Small Options, Great Improvement

A Complete Warehouse Store for Your Laser Options

High efficiency and premium quality in production are being most concerned by manufacturers. By partnering with trusted industry-leading brands, MimoWork is able to provide the most suitable laser options with the best performance for our clients to further improve the production conditions and achieve a smooth and efficient production flow. MimoWork offers several options covering software, hardware, and replaceable mechanical devices for the laser cutter, laser engraver and galvo laser machine. These multi-functional laser options broaden extensibility and flexibility on processing methods and operation. They simplify pre-preparation, optimize cutting flow and post-treatment.

Except for that, working safety and waste treatment (environment protection) are the highlights that are also worth mentioning. Following your production adjustment and improvement, it is necessary for options to be timely updated and flexibly replaced, which can make a huge difference in your future workflow. Last but not least, customized laser machine options can be realized according to your specific requirements.

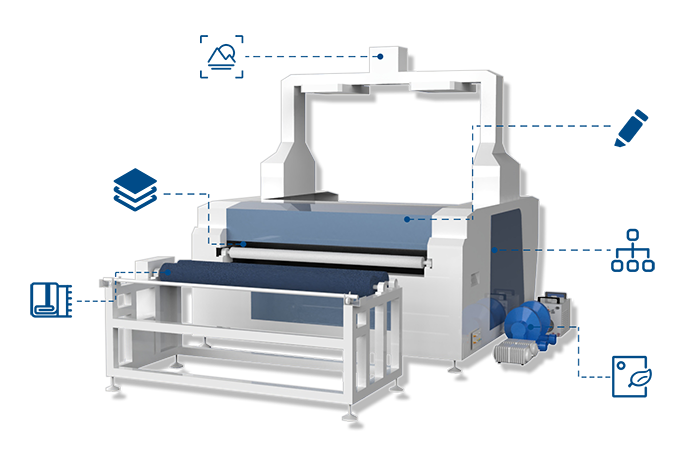

Digital support for easy and precise laser cutting

● Simplify your laser cutting and engraving flow

● Digital control system minimizes error

● Automatic operation saves labor and time

Accurate laser cutting and engraving, graphic design & auto nesting, and additional laser positioning system are supported by well-configured laser software. MimoCUT, MimoNest, MimoPROTOTYPE, MimoPROJECTION help you to realize digital and automatic control while ensuring the right and efficient practical laser cutting.

Auto Nesting Software for Laser Cutting

Uncover the basics of using nesting software to enhance your production processes, whether you're involved in laser cutting fabric, leather, acrylic, or wood. The video provides insights into the high automation and cost-saving features of autonest, particularly in laser cut nesting software.

Discover how automatic nesting software can significantly improve production efficiency and output, making it a valuable and cost-effective investment for mass production. Learn the secrets of maximizing material saving with laser nesting software and elevate your manufacturing capabilities.

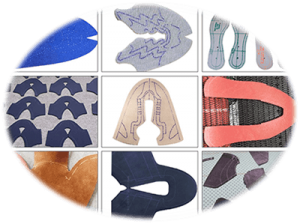

Helper for accurate laser cutting patterned materials

● Accurate recognition means precise cutting

● High automation for convenient adjustment and inspection

● Suitable for patterned materials

● Minimal defect by amending print errors

What is optical recognitiong system? For patterned materials, Optical Recognition Systems from MimoWork are necessary to realize accurate recognition and positioning for precise materials outline cutting. Dye-sublimation products such as jersey, sportswear, swimwear, apparel accessories like embroidery patch, print patch, tackle twill number, label, and other applications need to be recognized are usually contour cut by laser cutter with Coutour Recognition, CCD Camera Positioning, and Template Matching.

Camera Laser Cutting Machine

Camera laser cutter, your ideal companion for precision cutting of sublimated sportswear. This cutting-edge machine excels in laser-cutting printed fabrics and activewear with advanced and automated methods. Equipped with a camera and scanner, our laser cutting machine offers unparalleled efficiency and high yield. The accompanying video showcases the prowess of this fully automatic vision laser cutter designed for apparel.

With dual Y-axis laser heads, it achieves incomparable efficiency, making it the go-to solution for laser cutting sublimation fabrics, including laser cutting jerseys. Elevate your cutting capabilities with the efficiency and precision of our latest camera laser cutter.

● Solid processing guarantee with even and stable laser table

● Modular and replaceable for different materials

● Extended functions to enhance efficiency

● Saving space with customized format

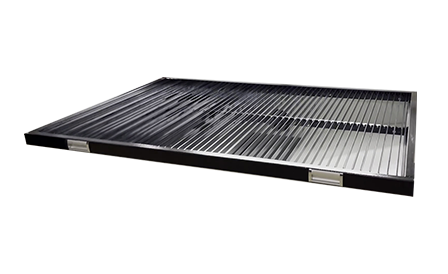

Different materials formats, gram weight, thickness, and density, as well as whether it is flexible or solid, these materials traits determine different choices for the laser cutter table. Except for that, aiming for high efficiency and materials treatment in good condition, MimoWork has developed several Working Table to advance laser cutting & engraving and full working flow for diverse customers’ requirements.

● Continuous feeding and laser cutting

● Diverse materials adaptability

● Saving labor and time cost

● Added automatic devices

● Adjustable feeding output

Suitable for roll materials with various weight, thickness, smooth degree, elasticity, and format, Feeding Systems with different configurations provide support and continuous feeding for materials at a given speed, ensuring cutting well with flatness, smoothness, and moderate tension. And it’s very top efficient and time-saving for Feeding Systems connected with the Conveyor Table.

Laser Cutter with Extension Table

Uncover a more efficient and time-saving approach to fabric cutting with the CO2 laser cutter featuring an extension table. The extension table facilitates the collection of finished pieces, significantly enhancing time-saving measures. If you're looking to upgrade your textile laser cutter and extend the laser bed without stretching your budget, the video suggests exploring the two-head laser cutter with an extension table.

Beyond efficiency, this industrial fabric laser cutter excels in handling ultra-long fabrics, making it ideal for patterns longer than the working table. Elevate your fabric-cutting capabilities with higher efficiency and extended possibilities.

● Accurate materials labeling by digital control

● Ideal for shortening subsequent sewing or alignment

● Various materials can be marked onto

● Available for different colors and shapes

Using marker pens and inkjet options, you can mark workpieces to simplify subsequent production. Especially in the case of sewing marks (cutting) in the textile manufacturing sector. For example, in the use of cutting filter cloth, selecting mark pen or ink-jet to mark the alignment lines directly on the piece, saving time and difficulty in subsequent operations.

CO2 Laser Cut & Mark Fabric

Experience the advanced capabilities of the 1810 fabric laser cutter, a cutting-edge industrial fabric laser cutting machine designed to revolutionize the fabric sewing process.

This innovative machine is equipped with an inkjet device that seamlessly follows the laser cutting head, marking and cutting fabric pieces in a single pass. The video showcases the simplicity this brings to the fabric sewing process, offering efficiency and precision.

● Guarantee for the safe working environment

● Protect materials from being polluted and damaged

An effective ventilation solution can help one puzzle out the bothersome dust and fumes while minimizing disruption to production. Collocated with the laser enhaust blower, the laser fume Extraction configured in the side or bottom of laser cutter ensures the waste gas treatment and helps you build a safe and clean working environment.