and reliability for your production

▶ The automatic feeding system and the conveying work platform work together to achieve an automatic roll-to-roll processing process, saving labor and improving efficiency

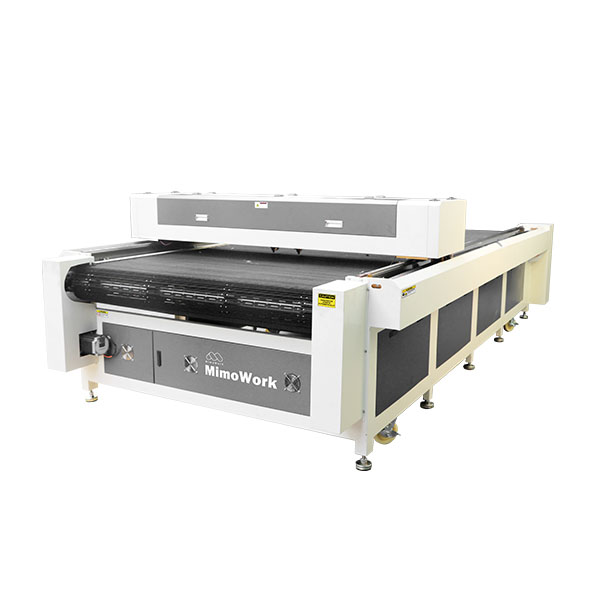

D&R for flexible fabric sublimation laser cutting

Large Working Table

With a larger and longer working table, it is suitable for a variety of industry applications. Whether you want to produce printed banners, flags, or ski-wear, a cycling jersey will be your right-hand man. With the auto-feeding system, it can help your cut out from a printed roll perfectly. And our working table width can be customized and perfectly fit with major printers and heat presses, such as Monti’s Calender for printing.

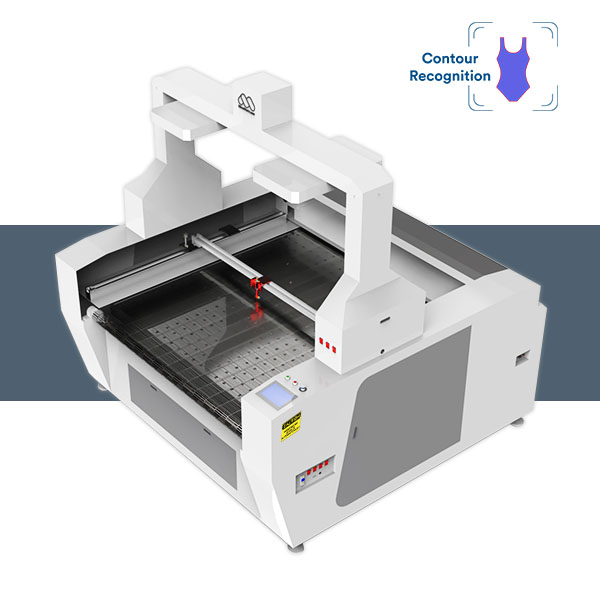

Cannon HD camera

Equipped Cannon HD camera on the top of the machine, this ensures that the Contour Recognition System can accurately identify the graphics that need to be cut. The system does not need to use original patterns or files. After automatic feeding, this is a fully automatic process without manual intervention. In addition, the camera will take pictures after the fabric is fed into the cutting area, and then adjust the cutting contour to eliminate deviation, deformation and rotation, and finally achieve a high-precision cutting effect.

Conveyor Working Table

An increase in productivity thanks to auto-loading and unloading during the cutting process. The conveyor system is made out of stainless steel mesh, suitable for lightweight and stretchy fabrics, such as polyester fabrics and spandex, that’s commonly used in dye-sublimation fabrics. And through the specially set down exhaust system under the Conveyor Working Table, the fabric is fixed on the processing table tamely. Combined with the contact-less laser cutting, no distortion will appear despite the direction that the laser head is cutting.

Video Display

<a href="https://www.mimowork.com/sublimation-fabrics-laser-cutter/" title="• Discover sublimation textile laser cutting” target=”_blank”>

• Discover sublimation textile laser cutting

<< Elastic Fabric Laser Cutting

For some stretch fabrics like spandex and Lycra fabric, accurate pattern cutting from Vision Laser Cutter helps enhance the cutting quality as well as eliminate error and defective rate.

Whether for sublimation printed or solid fabric, contact-less laser cutting ensures textiles are fixed and not being damaged.

How to Laser Cut Flag >>

To meet the demands of accurate cutting along the contour in printed advertising field, MimoWork recommends the laser cutter for sublimation textiles like teardrop flag, banner, signage, etc.

Besides for the smart camera recognition system, the contour laser cutter features large format working table and dual laser heads, facilitating flexible and quick production as different market needs.

Find more videos about our laser cutters at our Video Gallery

Any questions about contour laser cutting and sublimation fabric

Fields of Application

Laser Cutting for Your Industry

Dye-Sublimation Sportswear, Polyester Laser Cutter

Cutting from the printed roll directly

✔ The contour recognition system allows the exact cut along the printed contours

✔ Fusion of cutting edges – no need for trimming

✔ Ideal for processing stretchy and easily distorted materials (Polyester, Spandex, Lycra )

Banners & Displays

Your popular and wise manufacturing direction

✔ Versatile and flexible laser treatments broaden the breadth of your business

✔ Cut along the pressure contours thank to the mark point positioning technology

✔ Value-added laser abilities like engraving, perforating, marking suitable for entrepreneurs and small business

Common materials and applications

of Contour Laser Cutter 180L

Materials: Polyester, Spandex, Lycra, Silk, Nylon, Cotton and other sublimation fabrics

Applications: Sublimation Accessories (Pillow), Rally Pennants, Flag, Signage, Billboard, Swimwear, Leggings, Sportswear, Uniforms

We’ve served dozens of clients in sublimation fabrics fields

Add yourself to the list!

Product detail pictures:

Related Product Guide:

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for China Wholesale Laser Cut Camping Sleeping Bags Quotes Pricelist - Laser Cut Sportswear Machine (180L) – MimoWork Laser , The product will supply to all over the world, such as: Norway , Jakarta , Boston , We have a excellent team supplying professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our products.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!