150W Laser Cutter

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 150W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* More sizes of laser working table are customized

* Higher Laser Tube Output Power Available

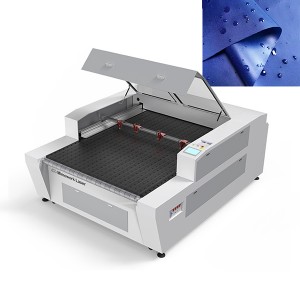

▶ FYI: The 150W Laser Cutter is suitable to cut and engrave on solid materials such as acrylic and wood. Honey comb working table and knife strip cutting table can carry the materials and help to reach best the cutting effect without dust and fume that can be sucked into and purified.

Video of Laser Engraving Photos on Wood

Laser engraving photos on wood offers a range of benefits, including the ability to customize and cut designs with flexibility, create clean and intricate patterns, and achieve a three-dimensional effect with adjustable power. These advantages make laser engraving on wood an ideal choice for personalized and high-quality wood products.

Typical materials for Laser Cutting & Engraving Wood

Bamboo, Balsa Wood, Beech, Cherry, Chipboard, Cork, Hardwood, Laminated Wood, MDF, Multiplex, Natural Wood, Oak, Plywood, Solid Wood, Timber, Teak, Veneers, Walnut…

Find more videos about our laser cutters at our Video Gallery

Crystal surface and exquisite engraving details

✔ Bringing about more economical and environment-friendly manufacturing process

✔ Customized patterns can be engraved whether for pixel and vector graphic files

✔ Quick response to market from samples to large-lot production