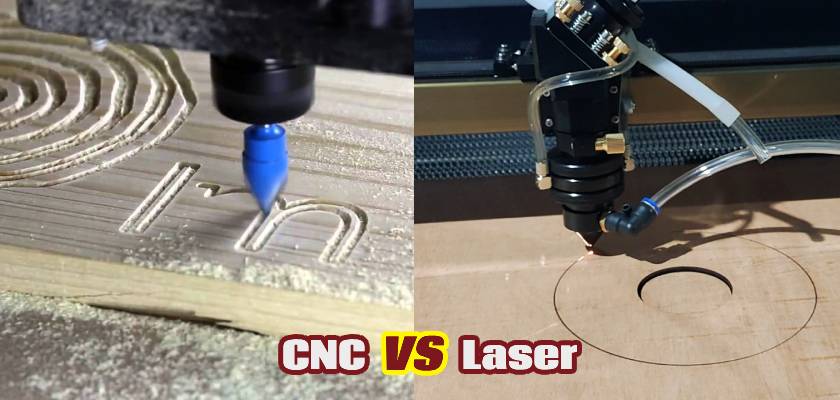

Mene ne bambanci tsakanin CNC na'ura mai ba da hanya tsakanin hanyoyin sadarwa da Laser cutter? Don yankan da sassaƙa itace, masu sha'awar aikin itace da ƙwararru sau da yawa suna fuskantar matsalar zaɓin kayan aikin da ya dace don ayyukansu. Shahararrun zabuka guda biyu sune masu amfani da hanyoyin sadarwa na CNC (Computer Number Control) da na'urorin Laser CO2, kowannensu yana da fa'ida da aikace-aikace na musamman. A cikin wannan labarin, za mu bincika bambance-bambancen da ke tsakanin waɗannan kayan aikin da kuma taimaka muku yin zaɓin da ya dace don bukatun aikin katako.

Da sauri >>

Mabuɗin Mabuɗin:

CNC Routers

Amfani:

• Cimma madaidaicin zurfin zurfin yanke tare da sarrafa axis Z.

• Mai inganci don sarrafa lanƙwasa a hankali da sassaƙaƙƙen sassaƙa.

• Ya dace da aikin katako na 3D da cikakkun kayayyaki.

Rashin hasara:

Iyakantaccen madaidaici wajen sarrafa kusurwoyi masu kaifi saboda yankan radius.

• Yana buƙatar kafaffen tarkacen abu, wanda zai iya haifar da tashin hankali a wasu lokuta.

Laser Cutters

Amfani:

• Yanke mara lamba tare da zafi mai tsanani.

• Madaidaici na musamman don sassauƙan yanke da kaifi.

• Hatimi gefuna don rage girman fadada itace da raguwa.

Rashin hasara:

• Yana iya haifar da canza launin itace, amma ana iya hana shi tare da matakan da suka dace.

• Ƙananan tasiri ga masu lanƙwasa a hankali da gefuna masu zagaye.

Rushewar Mataki ta Mataki >>

Fassarar Gabaɗaya:

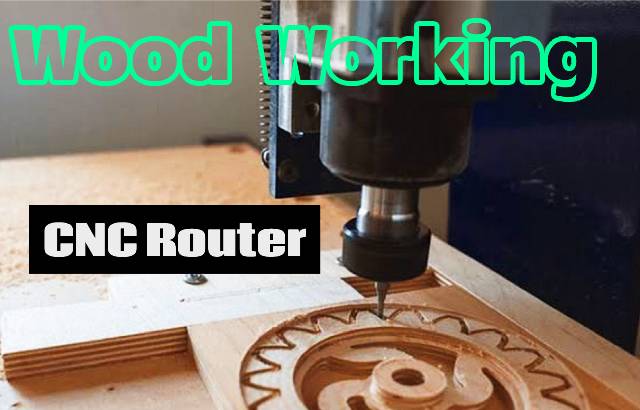

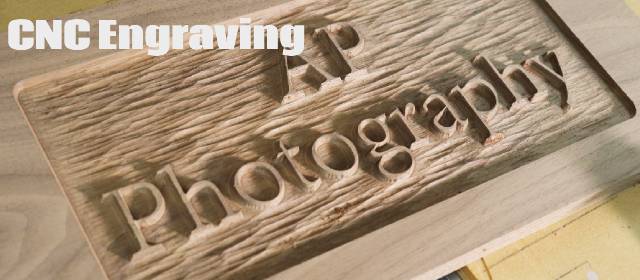

1. Menene CNC Router don itace?

A CNC (Computer Number Control) na'ura mai ba da hanya tsakanin hanyoyin sadarwa na'ura mai ba da hanya tsakanin hanyoyin sadarwa ita ce kayan aikin itace da ya rikide ya canza duniyar fasahar kere-kere da aikin katako. Sarrafa shirye-shiryen kwamfuta, masu amfani da hanyar sadarwa na CNC suna aiki tare da daidaitaccen tsari kuma suna iya samar da ƙira mai rikitarwa da yanke a itace. Suna amfani da ɗan juzu'i don cire kayan daga kayan aiki, suna sa su dace da ayyuka daban-daban, daga cikakken zane-zane da aikin katako na 3D zuwa ainihin bayanan martaba, har ma da zane-zane. A cikin wannan labarin, za mu bincika iyawa da fa'idodin masu amfani da hanyoyin CNC a cikin mahallin aikin katako, yana taimaka muku fahimtar yadda wannan fasaha ta zama kayan aiki mai mahimmanci ga masu sha'awar aikin katako da ƙwararru.

2. Menene Laser Cutter na itace?

Masu yankan Laser, masu amfani da hasken wuta mai ƙarfi, sun fito a matsayin kayan aikin juyin juya hali a fagen aikin katako. Waɗannan injunan suna amfani da ingantattun na'urori don yin ƙulle-ƙulle kuma daidaitattun sassa, da kuma zane-zane, a cikin kayan daban-daban, ciki har da itace. Tare da ikon ƙirƙirar gefuna masu kyau da kaifi, masu yankan Laser sun sami karɓuwa saboda ƙayyadaddun ƙwarewarsu na musamman da ƙaƙƙarfan ikon yankewa a cikin aikin katako, ko don ƙira, tsarawa, ko sassaƙan saman itace. A cikin wannan labarin, za mu shiga cikin duniyar CO2 Laser cutters da kuma bincika aikace-aikacen su a cikin aikin katako, yana taimaka muku fahimtar yadda wannan fasaha ta fasaha ta sake fasalin iyakokin kerawa da fasaha.

3. Bambanci: CNC VS. Laser Cutter

◼ Zurfafa cikin ƙa'idar Aiki - Yaya yake aiki?

CNC Routers

CNC na'ura mai ba da hanya tsakanin hanyoyin sadarwa tana aiki akan ƙa'idar masana'anta mai ragi. Yana da gaske na'ura mai sarrafa kwamfuta wanda ke amfani da kayan yankan kadi, kamar na'ura mai ba da hanya tsakanin hanyoyin sadarwa ko na'ura mai ƙarewa, don cire abu daga kayan aiki. Na'ura mai ba da hanya tsakanin hanyoyin sadarwa bit yana jujjuya cikin sauri kuma ana shigar da shi tare da kayan, wanda zai iya zama itace, filastik, ko wasu kayan aiki. Yayin da bit ɗin ke yin tuntuɓar, a hankali yana sassaƙa kayan, yana ƙirƙirar siffofi, ƙira, da ƙira.

Ana sarrafa motsin na'ura mai ba da hanya tsakanin hanyoyin sadarwa daidai gwargwado a cikin girma uku (X, Y, da Z) ta tsarin kwamfuta. Wannan yana ba da damar madaidaicin iko akan matsayi da zurfin kayan aiki. Masu amfani da hanyar sadarwa na CNC sun yi fice wajen yanke, siffata, sassaƙa, da fashe abubuwa. Sun dace sosai don ayyukan da ke buƙatar ƙaƙƙarfan aiki, 3D, ko cikakken aiki, kuma ana iya amfani da su don sassaƙawa ta hanyar sarrafa zurfin da saurin mai yankewa a hankali.

Lase Cutters

Masu yankan Laser suna aiki akan wata ka'ida ta daban wacce aka sani da masana'antar photonic subtractive. Maimakon tuntuɓar jiki tare da kayan, suna amfani da katako mai ƙarfi na Laser don narke, tururi, ko ƙona abu daga kayan aikin. Ana amfani da masu yankan Laser sau da yawa tare da kayan aiki iri-iri, gami da itace, kuma ana iya yanke su da daidaito. Har ila yau, suna da damar zane-zane, ƙirƙirar ƙira mai mahimmanci ta hanyar bambanta ƙarfi da tsawon lokacin katako na Laser.

Tsarin sarrafa kwamfuta na Laser cutter yana jagorantar katakon Laser don bin takamaiman hanyoyi, ƙirƙirar sassauƙan yankewa da zane-zane. Babban maɓalli a nan shi ne hanyar da ba ta sadarwa ba ce. Laser yana da madaidaicin gaske kuma yana iya ƙirƙirar cikakkun bayanai masu kyau da kaifi mai kaifi. Yana da tasiri musamman don yankan da sassaƙa itace, robobi, da sauran kayan inda ake buƙatar daidaitaccen cire kayan abu kaɗan.

◼ Idan Kuna Yanke Itace:

CNC Routers

Masu amfani da hanyar CNC sune dawakan aikin katako da aka yi bikin saboda ikonsu na haɗa ikon yanke ba tare da matsala ba tare da kulawa mai zurfi. Waɗannan injunan suna da yawa, suna sa su dace don ƙirƙirar ƙirƙira ƙira, sassaƙa, da tsara itace. Abin da ya banbanta su shine daidaiton su wajen cimma zurfafa daban-daban. Tare da ikon Z-axis, kuna da ikon daidaita zurfin yanke da kyau. Ko dalla-dalla sassaka ne, aikin katako na 3D, ko samar da bayanan martaba masu rikitarwa, masu amfani da hanyoyin CNC suna ba da damammaki iri-iri. Zurfin yankan da gaske an ƙaddara ta tsawon kayan aikin yankan da ƙarfin axis na Z-axis.

Lase Cutters

Masu yankan Laser, yayin da ake ba su daraja don daidaitattun yankan su, suna aiki daban-daban idan ya zo zurfin. Sun yi fice wajen ƙirƙirar madaidaici, yanke mara zurfi da zane-zane-matakin saman ƙasa, suna jaddada finesse akan zurfin. Waɗannan injina ƙwararru ne wajen samar da ƙira mai ƙima, cikakkun bayanai, da kaifi mai kaifi. Yayin da za su iya yanke itace, babban abin da aka fi mayar da hankali shi ne kan ingancin saman maimakon yawan cire kayan. Masu yankan Laser sune zakarun madaidaicin, ƙera ƙira mai ƙima akan saman itace. Ikon zurfin sarrafawa, duk da haka, yana iyakance idan aka kwatanta da masu amfani da hanyoyin CNC, yawanci daidai da kauri na kayan da suke aiki da su.

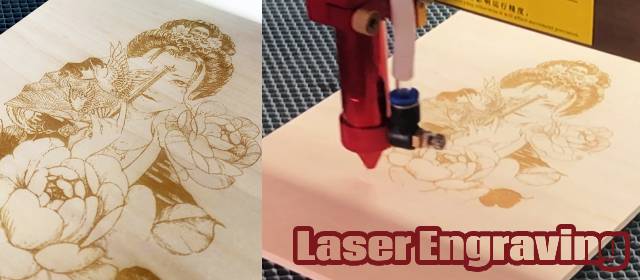

◼ Idan Kuna Aiki akan Zane itace:

Laser engraving itacehakika ya fi kyau don ƙirƙirar dalla-dalla na zane-zane, musamman idan ana batun zane-zane na raster, wanda ya haɗa da shading ko bambancin zurfin zane don samar da ƙirƙira ƙira ko hotuna. Madaidaicin madaidaicin yanayi na lasers yana sa su zama cikakke don cimma lafiya, ƙira dalla-dalla akan kayan daban-daban, gami da itace.

A gefe guda, masu amfani da hanyoyin sadarwa na CNC sun fi dacewa da ayyukan da ke buƙatar sassaƙaƙƙun sassaka, tsarawa, da aikin katako na 3D amma maiyuwa ba za su yi fice ba wajen samar da matakin dalla-dalla a cikin zane-zane kamar masu yankan Laser. Masu amfani da hanyar sadarwa na CNC suna da kima don ƙirƙirar filaye masu rubutu da hadaddun bayanan martaba, suna mai da su kayan aiki iri-iri a aikin katako.

Wasu Shawarwari:

Haƙiƙa masu yankan Laser sun fi ƙirƙira dalla-dalla na zane-zane, musamman idan ana batun zanen raster, wanda ya haɗa da shading ko bambancin zurfin zane don samar da ƙira ko hotuna masu rikitarwa. Madaidaicin dabi'a na lasers ba tare da tuntuɓar ba ya sa su zama cikakke don cimma lafiya, ƙira dalla-dalla akan kayan daban-daban, gami da itace.

◼ Yi la'akari da inganci da saurin aikin katako

Lokacin zabar tsakanin masu amfani da hanyoyin CNC da masu yankan Laser don aikin aikin katako, fahimtar saurin yankan su da zanen su yana da mahimmanci. Masu amfani da hanyar sadarwa na CNC suna aiki ta hanyar taɓa kayan a zahiri, wanda ke gabatar da wasu juzu'i kuma yana iya haifar da ƙarin lokacin yankewa. A wasu lokuta, ana iya buƙatar wucewa da yawa don kammala yanke. Sabanin haka, masu yankan Laser sun shahara saboda saurinsu da ingancinsu. Suna iya wucewa da sauri ta cikin kayan, galibi suna kammala ayyuka a cikin wucewa ɗaya.

Misali, yankan MDF na 6mm, na'ura mai ba da hanya tsakanin hanyoyin sadarwa na CNC na iya yanke ta cikin saurin 25mm a sakan daya, amma Laser ya fi sauri, zai iya cimma aikin yankan a 50mm a sakan daya don Laser 300W. Koyaya, yana da mahimmanci a lura cewa yayin da kauri na kayan ya ƙaru, saurin da ingancin yankan Laser na iya raguwa. Don kyawawan itace mai kauri, cnc na'ura mai ba da hanya tsakanin hanyoyin sadarwa yana da ƙarfi don ɗauka. Amma idan sauri da dalla-dalla dalla-dalla sune buƙatunku na farko, na'urar yankan Laser na iya zama zaɓin da kuka fi so. Cikakken bayani gatambaye mu>>

IDAN Kuna da buƙatu na musamman don ƙirar itace ta al'ada,

zuwa neman shawara tare da gwani na laser!

◼ Aiki yana da sauki ko kuwa?

Lokacin zabar tsakanin masu amfani da hanyoyin CNC da masu yankan Laser don aikin aikin katako, fahimtar saurin yankan su da zanen su yana da mahimmanci. Masu amfani da hanyar sadarwa na CNC suna aiki ta hanyar taɓa kayan a zahiri, wanda ke gabatar da wasu juzu'i kuma yana iya haifar da ƙarin lokacin yankewa. A wasu lokuta, ana iya buƙatar wucewa da yawa don kammala yanke. Sabanin haka, masu yankan Laser sun shahara saboda saurinsu da ingancinsu. Suna iya wucewa da sauri ta cikin kayan, galibi suna kammala ayyuka a cikin wucewa ɗaya.

Bambance-bambancen gaske, injinan CNC sun ƙunshi ƙarin hadadden tsarin koyo. Don ƙware su, dole ne ku zurfafa cikin ɓarna, waɗanda suka haɗa da fahimtar raƙuman na'ura mai ba da hanya tsakanin hanyoyin sadarwa da takamaiman amfaninsu, tare da daidaita kewayon sigogi don kyakkyawan sakamako. Idan kuna la'akari da injin CNC, yi tsammanin ingantaccen tsarin koyo, yana buƙatar saka hannun jari mai mahimmanci na lokaci don fahimtar kayan aikin da cikakkun bayanan sa.

◼ Wanne ne ya dace da muhalli?

• Surutu

CNC Router:

CNC magudanar ruwa yawanci samar da karin amo idan aka kwatanta da Laser cutters. Matsayin amo zai iya bambanta dangane da nau'in na'ura mai ba da hanya tsakanin hanyoyin sadarwa, kayan aikin yankan, da kayan da ake sarrafa su. Yana da kyawawa gabaɗaya a yi amfani da kariya ta ji yayin aiki da na'ura mai ba da hanya tsakanin hanyoyin sadarwa na CNC, musamman na tsawon lokaci.

Laser Cutter:

Masu yankan Laser sun fi natsuwa a aiki. Yayin da suke haifar da hayaniya, gabaɗaya yana a ƙaramin matakin decibel fiye da na'urorin CNC. Duk da haka, yana da mahimmanci a lura cewa masu shaye-shaye da tsarin tace iska, waɗanda galibi ana amfani da su tare da masu yankan Laser don cire hayaki, na iya ba da gudummawa ga yawan amo.

• Tsaro

CNC Router:

Ana la'akari da hanyoyin CNC mafi aminci dangane da rage haɗarin shakar hayaki ko ƙurar da aka samar yayin aiwatar da yanke. Duk da haka, matakan tsaro ya kamata su kasance a wurinsu, kamar tsarin tattara ƙura da samun iska mai kyau, don rage haɗarin lafiya da ke tattare da ƙurar itace.

Laser Cutter:

Masu yankan Laser na iya haifar da damuwa ta aminci saboda yuwuwar sakin hayaki da ɓangarorin kwayoyin halitta lokacin yanka ko sassaƙa itace. Kayan aiki kamar MDF da plywood na iya haifar da hayaki mai cutarwa, kuma ingantacciyar iska da tsarin shayewa suna da mahimmanci don kiyaye yanayin aiki mai aminci. Dole ne a bi ka'idodin aminci na Laser sosai don kariya daga radiation na Laser.

4. Yadda za a zabi CNC ko Laser?

Yi La'akari da Bukatun Ayyukanku:

Don sassaƙaƙƙen sassaka, aikin katako na 3D, da tsara ayyuka, masu tuƙi na CNC zaɓi ne mai ƙarfi.

Idan daidaito, kyakkyawan bayyani, da zane-zane masu ban mamaki sune abubuwan fifikonku, zaɓi na'urar yankan Laser.

Gudu da inganci:

Masu amfani da hanyar sadarwa na CNC sun yi fice a cikin cire kayan aiki da tsara ayyuka, suna sa su sauri don waɗannan ayyukan.

Masu yankan Laser suna da sauri da inganci idan ana batun yankan daidai da ayyuka masu rikitarwa.

Surutu da Tsaro:

CNC na'ura mai ba da hanya tsakanin hanyoyin sadarwa sun fi surutu yayin aiki, don haka la'akari da juriyar amo kuma amfani da kariya ta ji.

Masu yankan Laser sun fi shuru amma suna buƙatar tsauraran matakan tsaro saboda yuwuwar hayaki da radiation na Laser.

Hanyar Koyo:

Masu amfani da hanyar sadarwa na CNC suna da tsarin koyo mai zurfi, suna buƙatar zurfin fahimtar kayan aiki da sigogi.

Masu yankan Laser suna ba da saurin koyo ga waɗanda ke neman ƙwarewar 'toshe-da-wasa'.

Cire Kayan Kaya vs. Cikakkun bayanai:

CNC na'ura mai ba da hanya tsakanin hanyoyin sadarwa sun fi dacewa don ƙaƙƙarfan cire kayan abu da ƙirƙirar filaye masu rubutu.

Laser cutters ne manufa domin daidaici da lafiya daki-daki a kan kayan ta saman.

Kaurin Abu:

Masu amfani da hanyar sadarwa na CNC na iya ɗaukar kayan mafi kauri da kyau saboda iyawar su mai zurfi.

Laser cutters sun fi dacewa da kayan da suka fi dacewa tare da mayar da hankali kan ingancin farfajiya.

Kuna da wasu matsaloli game da cnc vs Laser ya zuwa yanzu? Me zai hana a tambaye mu amsoshi!

Idan kana sha'awar itace Laser abun yanka

Duba injin da ke da alaƙa >>

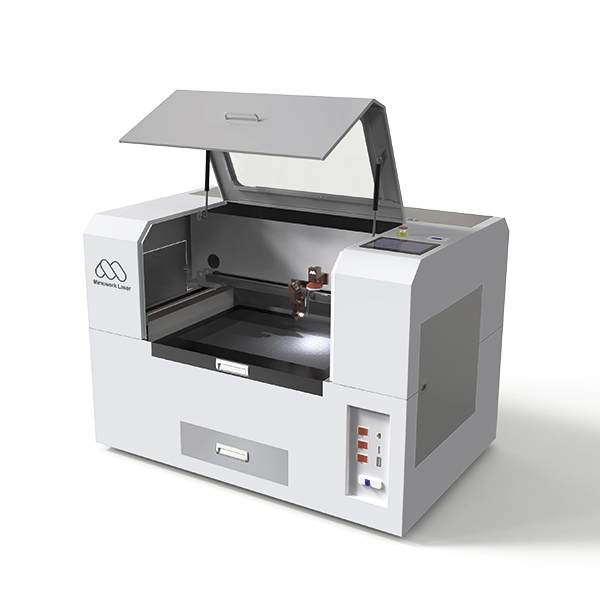

Girman Teburin Aiki:600mm * 400mm (23.6" * 15.7")

Zaɓuɓɓukan Ƙarfin Laser:65W

Bayanin Desktop Laser Cutter 60

Flatbed Laser Cutter 60 samfurin tebur ne. Ƙaƙƙarfan ƙira ɗin sa yana rage buƙatun sarari na ɗakin ku. Kuna iya sanya shi cikin dacewa akan tebur don amfani, yana mai da shi kyakkyawan zaɓi na matakin shigarwa don farawa da ke hulɗa da ƙananan samfuran al'ada.

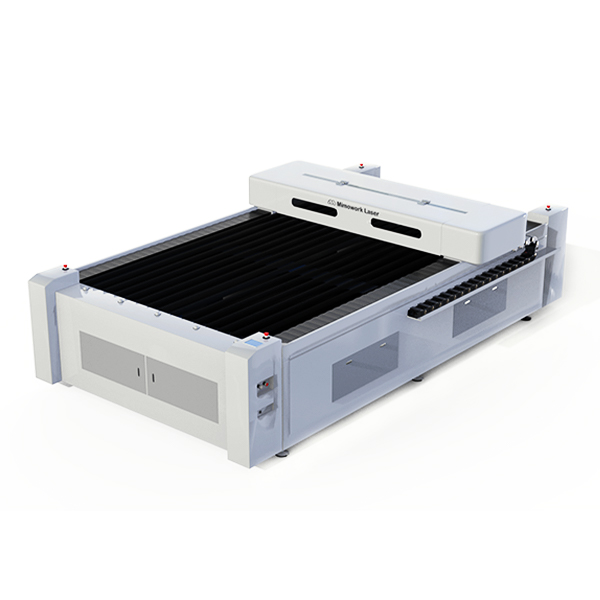

Girman Teburin Aiki:1300mm * 900mm (51.2"* 35.4")

Zaɓuɓɓukan Ƙarfin Laser:100W/150W/300W

Bayanin Flatbed Laser Cutter 130

Flatbed Laser Cutter 130 shine mafi mashahuri zaɓi don yankan itace. Tsarin teburin aikinta na gaba da baya ta nau'in nau'in aikin yana ba ku damar yanke allunan katako fiye da wurin aiki. Haka kuma, shi yayi versatility ta samar da Laser shambura na kowane iko rating don saduwa da bukatun yankan itace da daban-daban kauri.

Girman Teburin Aiki:1300mm * 2500mm (51.2"* 98.4")

Zaɓuɓɓukan Ƙarfin Laser:150W/300W/500W

Bayani na Flatbed Laser Cutter 130L

Flatbed Laser Cutter 130L babban inji ne. Ya dace da yankan manyan allunan katako, kamar wanda aka saba samu 4ft x 8ft alluna a kasuwa. Da farko yana ba da samfuran manyan kayayyaki, yana mai da shi zaɓin da aka fi so a masana'antu kamar talla da kayan ɗaki.

Kuna so ku fara Kasuwancin Yankan Laser naku / Laser Engraving Business?

▶Bayanin gefe: Bayan itace, kayan kamarplywoodkumaMDF panelsana kuma amfani da su a masana'antu.

Lokacin aikawa: Oktoba-18-2023