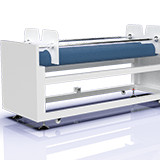

1610 CO2 Laser Cutting Machine

◉ Flexible & quick cutting:

Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs

◉ Safe and stable laser structure:

The addition of a vacuum suction function has resulted in a substantial improvement in cutting stability and safety. The vacuum suction function is seamlessly integrated into the laser cutting machine, providing reliable and consistent performance.

◉ Popular size for multiple materials:

Standard 1600mm * 1000mm is accord with most materials formats like fabric and leather (working size can be customized)

◉ Automatic production - less labor:

Automatic feeding and conveying allow unattended operation which saves your labor cost, and lower the rejection rate (optional). Mark pen makes the labor-saving processes and efficient cutting and materials labeling operations possible

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Servo Motor Upgrade Available

(As Your Garment Laser Cutter, Leather Laser Cutter, Lace Laser Cutter)

R&D for 1610 Laser Cutting Machine

Two / Four / Multiple Laser Heads

Customize Your Order to Meet your Requirments

MimoWork is here to help you with Laser Advice!

Video Display of Textile Laser Cutting

Dual Heads Laser Cutting on Denim

• The Auto Feeder and Conveyor System integrated into the laser cutting process is a game-changer for those looking to increase efficiency and decrease labor costs. The Auto Feeder allows for the fast conveyance of roll fabric to the laser table, preparing it for the laser cutting process without any manual intervention. The Conveyor System complements this by efficiently transporting the material through the laser system, ensuring stress-free material feeding and preventing material distortion.

• In addition, laser cutting technology is versatile and offers excellent penetration power through fabrics and textiles. This allows for precise, flat, and clean cutting quality to be achieved in a shorter amount of time than traditional cutting methods. This is especially useful for those in the textile industry who need to produce high volumes of cut materials quickly and with high accuracy.

Details Explanation

you can see the smooth and crisp cutting edge without any burr. That is incomparable with traditional knife cutting. Non-contact laser cutting ensures being intact and undamaged for both fabric and laser head. Convenient & safe laser cutting becomes ideal choice for the apparel, sportswear equipment, home textiles manufacturers.

Fields of Application

Laser Cutting for Your Industry

Common materials and applications

of Flatbed Laser Cutter 160

Materials: Fabric, Leather, Cotton, Nylon, Film, Foil, Foam, Spacer Fabric, and other Composite Materials

Applications: Footwear, Plush Toys, Garment, Fashion, Garment Accessories, Filter Media, Airbag, Fabric Duct, Car Seat, etc.

Engraving, marking, and cutting can be realized in single process

✔ MimoWork laser guarantees the exacting cutting quality standards of your products

✔ Fewer material waste, no tool wear, better control of production costs

✔ Ensures a safe working environment during operation

The laser's precision is second to none, ensuring that the output is of the highest quality. The smooth and lint-free edge is achieved through the heat treatment process, ensuring that the end product is clean and presentable.

With the machine's conveyor system in place, the roll fabric can be conveyed quickly and easily to the laser table, preparing for laser cutting much faster and less labor-intensive.

Your popular and wise manufacturing direction

✔ Smooth and lint-free edge through heat treatment

✔ High quality brought by fine laser beam and contact-less processing

✔ Greatly saving cost to avoid materials waste

The secret of exquisite pattern cutting

✔ Achieve an uninterrupted cutting process, reduce the need for manual intervention, and streamline workload with automated laser cutting.

✔ With high-quality laser treatments, such as engraving, perforating, and marking, you can add value and customization to your products.

✔ Tailored laser cutting tables can accommodate a wide range of materials and formats, ensuring that you can meet all your cutting needs with precision and ease.