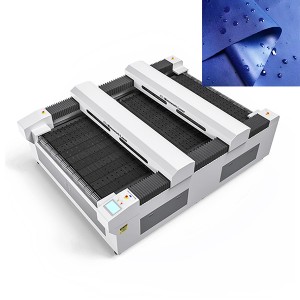

Umsiki weLaser yoMzimveliso woMthi omkhulu kunye noThiyelo (Ukuya kuthi ga kwi-30mm)

▶ Isigawuli selaser esinefomathi enkulu yeplanga

Idatha yoBugcisa

| Indawo yokusebenzela (W * L) | 1300mm * 2500mm (51” * 98.4”) |

| Isoftware | Isoftware engasebenziyo |

| Amandla eLaser | 150W/300W/450W |

| Umthombo weLaser | CO2 Glass Laser Tube |

| Inkqubo yoLawulo loomatshini | Ibhola Screw & Servo Motor Drive |

| Itheyibhile yokuSebenza | Icwecwe lemela okanye iTayibhile yokuSebenza yeQophe lobusi |

| Isantya esiphezulu | 1-600mm/s |

| Isantya sokukhawulezisa | 1000~3000mm/s2 |

| Ukuchaneka kwesikhundla | ≤± 0.05mm |

| Ubungakanani bomatshini | 3800 * 1960 * 1210mm |

| I-Voltage yokusebenza | AC110-220V ± 10%, 50-60HZ |

| Imo yokupholisa | Ukupholisa kwamanzi kunye neNkqubo yoKhuselo |

| Indawo yokusebenza | Iqondo lobushushu:0—45℃ Ukufuma:5%—95% |

| Ubungakanani bepakethi | 3850mm * 2050mm * 1270mm |

| Ubunzima | 1000kg |

▷Iimpawu ze-1325 Laser Cutter

Umtsi omkhulu kwiMveliso

◾ Uzinzile kunye noMgangatho oGqwesileyo wokusika

Uyilo lweNdlela ye-Optical rhoqo

Ngobude obuphezulu bendlela yokukhanya, umqadi we-laser ongaguqukiyo nakweyiphi na indawo kuluhlu lwetafile yokusika unokubangela ukunqunyulwa kuyo yonke into, nokuba bubunzima kangakanani. Ndiyabulela kuloo nto, unokufumana isiphumo esingcono sokusika i-acrylic okanye umthi kunendlela ye-laser enesiqingatha.

◾ Ukusebenza okuphezulu kunye nokuchaneka

Inkqubo yoThumelo oluLungileyo

Imodyuli ye-screw ye-X-axis, i-Y-axis unilateral ibhola screw inika uzinzo olugqwesileyo kunye nokuchaneka kwentshukumo yesantya esiphezulu se-gantry. Idityaniswe ne-servo motor, inkqubo yokuhambisa idala imveliso ephezulu ngokufanelekileyo.

◾ Ubomi obude kunye nenkonzo ende

Ulwakhiwo loomatshini oluzinzileyo

Umzimba womatshini udityaniswe ngetyhubhu ye-square eyi-100mm kwaye ufumana ukuguga kwe-vibration kunye nonyango lwendalo lokuguga. I-Gantry kunye nokusika intloko kusetyenziswa i-aluminium edibeneyo. Ulungelelwaniso lulonke luqinisekisa imo yokusebenza ezinzileyo.

◾ Ukwenziwa kwesantya esiphezulu

Isantya esiphezulu sokusika kunye nokukrola

I-1300 * 2500mm i-laser cutter yethu inokufezekisa i-1-60,000mm / min isantya sokukrola kunye ne-1-36,000mm / min isantya sokusika.

Kwangaxeshanye, ukuchaneka kwesikhundla kukwaqinisekisiwe ngaphakathi kwe-0.05mm, ukuze ikwazi ukusika kwaye ikrole amanani ayi-1x1mm okanye oonobumba, akukho ngxaki kwaphela.

Kutheni ukhetha iMimoWork Laser

130250 umatshini laser uthelekiso iinkcukacha

|

| Eyomnye umenzi | Umatshini weMimoWork laser |

| Ukusika isantya | 1-15,000mm / min | 1-36,000mm/min |

| Ukuchaneka kwesikhundla | ≤±0.2mm | ≤± 0.05mm |

| Amandla eLaser | 80W/100W/130W/150W | 100W/130W/150W/300W/500W |

| Indlela yeLaser | Indlela ye-laser enesiqingatha | Indlela yokubona rhoqo |

| Inkqubo yothumelo | Ibhanti yokuhambisa | I-Servo motor + isikrufu sebhola |

| Inkqubo yokuqhuba | Umqhubi wenyathelo | Servo motor |

| Inkqubo yokulawula | Inkqubo endala, ngaphandle kwentengiso | Inkqubo entsha yolawulo yeRDC edumileyo |

| Uyilo lombane olukhethiweyo | No | CE/UL/CSA |

| Umzimba ophambili | Traditional welding fuselage | Ibhedi eyomeleziweyo, ulwakhiwo lulonke ludityaniswe nge-100mm yesikwere ityhubhu, kwaye lufumana ukuguga kwe-vibration kunye nonyango lwendalo lokuguga. |

Iisampulu evela Wood Laser Cutter

Izinto ezifanelekileyo zokhuni

MDF, Basswood, White Pine, Alder, Cherry, Oak, Baltic Birch Plywood, Balsa, Cork, Cedar, Balsa, Solid Wood, Plywood, Timber, Teak, Veneers, Walnut, Hardwood, laminated Wood kunye Multiplex

Usetyenziso olubanzi

• Izixhobo zomculo

• Ibhokisi yokuGcina

• Imifuziselo yoYilo

• Ukuhombisa iziBonelelo zoMgangatho

Iividiyo | Ingakwenzela ntoni i-laser cutter?

Laser uMzobo ifoto phezu Wood

Fumana iWood Laser Cutter ukuze uphucule ishishini lakho

Yonwabela inkuni laser fun!

▶ Isigawuli selaser esinefomathi enkulu yeplanga

Phucula iiNdlela ozikhethayo

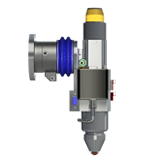

Intloko yeLaser exutyiweyo

Ugxininiso oluzenzekelayo

IIkhamera yeCCDinokuqonda kwaye ibeke ipateni kwi-acrylic eprintiweyo, inceda i-laser cutter ukuba iqonde ukusika okuchanekileyo kunye nomgangatho ophezulu. Naluphi na uyilo olulungiselelweyo lwegraphic olushicilelweyo lunokutshintshwa ngokuguquguqukayo kunye nolwandlalo kunye nenkqubo yamehlo, idlala indima ebalulekileyo kwintengiso kunye nolunye ushishino.

Imibuzo eNxulumeneyo: Unokuba Nomdla

1. Ndingasebenzisa naluphi na uhlobo lomthi wokusika i-laser, okanye ngaba kukho iindidi ezithile zomthi ezisebenza kakuhle?

2. Bubuphi ubunzima bomthi onokuthi umatshini wokusika i-CO2 laser uphathe ngokufanelekileyo?

Ewe, ukhuseleko lubalulekile xa usebenza ngeelaser. Qinisekisa ukungena komoya okufanelekileyo kwindawo yakho yokusebenza ukuze ususe umsi owenziwe ngexesha lokusika. Soloko unxibe izixhobo ezifanelekileyo zokuzikhusela (PPE), kuqukwa neendondo zokhuseleko. Ukongeza, qiniseka ukuba iinkuni azinanto yokwaleka, izinto zokugqibezela, okanye iikhemikhali ezinokuvelisa umsi oyingozi xa zibekwe kwilaser.

Ukugawula iinkuni: IiRouter zeCNC VS Laser

1. Izinto ezilungileyo zeCNC Routers

Ngokwembali, enye yeenzuzo eziphambili zokukhetha i-router ngokuchasene ne-laser yayikukwazi ukufezekisa ubunzulu bokusika obuchanekileyo. I-router ye-CNC inikezela ngokulula kohlengahlengiso oluthe nkqo (kunye ne-Z-axis), evumela ulawulo oluthe ngqo phezu kobunzulu bokunqunyulwa. Ngamagama alula, unokuhlengahlengisa ubude bomsiki ukuba ukhethe ukususa kuphela inxalenye yendawo yomthi.

2. Ukungalungi kwe-CNC Routers

Iirutha zigqwesa ekuphatheni iigophe ngokuthe ngcembe kodwa zinemida xa isizaiiengile ezibukhali. Ukuchaneka abanikezelayo kunyanzeliswa yiradius ye-bit cut. Ngamagama alula,ububanzi be-cut buhambelana nobukhulu be-bit ngokwayo. Awona masuntswana e-router amancinci ane-radius emalunga1 mm.

Kuba ii-routers zinqumle ukungqubana, kubalulekile ukuqinisa ngokukhuselekileyo impahla kwindawo yokusika. Ngaphandle kokulungiswa okufanelekileyo, i-torque ye-router inokubangela ukuba izinto ezijikelezayo okanye zitshintshe ngokukhawuleza. Ngokuqhelekileyo, iinkuni zibotshelelwa endaweni kusetyenziswa i-clamps. Nangona kunjalo, xa i-router-speed bit bit isetyenziswe kwizinto ezifakwe ngokuqinileyo, ukuxhatshazwa okubalulekileyo kuveliswa. Olu xinzelelo lunamandla okubaijike okanye yenzakalise iinkuni, ukuveza ucelomngeni xa usikwa izinto ezibhityileyo okanye eziethe-ethe.

3. Izinto eziluncedo kunye nokungalunganga kweLaser

Ngokufana nee-router ezizenzekelayo, i-laser cutters ilawulwa yi-CNC (i-Computer Numerical Control system). Nangona kunjalo, umahluko osisiseko ukwindlela yabo yokusika. Abasiki beLasermusa ukuthembela kungquzulwano; endaweni yoko, basika izixhobo besebenzisaubushushu obukhulu. Umqadi wokukhanya onamandla kakhulu utshisa ngokufanelekileyo ngamaplanga, ngokuchasene nenkqubo yemveli yokukrola okanye yomatshini.

Njengoko kuphawuliwe ngaphambili, ububanzi bokusikwa bunqunywe ngubukhulu besixhobo sokusika. Ngelixa eyona mitha incinci ye-router ineradiyasi engaphantsi kancinane kwe-1 mm, umqadi welaser unokulungiswa ukuze ube neradiyasi encinci njenge.0.1 mm. Esi sikhundla sivumela ukuyilwa kokusikwa okuntsokothileyo ngeukuchaneka okumangalisayo.

Ngenxa yokuba abasiki be-laser basebenzisa inkqubo yokutshisa ukugawula iinkuni, bayavelisaimiphetho ebukhali kakhulu kwaye ekhrisimesi. Nangona oku kutsha kunokukhokelela ekutshintsheni kombala othile, amanyathelo anokuphunyezwa okuthintela amabala okutsha angeyomfuneko. Ukongeza, isenzo esivuthayo sitywina imiphetho, ngaloo ndlelaukunciphisa ukwanda kunye nokucuthekazokhuni ezisikiweyo.

Umatshini weLaser ohambelanayo

ngokhuni kunye ne-acrylic laser cutting

• Ukrolo olukhawulezayo noluchanekileyo lwemathiriyeli eyomeleleyo

• Uyilo lokungena ngeendlela ezimbini luvumela imathiriyeli emide kakhulu ebekwe kwaye isikwe

ngokhuni kunye ne-acrylic laser ekrola

• Ukukhanya kunye noyilo oludibeneyo

• Kulula ukusebenza kwabaqalayo