ILace Laser Cutting Machine kunye High Precision

| Indawo yokusebenzela (W *L) | 1600mm * 1,000mm (62.9”* 39.3”) - Umgangatho |

| 1600mm * 1200mm (62.9” * 47.2”) -Yandisiwe | |

| Isoftware | Isoftware yoBhaliso lweCCD |

| Amandla eLaser | 100W / 150W / 300W |

| Umthombo weLaser | CO2 Glass Laser Tube okanye CO2 RF Metal Laser Tube |

| Inkqubo yoLawulo loomatshini | Inyathelo leMoto yokuQhuba kunye noLawulo lwebhanti |

| Itheyibhile yokuSebenza | Itheyibhile eSebenzayo yeConveyor yentsimbi |

| Isantya esiphezulu | 1~400mm/s |

| Isantya sokukhawulezisa | 1000~4000mm/s2 |

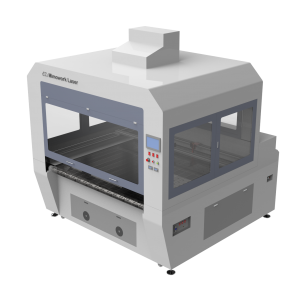

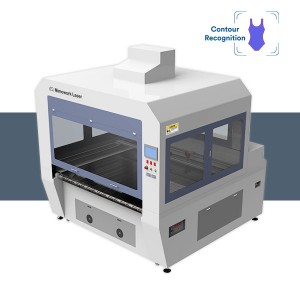

ILace Laser Cutter (Ivalwe ngokupheleleyo)

| Indawo yokusebenzela (W *L) | 1800mm * 1300mm (70.87'' * 51.18'') |

| Ubukhulu beMaterial Width | 1800mm ( 70.87'') |

| Amandla eLaser | 100W/ 130W/ 150W/ 300W |

| Umthombo weLaser | CO2 Glass Laser Tube / RF Metal Tube |

| Inkqubo yoLawulo loomatshini | Ukuhanjiswa kwebhanti kunye ne-Servo Motor Drive |

| Itheyibhile yokuSebenza | Itheyibhile eSebenzayo yeConveyor yentsimbi |

| Isantya esiphezulu | 1~400mm/s |

| Isantya sokukhawulezisa | 1000~4000mm/s2 |

Khulula ubuGcisa: Ukuchaneka kuhlangana nobuGcisa

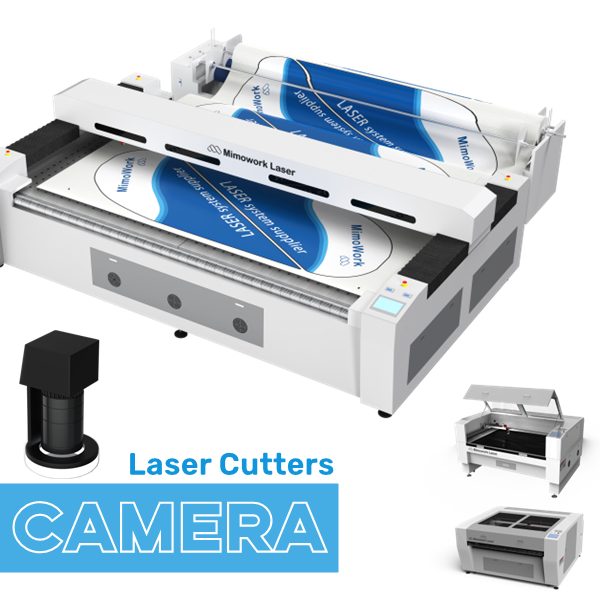

YeLace Laser Cutter 160 & 160L (Esemgangathweni & Eyandisiweyo):

◉Ukusika i-laser ye-sublimation yezinto eziguquguqukayo ezifanaIleyisikunye OkunyeImpahla yezixhobo

◉ Ukuphucula iintloko ezimbini ze-laser, ukwandisa kakhulu imveliso yakho (Unyuso oluKhethayo)

◉I-CNC (Ulawulo lwamanani eKhompyutha) kunye nedatha yekhompyuter yenkxaso yokwenziwa kwe-automation ephezulu kunye nemveliso ezinzileyo ekumgangatho ophezulu.

◉MimoWork SmartUmbono weLaser Cutter Softwareilungisa ngokuzenzekelayo deformation kunye nokutenxa

◉Usetyenziso olubanzi kumashishini afanaUshicilelo lweDijithali, iMathiriyeli eDityanisiweyo, iMpahla kunye neeMpahla zaseKhaya

◉ Itekhnoloji yokusika i-laser yeMimoWork eguquguqukayo nekhawulezayo inceda iimveliso zakho ziphendule ngokukhawuleza kwiimfuno zentengiso

◉ Auto-feederinikezaukutya okuzenzekelayo, ukuvumela ukusebenza okungajongwanga okonga iindleko zakho zokusebenza, kunye nezinga elisezantsi lokwaliwa (Unyuso oluKhethayo)

EyeLace Laser Cutter (Ivalwe Ngokupheleleyo):

◉Usetyenziso olubanzi kumashishini afana noshicilelo lwedijithali, imathiriyeli ehlanganisiweyo, impahla kunye nempahla yasekhaya

◉ Uguquguqukayo kwaye uyakhawulezaItekhnoloji yokusika iMimoWork laser inceda iimveliso zakho ukuba ziphendule ngokukhawuleza kwiimfuno zentengiso

◉EndalekoITekhnoloji yoKubonwa okuBonwayokunye nesoftware enamandla ibonelela ngomgangatho ophezulu kunye nokuthembeka kwishishini lakho.

◉ Ukutya okuzenzekelayoivumela umsebenzi ongajongwanga ogcina ixabiso lakho lomsebenzi kwaye uthobe izinga lokwaliwa (ukhetho)

◉IUlwakhiwo oluvalwe ngokupheleleyoyongezwa kuMbono wesiqhelo weLaser Cutting Machine.

Nazi3iindawo zokuphucula ukusebenza kwesi sikhi se-laser contour:

1. Ukhuseleko loMsebenzisi

2. Indawo yokusebenza ecocekileyo kunye nesiphumo esingcono sokukhupha uthuli

3. Isakhono esingcono sokuqaphela ukukhanya

Iimbalasane zoomatshini bokusika iLace Laser

IIkhamera yeCCDixhotyiswe ecaleni kwentloko ye-laser inokubona iimpawu zeempawu zokufumana iipateni eziprintiweyo, ezilukiweyo, okanye ezilukiweyo kwaye isoftware iya kusebenzisa ifayile yokusika kwipatheni eyiyo ngokuchaneka kwe-0.001mm ukuze kuqinisekiswe isiphumo esixabisekileyo sokusika.

IInkqubo yokuQatshelwa kweContouribhaqa i-contour ngokomahluko wombala phakathi kolwandlalo loshicilelo kunye nemvelaphi yemathiriyeli. Akukho mfuneko yokusebenzisa iipateni zoqobo okanye iifayile. Emva kokutya okuzenzekelayo, amalaphu aprintiweyo aya kubonwa ngokuthe ngqo. Le yinkqubo ezenzekelayo ngokupheleleyo ngaphandle kokungenelela komntu. Ngaphezu koko, ikhamera iya kuthatha iifoto emva kokuba ilaphu lityiswe kwindawo yokusika. I-contour yokusika iya kulungelelaniswa ukuze kupheliswe ukutenxa, ukuguqulwa, kunye nokujikeleza, ngoko ke, ekugqibeleni unokufikelela kwisiphumo esichanekileyo sokusika.

Xa uzama ukusika iicontours ezigqwethekileyo okanye ulandele iipatches ezichanekileyo eziphezulu kunye neelogo,IsiXokelelwano sokuTshaniswa koMfanekisoifaneleke ngakumbi kune-contour cut. Ngokuthelekisa iithempleyithi zakho zoyilo loqobo kunye neefoto ezithathwe yikhamera yeHD, unokufumana ngokulula eyona contour ifanayo ofuna ukuyisika. Kwakhona, unokuseta umgama wokutenxa ngokweemfuno zakho zobuqu.

Iintloko ezimbini ezizimeleyo ezizimeleyo-uPhuculo oluKhethekileyo

Kumatshini wokusika iintloko ezimbini ze-laser, iintloko ezimbini ze-laser zifakwe kwi-gantry efanayo, ngoko ke azikwazi ukusika iipatheni ezahlukeneyo ngexesha elinye. Nangona kunjalo, kumashishini amaninzi efashoni afana neengubo ze-sublimation yedayi, umzekelo, banokuba nomphambili, umva, kunye nemikhono yejezi yokusika. Ngeli xesha, iintloko ezimbini ezizimeleyo ziyakwazi ukuphatha iziqwenga zeepateni ezahlukeneyo ngexesha elinye. Olu khetho luphakamisa ukusebenza kakuhle kunye nokuguquguquka kwemveliso ukuya kwinqanaba elikhulu. Imveliso inokunyuswa ukusuka kwi-30% ukuya kwi-50%.

Auto Feederiyunithi yokondla eqhuba ngokuhambelana nomatshini wokusika we-laser. Ilungelelaniswe neitafile yokuhambisa, i-auto feeder inokuhambisa izinto zomqulu kwitafile yokusika emva kokuba ubeke imiqulu kwi-feeder. Ukutshatisa imathiriyeli yefomathi ebanzi, iMimoWork icebisa i-auto-feeder eyandisiweyo ekwaziyo ukuthwala umthwalo onzima ngefomathi enkulu, kunye nokuqinisekisa ukondla ngokutyibilikayo. Isantya sokutya sinokusetwa ngokwesantya sakho sokusika. Inzwa ixhotyiswe ukuqinisekisa ukubekwa kwezinto ngokugqibeleleyo kunye nokunciphisa iimpazamo. I-feeder iyakwazi ukudibanisa i-shaft diameters ezahlukeneyo zemiqulu. I-roller ye-pneumatic inokulungelelanisa iingubo kunye noxinzelelo kunye nobukhulu obahlukeneyo. Le yunithi ikunceda ukuba uqaphele inkqubo yokusika ngokuzenzekelayo.

I-Y-axis Gear kunye ne-X-axis Belt Drive

Umatshini wokusika wekhamera wekhamera ubonisa i-Y-axis rack & pinion Drive kunye ne-X-axis belt transmission. Uyilo lunikeza unyango olugqibeleleyo phakathi kwendawo yokusebenza yefomathi enkulu kunye nokuhanjiswa okugudileyo. I-Y-axis rack & pinion luhlobo lwe-actuator yomgca equka igiya ejikelezayo (iphini) ebandakanya igiya yomda (i-rack), esebenza ukuguqulela isindululo esijikelezayo kwintshukumo yomgca. I-rack kunye ne-pinion ziqhubana ngokuzenzekelayo. Iigiya ezithe ngqo kunye ne-helical ziyafumaneka kwi-rack & pinion. Ukuhanjiswa kwebhanti ye-X-axis kunika ukuhanjiswa okugudileyo kwaye okuzinzileyo kwintloko ye-laser. Ukusika kwe-laser ephezulu kunye nokuchaneka okuphezulu kunokugqitywa.

IiMoto eziKhethekileyo zeServo

Vula isantya sokusika umbane kunye nenkqubo yentshukumo ye-servo motor. Phakamisa ukusebenza koomatshini beLaser Cutter ye-Sublimation Laser ukuya kubude obutsha njengoko ngaphandle kokuzama ukukrola imizobo entsonkothileyo yecontour yangaphandle ngokuchaneka okungagungqiyo. Yamkela amandla e-servo kunye namava uzinzo kunye nesantya esingenakulinganiswa.

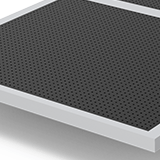

IUkufunxa iVacuumilele phantsi kwetafile yokusika. Ngemingxuma emincinci kunye nenzulu kumphezulu wetafile yokusika, umoya 'uqinisa' izinto eziphezu kwetafile. Itheyibhile ye-vacuum ayifumani kwindlela ye-laser beam ngexesha lokusika. Ngokuchasene noko, kunye nefeni enamandla yokukhupha, yongeza umphumo womsi kunye nokuthintela uthuli ngexesha lokusika.

Uyilo oluvalekileyo oluvalekileyo-uPhuculo ngokuKhethayo

Ngoyilo olukhethekileyo lomnyango ovalwe ngokupheleleyo, iI-Contour Laser Cutter evalelweyoinokuqinisekisa ukuphelelwa ngcono kunye nokuphucula ngakumbi umphumo wokuqaphela ikhamera ye-HD ukuphepha i-vignetting echaphazela ukuqatshelwa kwe-contour kwimeko yokukhanya okungahambi kakuhle. Umnyango kuwo onke amacala amane omatshini unokuvulwa, ongayi kuchaphazela ukugcinwa kunye nokucoca imihla ngemihla.

Ilaphu leLaser yokusika iLace (I-Applique, iEmbroidery)

Uyilo oluvalekileyo oluvalekileyo-umboniso

Fumana iividiyo ezingakumbi malunga nabasiki bethu belaser kwindawo yethuIgalari yevidiyo

Imiba yosetyenziso

yeLace Laser Cutting Machines

Yamkela Ubuhle, Ukuchaneka Kudibana Nobucukubhede

✔ Ikhamera yeCCD iwabeka ngokuchanekileyo amanqaku obhaliso

✔ Iintloko ezimbini ze-laser ezikhethwayo zinokunyusa kakhulu imveliso kunye nokusebenza kakuhle

✔ Coca kwaye uchanekile umphetho wokusika ngaphandle kokucheba emva kokusika

✔ Sika iicontours zokushicilela emva kokufumana amanqaku

✔ Ukuchaneka okuphezulu ngaphakathi koluhlu lwempazamo ye-0.1 mm

✔ Umatshini wokusika i-Laser ulungele zombini imveliso yexesha elifutshane kunye nemiyalelo yokuvelisa ngobuninzi

✔ Vula iimfihlo zokusikwa kwelaser kwiZincedisi zeLace kwaye ukhulule umhlaba wamathuba

✔ Fumana ukuchaneka okungenasiphako, uyilo oluntsonkothileyo, ubuhle obuqaqambileyo, kunye nokwenza ngokwezifiso

✔ Phakamisa indalo yakho ibe phezulu ngobugcisa kunye nokusebenza kakuhle kwetekhnoloji yokusika i-laser

✔ Ngena kwikamva lemveliso yeLace Accessory kwaye ubukele ubuchule bakho buphila ngokweenkcukacha eziphefumlayo

Ukugqibelela okungenasiphako kunye noBuchule obungenamda

Ngokufanelekileyo, ngalo lonke ixesha: Ukufezekisa ukucutha okuhambelanayo, okulungiselelwe okuqinisekisa ukulungelelaniswa ngokugqibeleleyo, ukuphucula induduzo kunye nokuzithemba kwiingubo zeleyisi.

Udibaniso olungenamthungo, ukuhamba komsebenzi oLundisiweyo: Hlanganisa ngokungenamthungo iteknoloji yokusika i-laser kwiinkqubo zokuvelisa ukwandisa ukusebenza kakuhle kunye nemveliso.

Phakamisa ubugcisa, Iinkcukacha ezigqwesileyo: Phakamisa ubugcisa bokwenza iileyisi ngokuchaneka kwelaser, ukuqaqambisa iinkcukacha ezintsonkothileyo kunye nokuphucula ubugcisa bobugcisa.

Unleash Ikhono leLace: Yamkela amandla okuguqula ukusika kwe-laser, ukutyhala imida yobugcisa be-lace kunye nokudala izinto ezingenakulibaleka, eziphefumulayo.

Imveliso eSebenzayo, Ubuhle obungapheliyo: Gcina ixesha kunye nezixhobo ngelixa ugcina ubuhle obungaphelelwa lixesha ngokukhawuleza, ukusika kwelaser okusebenzayo kwezixhobo zeleyisi.

ye-Sublimation Laser Cutting Machines

Izixhobo:

Twill,Velvet, I-Velcro, InayiloniiPolyester,Ifilimu, I-Foil, kunye nezinye iiPattered Materials

Ilaphu lePolyester,Spandex,Inayiloni,Isilika,I-Velvet eprintiweyo,Umqhaphu, kunye nezinyeI-Sublimation Textiles

Usetyenziso:

Isinxibo,Izixhobo zeMpahla, Ileyisi, Iimpahla zaseKhaya, Isakhelo seFoto, iilebhile, isincamathelisi, i-Applique

Isinxibo esiSebenzayo, isinxibo sezemidlalo (Isinxibo seBhayisekile, iijezi zeHoki, iijezi zeBaseball, iijezi zeBasketball, iijezi zeBhola ekhatywayo, iijezi zeVolleyball, iijezi zeLacrosse, iijezi zeRingette)

Iyunifomu, iimpahla zokuqubha,IiLeggings,Izincedisi ze-Sublimation(Imikhono yeengalo, imikhono yomlenze, iBandanna, ibhande lentloko, isigqubuthelo sobuso, iimaski)