Lace Laser Cutting Machine with High Precision

| Working Area (W *L) | 1600mm * 1,000mm (62.9”* 39.3”) - Standard |

| 1600mm * 1200mm (62.9” * 47.2”) - Extended | |

| Software | CCD Registration Software |

| Laser Power | 100W / 150W / 300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Drive & Belt Control |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

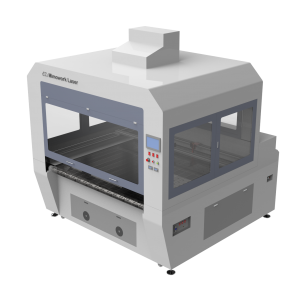

Lace Laser Cutter (Fully Enclosed)

| Working Area (W *L) | 1800mm * 1300mm (70.87’’ * 51.18’’) |

| Max Material Width | 1800mm ( 70.87’’ ) |

| Laser Power | 100W/ 130W/ 150W/ 300W |

| Laser Source | CO2 Glass Laser Tube / RF Metal Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Unleash the Artistry: Precision meets Elegance

For Lace Laser Cutter 160 & 160L (Standard & Extended):

◉ Sublimation laser cutting for flexible materials like Lace and Other Garment Accessories

◉ Enhanced two laser heads, significantly increasing your productivity (Optional Upgrades)

◉ CNC (Computer Numerical Control) and computer data support high automation processing and constant stable high-quality output

◉ MimoWork Smart Vision Laser Cutter Software automatically corrects deformation and deviation

◉ Wide applications in industries such as Digital Printing, Composite Materials, Clothing & Home Textiles

◉ Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs

◉ Auto-feeder provides automatic feeding, allowing unattended operation which saves your labor cost, and lower rejection rate (Optional Upgrades)

For Lace Laser Cutter (Fully Enclosed):

◉ Wide applications in industries such as digital printing, composite materials, clothing & home textiles

◉ Flexible and fast MimoWork laser cutting technology helps your products to quickly respond to market needs

◉ Evolutionary Visual Recognition Technology and powerful software provide higher quality and reliability for your business.

◉ Automatic feeding allows unattended operation which saves your labor cost and lowers the rejection rate (optional)

◉ The Fully Enclosed Structure is added to the conventional Vision Laser Cutting Machine.

There are 3 areas of improvement in the performance of this contour laser cutter:

1. Safety of Operator

2. Clean working environment and better dust exhausting effect

3. Better optical recognition ability

Highlights of the Lace Laser Cutting Machines

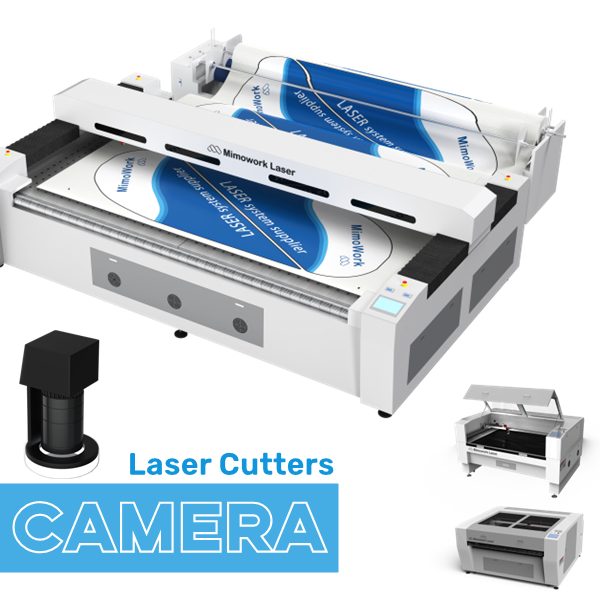

The CCD Camera equipped next to the laser head can detect feature marks to locate the printed, embroidered, or woven patterns and the software will apply the cutting file to the actual pattern with 0.001mm accuracy to ensure the highest precious cutting result.

The Contour Recognition System detects the contour according to the color contrast between the printing outline and the material background. No need to use the original patterns or files. After automatic feeding, printed fabrics will be directly detected. This is a fully automatic process without human intervention. Moreover, the camera will take photos after the fabric is fed to the cutting area. The cutting contour will be adjusted to eliminate deviation, deformation, and rotation, thus, you can eventually achieve a highly precise cutting result.

When you are trying to cut high-distortion contours or pursue super high precise patches and logos, the Template Matching System is more suitable than the contour cut. By matching your original design templates with the photos taken by the HD camera, you can easily get the exact same contour that you want to cut. Also, you can set deviation distances according to your personalized requirements.

Independent Dual Heads - Optional Upgrade

For a basic two laser heads cutting machine, the two laser heads are mounted on the same gantry, so they can not cut different patterns at the same time. However, for many fashion industries like dye sublimation apparel, for example, they may have the front, back, and sleeves of a jersey to cut. At this point, the independent dual heads can handle pieces of different patterns at the same time. This option boosts the cutting efficiency and production flexibility to the largest degree. Output can be increased from 30% to 50%.

Auto Feeder is a feeding unit that runs synchronously with the laser cutting machine. Coordinated with conveyor table, the auto feeder can convey the roll materials to the cutting table after you put the rolls on the feeder. To match the wide format materials, MimoWork recommends the widened auto-feeder which is able to carry a bit of heavy load with large format, as well as ensure feeding smoothly. Feeding speed can be set according to your cutting speed. A sensor is equipped to ensure perfect material positioning and minimize errors. The feeder is able to attach different shaft diameters of rolls. The pneumatic roller can adapt textiles with various tension and thickness. This unit helps you to realize a completely automatic cutting process.

Y-axis Gear & X-axis Belt Drive

The camera laser cutting machine features a Y-axis rack & pinion Drive and X-axis belt transmission. The design offers a perfect remedy between a large format working area and smooth transmission. Y-axis rack & pinion is a type of linear actuator that comprises a circular gear (the pinion) engaging a linear gear (the rack), which operates to translate rotational motion into linear motion. The rack and the pinion drive each other spontaneously. Straight and helical gears are available for the rack & pinion. X-axis belt transmission provides a smooth and steady transmission to the laser head. High-speed and high precision laser cutting can be completed.

Optional Servo Motor

Unlock lightning-fast cutting speeds with the dynamic servo motor motion system. Elevate the performance of the Sublimation Laser Cutter Machines to new heights as it effortlessly carves intricate outer contour graphics with unwavering precision. Embrace the power of servo and experience unrivaled stability and speed.

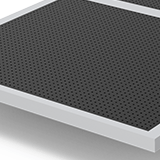

The Vacuum Suction lies under the cutting table. Through the small and intensive holes on the surface of the cutting table, the air 'fastens' the material on the table. The vacuum table does not get in the way of the laser beam while cutting. On the contrary, together with the powerful exhaust fan, it enhances the effect of smoke & dust prevention during cutting.

Fully Enclosure Design - Optional Upgrade

With the special design of the fully enclosed door, the Enclosed Contour Laser Cutter can ensure a better exhausting and further improve the recognition effect of the HD camera to avoid vignetting that affects the contour recognition in the case of poor lighting conditions. The door on all four sides of the machine can be opened, which will not affect daily maintenance and cleaning.

Laser Cutting Lace Fabric (Applique, Embroidery)

Fully Enclosure Design - Showcase

Find more videos about our laser cutters at our Video Gallery

Fields of Application

for Lace Laser Cutting Machines

Embrace Elegance, Precision Meets Intricacy

✔ The CCD Camera accurately locates the registration marks

✔ Optional dual laser heads can greatly increase the output and efficiency

✔ Clean and accurate cutting edge without post-trimming

✔ Cut along the press contours after detecting the mark points

✔ Laser cutting machine is suitable for both short-run production and mass-production orders

✔ High Precision within the 0.1 mm error range

✔ Unlock the secrets of laser cutting for Lace Accessories and unleash a world of possibilities

✔ Experience flawless precision, intricate designs, vibrant elegancy, and seamless customization

✔ Elevate your creations to new heights with the artistry and efficiency of laser-cutting technology

✔ Step into the future of Lace Accessory production and watch your creativity come to life in breathtaking detail

Flawless Perfection with Limitless Creativity

Perfect Fit, Every Time: Achieve consistent, tailored cuts that ensure a perfect fit, enhancing comfort and confidence in lace garments.

Seamless Integration, Streamlined Workflow: Seamlessly integrate laser cutting technology into production processes for increased efficiency and productivity.

Elevate Craftsmanship, Exquisite Details: Elevate the art of lace-making with laser precision, highlighting intricate details and enhancing the overall craftsmanship.

Unleash Lace's Potential: Embrace the transformative power of laser cutting, pushing the boundaries of lace craftsmanship and creating unforgettable, breathtaking designs.

Efficient Production, Timeless Elegance: Save time and resources while maintaining timeless elegance with fast, efficient laser cutting for lace materials.

of Sublimation Laser Cutting Machines

Materials:

Twill, Velvet, Velcro, Nylon, Polyester, Film, Foil, and other Patterned Materials

Polyester Fabric, Spandex, Nylon, Silk, Printed Velvet, Cotton, and other Sublimation Textiles

Applications:

Apparel, Clothing Accessories, Lace, Home Textiles, Photo Frame, Labels, Sticker, Applique

Active Wear, Sportswear (Cycling Wear, Hockey Jerseys, Baseball Jerseys, Basketball Jerseys, Soccer Jerseys, Volleyball Jerseys, Lacrosse Jerseys, Ringette Jerseys)

Uniforms, Swimwear, Leggings, Sublimation Accessories (Arm Sleeves, Leg Sleeves, Bandanna, Headband, Face Cover, Masks)