Laser-ku wuxuu u qalmaa kan ugu habboon in la gooyo akril! Maxaan sidaas u leeyahay? Sababtoo ah waafaqid ballaadhan oo ay la leedahay noocyo iyo cabbirro kala duwan oo akrilik ah, saxsanaan sare oo aad u sarreeya iyo xawaaraha degdegga ah ee jarista akriliga, fududahay in la barto oo lagu shaqeeyo, iyo in ka badan. Haddii aad tahay qof hiwaayad u leh, goynta alaabooyinka akril ee ganacsiga, ama isticmaalka warshadaha, jarista laser-ka ayaa buuxinaysa ku dhawaad dhammaan shuruudaha. Haddii aad raadinayso tayo aad u fiican iyo dabacsanaan sare, oo aad rabto in aad si dhakhso ah u barato, gooyaha laser acrylic ayaa noqon doona doorashadaada koowaad.

Faa'iidooyinka Laser Goynta Acrylic

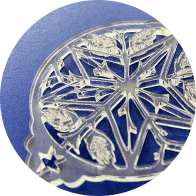

✔ Goynta Si Wacan

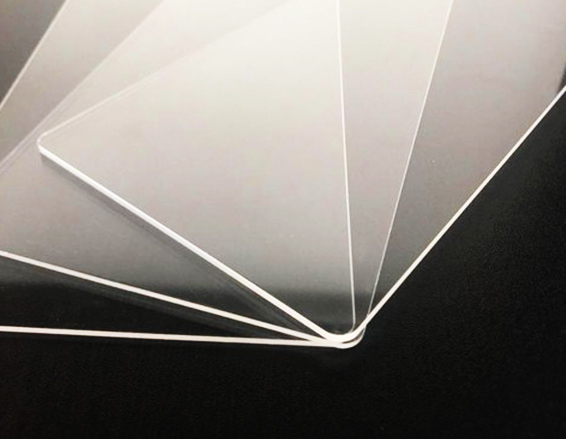

Tamarta laysarka ee xoogga badan waxay isla markiiba goyn kartaa xaashida akriliga ee jihada toosan. Kuleylku wuxuu xiraa oo nadiifiyaa cidhifka si uu u noqdo mid siman oo nadiif ah.

✔ Goynta Aan La Xiriirin

Laser cutter wuxuu leeyahay habayn aan xidhiidh la lahayn, isaga oo ka takhalusaya welwelka ku saabsan xagashada alaabta iyo dildilaaca sababtoo ah ma jiro cadaadis farsamo. Looma baahna in la beddelo qalabka iyo qashinka.

✔ Saxnaanta Sare

Saxnimada sare ee sare waxay ka dhigtaa gooyaha laser acrylic oo gooyay qaabab qalafsan iyadoo loo eegayo faylka la qorsheeyay. Ku habboon qurxinta akril ee caadooyinka qurxoon iyo warshadaha & sahayda caafimaadka.

✔ Xawaaraha iyo Hufnaanta

Tamar laser xoog leh, ma jirto cadaadis farsamo, iyo xakamaynta dhijitaalka ah, waxay si weyn u kordhisaa xawaaraha goynta iyo waxtarka wax soo saarka oo dhan.

✔ Wax-qabad

Goynta laser CO2 waa mid aad u kala duwan si loo gooyo xaashida akril ee dhumucyada kala duwan. Waxay ku habboon tahay qalabka akril ee dhuuban iyo dhumucdiisuna, iyadoo siinaya dabacsanaan codsiyada mashruuca.

✔ Qashinka Alaabta Ugu Yar

Laydhka diiradda la saaray ee laser CO2 wuxuu yareeyaa qashinka walxaha isagoo abuuraya ballaadhka kerf cidhiidhi ah. Haddii aad la shaqaynayso wax soo saarka ballaaran, software buul laysarka caqliga leh ayaa wanaajin kara dariiqa goynta, oo kor u qaadi kara heerka isticmaalka walxaha.

cidhif-cad

Habka goynta qalafsan

Sawirro ku xardhan akrilik

▶ Si aad u dhow u fiirso: Waa maxay Laser Cutting Acrylic?

Laser Goynta Flake Akril ah

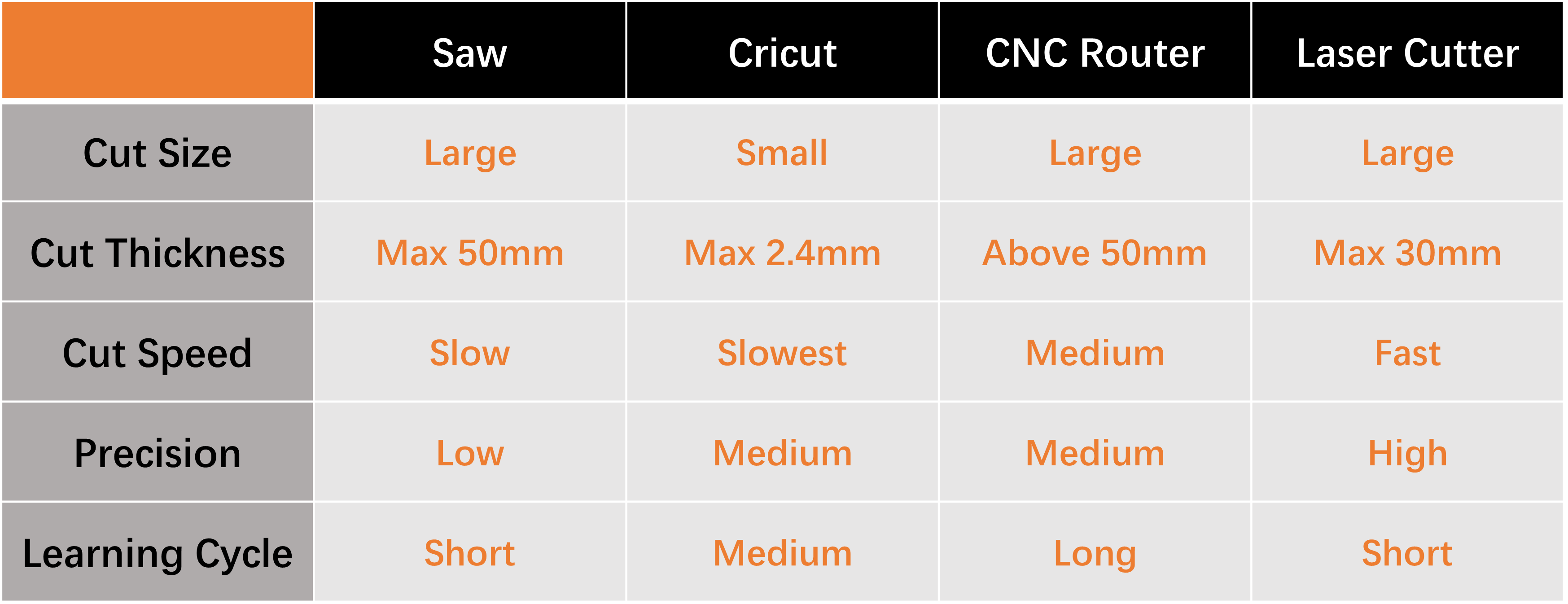

4 Qalabka Goynta - Sidee loo gooyaa acrylic?

Jigsaw & Wareegto Saw

Miishaar, sida miinshaar wareeg ah ama jigsaw, waa qalab wax lagu gooyo oo badan oo caadi ahaan loo isticmaalo akril. Waxay ku habboon tahay goyn toosan iyo qaar qaloocan, taasoo ka dhigaysa mid la heli karo mashaariicda DIY iyo codsiyada baaxadda leh.

Cricut

Mashiinka Cricut waa qalab goyn sax ah oo loogu talagalay samaynta iyo mashaariicda DIY. Waxay isticmaashaa daab fiican si ay u gooyso walxo kala duwan, oo ay ku jiraan akril, si sax ah oo sahlan.

CNC Router

Mashiin goynta kombuyuutarku maamusho oo leh jajabyo kala duwan oo goyn ah. Waa mid aad u wanagsan, awoodna u leh in ay wax ka qabato agabyo kala duwan, oo ay ku jiraan akril, goyn baaxad leh iyo mid adag labadaba.

Laysarka Goynta

Qalabka laysarka wuxuu shaqeeyaa laydhka laysarka si uu u gooyo akril leh oo sax ah. Waxaa caadi ahaan loo adeegsadaa warshadaha u baahan naqshado qalafsan, tafaasiil fiican, iyo tayada goynta joogtada ah.

Sida loo doorto Gooyaha Acrylic A kugu habboon?

sababteeda

Kala duwanaansho, Dabacsanaan, Waxtarka…

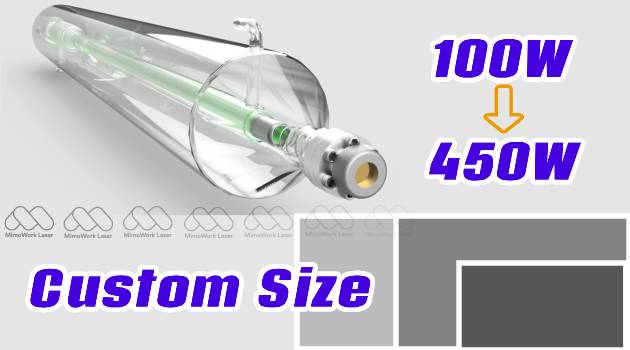

☻Awoodda Laser-ka ugu Wacan ee Goynta Acrylic:

Tusaalooyinka Qaar ka mid ah Goynta Laser Acrylic

Muujinta Xayeysiiska

• Sanduuqa Kaydinta

• Calaamadaha

• Koob

Qaabka

• Keychain

• Keega Sare

Hadyad & Qurxinta

• Alaabta guriga

• Dahab

▶ Goynta Laser-ka Ma Sunta Akril ma tahay?

▶ Sida Laser-ka loo gooyo Akril cad?

▶ Waa maxay Laser-ka ugu Wanaagsan ee Goynta Akril?

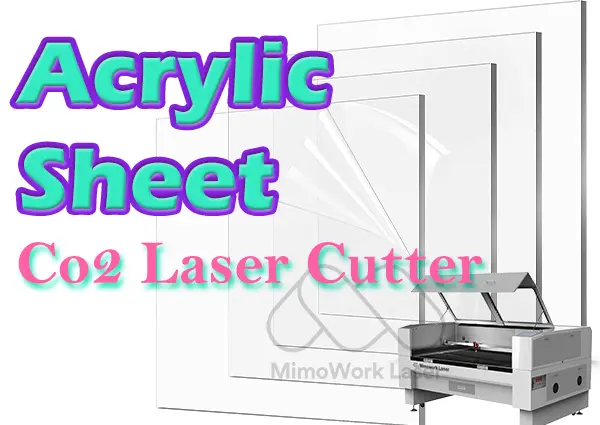

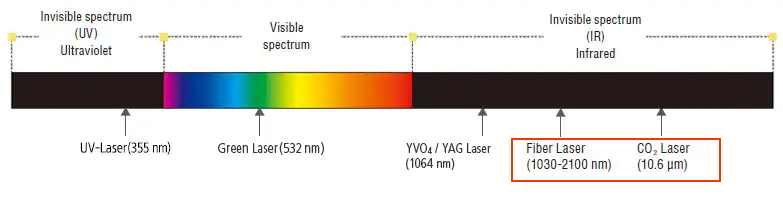

Goynta acrylic gaar ahaan, CO2 laser ayaa inta badan loo arkaa doorashada ugu fiican sababtoo ah sifooyinkiisa hirarka dhererka, bixinta nadiif ah oo sax ah jarida dhumucdiisuna kala duwan yihiin acrylic. Si kastaba ha ahaatee, shuruudaha gaarka ah ee mashaariicdaada, oo ay ku jiraan tixgelinta miisaaniyadda iyo alaabta aad qorsheyneyso inaad ku shaqeyso, waa inay sidoo kale saameyn ku yeeshaan doorashadaada. Had iyo jeer hubi qeexida nidaamka laysarka oo hubi inuu la socdo codsiyada aad damacsan tahay.

▶ CO2 Laser Cutter oo lagu taliyay oo loogu talagalay akril

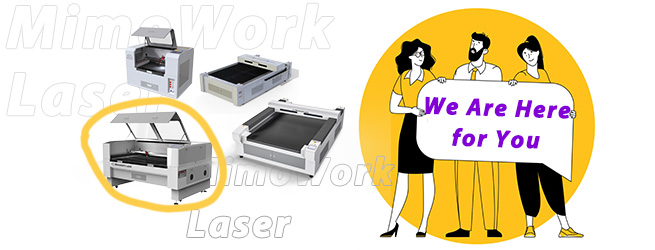

Laga soo bilaabo MimoWork Laser Series

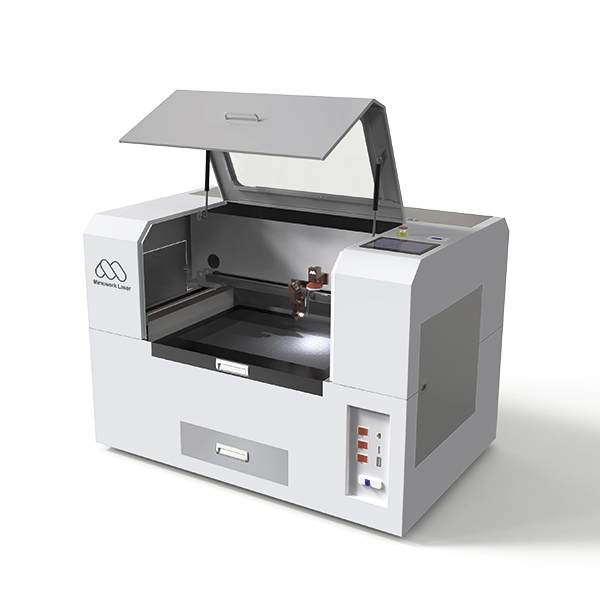

Cabbirka Miiska Shaqada:600mm * 400mm (23.6" * 15.7")

Ikhtiyaarada Laydhka:65W

Dulmar guud ee Desktop Laser Cutter 60

Modelka Desktop - Flatbed Laser Cutter 60 wuxuu ku faanaa naqshad is haysta oo si wax ku ool ah u yaraynaysa baahida bannaan ee qolkaaga. Waxay si ku habboon u fadhiisataa miis dushiisa, iyadoo isu soo bandhigaysa inay tahay doorashada heerka gelitaanka ku habboon ee kuwa bilawga ah ee ku hawlan abuurista alaabooyin yaryar oo caado u ah, sida abaal-marinnada akriliga, qurxinta, iyo dahabka.

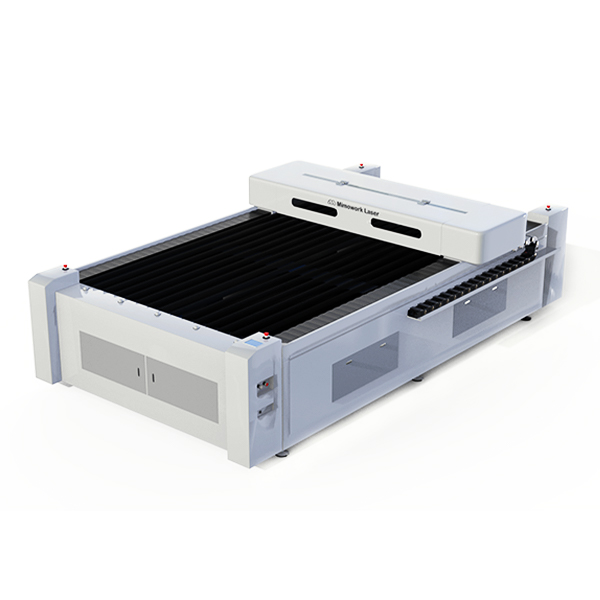

Cabbirka Miiska Shaqada:1300mm * 900mm (51.2" * 35.4")

Ikhtiyaarada Laydhka:100W/150W/300W

Dulmarka Laser Cutter Flatbed 130

Cutter Laser Flatbed 130 waa doorashada ugu caansan ee goynta akriliska. Naqshadeynta miiska shaqada ee ka gudubta waxay awood kuu siineysaa inaad gooyso cabbirka weyn ee xaashida akril ee ka dheer goobta shaqada. Waxaa intaa dheer, waxay bixisaa wax-qabad leh iyadoo lagu qalabeynayo tuubooyinka laysarka ee qiimeynta awood kasta si loo daboolo baahida loo qabo jarista acrylic leh dhumucyo kala duwan.

Cabbirka Miiska Shaqada:1300mm * 2500mm (51.2" * 98.4")

Ikhtiyaarada Laydhka:150W/300W/500W

Dulmarka Laser Cutter Flatbed 130L

Cutter-ka weyn ee Flatbed Laser Cutter 130L wuxuu si fiican ugu habboon yahay goynta go'yaal akrilik ah oo la taaban karo, oo ay ku jiraan looxyada 4ft x 8ft ee inta badan laga isticmaalo suuqa. Mashiinkan waxa si gaar ah loogu habeeyey inuu dejiyo mashaariicda waaweyn sida calaamadaha xayaysiisyada dibadda, qaybaha gudaha, iyo qalabka ilaalinta qaarkood. Natiijo ahaan, waxay u taagan tahay ikhtiyaarka la door bidayo ee warshadaha sida xayeysiinta iyo soosaarka alaabta guriga.

▶ Hagaha hawlgalka: Sidee loo gooyaa laser-ka akril?

Iyada oo ku xidhan nidaamka CNC iyo qaybaha mashiinka saxda ah, mashiinka goynta laser acrylic waa mid toos ah oo sahlan in la shaqeeyo. Kaliya waxaad u baahan tahay inaad ku dhejiso faylka naqshadeynta kombiyuutarka, oo aad dejiso cabbirada iyadoo loo eegayo sifooyinka walxaha iyo shuruudaha goynta. Inta soo hartay waxaa loo dayn doonaa laysarka. Waa waqtigii aad xorayn lahayd gacmahaaga oo aad dhaqaajin lahayd hal-abuurka iyo male-awaalka maskaxda.

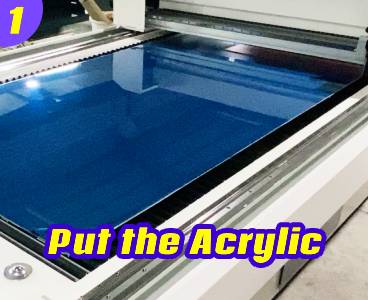

Tallaabada 1. Diyaari mashiinka iyo akril

Diyaarinta akril:Akrilik ku hay mid siman oo nadiif ah miiska shaqada, oo si fiican u tijaabi adigoo isticmaalaya qashinka ka hor goynta laser dhabta ah.

Mashiinka laser:go'aami cabbirka akriliga, cabbirka qaabka goynta, iyo dhumucda akriliga, si aad u doorato mashiinka ku habboon.

▶

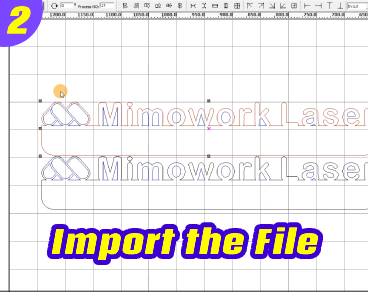

Tallaabada 2. dejiso software

Naqshad File:soo deji faylka goynta software-ka.

Dejinta laser: La hadal khabiirkayaga laysarka si aad u heshid cabbirada goynta guud. Laakiin walxo kala duwan ayaa leh dhumucyo kala duwan, nadiif ah, iyo cufnaan, markaa tijaabinta ka hor ayaa ah doorashada ugu fiican.

▶

Tallaabada 3. laser cut acrylic

Bilaw Goynta Laser-ka:Laysarka ayaa si toos ah u gooyn doona qaabka iyadoo loo eegayo dariiqa la bixiyay. Xusuusnow inaad furto hawo-qaadista si aad qiiqa iskaga saarto, oo hoos u daa hawadu afuufayso si aad u hubiso in cidhifku siman yahay.

Casharrada Fiidiyowga: Goynta Laser-ka & Qalabaynta Akril

▶ Sidee loo doortaa Laser Cutter?

Waxaa jira dhowr tixgalin marka aad dooranayso gooyaha laser akril ee ku habboon mashruucaaga. Marka hore waxaad u baahan tahay inaad ogaato macluumaadka walxaha sida dhumucda, cabbirka, iyo sifooyinka. Oo go'aami sharuudaha goynta ama xaradhka sida saxnaanta, xallinta xaradhka, hufnaanta goynta, cabbirka qaabka, iwm. Marka xigta, haddii aad leedahay shuruudo gaar ah oo loogu talagalay soosaarka aan qiiqa ahayn, qalabaynta qiiqa qiiqa ayaa diyaar ah. Intaa waxaa dheer, waxaad u baahan tahay inaad tixgeliso miisaaniyaddaada iyo qiimaha mashiinka. Waxaan kugula talineynaa inaad doorato alaab-qeybiye mashiinka laysarka si aad u hesho qiimo-jaban, adeeg dhammaystiran, iyo tignoolajiyada wax-soo-saarka la isku halayn karo.

Waxaad u baahan tahay inaad tixgeliso

Waa maxay macluumaadka aad u baahan tahay inaad bixiso?

> Macluumaadka xiriirkayaga

> Qiimaha mashiinka goynta laser akril

> Haddii ay doortaan ikhtiyaarrada mashiinka laysarka

▶ Isticmaalka Mashiinka

> Intee qaro weyn oo akril ah ayaa laysarka jari kara?

Dhumucda akril ee CO2 laser gooyn karaa waxay ku xiran tahay awoodda gaarka ah ee laysarka iyo sifooyinka habka goynta laysarka. Guud ahaan, CO2 lasers ayaa awood u leh inay gooyaan go'yaal akril leh oo dhumucdoodu kala duwan yihiin ilaa 30mm. Intaa waxaa dheer, arrimo ay ka mid yihiin diiradda laydhka laysarka, tayada indhaha, iyo naqshadeynta gaarka ah ee gooyaha laysarka ayaa saameyn ku yeelan kara waxqabadka goynta.

Kahor intaadan isku dayin inaad gooyso xaashida akril ee dhumuc weyn, waxaa lagugula talinayaa inaad hubiso qeexida ay bixiso soo saaraha CO2 laser jeexahaaga. Samaynta tijaabooyinka qaybo ka samaysan akril oo dhumucyo kala duwan leh ayaa kaa caawin kara in la go'aamiyo goobaha ugu fiican ee mashiinkaaga gaarka ah.

Caqabada: Goynta Laser-ka 21mm Dhumucda Akril

Sidee looga fogaadaa qiiqa akril-ka ee goynta laser?

> Casharrada loo yaqaan 'acrylic laser cutter'

Sidee loo helaa diiradda lenska laysarka?

Sidee loo rakibaa tube laser?

Sidee loo nadiifiyaa muraayada laysarka?

Wax badan ka baro Laser Cutting Acrylic,

Riix halkan si aad nala hadasho!

CO2 Laser Cutter for Acrylic waa mashiin caqli badan oo otomaatig ah iyo lammaane lagu kalsoonaan karo oo xagga shaqada iyo nolosha ah. Si ka duwan farsamaynta farsamada dhaqameed ee kale, gooyayaasha laysarka waxay isticmaalaan nidaamka xakamaynta dhijitaalka ah si loo xakameeyo jidka goynta iyo goynta saxda ah. Iyo qaab dhismeedka mashiinka xasilloon iyo qaybaha ayaa dammaanad qaadaya hawlgal siman.

MimoWork LASER MACHINE Lab

Jahawareer kasta ama su'aalo kasta oo ku saabsan gooyaha laser akril, kaliya na weydii wakhti kasta

Waqtiga boostada: Dec-11-2023