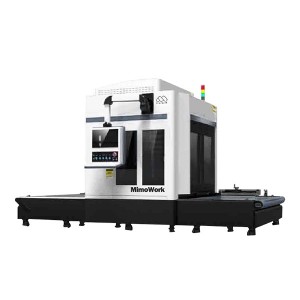

3D Laser Series [For Subsurface Laser Engraving]

Technical Data

| Configuration Detail | Starter#1 | Starter#2 |

| Max Engraving Size (mm) | 400*300*120 | 120*120*100 (Circle Area) |

| Max Crystal Size (mm) | 400*300*120 | 200*200*100 |

| No Tilling Area* | 50*80 | 50*80 |

| Laser Frequency | 3000Hz | 3000Hz |

| Motor Type | Step Motor | Step Motor |

| Pulse Width | ≤7ns | ≤7ns |

| Point Diameter | 40-80μm | 40-80μm |

| Machine Size (L*W*H) (mm) | 860*730*780 | 500*500*720 |

No Tilling Area*: The area where the image will not be split into different sections when engraved, higher = better.

| Configuration Detail | Mid-Range#1 | Mid-Range#2 |

| Max Engraving Size (mm) | 400*300*150 | 150*200*150 |

| Max Crystal Size (mm) | 400*300*150 | 150*200*150 |

| No Tilling Area* | 150*150 | 150*150 |

| Laser Frequency | 4000Hz | 4000Hz |

| Motor Type | Servo Motor | Servo Motor |

| Pulse Width | ≤6ns | ≤6ns |

| Point Diameter | 20-40μm | 20-40μm |

| Machine Size (L*W*H) (mm) | 860*760*1060 | 500*500*720 |

No Tilling Area*: The area where the image will not be split into different sections when engraved, higher = better.

| Configuration Detail | High-End#1 | High-End#2 |

| Max Engraving Size (mm) | 400*600*120 | 400*300*120 |

| Max Crystal Size (mm) | 400*600*120 | 400*300*120 |

| No Tilling Area* | 200*200 Circle | 200*200 Circle |

| Laser Frequency | 4000Hz | 4000Hz |

| Motor Type | Servo Motor | Servo Motor |

| Pulse Width | ≤6ns | ≤6ns |

| Point Diameter | 10-20μm | 10-20μm |

| Machine Size (L*W*H) (mm) | 910*730*1650 | 900*750*1080 |

No Tilling Area*: The area where the image will not be split into different sections when engraved, higher = better.

| Universal Configurations: Applies to All Three Configurations (Starter/ Mid-Range/ High-End) | ||

| Motion Control | 1 Galvo+X, Y, Z | |

| Repeated Location Accuracy | <10μm | |

| Engraving Speed | Maximum: 3500 points/s 200,000dots/m | |

| Diode Laser Module Life | >20000 hours | |

| Supported File Format | JPG, BMP, DWG, DXF, 3DS, etc | |

| Noise Level | 50db | |

| Cooling Method | Air Cooling | |

(The Perfected Future is Here - 3D Crystal Laser Engraving)

Highlights of 3D Crystal Engraving

Designed for Crystal Engraving: Diode Pumped Nd:YAG 532nm Green Laser

(High Precision, High Repetition Rate, Long Lifetime)

Surgical Precision in 3D Subsurface Laser Engraving Crystal

(≤6ns Pulse Width, Enhanced Precision with Minimal Material Damage)

Repeated Location Accuracy at <10μm in 3D Subsurface Laser Engraving

(Consistent Engraving Results for High Volume Production)

The Affordable Future is Here!

Start your 3D Crystal Engraving Business Now!

(The Start of a Successful Business - 3D Subsurface Crystal Laser Engraving)

Fields of Application

The Power of the Laser in the Palm of your Hand

3D laser crystal engraving has a wide range of applications, from personalized gifts and awards to corporate branding and promotional items. The versatility and precision of 3D laser crystal engraving make it a valuable tool for personalization, recognition, and creating memorable, high-quality products.

Common Applications

of 3D Laser Series [For Subsurface Laser Engraving]

Personalized Gifts and Awards: 3D laser crystal engraving is frequently used to create customized gifts and awards.

Corporate Branding and Promotions: Many businesses leverage 3D laser crystal engraving to produce promotional items and corporate gifts.

Memorials and Commemorations: 3D laser crystal engraving is often employed to create plaques, monuments, and headstones.

Art and Décor: Artists and designers harness the capabilities of 3D laser crystal engraving to craft distinctive art pieces and decorative objects.

Jewelry and Accessories: In the jewelry industry, photographs on crystal pendants, bracelets, and other accessories, add a personalized touch.

Crystal Awards: 3D laser crystal engraving is widely used to create awards for various industries and events.

Wedding Gifts: Personalized crystal wedding gifts, such as engraved photo frames or crystal sculptures, are popular applications of 3D laser crystal engraving.

Corporate Gifts: Many companies utilize 3D laser crystal engraving to create customized gifts for clients, employees, or business partners.

Memorial Keepsakes: 3D laser crystal engraving is often employed to create memorial keepsakes, to honor and remember loved ones who have passed away.

![3D Laser Series [For Subsurface Laser Engraving] Featured Image](https://cdnus.globalso.com/mimowork/3d-laser-series-high-end-1.png)

![3D Laser Series [For Subsurface Laser Engraving]](https://cdnus.globalso.com/mimowork/3d-laser-series-high-end-1-300x300.png)

![3D Laser Series [For Subsurface Laser Engraving]](https://cdnus.globalso.com/mimowork/3d-laser-series-high-end-2-300x300.png)

![3D Laser Series [For Subsurface Laser Engraving]](https://cdnus.globalso.com/mimowork/3d-laser-series-high-end-3-300x300.png)

![3D Laser Series [For Subsurface Laser Engraving]](https://cdnus.globalso.com/mimowork/3d-laser-series-starter-300x300.png)

![3D Fiber Laser Engraving Machine [Dynamic Focusing]](https://cdnus.globalso.com/mimowork/3d-fiber-laser-engraving-machine-300x300.png)