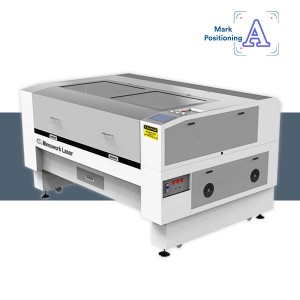

Laser Cut Sportswear Machine (180L)

| Working Area (W *L) | 1800mm * 1300mm (70.87’’ * 51.18’’) |

| Max Material Width | 1800mm / 70.87’’ |

| Laser Power | 100W/ 130W/ 300W |

| Laser Source | CO2 Glass Laser Tube / RF Metal Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Dual-Laser-Heads option is avaliable

Laser Cutting Sublimation Sportswear in Style

Changing the Game in Sublimation Cutting

▶ MimoWork's Laser Cut Sportswear Machine (180L) with a generous working table size of 1800 mm*1300 mm is your ticket to effortless and precise cutting of sublimation fabrics!

▶ Perfectly suited for a range of industries, including digital printing products like advertising banners, clothing, and home textiles, this innovative technology allows for fast and accurate cutting of dye sublimation textiles.

▶ No need to worry about the challenge of cutting stretchy fabrics. Our Advanced Visual Recognition Technology and powerful software recognizes distortions or stretches in the fabric, ensuring the printed pieces are cut to the correct size and shape.

▶ But wait, there's more! Our Automatic Feeding System and the conveying work platform work together to achieve an automatic roll-to-roll processing process, saving labor and boosting efficiency. And with laser cutting, the edges are sealed directly during the cut, so no additional processing is required.

D&R for Laser Cutting Sublimation Sportswear

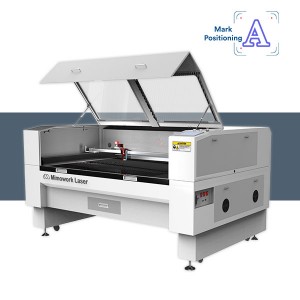

Large Working Table

With a larger and longer working table, it is suitable for a variety of industry applications. Whether you want to produce printed banners, flags, or ski-wear, a cycling jersey will be your right-hand man. With the auto-feeding system, it can help your cut out from a printed roll perfectly. And our working table width can be customized and perfectly fit with major printers and heat presses, such as Monti's Calender for printing.

Equipped Cannon HD camera on the top of the machine, this ensures that the Contour Recognition System can accurately identify the graphics that need to be cut. The system does not need to use original patterns or files. After automatic feeding, this is a fully automatic process without manual intervention. In addition, the camera will take pictures after the fabric is fed into the cutting area, and then adjust the cutting contour to eliminate deviation, deformation and rotation, and finally achieve a high-precision cutting effect.

An increase in productivity thanks to auto-loading and unloading during the cutting process. The conveyor system is made out of stainless steel mesh, suitable for lightweight and stretchy fabrics, such as polyester fabrics and spandex, that's commonly used in dye-sublimation fabrics. And through the specially set down exhaust system under the Conveyor Working Table, the fabric is fixed on the processing table tamely. Combined with the contact-less laser cutting, no distortion will appear despite the direction that the laser head is cutting.

Video Display

Looking to streamline your sublimation printing process? Look no further than our sublimation laser cutter with camera recognition technology! With automatic pattern positioning and contour cutting, this innovative machine eliminates the need for manual intervention and post-trimming. Say goodbye to lengthy workflows and hello to improved production efficiency!

Whether for sublimation printed fabric or solid fabric, contactless laser cutting ensures textiles are fixed and not damaged.

Find more videos about our laser cutters at our Video Gallery

Having Doubts About Sublimation Sportswear Laser Cutting?

Fields of Application

The Bright Future of Laser Cutting Sublimation Sportswear

Designed for & Excelled at Sublimation Sportswear Cutting

High-precision cutting: Laser cutting technology provides precise and clean cuts for sportswear materials, creating intricate and complex designs with ease.

Versatility: Laser cutting machines can cut a wide range of materials, including fabrics, leather, and plastics, making it a versatile option for sportswear designers.

Increased efficiency: Laser cutting allows for faster and more efficient production of sportswear, reducing lead times and increasing productivity.

Reduced waste: With laser cutting, there is minimal material wastage, as the machine optimizes the use of materials, resulting in cost savings for the manufacturer and a more environmentally-friendly production process.

Customization: Laser cutting can create personalized designs on sportswear, providing customers with unique and individualized products.

Safety: Laser-cutting machines have safety features to protect the operator, reducing the risk of accidents or injuries during the manufacturing process.

of Laser Cut Sportswear Machine (180L)

Materials: Spandex, Lycra, Silk, Nylon, Cotton, and other sublimation fabrics

Applications: Rally Pennants, Flag, Signage, Billboard, Swimwear, Leggings, Sportswear, Uniforms