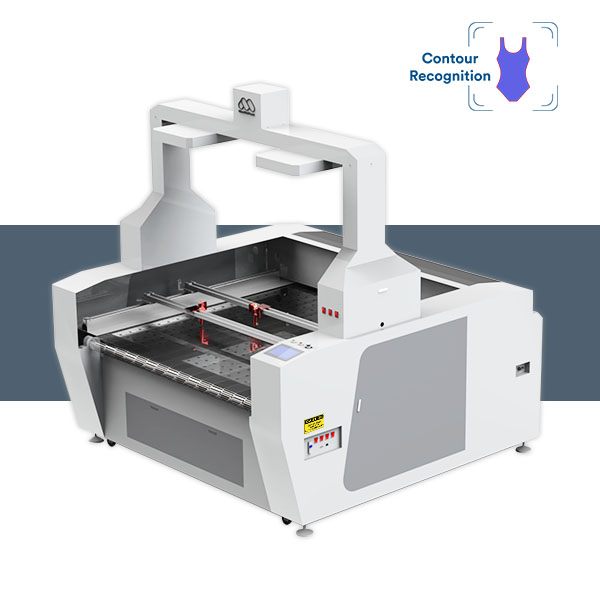

Contour Laser Cutter 180L

| Working Area (W *L) | 1800mm * 1300mm (70.87’’ * 51.18’’) |

| Max Material Width | 1800mm / 70.87’’ |

| Laser Power | 100W/ 130W/ 300W |

| Laser Source | CO2 Glass Laser Tube / RF Metal Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Dual-Laser-Heads option is available

A Giant Leap from Digital Sublimation Laser Cutting Machine

Best Choice for Cutting Large-Format Printed Fabrics

▶ Widely used in digital printing products like advertising banners, clothing and home textiles and other industries

▶ Thanks to MimoWork latest innovative technology, our customers can realize efficient production with fast & accurate laser cutting of dye sublimation textiles

▶ Advanced visual recognition technology and powerful software provide higher quality and reliability for your production

▶ The automatic feeding system and the conveying work platform work together to achieve an automatic roll-to-roll processing process, saving labor and improving efficiency

D&R for Flexible Fabric Sublimation Laser Cutting

Large Working Table

With a larger and longer working table, it is suitable for a variety of industry applications. Whether you want to produce printed banners, flags, or ski-wear, a cycling jersey will be your right-hand man. With the auto-feeding system, it can help your cut out from a printed roll perfectly. And our working table width can be customized and perfectly fit with major printers and heat presses, such as Monti's Calender for printing.

Equipped Cannon HD camera on the top of the machine, this ensures that the Contour Recognition System can accurately identify the graphics that need to be cut. The system does not need to use original patterns or files. After automatic feeding, this is a fully automatic process without manual intervention. In addition, the camera will take pictures after the fabric is fed into the cutting area, and then adjust the cutting contour to eliminate deviation, deformation and rotation, and finally achieve a high-precision cutting effect.

An increase in productivity thanks to auto-loading and unloading during the cutting process. The conveyor system is made out of stainless steel mesh, suitable for lightweight and stretchy fabrics, such as polyester fabrics and spandex, that's commonly used in dye-sublimation fabrics. And through the specially set down exhaust system under the Conveyor Working Table, the fabric is fixed on the processing table tamely. Combined with the contact-less laser cutting, no distortion will appear despite the direction that the laser head is cutting.

Video Display

<< Elastic Fabric Laser Cutting

For some stretch fabrics like spandex and Lycra fabric, accurate pattern cutting from Vision Laser Cutter helps enhance the cutting quality as well as eliminate error and defective rate.

Whether for sublimation printed or solid fabric, contact-less laser cutting ensures textiles are fixed and not being damaged.

How to Laser Cut Flag >>

To meet the demands of accurate cutting along the contour in printed advertising field, MimoWork recommends the laser cutter for sublimation textiles like teardrop flag, banner, signage, etc.

Besides for the smart camera recognition system, the contour laser cutter features large format working table and dual laser heads, facilitating flexible and quick production as different market needs.

Find more videos about our laser cutters at our Video Gallery

Any Questions about Contour Laser Cutting and Sublimation Fabric

Cutting from the printed roll directly

✔ The contour recognition system allows the exact cut along the printed contours

✔ Fusion of cutting edges - no need for trimming

✔ Ideal for processing stretchy and easily distorted materials (Polyester, Spandex, Lycra )

Your popular and wise manufacturing direction

✔ Versatile and flexible laser treatments broaden the breadth of your business

✔ Cut along the pressure contours thank to the mark point positioning technology

✔ Value-added laser abilities like engraving, perforating, marking suitable for entrepreneurs and small business

of Contour Laser Cutter 180L

Materials: Polyester, Spandex, Lycra, Silk, Nylon, Cotton and other sublimation fabrics

Applications: Sublimation Accessories (Pillow), Rally Pennants, Flag, Signage, Billboard, Swimwear, Leggings, Sportswear, Uniforms

The Newest Update about camera laser cutter

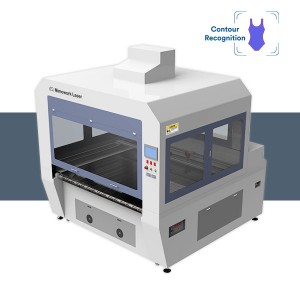

Super Camera Laser Cutter for Sportswear

✦ Updated Dual-Y-Axis Laser Heads

✦ 0 Delay Time - Continuous Processing

✦ High Automation - Less Labors

The sublimation fabric laser cutter is equipped with HD camera and extended collection table, that is more efficient and convenient for the whole laser cutting sportswear or other sublimation fabrics. We updated the dual laser heads into Dual-Y-Axis, which is more suitable for laser cutting sportswear, and further enhances cutting efficiency without any interference or delay.

Difference Between Traditional and Vision Laser Cutter

A Unqiue Challenge

In the realm of garment manufacturing, especially for heat-transfer printed apparel like sportswear, swimwear, yoga pants, and baseball jerseys, achieving precise and accurate cuts poses a unique challenge. The thermal transfer process subjects fabrics to high temperatures, leading to thermal expansion and contraction, resulting in unpredictable deformations. This, in turn, affects the fidelity of the printed designs.

Traditional CNC laser cutting devices, reliant on imported cutting designs executed through control software, face limitations when dealing with fabrics post-heat transfer printing. The inherent mismatch between the initially designed graphics and the actual fabric patterns calls for a more adaptive solution – the Vision Laser Cutting Machine.

Beyond the Conventional

This cutting-edge machine goes beyond the conventional by integrating an industrial-grade camera into its system. This camera captures the intricate details of each fabric piece, creating a visual record of the specific pattern. What sets the Vision Laser Cutting Machine apart is its ability to instantaneously process this visual data, automatically generating cutting contours that precisely align with the unique features of the fabric.

By leveraging this technology, manufacturers can significantly enhance the accuracy and precision of their cutting processes. The Vision Laser Cutting Machine addresses the challenges posed by thermal deformations, ensuring that the final cut aligns seamlessly with the intended design. This not only minimizes material waste but also maximizes the overall efficiency of the manufacturing workflow.

Dynamic Production

Furthermore, the machine's adaptability proves invaluable in a dynamic production environment where diverse fabrics and intricate designs are the norm. Whether it's intricate logos on baseball jerseys or detailed patterns on yoga pants, the Vision Laser Cutting Machine provides a versatile and reliable solution, catering to the specific needs of the heat-transfer printed garment industry.

In Conclusion

The Vision Laser Cutting Machine emerges as a game-changer in the garment manufacturing landscape, offering a sophisticated and efficient approach to cutting heat-transfer printed fabrics. Its integration of industrial cameras and real-time processing capabilities sets a new standard for precision, ultimately contributing to the production of high-quality, accurately cut garments in the competitive world of fashion manufacturing.