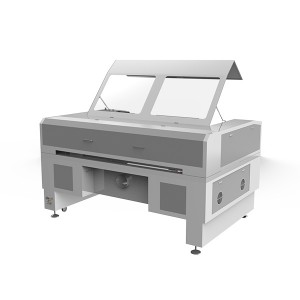

I-Acrylic Laser Engraving Machine 130 (Laser Engraving Plexiglass/PMMA)

▶ Umshini Wokuqopha I-Laser we-Acrylic (Umshini Oncane Wokusika we-Acrylic Laser)

Idatha Yezobuchwepheshe

| Indawo yokusebenza (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Isoftware | Isoftware engaxhunyiwe ku-inthanethi |

| Laser Amandla | 100W/150W/300W |

| Umthombo we-Laser | I-CO2 Glass Laser Tube noma i-CO2 RF Metal Laser Tube |

| IMechanical Control System | Isinyathelo Motor Belt Control |

| Ithebula Lokusebenza | I-Honey Comb Working Table noma I-Knife Strip Working Table |

| Isivinini esikhulu | 1~400mm/s |

| Isivinini Sokusheshisa | 1000~4000mm/s2 |

| Usayizi Wephakheji | 2050mm * 1650mm * 1270mm (80.7'' * 64.9'' * 50.0'') |

| Isisindo | 620kg |

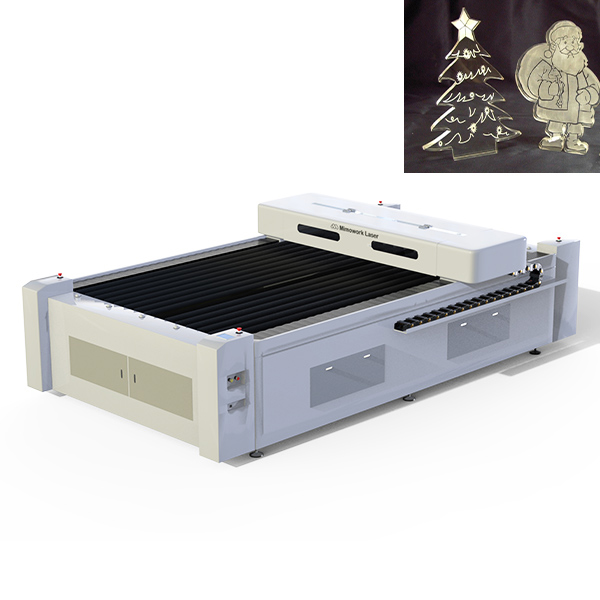

(Nge-Acrylic Laser Engraver, Ungakwazi Ukuqopha I-Laser Isithombe Nge-Acrylic, I-Acrylic Laser Cut Shapes)

Ezinye Izinketho Zokuthuthukisa Ongazikhetha

I-DC Brushless Motors

I-Servo Motors

Okunamathiselwe kwe-Rotary

I-Auto Focus

I-Lifting Platform

Ibhola & Isikulufa

Ukusebenzisa i-Acrylic Laser Engraver

Senza omaka be-Acrylic

▷

Umqophi we-laser we-acrylic unezinketho ezahlukene zamandla ongazikhetha, ngokubeka imingcele ehlukene, ungabona ukuqoshwa nokusika i-acrylic emshinini owodwa, futhi ngokuhamba okukodwa.

Hhayi kuphela i-acrylic(plexiglass/PMMA), kodwa nezinye ezingezona izinsimbi. Uma uzokhulisa ibhizinisi lakho ngokwethula ezinye izinto, umshini we-CO2 laser uzokuxhasa. Njengokhuni, ipulasitiki, ukuzwa, igwebu, indwangu, itshe, isikhumba, njalonjalo, lezi zinto zingasikwa futhi ziqoshwe ngomshini we-laser. Ngakho-ke ukutshala imali kuyo kubiza kakhulu futhi kunenzuzo yesikhathi eside.

Yini ozoyenza ngomshini wokuqopha nokusika we-laser we-acrylic?

Thuthukisa nge

Ikhamera ye-CCD ye-acrylic yakho ephrintiwe

IIkhamera ye-CCDi-laser cutter isebenzisa ubuchwepheshe bekhamera obuthuthukisiwe ukubona ngokunembile amaphethini aphrintiwe kumashidi e-acrylic, okuvumela ukusika okunembile nokungenamthungo.

Lesi sisiki se-laser se-acrylic esisha siqinisekisa ukuthi imiklamo eyinkimbinkimbi, ama-logo, noma umsebenzi wobuciko we-acrylic uphindaphindwa ngokunembile ngaphandle kwamaphutha.

① Yini ikhamera ye-CCD?

② Isebenza Kanjani Ukusika Ikhamera Yekhamera?

Ikhamera ye-CCD ingabona futhi ithole iphethini ephrintiwe ebhodini le-acrylic ukusiza i-laser ngokusika okunembile. Ibhodi lokukhangisa, imihlobiso, izimpawu, amalogo omkhiqizo, ngisho nezipho ezikhumbulekayo nezithombe ezenziwe nge-acrylic ephrintiwe zingacutshungulwa kalula.

Umhlahlandlela Wokusebenza:

Isinyathelo 1.

I-UV phrinta iphethini yakho eshidini le-acrylic

Isinyathelo sesi-3.

Thatha izingcezu zakho eziqediwe

Noma yimiphi imibuzo mayelana nomshini wokuqopha we-Laser we-Acrylic?

Izithombe Dlulisa amehlo

Izicelo ezidumile ze-Laser Engraving Acrylic

• Izibonisi Zokukhangisa

• Imodeli Yezakhiwo

• Ukulebula kweNkampani

• Izindebe ezithambile

• Ifenisha Yesimanje

• Isitendi Somkhiqizo

• Izimpawu Zomdayisi

• Ukususwa kweSprue

• Ubakaki

• Ukuthenga ezitolo

• I-Cosmetic Stand

Amavidiyo - I-Laser Cut & Uqophe Isibonisi Se-Acrylic

Indlela Yokuqopha I-Acrylic Ecacile Nge-Laser?

→ Ngenisa ifayela lakho lokuklama

→ Qala umbhalo we-laser

→ Hlanganisa isisekelo se-acrylic ne-LED

→ Xhuma emandleni

Isibonisi se-LED esikhazimulayo nesimangalisayo senziwe kahle!

Amaphuzu avelele we-Laser Engraved Acrylic

✔Iphethini eqoshiwe ecashile enemigqa ebushelelezi

✔Umaki wokuqopha unomphela nendawo ehlanzekile

✔Asikho isidingo sokupholisha ngemuva

Iyiphi i-Acrylic Engaqoshwa nge-Laser?

Ngaphambi kokuthi uqale ukuhlola i-acrylic ku-laser yakho, kubalulekile ukuqonda umehluko phakathi kwezinhlobo ezimbili eziyinhloko zale nto: i-acrylic eqoshiwe ne-extruded.

1. Cast Acrylic

Amashidi e-acrylic acijile akhiwe nge-acrylic ewuketshezi ethelwa esikhunjeni, okuholela ezinhlobonhlobo zobumo nosayizi.

Lolu uhlobo lwe-acrylic oluvame ukusetshenziswa ekwenzeni imiklomelo nezinto ezifanayo.

I-Cast acrylic ifaneleka kahle ukuqoshwa ngenxa yesici sayo sokuphendula umbala omhlophe qhwa uma iqoshwa.

Nakuba ingasikwa nge-laser, ayikhiqizi imiphetho epholishwe ngamalangabi, iyenze ifaneleke kangcono izinhlelo zokusebenza zokuqoshwa nge-laser.

2. I-Acrylic Ekhishiwe

I-acrylic enwetshiwe, ngakolunye uhlangothi, iyinto ethandwa kakhulu yokusika i-laser.

Ikhiqizwa ngenqubo yokukhiqiza ivolumu ephezulu, evame ukuyenza ibe nezindleko ezingcono kune-cast acrylic.

I-acrylic enwetshiwe isabela ngendlela ehlukile ku-laser beam—isika ngokuhlanzekile nangokushelela, futhi lapho isikwa nge-laser, ikhiqiza imiphetho epholishwe ngamalangabi.

Nokho, lapho iqoshwa, ayikhiqizi isithwathwa; kunalokho, uthola umbhalo ocacile.

Isifundo Sevidiyo: I-Laser Engraving & Cutting Acrylic

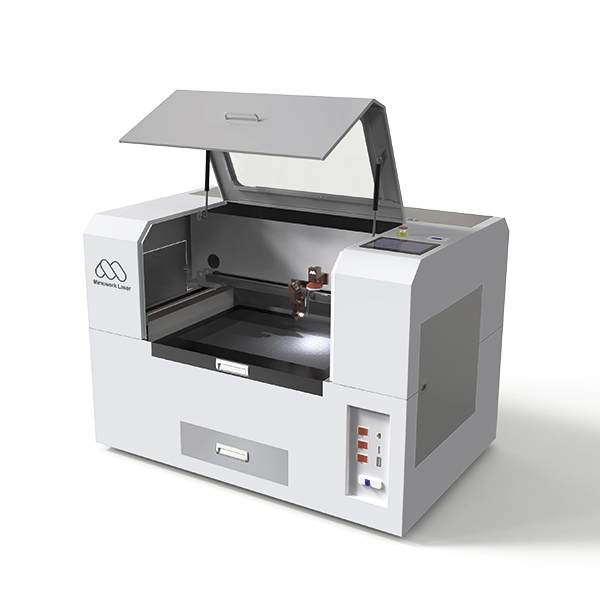

Umshini We-Laser Ohlobene we-Acrylic

ukusika i-acrylic ne-laser yokhuni

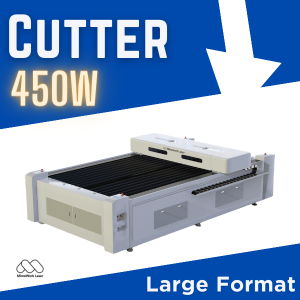

• Ifanele izinto eziqinile zefomethi enkulu

• Ukusika ukujiya okuningi ngamandla ozikhethela we-laser tube

nge-acrylic ne-laser yokhuni eqoshiwe

• Idizayini elula futhi ehlangene

• Kulula ukusebenza kwabaqalayo

Ngithanda umshini wokusika nokuqopha i-laser

FAQ - Acrylic Laser Engraving & Cutting

# Uyisika kanjani i-Acrylic Ngaphandle kokuyiklebhula?

Ukusika i-acrylicngaphandle kokuyihlikihla, ukusebenzisa i-CO2 laser cutter kungenye yezindlela ezingcono kakhulu. Nawa amanye amathiphu okuthola ukusikeka okuhlanzekile nokungena-crack:

Sebenzisa i-Amandla Angakwesokudla Nesivinini: Lungisa amandla nesivinini sokusika se-CO2 laser cutter ngokufanele ubukhulu be-acrylic. Ijubane lokusika elihamba kancane elinamandla aphansi liyanconywa nge-acrylic ewugqinsi, kuyilapho amandla aphakeme nesivinini esisheshayo afanele amashidi azacile.

Qinisekisa Ukugxila Okufanelekile: Gcina iphoyinti eliqondile le-laser beam ebusweni be-acrylic. Lokhu kuvimbela ukushisa ngokweqile futhi kunciphisa ingozi yokuqhekeka.

Sebenzisa Ithebula Lokusika Izinyosi: Beka ishidi le-acrylic etafuleni lokusika ikhekhe lezinyosi ukuze uvumele intuthu nokushisa kuhlakazeke ngokuphumelelayo. Lokhu kuvimbela ukwakheka kokushisa futhi kunciphisa amathuba okuqhekeka...

# Ungabuthola Kanjani Ubude Obugxile BeLaser?

Ukusika kwe-laser ephelele kanye nomphumela wokuqopha kusho umshini we-laser we-CO2 ofaneleubude bokugxila.

Le vidiyo ikuphendula ngezinyathelo ezithile zokusebenza zokulungisa ilensi ye-CO2 laser ukuze utholeubude bokugxila kwesokudlangomshini we-CO2 laser engraver.

I-focus lens co2 laser igxilisa i-laser beam endaweni okugxilwe kuyo okuyiindawo thinnestfuthi unamandla anamandla.

Amanye amathiphu nokusikisela kuyashiwo kuvidiyo.

# Ungawukhetha Kanjani Umbhede Wokusika I-Laser Wokukhiqiza Kwakho?

Ukuze izinto ezahlukene zisikwe noma ziqoshwe nge-laser, yiliphi ithebula lomshini wokusika i-laser elingcono kakhulu?

1. I-Honeycomb Laser Cutting Bed

2. Ummese Strip Laser Cutting Umbhede

3. Ithebula Lokushintshanisa

4. I-Lifting Platform

5. Ithebula le-Conveyor

* Nge-Laser Engraving Acrylic, I-Honeycomb Laser Bed iyindlela engcono kakhulu yokukhetha!

# Ingakanani I-Acrylic Ingakwazi Ukusika I-Laser Cutter?

Ubukhulu bokusika be-acrylic nge-CO2 laser cutter buncike emandleni e-laser kanye nohlobo lomshini we-CO2 laser osetshenziswayo. Ngokuvamile, i-CO2 laser cutter ingasika amashidi e-acrylic kusukelaamamilimitha ambalwa ukuya kumasentimitha amaninganangokuqina.

Kwabasiki be-laser be-CO2 abanamandla aphansi abavame ukusetshenziswa ku-hobbyist kanye nezicelo ezincane, bangakwazi ukusika amashidi e-acrylic azungeze.6mm (1/4 intshi)ngokuqina.

Kodwa-ke, abasiki be-laser be-CO2 abanamandla kakhulu, ikakhulukazi labo abasetshenziswa kuzilungiselelo zezimboni, bangakwazi ukuphatha izinto eziwugqinsi ze-acrylic. Ama-laser e-CO2 anamandla amakhulu anganqamula amashidi e-acrylic kusukela12mm (1/2 intshi) kufika ku-25mm (1 intshi)noma ngisho nakakhulu.

Sibe nesivivinyo sokusika i-acrylic ewugqinsi nge-laser kuze kufike ku-21mm ngamandla we-laser angu-450W, umphumela muhle. Bheka ividiyo ukuze uthole okwengeziwe.

Indlela yokusika i-Laser engu-21mm Thick Acrylic?

Kule vidiyo, sisebenzisa i-13090 umshini wokusika we-laserukusika umucu we21mm ubukhulu acrylic. Ngokudluliswa kwemojula, ukunemba okuphezulu kukusiza ukuthi ulinganise phakathi kwejubane lokusika kanye nekhwalithi yokusika.

Ngaphambi kokuqala umshini wokusika we-acrylic owugqinsi, into yokuqala oyicabangelayo ukunqumaukugxila kwe-laserfuthi uyilungise endaweni efanele.

Nge-acrylic ewugqinsi noma ukhuni, siphakamisa ukuthi ukugxila kufanele kulale ku-maphakathi nendaba. Ukuhlolwa kwe-laserokudingekayongezinto zakho ezihlukene.

# Ingabe I-Laser Ingakwazi Ukusika Izimpawu Ze-Acrylic Ezengeziwe?

Ungasika kanjani i-laser uphawu lwe-acrylic olukhulu kunombhede wakho we-laser? I1325 umshini wokusika we-laser(4 * 8 izinyawo laser cutting umshini) kuyoba ukukhetha kwakho kokuqala. Nge-pass-through laser cutter, ungakwazi ukusika uphawu lwe-acrylic olukhulu kakhulunkulu kunombhede wakho we-laser. Izimpawu zokusika i-laser ezihlanganisa izinkuni kanye ne-acrylic sheet cutting kulula kakhulu ukuqedela.

Ungasika kanjani i-Laser Signage Enkulu?

Umshini wethu wokusika we-laser ongu-300W unesakhiwo sokudlulisa esizinzile - igiya & iphinikhodi kanye nedivayisi yokushayela enembe kakhulu ye-servo motor, iqinisekisa yonke i-plexiglass yokusika i-laser enekhwalithi ephezulu eqhubekayo nokusebenza kahle.

Sinamandla aphezulu angu-150W, 300W, 450W, kanye nama-600W ebhizinisi lakho le-laser cutting machine acrylic sheet.

Ngaphandle kwe-laser cutting acrylic sheets, umshini wokusika we-laser we-PMMA ungaqaphelaukuqoshwa kwe-laser okuyinkimbinkimbingokhuni ne-acrylic.