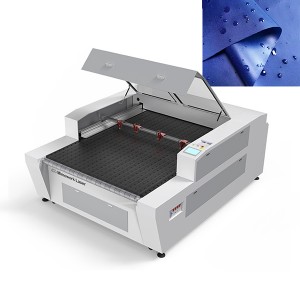

300W Laser Cutting Machine

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* More sizes of laser working table are customized

▶ FYI: The 300W Laser Cutting Machine is suitable to cut and engrave on solid materials such as acrylic and wood. Honey comb working table and knife strip cutting table can carry the materials and help to reach best the cutting effect without dust and fume that can be sucked into and purified.

Video of Laser Cutting & Engraving Acylic (PMMA)

Proper and right laser power guarantees heat energy uniformly melts through acrylic materials. Precise cutting and fine laser beams create unique acrylic artwork with a flame-polished edge. Laser is the ideal tool to process acrylic.

Highlights From: Acrylic Laser Cutting & Engraving

✔ Perfectly polished clean cutting edges in a single operation

✔ No need to clamp or fix the acrylic due to contactless processing

✔ Flexible processing for any shape or pattern

✔ Subtle engraved pattern with smooth lines

✔ Permanent etching mark and clean surface

✔ No need for post-polishing

Video of Laser Engraving Wood Board

Wood can be easily worked on laser and its tenacity makes it suitable to apply to many applications. You can make so many sophisticated creatures out of wood. What's more, due to the fact of thermal cutting, the laser system can bring exceptional design elements in wood products with dark-colored cutting edges and brownish-colored engravings.

Excellent Laser Engraving Effect on Wood

✔ No shavings – thus, easy cleaning up after processing

✔ super-fast wood laser engraving for the intricate pattern

✔ Delicate engravings with exquisite & fine details

Find more videos about our laser cutters at our Video Gallery

Crystal surface and exquisite engraving details

✔ Bringing about more economical and environment-friendly manufacturing process

✔ Customized patterns can be engraved whether for pixel and vector graphic files

✔ Quick response to market from samples to large-lot production

Unique advantages of laser cutting signs & decorations

Laser cutting and engraving signs and decorations offer unparalleled benefits for advertising and gifts. With thermal melting technology, it delivers clean and smooth edges on processed materials, ensuring high-quality output. Unlike traditional methods, laser cutting has no limitations on shape, size, and pattern, allowing for flexible customization options that cater to your specific needs. With customized laser tables, you can process a variety of materials in different formats, making it the perfect solution for your advertising and gift-giving needs.