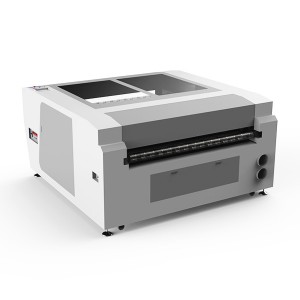

Contour Laser Cutter 160

| Wurin Aiki (W *L) | 1600mm * 1,000mm (62.9''* 39.3'') |

| Software | Software na Rijistar CCD |

| Ƙarfin Laser | 100W / 150W / 300W |

| Tushen Laser | CO2 Gilashin Laser Tube ko CO2 RF Metal Laser Tube |

| Tsarin Kula da Injini | Matakin Tuba Motoci & Kula da Belt |

| Teburin Aiki | Teburin Aiki Mai Sauƙi Karfe |

| Max Gudun | 1 ~ 400mm/s |

| Gudun Haɗawa | 1000 ~ 4000mm/s2 |

Amfanin Injin Cutter Laser Machine 160

Babban tsari, Faɗin aikace-aikace

◉Sublimation Laser sabon ga m kayan kamarmasana'anta sublimationkumakayan haɗi na tufafi

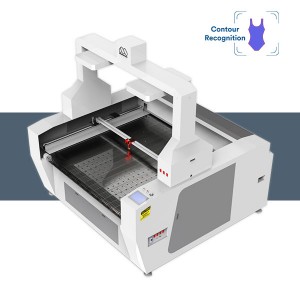

◉ Haɓaka kawunan Laser guda biyu, haɓaka haɓakar ku sosai (na zaɓi)

◉CNC (Kwamfutar Lambobin Kwamfuta) da bayanan kwamfuta suna goyan bayan babban sarrafa sarrafa kansa da ingantaccen ingantaccen fitarwa mai inganci

◉MimoWork SmartVision Laser Cutter Softwareta atomatik gyara nakasawa da karkata

◉ Mai ciyar da kaiyana ba da ciyarwa ta atomatik & ciyarwa mai sauri, yana ba da izinin aiki mara kulawa wanda ke adana kuɗin aikin ku, ƙarancin ƙi (na zaɓi)

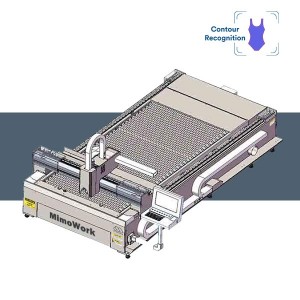

Karin bayanai na Injin Yankan Laser Vision

Gidan yanar gizo na bakin karfe zai dace da kayan sassauƙa kamar allura kai tsaye da yadudduka da aka buga ta dijital. Tare daTebur Mai Canjawa, ci gaba da aiwatar da za a iya sauƙi gane, ƙwarai ƙara your yawan aiki.

TheCCD Kamarasanye take kusa da Laser shugaban iya gane alama alamomi don gano wuri da buga, embroidered, ko saka alamu da software za su yi amfani da yankan fayil zuwa ainihin abin kwaikwaya tare da 0.001mm daidaito don tabbatar da mafi girma daraja yankan sakamakon.

Motar Servo na zaɓi

Za'a iya zaɓar tsarin motsi na motsi na Servo don samar da saurin yankewa mafi girma. Motar Servo zai inganta ingantaccen aikin C160 yayin yanke hadaddun zanen kwane-kwane na waje.

Fim ɗin Canja wurin zafi na Laser don Na'urorin haɗi

Injin Yankan Fabric | Sayi Laser ko CNC Cutter Wuka?

Nemo ƙarin bidiyoyi game da masu yankan Laser ɗin mu a wurin muGidan Bidiyo

Filayen Aikace-aikace

Goge baki da ingantaccen yankan kwane-kwane

✔ Kamara ta CCD tana gano alamar rajista daidai

✔ Zaɓuɓɓuka dual Laser shugabannin iya ƙwarai ƙara da fitarwa da kuma yadda ya dace

✔ Tsaftace kuma daidaitaccen yanki ba tare da gyarawa ba

Daidaituwa da sassauci

✔ Yanke tare da kwatancen latsa bayan gano alamun alamun

✔ Laser sabon na'ura ya dace da duka gajeren gudu da kuma umarni samar da taro

✔ Babban Madaidaici tsakanin kewayon kuskure 0.1 mm

na Contour Laser Cutter 160

Kayayyaki:Twill,Karammiski, Velcro, Nailan, Polyester,Fim, Tsaye, da sauran kayan ƙira

Aikace-aikace:Tufafi,Kayayyakin Tufafi, Yadin da aka saka, Kayan Kayan Gida, Tsarin Hoto, Lakabi, Sitika, Applique

Kwatanta Tsakanin Wuka da Yankan Laser

Lokacin da ake tattaunawa game da masu yankan wuka, da farko suna jagorantar wukar ta hanyar manyan abubuwa kamar banners da sauran alamun laushi masu kauri. Wannan hanya tana da tasiri ga kayan da ke da kauri mai yawa.

Ribobi & Fursunoni: Yankan Wuka

Matsala ta sassauci

Duk da haka, wannan dabarar ta zama matsala yayin da ake hulɗa da riguna masu sassaucin ra'ayi, musamman idan aka yi la'akari da shimfidar kayan kamar Spandex, Lycra, da Elastin.

Wuka mai ja yana ƙoƙarin jawowa da karkatar da irin waɗannan yadudduka nan take, yana haifar da plies da nakasu. Sakamakon haka, mai yankan wuka mai laushi ba zaɓi mai dacewa don kayan wasanni da kayan laushi ba.

Akasin haka, abin yanka wuka mai laushi ya yi fice wajen yankan auduga, denim, da sauran zaruruwan yanayi masu kauri. Ko da yake manual yankan tsari na iya zama m, ya tabbatar da tasiri ga yankan daban-daban masana'anta iri.

Ribobi & Fursunoni: Yankan Laser

Daidaituwa da sassauci

Tsarin laser yana fitowa a matsayin mafita mai kyau don yanke kayan wasanni na polyester da alamar laushi. Koyaya, yankan Laser bazai zama mafi kyawun zaɓi don zaruruwan yanayi ba, saboda yana barin alamar ƙona kaɗan a gefen masana'anta.

Duk da yake wannan ba shi da mahimmanci idan masana'anta na buƙatar sutura, ya zama sananne a cikin yanayi mai tsabta. Masu yankan Laser na gargajiya sukan haifar da ƙona gefuna waɗanda ke da zafi da hayaƙi mai ɗorewa, wanda ke haifar da ƙananan kumfa mai narkewa tare da yanke.

Tsarin yankan Laser na MimoWork sun magance wannan batun yadda ya kamata ta hanyar mafita ta mallaka. Haɓaka tsarin tsotsa na musamman a MimoWork Laser yankan kai, haɗe tare da ingantaccen tsarin hakar injin, yana aiki don ragewa ko kawar da wannan matsalar.

Duk da yake abokan ciniki masu laushi mai laushi bazai iya samun wannan batu game da shi ba, yana haifar da kalubale ga abokan cinikin wasanni waɗanda za su fi son kauce wa kumfa mai narkewa.

Sakamakon haka, MimoWork ya sadaukar da ƙoƙarce-ƙoƙarce don tabbatar da yanke mara aibi ba tare da ragowar narkewa ba. Ana samun wannan ta hanyar kawar da duk wani hayaki da aka saki yayin yankewa da sauri, tare da hana su shafar launi na masana'anta na polyester.

A lokaci guda, tsarin MimoWork yana hana tokar da ke iyo daga ƙonawa sake shiga masana'anta, wanda in ba haka ba zai iya barin launin rawaya. Tsarin hakar hayaki na MimoWork yana ba da garantin launin launi kuma babu ragowar narkewa tare da gefen masana'anta.