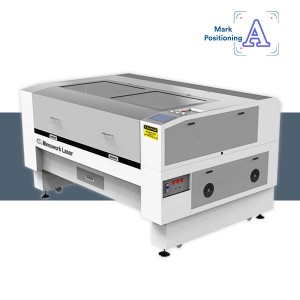

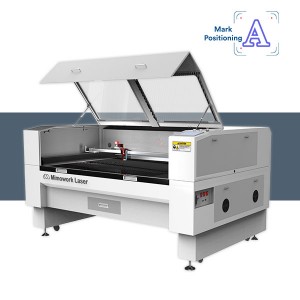

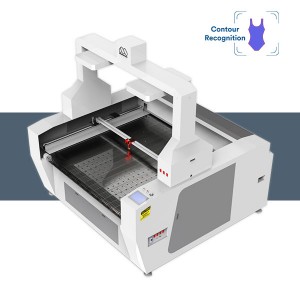

6090 Contour Laser Cutter

Technical Data

| Working Area (W*L) | 900mm * 500mm (35.4” * 19.6”) |

| Software | CCD Software |

| Laser Power | 50W/80W/100W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Drive & Belt Control |

| Working Table | Honey Comb Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Advantages of 6090 Contour Laser Cutter

Best Entry-level Model with Excellent Cutting Performance

◉ Flexible and fast label laser cutting technology helps your products quickly respond to market needs

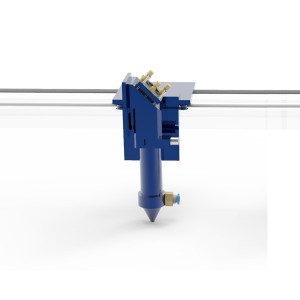

◉ Mark pen makes the labor-saving process and efficient cutting & marking operations possible

◉ Upgraded cutting stability and safety - improved by adding the vacuum suction function

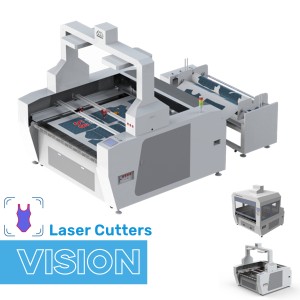

◉ Automatic feeding allows unattended operation which saves your labor cost, lowers the rejection rate (Optional auto-feeder)

◉ Advanced mechanical structure allows laser options and customized working table

Highlights of the CCD Laser Cutter

The precise calculation capabilities of the CCD Camera make it an essential component in the operation of the woven label laser cutting machine. By accurately locating the position of small patterns, it ensures that each cutting instruction is highly accurate, with positioning errors being within one-thousandth of a millimeter. This results in consistently high-quality cuts, ensuring the perfect shape and size of your woven label designs. With the CCD Camera's exceptional accuracy and the woven label laser cutting machine's advanced technology, you can achieve excellent cutting results that will impress your clients and meet their demands.

The Shuttle Table option for our laser cutting machine provides dual working tables that can operate interchangeably, greatly enhancing productivity. While one table is cutting, the other can be loaded and unloaded, enabling continuous work without interruptions. This feature saves time and increases efficiency by allowing the collection, placement, and cutting of materials simultaneously. With the Shuttle Table, your workflow can be streamlined to maximize production output.

The 6090 Contour Laser Cutter is an advanced and reliable machine that comes equipped with an integrated water-protection system. This feature is designed to provide maximum protection for the laser tube, ensuring optimal performance and longevity. The water-protection system helps to prevent damage to the laser tube caused by overheating, which can occur due to prolonged use or other factors.

Compact Machine body design

The 6090 Contour Laser Cutter is a versatile machine that is comparable in size to an office table, making it an ideal choice for factories and workshops where space is at a premium. Whether it's for use in the proofing room or on the production floor, this label-cutting machine can be placed anywhere you need it. Despite its compact size, the 6090 Contour Laser Cutter packs a powerful punch and can deliver accurate, high-quality cuts on a wide range of materials, including labels, patches, stickers, and other garment accessories. Its small size makes it easy to move around and install, without sacrificing functionality or precision. With the 6090 Contour Laser Cutter, you can get the job done efficiently and effectively, no matter where you are in your factory or workshop.

Find more videos about our laser sticker cutters at our Video Gallery

The secret of exquisite pattern cutting

✔ Realize unattended cutting process, reduce manual workload

✔ High-quality value-added laser treatments like engraving, perforating, marking from MimoWork adaptable laser ability, suitable to cut diverse materials

✔ Customized tables meet requirements for varieties of materials formats

of 6090 Contour Laser Cutter

Laser-friendly Materials: dye sublimation fabric, film, foil, plush, fleece, nylon, velcro, leather, non-woven fabric, and other non-metal materials.

Typical applications: embroidery, patch, woven label, sticker, applique, lace, clothing accessories, home textiles, and industrial fabrics.