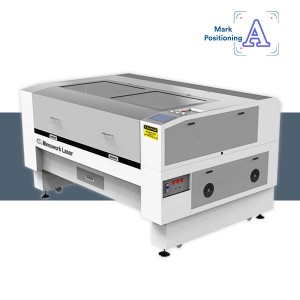

Embroidery Patch Laser Cutting Machine 90

Laser Cutting Embroidery Patches with the Best

Technical Data

| Working Area (W*L) | 900mm * 500mm (35.4” * 19.6”) |

| Software | CCD Software |

| Laser Power | 50W/80W/100W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Drive & Belt Control |

| Working Table | Honey Comb Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Advantages of Cutting Embroidery Patches with Laser

Laser Cutting Embroidery Patches - The Wonders of Engineering

◉ Flexible and fast label laser cutting technology helps your products quickly respond to market needs

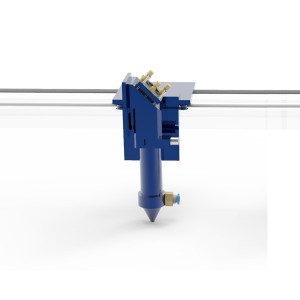

◉ Mark pen makes the labor-saving process and efficient cutting & marking operations possible

◉ Upgraded cutting stability and safety - improved by adding the vacuum suction function

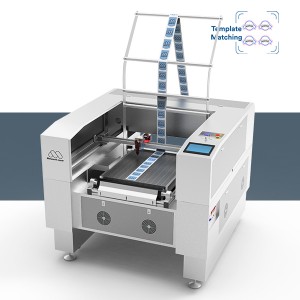

◉ Automatic feeding allows unattended operation which saves your labor cost, lower rejection rate (optional auto-feeder)

◉ Advanced mechanical structure allows laser options and customized working table

Embroidery Patch Laser Cutting Machine 90 - Highlights

The CCD Camera can accurately locate the position of the small patterns through precise calculation, and every time positioning error is only within one-thousandth of a millimeter. That provides accurate cutting instruction for the woven label laser cutting machine.

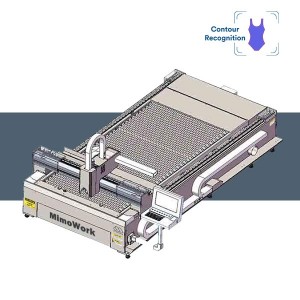

With the optional Shuttle Table, there will be two working tables that can work alternately. When one working table completes the cutting work, the other one will replace it. Collecting, placing material and cutting can be carried out at the same time to ensure production efficiency.

Compact Machine body design

Embroidery Patch Laser Cutting Machine 90 is like an office table, which does not require a large area. The label cutting machine can be placed anywhere in the factory, no matter the proofing room or workshop. Small in size but provides you with great help.

Find more videos about our laser sticker cutters at our Video Gallery

✔ Realize unattended cutting process, reduce manual workload

✔ High-quality value-added laser treatments like engraving, perforating, marking from MimoWork adaptable laser ability, suitable to cut diverse materials

✔ Customized tables meet requirements for varieties of materials formats

Why Cutting Embroidery Patches with Laser?

The Secret of Exquisite Pattern Cutting

Laser cutting Embroidery Patches isn't just efficient - it's also incredibly versatile. From leather and felt to cotton and polyester, the laser cutter can work with a variety of materials, allowing you to create patches that perfectly match your vision.

Whether you're a small business looking to expand your patch-making capabilities or an individual looking to add a personal touch to your wardrobe, laser-cutting embroidery patches are the way to go. Say goodbye to tedious cutting and hello to a faster, more efficient, and more creative way of creating patches.

of Embroidery Patch Laser Cutting Machine 90

Laser-friendly Materials: dye sublimation fabric, film, foil, plush, fleece, nylon, velcro, leather, non-woven fabric, and other non-metal materials.

Typical applications: embroidery, patch, woven label, sticker, applique, lace, clothing accessories, home textiles, and industrial fabrics.