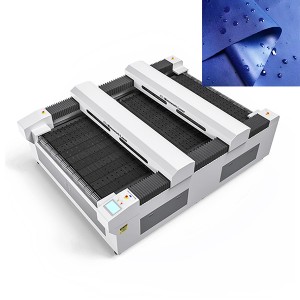

Laser Wood Laser Cutter don Manyan Itace & Kauri (Har zuwa 30mm)

▶ Large format Laser abun yanka na itace

Bayanan Fasaha

| Wurin Aiki (W * L) | 1300mm * 2500mm (51"* 98.4") |

| Software | Software na kan layi |

| Ƙarfin Laser | 150W/300W/450W |

| Tushen Laser | CO2 Glass Laser tube |

| Tsarin Kula da Injini | Ball Screw & Servo Motor Drive |

| Teburin Aiki | Wuka mai wuƙa ko Teburin Aiki na Zuma |

| Max Gudun | 1 ~ 600mm/s |

| Gudun Haɗawa | 1000 ~ 3000mm/s2 |

| Daidaiton Matsayi | ≤± 0.05mm |

| Girman Injin | 3800 * 1960 * 1210mm |

| Aiki Voltage | AC110-220V± 10%,50-60HZ |

| Yanayin sanyaya | Tsarin Ruwa da Sanyaya Ruwa |

| Muhallin Aiki | Zazzabi: 0-45 ℃ Danshi: 5% - 95% |

| Girman Kunshin | 3850mm * 2050*1270mm |

| Nauyi | 1000kg |

▷Features na 1325 Laser Cutter

Giant Leap a cikin Haɓakawa

◾ Stable & Kyakkyawan Yanke Ingancin

Zane-zanen Tafarkin gani na dindindin

Tare da mafi kyawun fitarwa na tsawon hanya mai kyau, daidaitaccen katako na laser a kowane matsayi a cikin kewayon tebur na yankan zai iya haifar da ko da yanke duk kayan, ba tare da la'akari da kauri ba. Godiya ga wannan, zaku iya samun sakamako mafi kyau ga acrylic ko itace fiye da hanyar laser mai tashi da rabi.

◾ Babban inganci da daidaito

Ingantacciyar Tsarin Watsawa

X-axis madaidaicin dunƙule module, Y-axis unilateral ball dunƙule samar da kyakkyawan kwanciyar hankali da daidaito ga high-gudun motsi na gantry. Haɗe tare da motar servo, tsarin watsawa yana haifar da ingantaccen ingantaccen samarwa.

◾ Rayuwa Mai Dorewa da Dogon Hidima

Tsararren Injin Injiniya

Jikin injin yana welded tare da bututu mai murabba'in 100mm kuma yana jurewa tsufa da jiyya na tsufa na halitta. Gantry da yanke kai suna amfani da hadedde aluminum. Tsarin gabaɗaya yana tabbatar da ingantaccen yanayin aiki.

◾ Haɓaka Sauri

Babban Gudun Yankewa da sassaƙawa

Mu 1300 * 2500mm Laser abun yanka na iya cimma 1-60,000mm / min engraving gudun da 1-36,000mm / min yankan gudun.

Hakanan, ana ba da garantin daidaiton matsayi tsakanin 0.05mm, ta yadda zai iya yanke da sassaƙa lambobi ko haruffa 1x1mm, gaba ɗaya babu matsala.

Me yasa zabar MimoWork Laser

130250 Laser cikakken inji cikakken kwatanta

|

| Sauran masana'anta | MimoWork Laser inji |

| Yanke gudun | 1-15,000mm/min | 1-36,000mm/min |

| daidaiton matsayi | ≤± 0.2mm | ≤± 0.05mm |

| Ƙarfin Laser | 80W/100W/130W/150W | 100W/130W/150W/300W/500W |

| Hanyar Laser | Hanyar Laser Rabin tashi | Tafarkin gani na dindindin |

| Tsarin watsawa | bel na watsawa | Servo motor + ball dunƙule |

| Tsarin tuki | Direba mataki | Servo motor |

| Tsarin sarrafawa | Tsohon tsarin, daga sayarwa | Sabon mashahurin tsarin sarrafa RDC |

| Tsarin lantarki na zaɓi | No | CE/UL/CSA |

| Babban jiki | Gargajiya waldi fuselage | Ƙarfafa gado, tsarin gaba ɗaya yana waldawa da bututu mai murabba'in 100mm, kuma yana fuskantar tsufa na girgiza da kuma maganin tsufa na halitta. |

Samfurori Daga Wood Laser Cutter

Kayan itace masu dacewa

MDF, Basswood, Farin Pine, Alder, Cherry, itacen oak, Baltic Birch Plywood, Balsa, Cork, Cedar, Balsa, m itace, Plywood, katako, Teak, veneers, gyada, Hardwood, Laminated itace da Multiplex

Faɗin aikace-aikace

• Kayan aiki

• Akwatin Ajiya

• Samfuran Gine-gine

• Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙasa

Bidiyo | Menene abin yankan Laser zai iya yi muku?

Hoton Zane Laser akan Itace

Sami Mai Cutar Laser na Itace don Inganta Kasuwancin ku

Ji dadin Laser itace fun!

▶ Large format Laser abun yanka na itace

Haɓaka Zaɓuɓɓuka don ku zaɓi

Mixed Laser Head

Mayar da hankali ta atomatik

TheCCD Kamaraiya gane da matsayi da juna a kan buga acrylic, taimaka Laser abun yanka don gane daidai yankan tare da high quality. Duk wani ƙirar zane da aka keɓance da aka buga za'a iya sarrafa shi cikin sassauƙa tare da faci tare da tsarin gani, yana taka muhimmiyar rawa a talla da sauran masana'antu.

Tambayoyi masu alaƙa: Wataƙila kuna sha'awar

1. Zan iya amfani da kowane nau'in itace don yankan Laser, ko akwai takamaiman nau'ikan itace waɗanda ke aiki mafi kyau?

2. Abin da kauri na itace iya CO2 Laser sabon inji rike yadda ya kamata?

Ee, aminci yana da mahimmanci yayin aiki tare da lasers. Tabbatar samun iska mai kyau a cikin filin aikin ku don cire hayaki da ke fitowa yayin aikin yanke. Koyaushe sanya kayan kariya masu dacewa (PPE), gami da gilashin tsaro. Bugu da ƙari, tabbatar da cewa itacen yana da 'yanci daga kowane sutura, ƙarewa, ko sinadarai waɗanda zasu iya haifar da hayaki mai cutarwa lokacin da aka fallasa shi da laser.

Yankan itace: CNC Routers VS Laser

1. Amfanin CNC Routers

A tarihi, ɗaya daga cikin fa'idodin farko na zaɓin na'ura mai ba da hanya tsakanin hanyoyin sadarwa sabanin na'ura mai ba da hanya tsakanin hanyoyin sadarwa shine ikonsa na cimma madaidaicin zurfin zurfin. CNC na'ura mai ba da hanya tsakanin hanyoyin sadarwa yana ba da sauƙi na gyare-gyare na tsaye (tare da Z-axis), yana ba da damar sarrafawa mai sauƙi a kan zurfin yanke. A cikin mafi sauƙi, zaku iya daidaita tsayin abin yanka don zaɓin cire wani yanki na saman itace kawai.

2. Rashin amfani da CNC Routers

Na'ura mai ba da hanya tsakanin hanyoyin sadarwa sun yi fice wajen sarrafa lankwasa a hankali amma suna da iyaka idan ya zokusurwoyi masu kaifi. Madaidaicin da suke bayarwa yana iyakance ta radius na yankan bit. A cikin sauki,nisa na yanke yayi daidai da girman bit ɗin kanta. Mafi ƙanƙanta na'ura mai ba da hanya tsakanin hanyoyin sadarwa yawanci suna da radius kusan1 mm.

Tun da masu amfani da hanyar sadarwa sun yanke ta hanyar gogayya, yana da mahimmanci don daidaita kayan zuwa saman yanke. Ba tare da gyare-gyaren da ya dace ba, jujjuyawar na'ura mai ba da hanya tsakanin hanyoyin sadarwa na iya haifar da jujjuyawar kayan ko motsi ba zato ba tsammani. Yawanci, ana ɗaure itace a wuri ta amfani da ƙugiya. Koyaya, lokacin da aka yi amfani da bit na na'ura mai sauri mai sauri zuwa kayan da aka matse, ana haifar da tashin hankali sosai. Wannan tashin hankali yana da yuwuwaryaƙe ko cutar da itace, gabatar da ƙalubale lokacin yankan sirara ko ƙayatattun abubuwa.

3. Abũbuwan amfãni & rashin amfani na Laser

Hakazalika da na'urori masu sarrafa kansu, masu yankan Laser ana sarrafa su ta tsarin CNC (Kwamfuta na Lamba). Duk da haka, ainihin bambanci yana cikin hanyar yanke su. Laser cutterskar a dogara da juzu'i; maimakon haka, sun yanke ta hanyar amfani da kayanzafi mai tsanani. Hasken hasken wuta mai ƙarfi yana ƙonewa ta hanyar itace, sabanin tsarin sassaƙa ko injina na gargajiya.

Kamar yadda aka gani a baya, an ƙayyade nisa na yanke ta girman girman kayan aiki. Yayin da mafi ƙarancin na'ura mai ba da hanya tsakanin hanyoyin sadarwa suna da radius na ɗan ƙasa da 1 mm, ana iya daidaita katako na Laser don samun radius ƙanƙanta kamar0.1 mm. Wannan damar yana ba da damar ƙirƙirar yankewa mai mahimmanci tare dana ban mamaki madaidaici.

Saboda masu yankan Laser suna amfani da tsari mai ƙonawa don yanke itace, suna samar da suna kwarai masu kaifi da santsin gefuna. Kodayake wannan ƙonawa na iya haifar da ɗanɗano launi, ana iya aiwatar da matakan hana ƙonawar da ba a so. Bugu da ƙari, aikin konawa yana rufe gefuna, ta hakarage girman haɓakawa da raguwana itacen yanke.

Injin Laser mai alaƙa

don itace da acrylic Laser sabon

• Fast & daidai engraving ga m kayan

• Ƙirar shiga ta hanyoyi biyu tana ba da damar sanya kayan aiki masu tsayi da tsayi

domin itace da acrylic Laser engraving

• Haske da ƙirar ƙira

• Sauƙi don aiki don masu farawa