Acrylic (PMMA) Laser Cutter

Haddii aad rabto in aad jarto xaashida akriliga (PMMA, Plexiglass, Lucite) si aad u samayso qaar ka mid ah calaamadaha akriliga, abaal-marinnada, qurxinta, alaabta guriga, xitaa dashboards baabuurta, qalabka ilaalinta, ama kuwa kale? Qalab noocee ah ayaa ah doorashada ugu fiican?

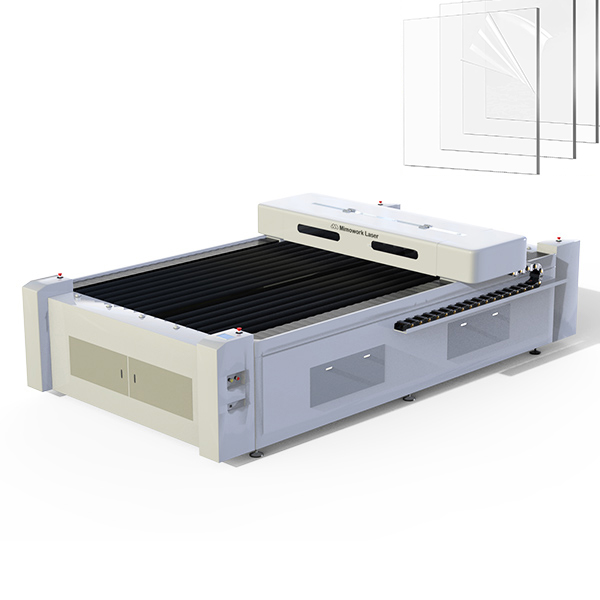

Waxaan kugula talineynaa mashiinka laysarka akril leh oo leh heer-warshadeed iyo heer hiwaayad.

Xawaaraha goynta degdega ah iyo saamaynta goynta aad u fiicanWaa faa'iidooyin aad u wanaagsan oo ah mashiinnada goynta laser-ka akril aad jeceshahay.

Ka sokow, mashiinka laysarka acrylic sidoo kale waa xardhaye laser akrilik ah, kaas oo awood u lehku xardho qaabab jilicsan oo qurxoon iyo sawirro xaashida akriliga ah. Waxaad ku samayn kartaa ganacsi caadadii xaradh yar oo akril ah, ama ballaadhiso wax soo saarkaaga acrylic by maal warshadaha qaab weyn oo xaashi laser goynta laysarka, kaas oo xamili kara ka weyn oo dhumucdiisuna xaashida acrylic xawaare sare, aad u weyn ee aad wax soo saarka ballaaran.

Maxaad ku samayn kartaa cutter laser ugu fiican ee akril? Sii wad si aad wax badan u sahamiso!

Fur Awoodda Buuxa ee Cutter Laser Acrylic

Tijaabada Shayga: Goynta Laser-ka 21mm Dhumucda Akril

Natiijada Imtixaanka:

Qalabka laser-ka sareeya ee loo yaqaan 'acrylic' wuxuu leeyahay awood goyn oo cajiib ah!

Waxay gooyn kartaa xaashida akril ee dhumucda 21mm, waxayna abuuri kartaa alaab tayo sare leh oo la dhammeeyey oo leh saameyn goyn ah oo ololaysa.

Waraaqaha acrylic ee khafiifka ah ee ka hooseeya 21mm, mishiinka goynta laysarka ayaa iyagana si dhib la'aan ah u maamula!

| Goobta Shaqada (W *L) | 1300mm * 900mm (51.2" * 35.4") |

| Software | MimoCUT Software |

| Awoodda leysarka | 100W/150W/300W/450W |

| Isha Laser | CO2 Tube Laser Glass ama CO2 RF Birta Laser tube |

| Nidaamka Xakamaynta Makaanikada | Talaabada Xakamaynta Suunka Matoorka |

| Shaxda Shaqada | Miiska Shaqada Shanlada Malabka ama Jeexitaanka Mindida |

| Xawaaraha ugu badan | 1 ~ 400mm/s |

| Xawaaraha Dardargelinta | 1000 ~ 4000mm/s2 |

Faa'iidooyinka laga helo Goynta Laser-ka Akril & Xardho

Dafiray & gees bir ah

Goynta qaabka dabacsan

Xardho qaabaysan oo adag

✔Cidhifyada goynta nadiifka ah ee nadiifka ah ee nadiifka ah hal hawlgal

✔Looma baahna in la isku dhejiyo ama la hagaajiyo akriliga sababtoo ah habayn la'aan

✔Habaynta dabacsan ee qaab kasta ama qaab kasta

✔Wax wasakh ah ma leh sida wax-shiididda oo ay taageerto qiiq-sooxaha

✔Goynta qaab sax ah oo leh nidaamyada aqoonsiga indhaha

✔Hagaajinta waxtarka quudinta, goynta ilaa ku-helidda miiska shaqada ee shittle

Mashiinada Goynta Laser Acrylic ee caanka ah

• Awoodda leysarka: 100W/150W/300W

• Goobta Shaqada: 1300mm * 900mm (51.2" * 35.4")

• Awoodda leysarka: 150W/300W/450W

Aagga Shaqada: 1300mm * 2500mm (51" * 98.4")

Xiiseynaya

Mashiinka Goynta Laser Acrylic

Qiimaha lagu daray ee MimoWork Laser Options

✦Kaamirada CCDwaxay siisaa mishiinka shaqada aqoonsiga ee jarida akrilik daabacan oo ay weheliso konturrada.

✦Si dhakhso leh oo xasiloon ayaa lagu xaqiijin karaaservo motor iyo moto aan burush lahayn.

✦Dhererka diiradda ugu fiican waxaa si toos ah looga heli karaaauto diiraddamarka la jarayo walxo qaro weyn oo kala duwan, looma baahna hagaajin gacanta.

✦Soo saarista qiiqawaxay kaa caawin kartaa in meesha laga saaro gaasaska raagay, ur xamaasad leh oo laga yaabo in la dhaliyo marka CO2 laser uu farsameeyo qaar ka mid ah qalabka gaarka ah, iyo hadhaaga hawada.

✦MimoWork waxay leedahay noocyo kala duwanMiisaska Goynta Laserqalabyo iyo codsiyo kala duwan. Thesariirta goynta laser malabkawaxay ku habboon tahay in la gooyo oo lagu xardho walxaha yaryar ee akril, iyomiiska goynta xadhig mindidaayaa u fiican in la gooyo akril qaro weyn.

Akrilik UV-daabacan oo leh midab qani ah iyo qaab ayaa caan noqday.Sidee loo gooyaa akrilik daabacan si sax ah oo degdeg ah? CCD Laser Cutter waa doorashada ugu fiican.

Waxay ku rakiban tahay kamarad CCD ah oo caqli badan iyoSoftware-ka Aqoonsiga indhaha, kaas oo aqoonsan kara oo meel dhigi kara qaababka, oo toosin kara madaxa laysarka si uu si sax ah u gooyo hareeraha.

silsiladaha furaha ah, looxyada xayaysiinta, qurxinta, iyo hadyado xusuus leh oo laga sameeyay akril sawir leh, Way fududahay in lagu dhammaystiro mashiinka goynta laser-ka ee daabacan.

Waxaad isticmaali kartaa laysarka si aad u gooyso akril daabacan oo loogu talagalay naqshadayntaada gaarka ah iyo wax soo saarka tirada badan, taas oo ku habboon oo aad u fiican.

Sida toos loogu gooyo alaabta daabacan | Acrylic & alwaax

Codsiyada Goynta & Xardhitaanka Laser Acrylic

Bandhigyada Xayeysiiska

• Dhismaha Model-dhismeedka

• Calaamadeynta Shirkadda

• Koobab jilicsan

• Akril daabacan

• Alaabooyinka Casriga ah

• Boodhadhka bannaanka

• Meesha alaabta

• Calaamadaha tafaariiqda

• Saaridda sprue

• Bracket

• Dukaamada ku habboon

• Joogsiga qurxinta

Isticmaalka Acrylic Laser Cutter

Waxaan Sameynay Qaar ka mid ah Calaamadaha Akril & Qurxinta

Sida Laser Cut Cake Topper

Sida laysarka loo gooyo qurxinta akriliga (flake)

Goynta Laser-ka iyo Xardhaminta Ganacsiga Acrylic

Waa maxay Mashruuc Akrilik ah oo aad la Shaqeyneyso?

Talooyin Wadaagista: Goynta Laser-ka Wanaagsan ee Acrylic

◆Kor u qaad saxanka akriliga si aanu u taaban miiska shaqada marka la jarayo

◆ Nadiifinta sare ee akril waxay gaari kartaa saamaynta goynta ka wanaagsan.

◆ Dooro gooyaha laysarka leh awoodda saxda ah ee cidhifyada ololka.

◆Afuufiddu waa inay noqotaa mid yar intii suurtogal ah si looga fogaado faafinta kulaylka taasoo sidoo kale horseedi karta cidhif gubasho.

◆Ku dheji looxa akrilik ee dhinaca dambe si ay u soo saaraan muuqaal muuqaal ah oo xagga hore ah.

Casharrada Fiidiyowga: Sida loo gooyo laser-ka oo loo xardho akril?

FAQ ee Laser Goynta Acrylic (PMMA, Plexiglass, Lucite)

1. Ma ku gooyn kartaa akril-jaraha laser-ka?

Goynta laser-ka xaashida akriliga waa hab caadi ah oo caan ah wax soo saarka akriliga. Laakiin leh noocyada kala duwan ee xaashida acrylic sida acrylic extruded, acrylic cast, acrylic daabacan, acrylic cad, acrylic muraayad, iwm, waxaad u baahan tahay inaad doorato mashiinka laysarka ee ku habboon noocyada acrylic intooda badan.

Waxaan kugula talineynaa CO2 Laser, kaas oo ah isha laysarka acrylic-saaxiibtinimo, waxayna soo saartaa saameyn goynta weyn iyo saameyn xardho xitaa leh akril cad.Waxaan ognahay in leysarka diode uu awoodo inuu gooyo akril khafiif ah laakiin kaliya loogu talagalay akril madow iyo madow. Markaa CO2 Laser cutter ayaa ka fiican in la gooyo oo lagu xardho akril.

2. Sidee loo gooyaa laysarka akril?

Laser goynta acrylic waa hab fudud oo iswada. Kaliya 3 tillaabo, waxaad heli doontaa alaab aad u fiican oo akril ah.

Tallaabada 1. Geli xaashida akriliga miiska goynta laysarka.

Tallaabada 2. Deji awoodda laysarka iyo xawaaraha software-ka laysarka.

Tallaabada 3. Bilow goynta laysarka iyo xaradhka.

Ku saabsan hagaha hawlgalka ee faahfaahsan, khabiirkayaga laser-ka ayaa ku siin doona tababar xirfad leh oo dhammaystiran ka dib markaad iibsato mishiinka laysarka. Markaa su'aal kasta, xor u noqo inaadla hadal khabiirkayaga laysarka.

@ Email: info@mimowork.com

WhatsApp: +86 173 0175 0898

3. Goynta & Xardhida Akril: CNC VS. Laser?

Dariiqyada CNC waxay adeegsadaan aaladda goynta wareegta ah si ay jir ahaan uga saaraan walxaha, oo ku habboon akrilik dhumucdiisuna tahay (ilaa 50mm) laakiin badanaa waxay u baahan yihiin suuf.

Qalab-jareyaasha laser-ka waxay isticmaalaan laambad layser ah si ay u dhalaaliyaan ama u soo saaraan walxaha, iyagoo siinaya saxan sare iyo cidhifyo nadiif ah iyada oo aan loo baahnayn suuf, ugu fiican akril khafiif ah (ilaa 20-25mm).

Ku saabsan saamaynta goynta, iyadoo ay ugu wacan tahay iftiinka laysarka ee fican ee gooyaha laysarka, goynta acrylic waa ka saxsan tahay oo nadiif ah marka loo eego goynta router cnc.

Xawaaraha jarista, router-ka CNC wuu ka dhakhso badan yahay gooyaha laser-ka ee jarista akriliga. Laakin xaradhka akriliga, leysarka ayaa ka sarreeya router CNC.

Haddaba haddii aad xiisaynayso mawduuca, oo aad ku wareersan tahay sida aad u kala dooran lahayd cnc iyo laser cutter, fiiri muuqaalka ama bogga si aad wax badan uga barato:CNC VS Laser oo loogu talagalay goynta iyo xaradhka akril

4. Sidee loo doortaa akril ku habboon goynta laysarka iyo xaradhka?

Acrylic waxay ku timaadaa noocyo kala duwan. Waxay dabooli kartaa baahiyo kala duwan oo ay ku kala duwan yihiin waxqabadka, midabada, iyo saamaynta bilicda.

In kasta oo dad badani ay ogyihiin in kabka iyo xaashida acrylic ee la saaray ay ku habboon yihiin farsamaynta laysarka, in yar ayaa yaqaan hababka ay ugu habboon yihiin isticmaalka laysarka.

Waraaqaha akril-ga ee Cast waxay soo bandhigaan saameyn farshaxan oo heer sare ah marka loo eego xaashida la soo saaray, taasoo ka dhigaysa inay ku habboon yihiin codsiyada xaradhka laysarka. Dhanka kale, xaashida la saaray ayaa aad u kharash badan waxayna ku habboon yihiin ujeedooyinka goynta laysarka.

5. Ma jari kartaa leysarka cabbirka akriliga?

Haa, waxaad laysarka gooyn kartaa calaamadda akriliga ee weyn adigoo isticmaalaya laysarka, laakiin waxay ku xidhan tahay cabbirka sariirta mashiinka. Gooyeyaashayada yar yar ee laser-ka waxay ka kooban yihiin karti-maskaxeed, taasoo kuu ogolaaneysa inaad ku shaqeyso waxyaabo waaweyn oo ka baxsan cabbirka sariirta.

Iyo go'yaal ballaadhan oo dheer oo akril ah, waxaanu haynaa mashiinka goynta laysarka qaab weyn oo leh 1300mm * 2500mm aagga shaqada, taas oo ay fududahay in lagu xakameeyo calaamadaha akriliga weyn.

Ma jiraan wax su'aalo ah oo ku saabsan goynta laysarka & xaradhka laysarka ee akril?

Aan ogaano oo aan kuu soo bandhigno talo iyo xal kale!

Horumarinta tignoolajiyada iyo hagaajinta awoodda laysarka, tignoolajiyada laysarka CO2 ayaa noqonaysa mid aad loo aasaasay mashiinka akril.

Dhib malahan waa la shubay (GS) ama la saaray (XT) galaas akril ah,laysarka ayaa ah qalabka ugu fiican ee lagu gooyo oo lagu xardho akril (plexiglass) oo leh kharashyo hawleed aad u hooseeya marka la barbar dhigo mishiinnada wax-shiidka ee dhaqameed.

Awood u leh farsamaynta qoto dheer ee walxaha kala duwan,MimoWork Laser Cuttersoo leh qaabaynta qaabaynta iyo awooda saxda ah waxay buuxin kartaa shuruudaha habaynta ee kala duwan, taasoo keentay in qalabyo akril ah oo qumman oo lehcrystal-cad, geesaha gooyay simanHawlgalka kelida ah, looma baahna in la iftiimiyo olol dheeraad ah.

Goynta Laser-yaqaanka ah iyo kuwa u qalma ee loo yaqaan 'acrylic'

Mashiinka laysarka acrylic wuxuu gooyn karaa go'yaal dhuuban oo dhumuc weyn leh oo leh gees goyn nadiif ah oo xiiran oo ku xardhay qaabab qurux badan oo faahfaahsan iyo sawiro ku yaal muraayadaha akriliga.

Iyada oo xawaaraha processing sare iyo nidaamka xakamaynta dhijitaalka ah, mashiinka goynta laser CO2 ee akril waxay gaari kartaa wax soo saarka ballaaran oo tayo fiican leh.

Haddii aad leedahay ganacsi yar ama harqaanle-sameeyey oo loogu talagalay alaabta akril, xaradhka laser yar ee akril waa doorasho ku habboon. Fudud in lagu shaqeeyo oo kharash-ool ah!